Understanding Low Cycle Fatigue Behavior of Alloy 617 Base Metal and Weldments at 900 °C

Abstract

:1. Introduction

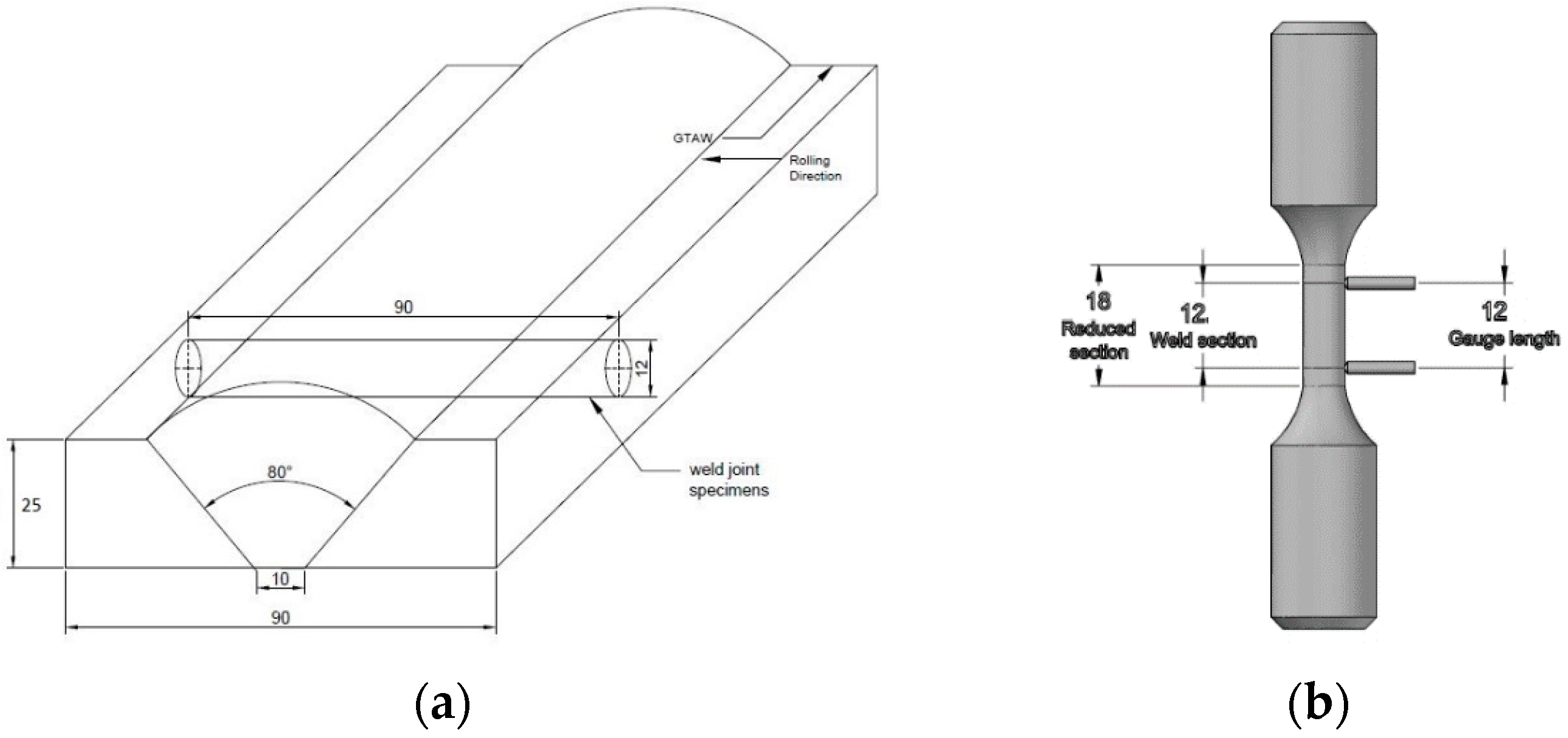

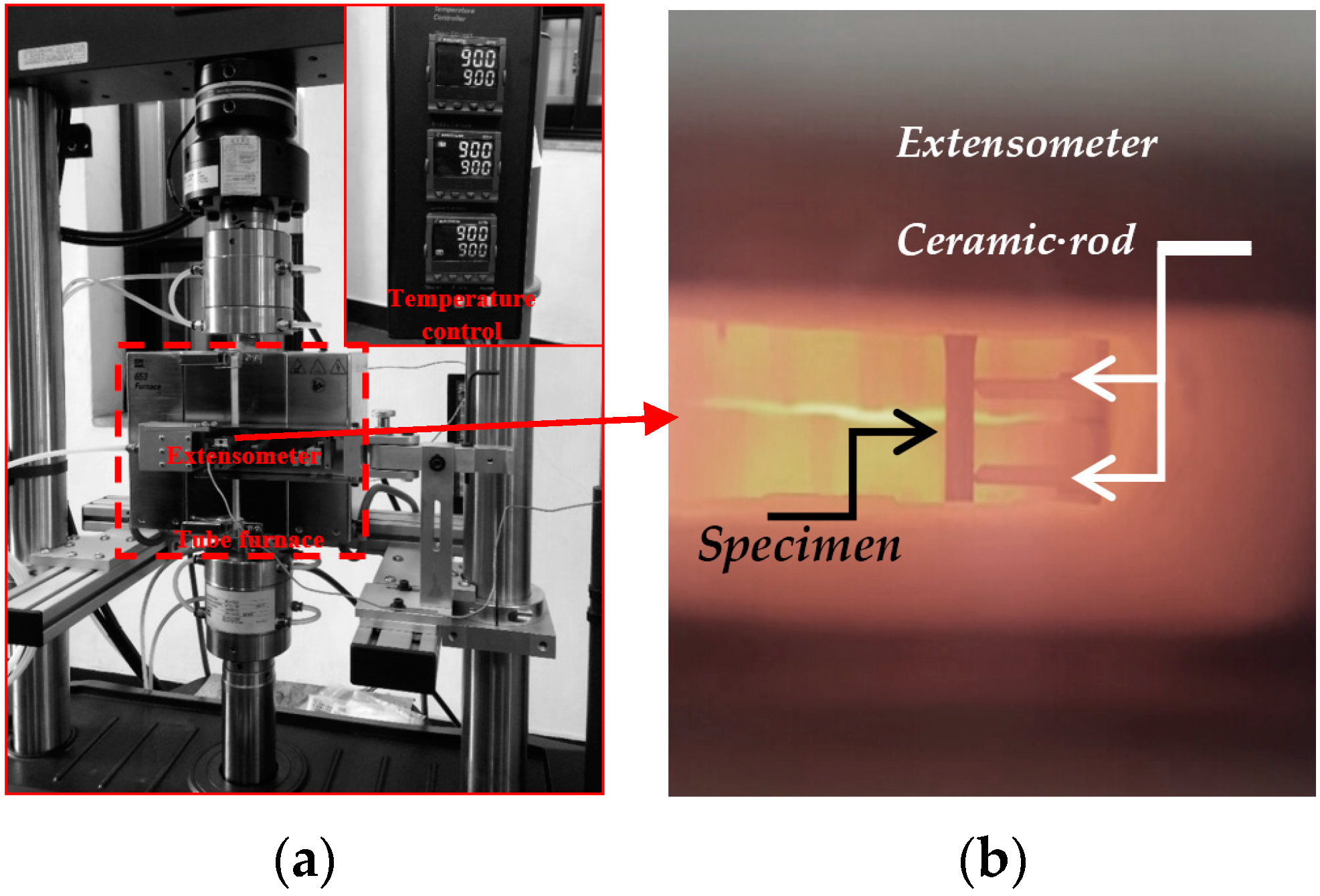

