Simulation Study on Thermo-Mechanical Controlled Process of 800 MPa-Grade Steel for Hydropower Penstocks

Abstract

:1. Introduction

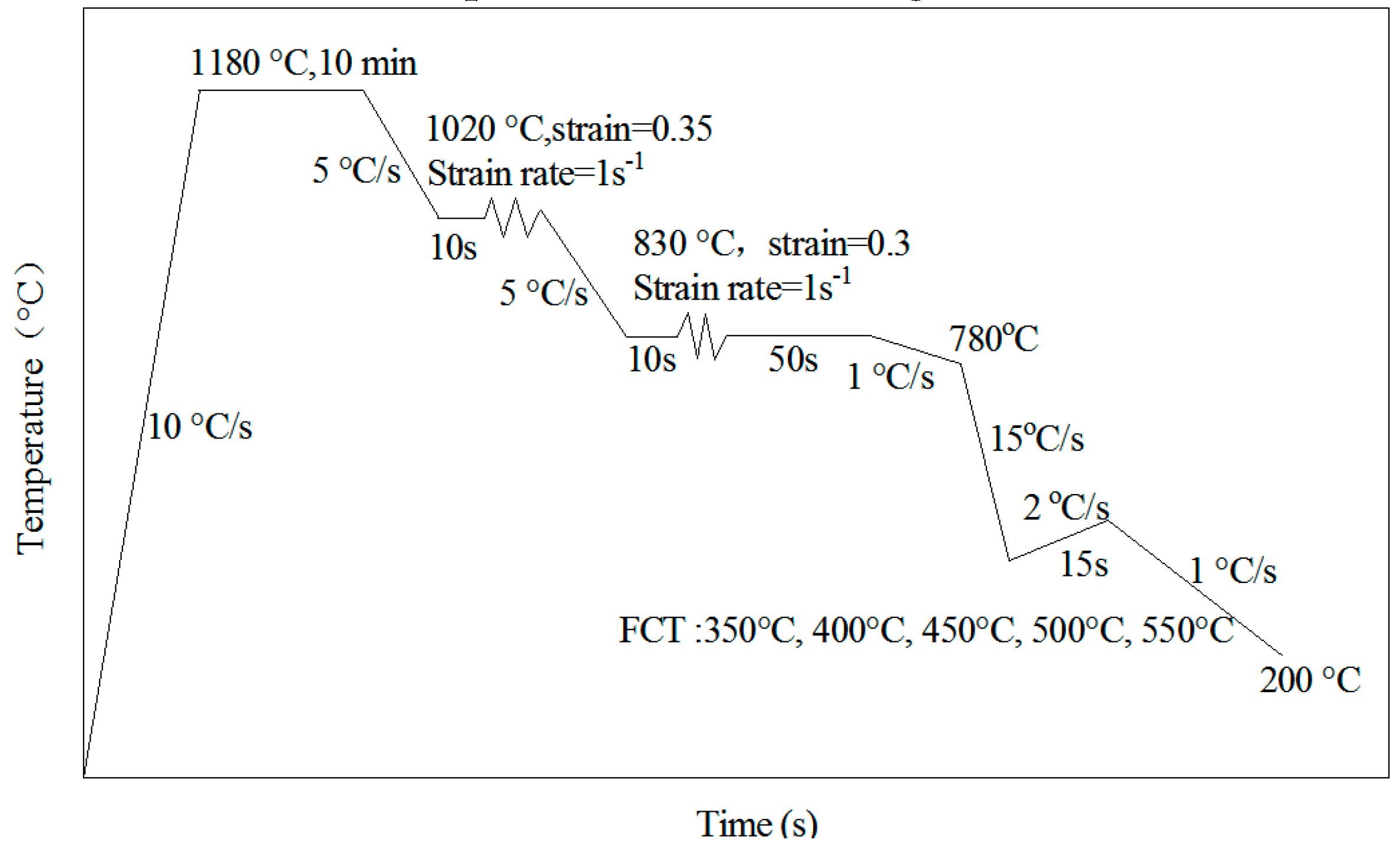

2. Materials and Methods

3. Results and Discussion

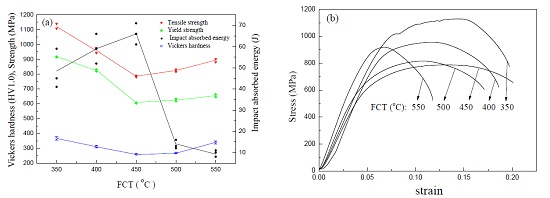

3.1. Effect of FCT on Mechanical Properties

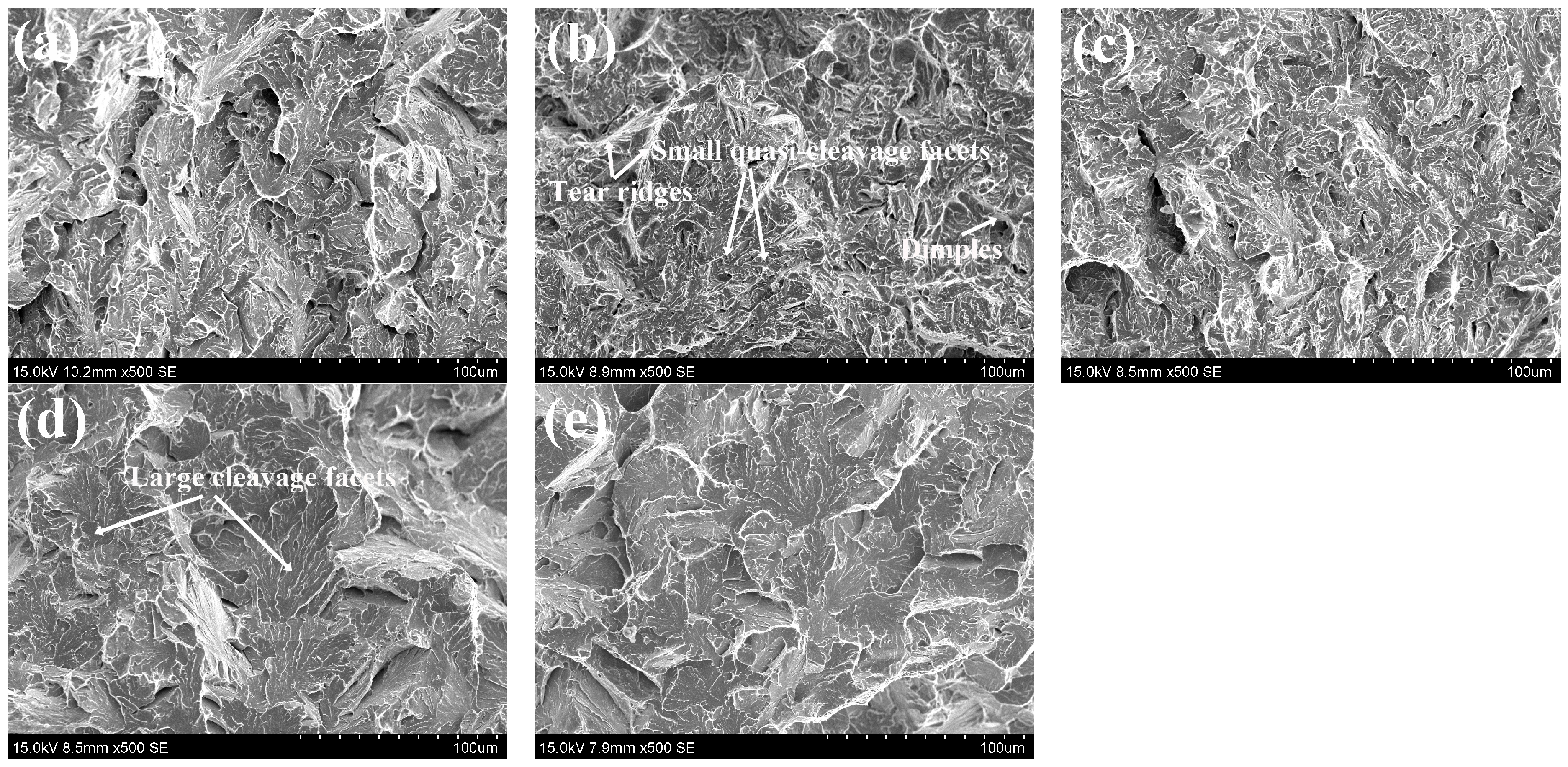

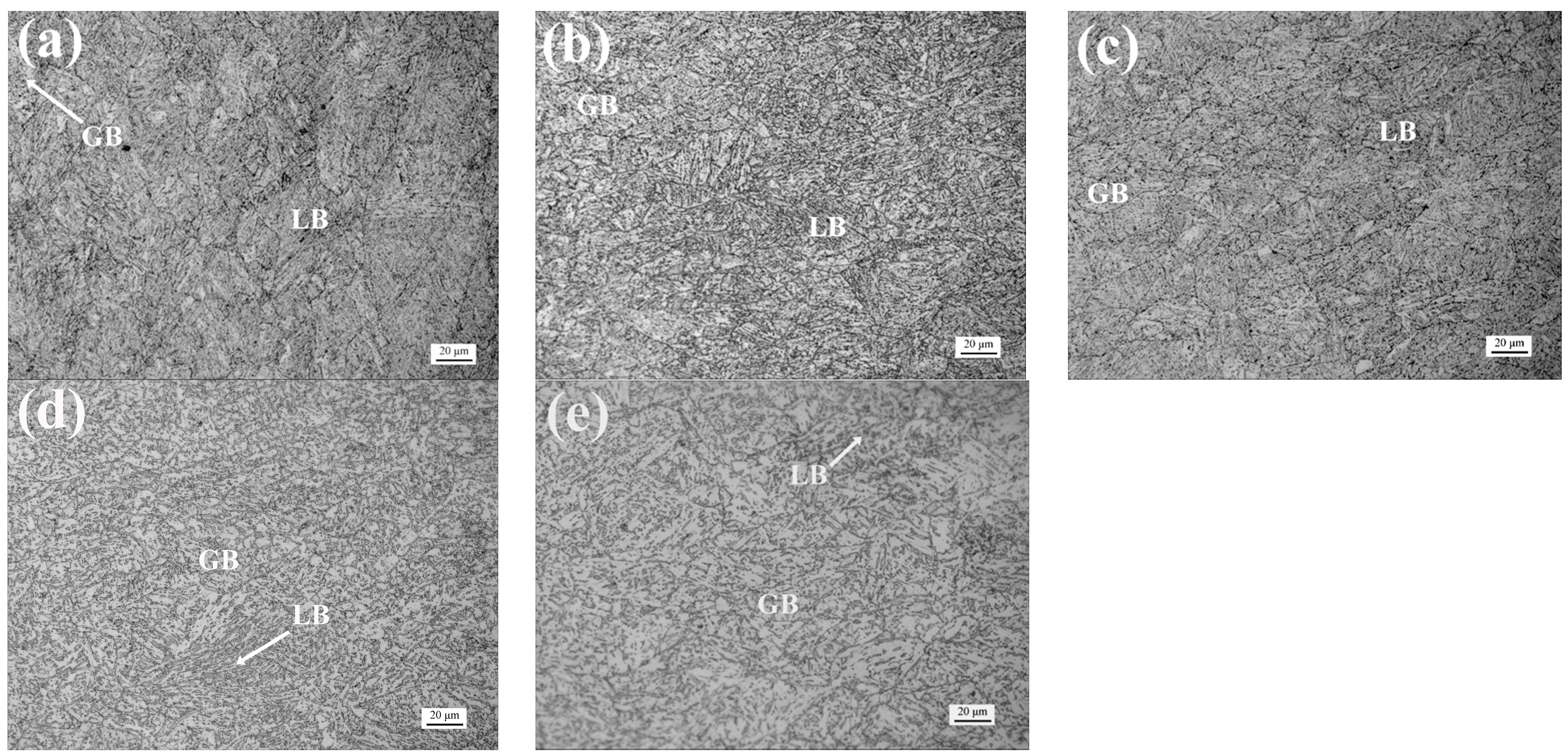

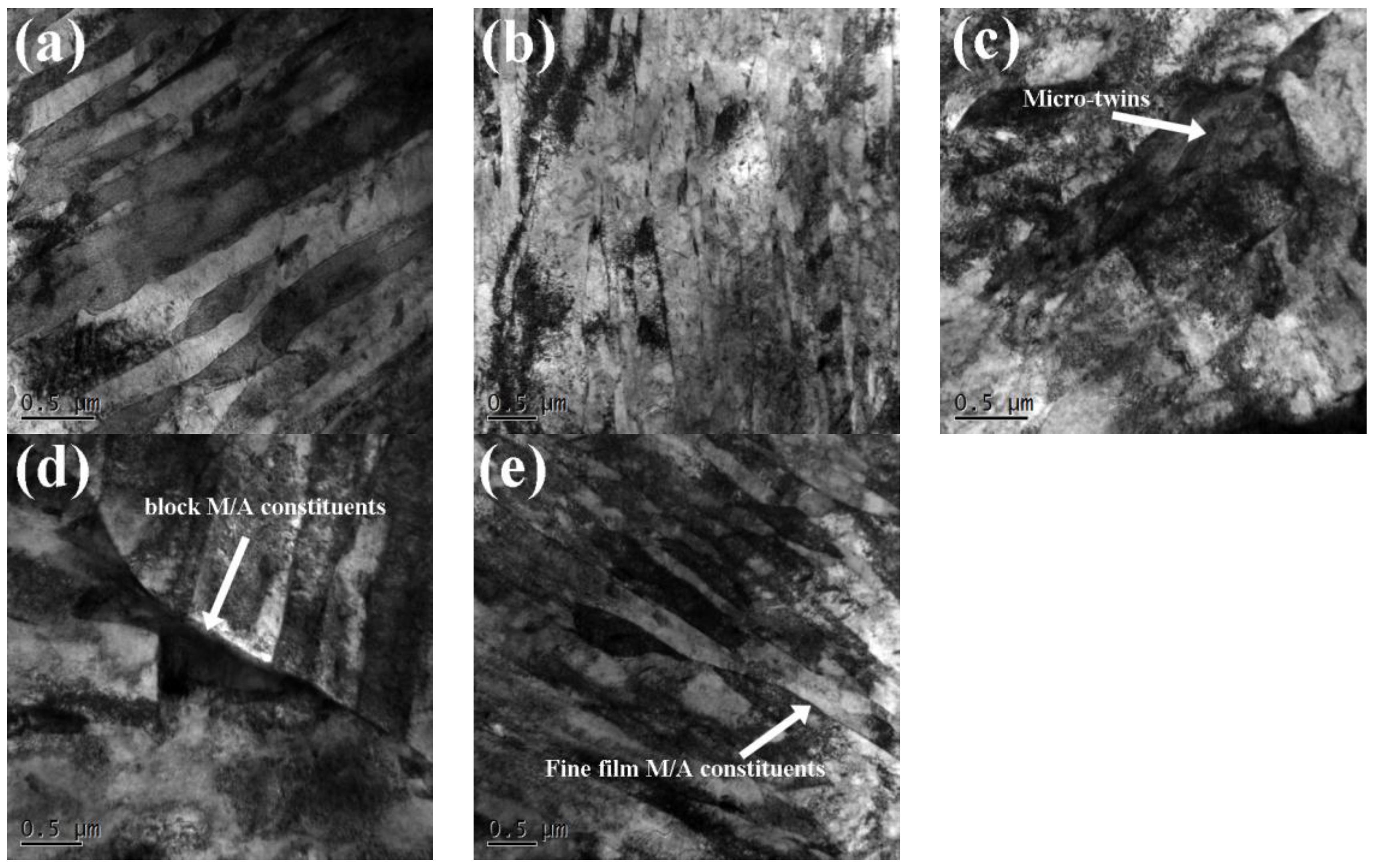

