Influence of Grain Growth Inhibitors and Powder Size on the Properties of Ultrafine and Nanostructured Cemented Carbides Sintered in Hydrogen

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

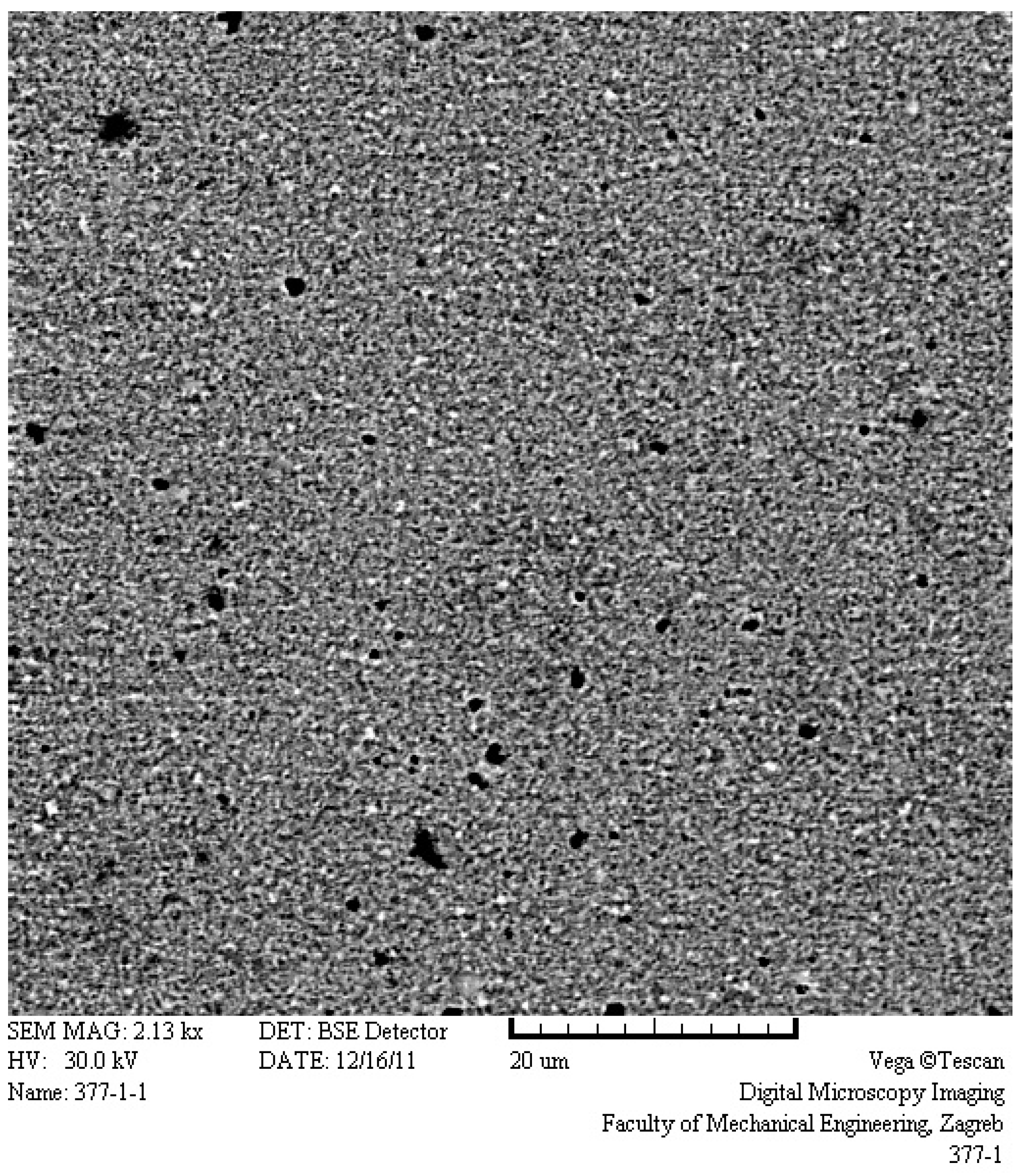

3.1. Density and Microstructural Characteristics

3.2. Mechanical Properties

4. Conclusions

- (1)

- In general, higher densities are achieved with higher Co content and greater grain size of the starting powder. Achieved densities of WC-9Co mixtures are close to theoretical densities. Comparing two WC-9Co mixtures with a 150 nm starting powder with different GGIs, it can be concluded that the addition of 0.45 wt. % Cr3C2 did not lead to lower density. The achieved densities are lower compared to densities which would be achieved with a sinter-HIP process or by sintering in vacuum.

- (2)

- The behavior of the 95 nm starting powder, classified as real nanopowder, is completely different compared to the 150 nm staring powder; higher pressures are needed for the consolidation of green parts. Even with higher pressures, a microstructure with a lower densities was obtained. The consolidation of real nanopowders only by sintering in hydrogen without isostatic pressing is not recommended. Sinter-HIP process would be more suitable for the consolidation of real nano powders.