2. Materials and Experiments

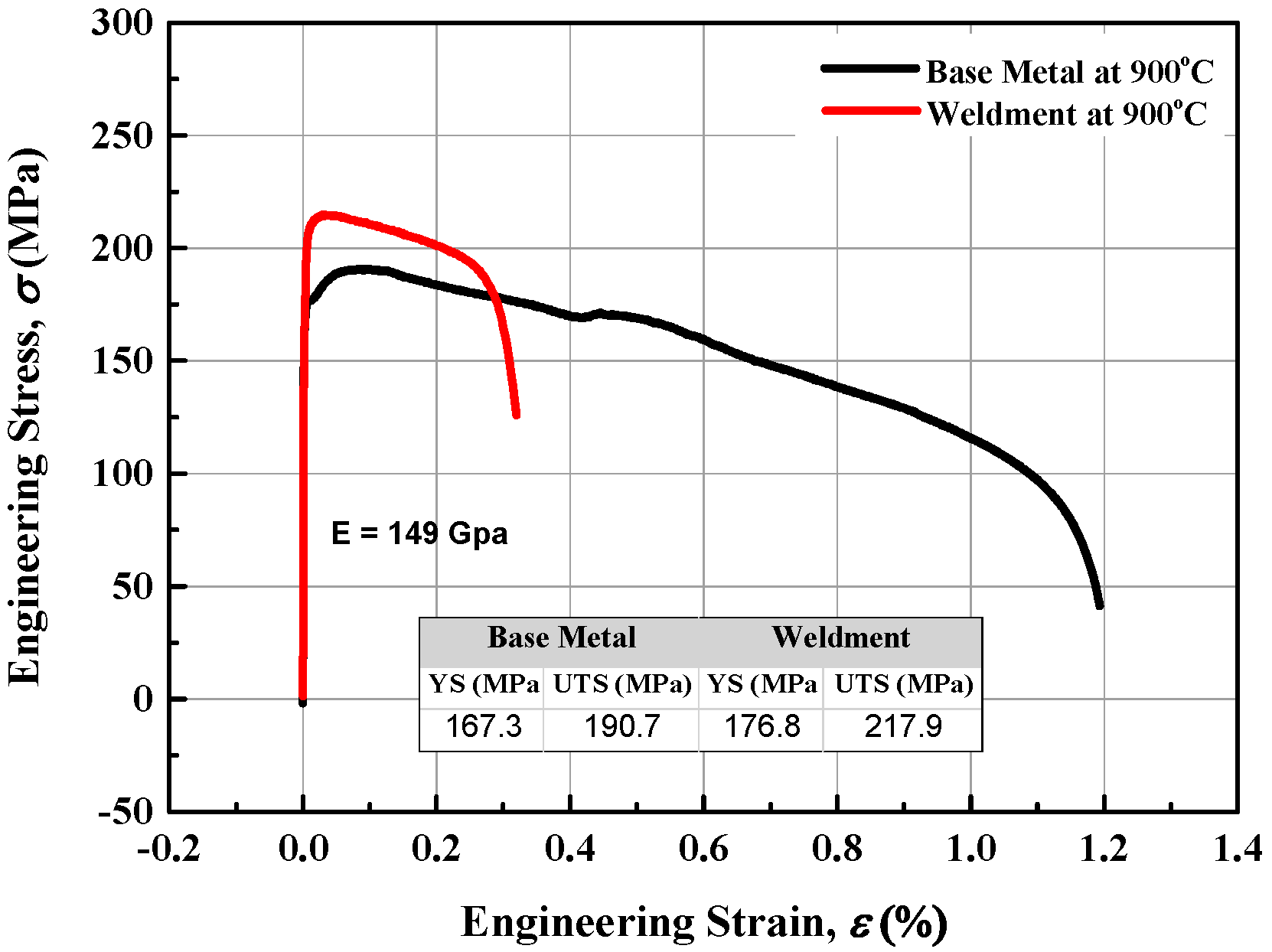

3. Results and Analysis