3.2. Relationship between Microstructure and Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chiaki, O. Development of Steel Plates by Intensive Use of TMCP and Direct Quenching Processes. ISIJ Int. 2001, 41, 542–553. [Google Scholar]

- Nishiokaand, K.; Ichikawa, K. Progress in thermo-mechanical control of steel plates and their commercialization. Sci. Technol. Adv. Mater. 2012, 13, 1–20. [Google Scholar]

- Ai, J.H.; Zhao, T.C.; Gao, H.J.; Hu, Y.H.; Xie, X.S. Effect of controlled rolling and cooling on the microstructure and mechanical properties of 60Si2MnA spring steel rod. J. Mater. Process. Technol. 2005, 160, 390–395. [Google Scholar] [CrossRef]

- Rasouli, D.; Asl, S.K.; Akbarzadeh, A.; Daneshi, G.H. Effect of cooling rate on the microstructure and mechanical properties of microalloyed forging steel. J. Mater. Process. Technol. 2008, 206, 92–98. [Google Scholar] [CrossRef]

- Yi, H.L.; Yang, X.; Sun, M.X.; Liu, Z.Y.; Wang, G.D. Influence of finishing cooling temperature and holding time on nanometer-size carbide of Nb-Ti microalloyed steel. J. Iron Steel Res. Int. 2014, 21, 433–438. [Google Scholar] [CrossRef]

- Onishi, K.; Katsumoto, H.; Kamo, T.; Sakaibori, H.; Kawabata, T.; FujiwAra, K.; Okaguchi, S. Study on application of advanced TMCP to high tensile strength steel plates for penstock. Weld World 2008, 52, 523–530. [Google Scholar]

- Tsuzuki, T.; Kawabata, N.; Okushima, M.; Tokunoh, K.; Okamura, Y. Development and Application of 950MPa and 780MPa Class High Strength Steel for Penstock. In Proceedings of the High Strength Steels for Hydropower Plants, Takasaki, Japan, 20–22 July 2009.