- (3)

- The sintering temperature significantly impacted the microstructure of ultrafine and nanostructured cemented carbides. Increased sintering temperatures lead to microstructural irregularities in a form of discontinuous WC growth, carbide agglomerates and abnormal grain growth, as well as significant hardness decrease, especially for the mixture with only VC as GGIs. The lowest sintering temperature resulted in a fine-grained homogenous microstructure. It is preferred to use a higher amount of GGIs in case of sintering in hydrogen atmosphere.

- (4)

- The characteristic of the starting powder (grain size and amount, as well as type of GGI) significantly influenced the microstructure and mechanical properties. The addition of 0.45% Cr3C2 contributed to microstructure homogeneity, reduced discontinuous and continuous grain growth, increased Vickers hardness by approximately 70 HV and fractured toughness by approximately 0.15 MN/m3/2. The reduction of the starting powder grain size from 150 nm to a real nanosize of 95 nm resulted in a significant hardness increase with a simultaneous small increase in fracture toughness.

- (5)

- Fracture toughness is not influenced by microstructural irregularities or the change in Vickers hardness.

Author Contributions

Conflicts of Interest

References

- Richter, V.; Poetschke, J.; Holke, R.; Michaelis, A. Nanoscaled Cemented carbides—Fiction or Reality? In Proceedings of the 18th International Plansee Seminar, Reutte, Austria, 3–7 June 2013.

- Fabijanić, T.A.; Alar, Ž.; Ćorić, D. Influence of consolidation process and sintering temperature on microstructure and mechanical properties of near nano and nano-structured WC-Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2016, 54, 82–89. [Google Scholar] [CrossRef]

- Al-Aqeeli, N.; Saheb, N.; Laoui, T.; Mohammad, K. The Synthesis of Nanostructured WC-Based Cemented carbides Using Mechanical Alloying and Their Direct Consolidation. J. Nanomater. 2014. [Google Scholar] [CrossRef]

- Weidow, J.; Norgren, S.; Andren, H. Effect of V, Cr and Mn Additions on the Microstructure of WC-Co. Int. J. Refract. Met. Hard Mater. 2009, 27, 817–822. [Google Scholar] [CrossRef]

- Poetschke, J.; Richter, V.; Holke, R. Influence and effectivity of VC and Cr3C2 grain growth inhibitors on sintering if binderless tungsten carbide. Int. J. Refract. Met. Hard Mater. 2012, 31, 218–223. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Wang, X.; Ryu, T.; Hwang, K.S.; Sohn, H.Y. Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide—A review. Int. J. Refract. Met. Hard Mater. 2009, 27, 288–299. [Google Scholar] [CrossRef]

- Gille, G.; Szesny, B.; Dreyer, K.; van den Berg, H.; Schmidt, J.; Gestrich, T.; Leitner, G. Submicron and ultrafine grained cemented carbides for microdrills and metal cutting inserts. Int. J. Refract. Met. Hard Mater. 2002, 20, 3–22. [Google Scholar] [CrossRef]

- Sun, L.; Jia, C.; Cao, R.; Lin, C. Effects of Cr3C2 additions on the densification, grain growth and properties of ultrafine WC-11Co composites by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2008, 26, 357–361. [Google Scholar] [CrossRef]

- Kishino, J.; Nomura, H.; Shin, S.-G.; Matsubara, H.; Tanase, T. Computational study on grain growth in cemented carbides. In Proceedings of the 15th Internationla Plansee Seminar, Reutte, Austria, May 2001; Kneringer, G., Rodhammer, P., Wildner, H., Eds.; Plansee AG: Reutte, Austria, 2001; Volume 2. [Google Scholar]

- Sivaprahasam, D.; Chandrasekar, S.B.; Sundaresan, R. Microstructure and mechanical properties of nanocrystalline WC-12Co consolidated by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2007, 25, 144–152. [Google Scholar] [CrossRef]

- Mannesson, K. WC Grain Growth during Sintering of Cemented Carbides. Ph.D. Thesis, KTH Industrial Engineering and Management, Stockholm, Sweden, April 2011. [Google Scholar]

- Wang, X.; Fang, Z.Z.; Sohn, H.Y. Grain growth during earla stage of sintering of nanosized WC-Co powder. Int. J. Refract. Met. Hard Mater. 2008, 26, 232–241. [Google Scholar] [CrossRef]

- Mannesson, K.; Elfwing, M.; Kusoffsky, A.; Norgeren, S.; Agren, J. Analysis of WC grain growth during sintering using electron backscatter diffraction and image analysis. Int. J. Refract. Met. Hard Mater. 2008, 26, 449–455. [Google Scholar] [CrossRef]

- Da Silva, A.G.P.; Schubert, W.D.; Lux, B. The Role of the Binder Phase in the WC-Co Sintering. Mat. Res. 2001. [Google Scholar] [CrossRef]