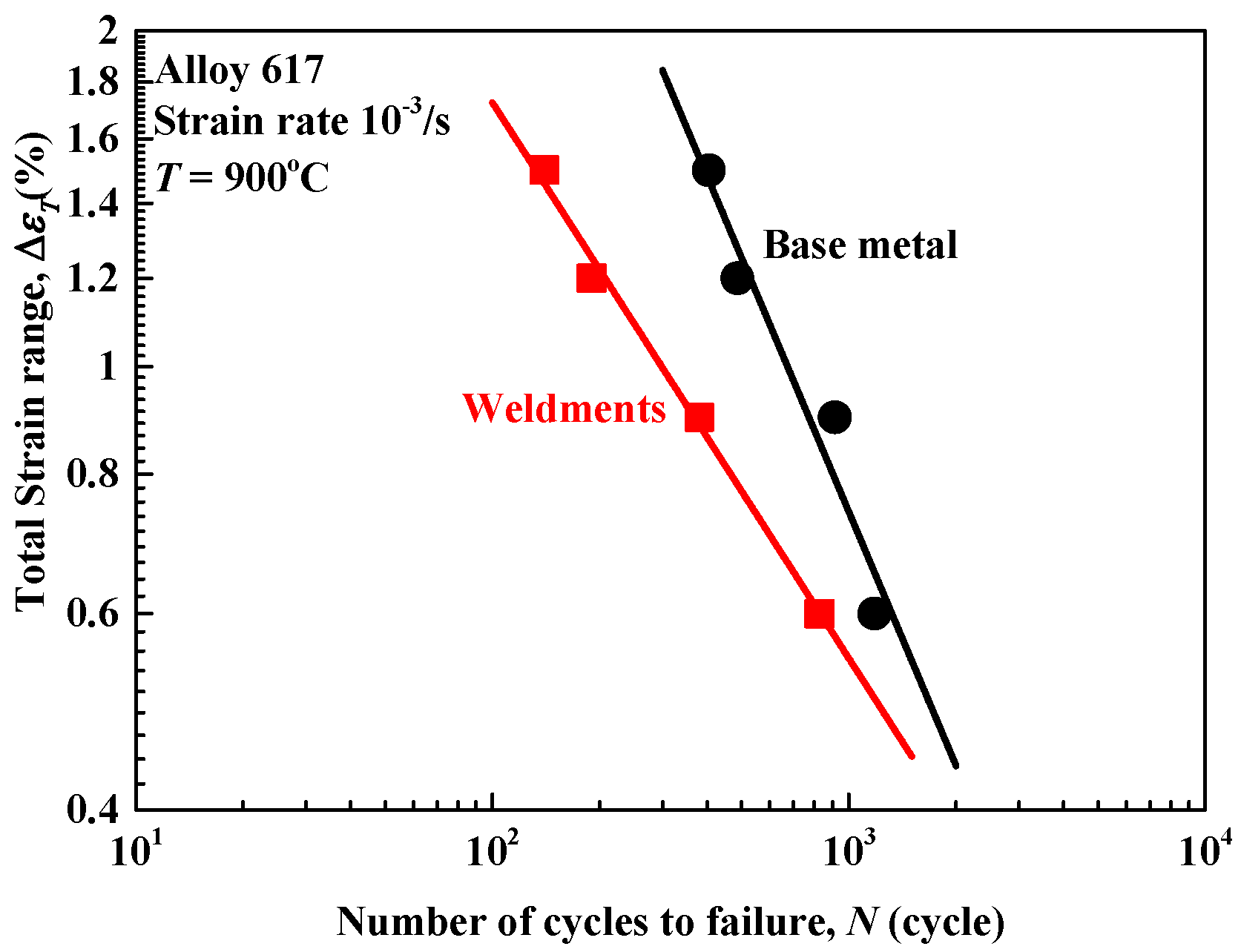

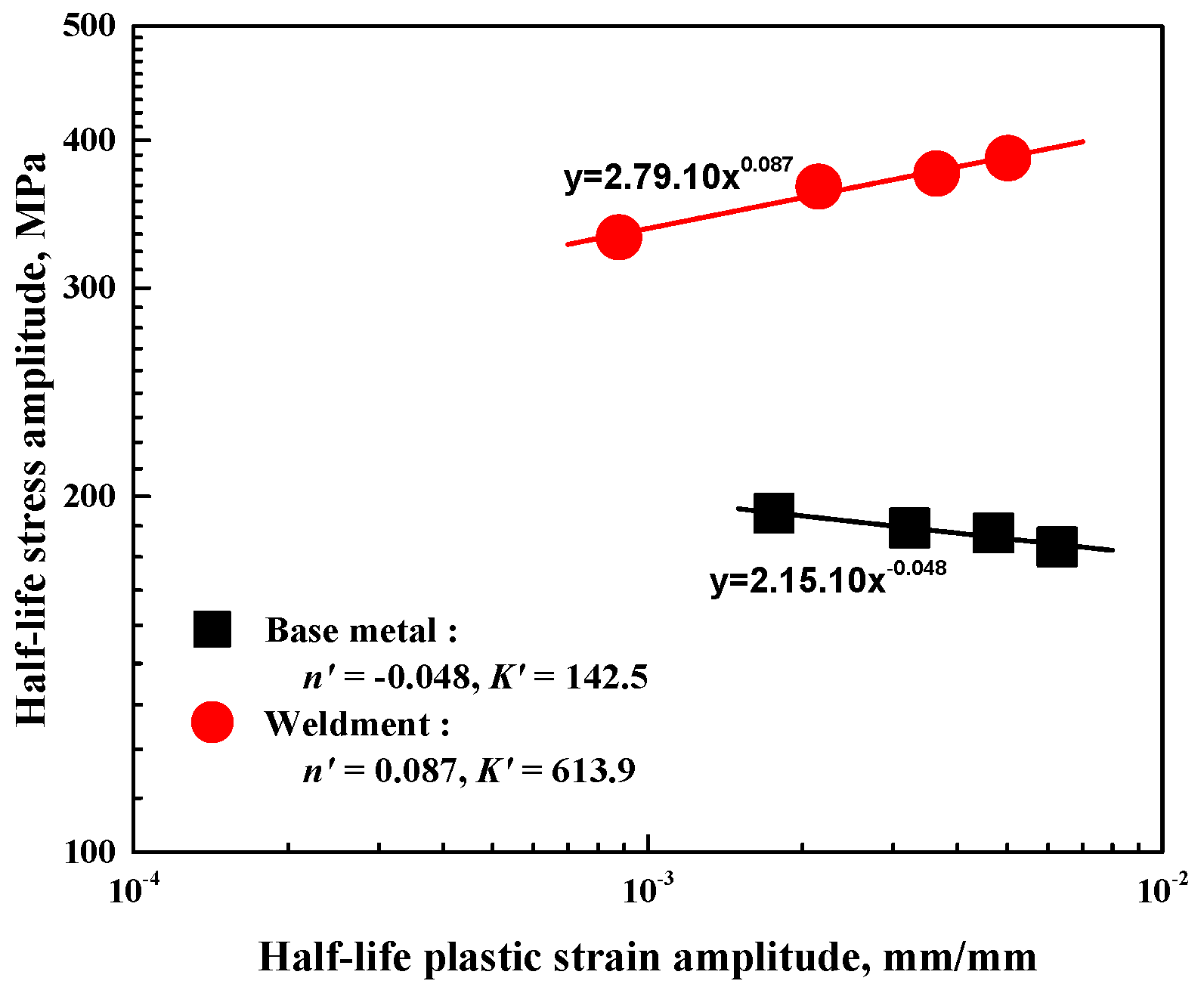