- Falko, S. Structural steel for the application in offshore, wind and hydro energy production: Comparison of application and welding properties of frequently used materials. Int. J. Microstruct. Mater. Prop. 2011, 6, 4–19. [Google Scholar]

- Xie, H.; Du, L.X.; Hu, J.; Misra, R.D.K. Microstructure and mechanical properties of a novel 1000 MPa grade TMCP low carbon microalloyed steel with combination of high strength and excellent toughness. Mater. Sci. Eng. A 2014, 612, 123–130. [Google Scholar] [CrossRef]

- Chu, R.Q.; Duan, Z.Q.; Dong, H.; Yang, K.; Li, S.X.; Wang, Z.G. Design of a kind of mini-tensile-specimen and its application in research of the high-performance pipe line steel. Acta Metall. Sin. 2000, 36, 626–629. [Google Scholar]

- Fan, L.; Wang, T.L.; Fu, Z.B.; Zhang, S.M.; Wang, Q.F. Effect of heat-treatment on-line process temperature on the microstructure and tensile properties of a low carbon Nb-microalloyed steel. Mater. Sci. Eng. A 2014, 607, 559–568. [Google Scholar] [CrossRef]

- Luo, Y.; Peng, J.M.; Wang, H.B.; Wu, X.C. Effect of tempering on microstructure and mechanical properties of a non-quenched bainitic steel. Mater. Sci. Eng. A 2010, 527, 3433–3437. [Google Scholar] [CrossRef]

- Zhao, Z.P.; Qiao, G.Y.; Tang, L.; Zhu, H.W.; Liao, B.; Xiao, F.R. Fatigue properties of X80 pipeline steels with ferrite/bainite dual-phase microstructure. Mater. Sci. Eng. A 2016, 657, 96–103. [Google Scholar] [CrossRef]

- Chen, X.W.; Qiao, G.Y.; Han, X.L.; Wang, X.; Xiao, F.R.; Liao, B. Effects of Mo, Cr and Nb on microstructure and mechanical properties of heat affected zone for Nb-bearing X80 pipeline steels. Mater. Des. 2014, 53, 888–901. [Google Scholar] [CrossRef]

- Wang, C.M.; Wu, X.F.; Liu, J.; Xu, N.A. Transmission electron microscopy of martensite/austenite islands in pipeline steel X70. Mater. Sci. Eng. A 2006, 438–440, 267–271. [Google Scholar] [CrossRef]

- Sung, H.K.; Lee, S.H.; Shin, S.Y. Effects of Start and Finish Cooling Temperatures on Microstructure and Mechanical Properties of Low-Carbon High-Strength and Low-Yield Ratio Bainitic Steels. Metall. Mater. Trans. A 2013, 45, 2004–2013. [Google Scholar] [CrossRef]

- Zhong, Y.; Xiao, F.R.; Zhang, J.W.; Shan, Y.Y.; Wang, W.; Yang, K. In situ TEM study of the effect of M/A films at grain boundaries on crack propagation in an ultra-fine acicular ferrite pipeline steel. Acta Mater. 2006, 54, 435–443. [Google Scholar] [CrossRef]

| C | Mn | Si | Cu | Ni | Cr | Mo | Nb | V | Ti | B | Ceq |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.09 | 1.50 | 0.30 | 0.20 | 0.50 | 0.40 | 0.25 | 0.025 | 0.045 | 0.013 | 0.0011 | 0.52 |

| FCT (°C) | 350 | 400 | 450 | 500 | 550 |

|---|---|---|---|---|---|

| LB(vol %) | 92 ± 6 | 60 ± 5 | 19 ± 5 | 8 ± 4 | 6 ± 3 |

| GB(vol %) | 8 ± 6 | 40 ± 5 | 81 ± 5 | 92 ± 4 | 94 ± 3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Q.; Wang, Y.; Wang, Q.; Wang, T. Simulation Study on Thermo-Mechanical Controlled Process of 800 MPa-Grade Steel for Hydropower Penstocks. Metals 2016, 6, 209. https://doi.org/10.3390/met6090209

Ding Q, Wang Y, Wang Q, Wang T. Simulation Study on Thermo-Mechanical Controlled Process of 800 MPa-Grade Steel for Hydropower Penstocks. Metals. 2016; 6(9):209. https://doi.org/10.3390/met6090209

Chicago/Turabian StyleDing, Qingfeng, Yuefeng Wang, Qingfeng Wang, and Tiansheng Wang. 2016. "Simulation Study on Thermo-Mechanical Controlled Process of 800 MPa-Grade Steel for Hydropower Penstocks" Metals 6, no. 9: 209. https://doi.org/10.3390/met6090209