- Breval, E.; Cheng, J.P.; Agrawal, D.K.; Gigl, P.; Dennis, M.; Roy, R.; Papworthc, A.J. Comparison between microwave and conventional sintering of WC/Co composites. Mater. Sci. Eng. A 2005, 391, 285–295. [Google Scholar] [CrossRef]

| Mixture | Powder | Grain Size, dBET, nm | Specific Surface, m2/g | GGI, wt. % | Co, % |

|---|---|---|---|---|---|

| WC-9Co/1 | WC DN 2-5/1 | 150 | 2.57 | 0.26% VC, 0.45% Cr3C2 | 9 |

| WC-9Co/2 | WC DN 2-5/2 | 150 | 2.59 | 0.27% VC | 9 |

| WC-6Co/1 | WC DN 2-5/1 | 150 | 2.57 | 0.26% VC, 0.45% Cr3C2 | 6 |

| WC-6Co/2 | WC DN 4-0 | 95 | 3.92 | 0.41%VC, 0.80% Cr3C2 | 6 |

| Mixture | Sample | Milling Time, h | Compaction Pressure, MPa | Tsint., °C | Holding Time, min | Heating Rate, °C/min |

|---|---|---|---|---|---|---|

| WC-9Co/1 | 1-1 | 72 | 180 | 1360 | 80 | 5 |

| 1-2 | 72 | 180 | 1400 | 80 | 5 | |

| 1-3 | 72 | 180 | 1420 | 80 | 5 | |

| WC-9Co/2 | 2-1 | 72 | 180 | 1360 | 80 | 5 |

| 2-2 | 72 | 180 | 1400 | 80 | 5 | |

| 2-3 | 72 | 180 | 1420 | 80 | 5 | |

| WC-6Co/1 | 3-1 | 48 | 180 | 1360 | 80 | 5 |

| 3-2 | 48 | 180 | 1400 | 80 | 5 | |

| 3-3 | 48 | 180 | 1420 | 80 | 5 | |

| WC-6Co/2 | 4-1 | 48 | 250 | 1360 | 80 | 5 |

| 4-2 | 48 | 250 | 1400 | 80 | 5 | |

| 4-3 | 48 | 250 | 1420 | 80 | 5 |

| Mixture | Sample | Porosity | ρ, % | dWC, µm | HV 30 | Wk, MN/m3/2 | ||

|---|---|---|---|---|---|---|---|---|

| A | B | C | ||||||

| WC-9Co/1 | 1-1 | A < 02, A02 | B00, B02 | C00 | 99.2 | 0.213 | 1880.1 | 9.52 |

| 1-2 | A < 02, A02 | B00, B02 | C00 | 99.6 | 0.249 | 1834.6 | 9.58 | |

| 1-3 | A < 02, A02 | B00, B02 | C00 | 99.5 | 0.261 | 1801.3 | 9.54 | |

| WC-9Co/2 | 2-1 | A < 02, A02 | B00, B02 | C00 | 99.2 | 0.251 | 1808.3 | 9.41 |

| 2-2 | A < 02, A02 | B00, B02 | C00 | 99.4 | 0.265 | 1763.1 | 9.33 | |

| 2-3 | A < 02, A02 | B00, B02 | C00 | 99.5 | 0.316 | 1729.3 | 9.42 | |

| WC-6Co/1 | 3-1 | A04 | B00, B02 | C00 | 99.2 | 0.209 | 2041.1 | 9.05 |

| 3-2 | A02 | B00, B02 | C00 | 99.0 | 0.235 | 2034.4 | 9.01 | |

| 3-3 | A02 | B00, B02 | C00 | 99.1 | 0.251 | 1988.2 | 9.10 | |

| WC-6Co/2 | 4-1 | A06 | B02, B04 | C00 | 98.6 | 0.166 | 2196.1 | 9.14 |

| 4-2 | A04 | B02, B04 | C00 | 98.6 | 0.175 | 2164.9 | 9.12 | |

| 4-3 | A04 | B02, B04 | C00 | 98.9 | 0.195 | 2103.9 | 9.14 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksandrov Fabijanić, T.; Jakovljević, S.; Franz, M.; Jeren, I. Influence of Grain Growth Inhibitors and Powder Size on the Properties of Ultrafine and Nanostructured Cemented Carbides Sintered in Hydrogen. Metals 2016, 6, 198. https://doi.org/10.3390/met6090198

Aleksandrov Fabijanić T, Jakovljević S, Franz M, Jeren I. Influence of Grain Growth Inhibitors and Powder Size on the Properties of Ultrafine and Nanostructured Cemented Carbides Sintered in Hydrogen. Metals. 2016; 6(9):198. https://doi.org/10.3390/met6090198

Chicago/Turabian StyleAleksandrov Fabijanić, Tamara, Suzana Jakovljević, Mladen Franz, and Ivan Jeren. 2016. "Influence of Grain Growth Inhibitors and Powder Size on the Properties of Ultrafine and Nanostructured Cemented Carbides Sintered in Hydrogen" Metals 6, no. 9: 198. https://doi.org/10.3390/met6090198

APA StyleAleksandrov Fabijanić, T., Jakovljević, S., Franz, M., & Jeren, I. (2016). Influence of Grain Growth Inhibitors and Powder Size on the Properties of Ultrafine and Nanostructured Cemented Carbides Sintered in Hydrogen. Metals, 6(9), 198. https://doi.org/10.3390/met6090198