3.1. Fatigue Life and Cyclic Stress Response Behavior

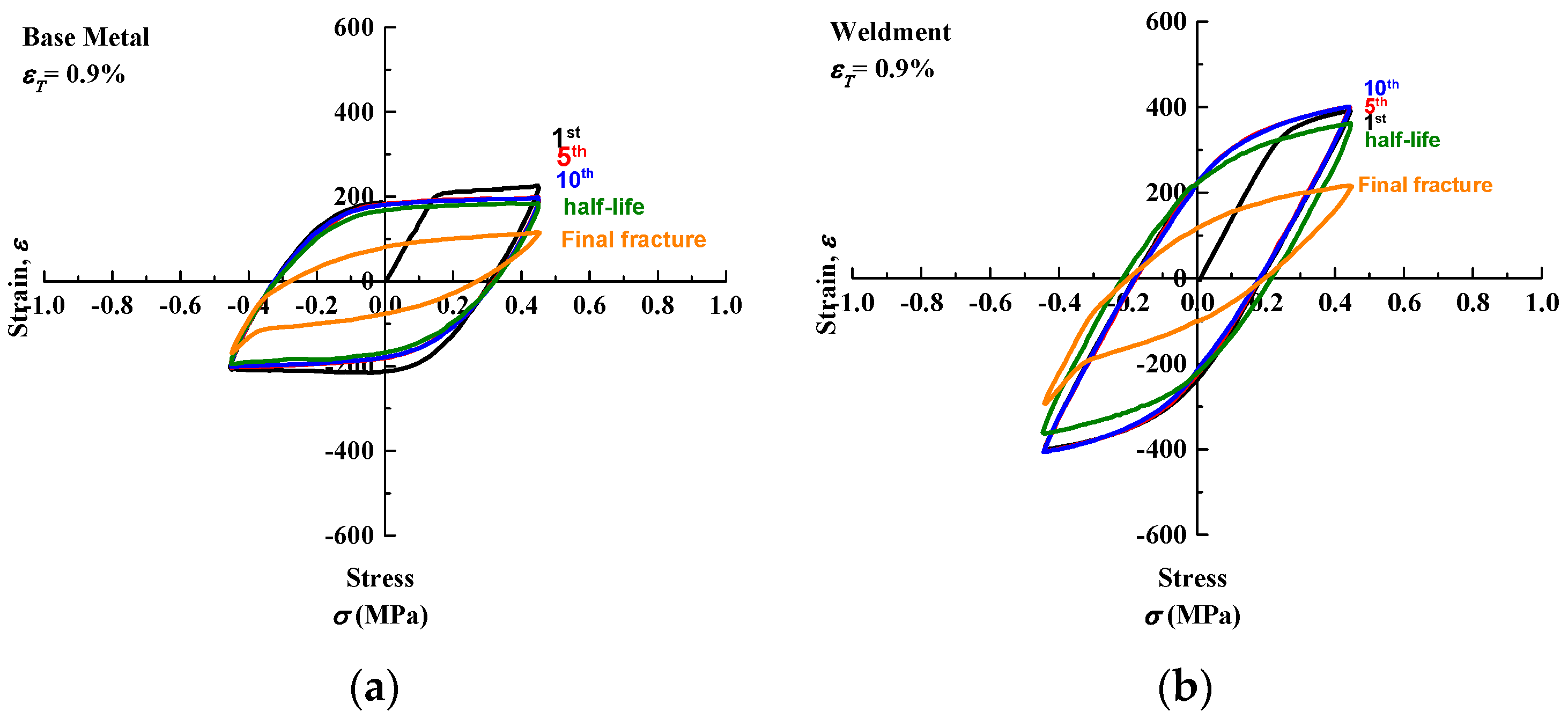

3.2. Stress-Strain Hysteresis Loops

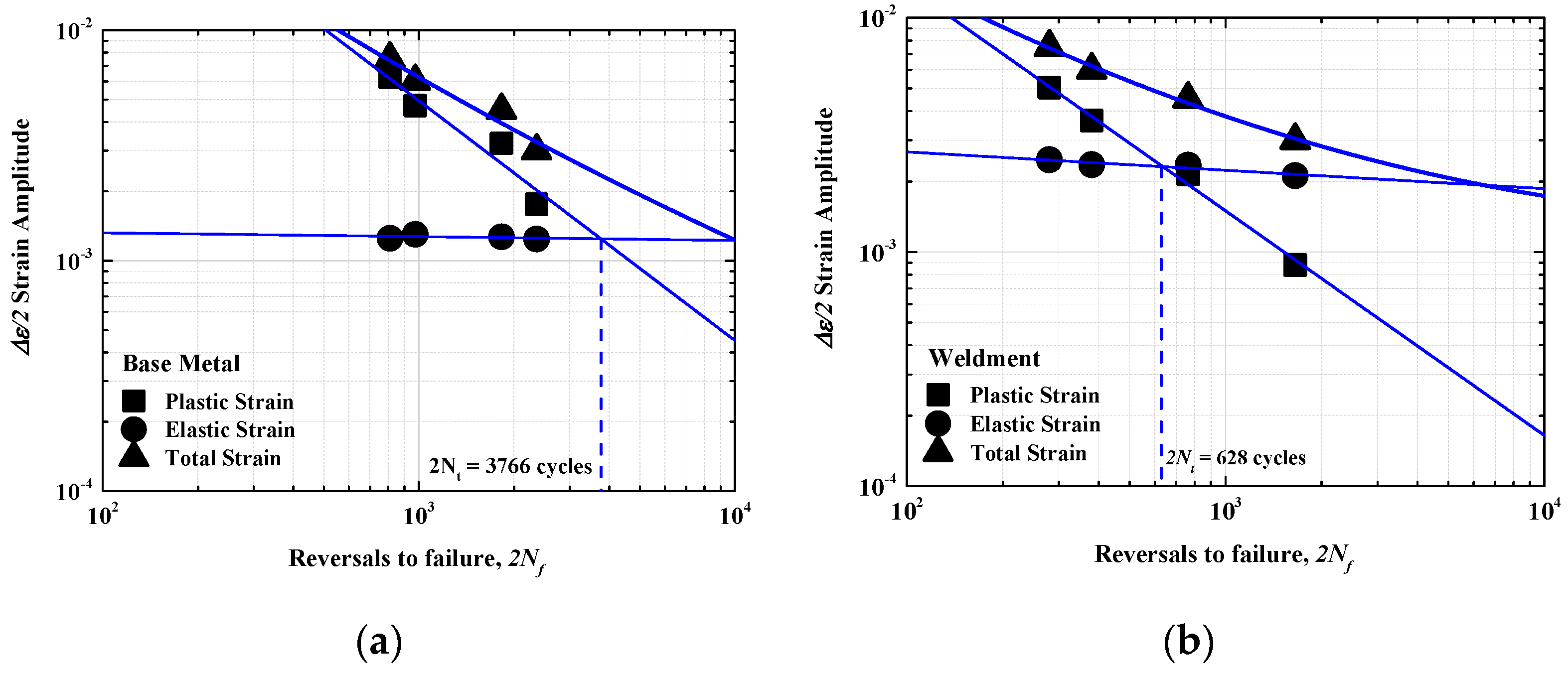

3.3. Strain-Life Data Analysis

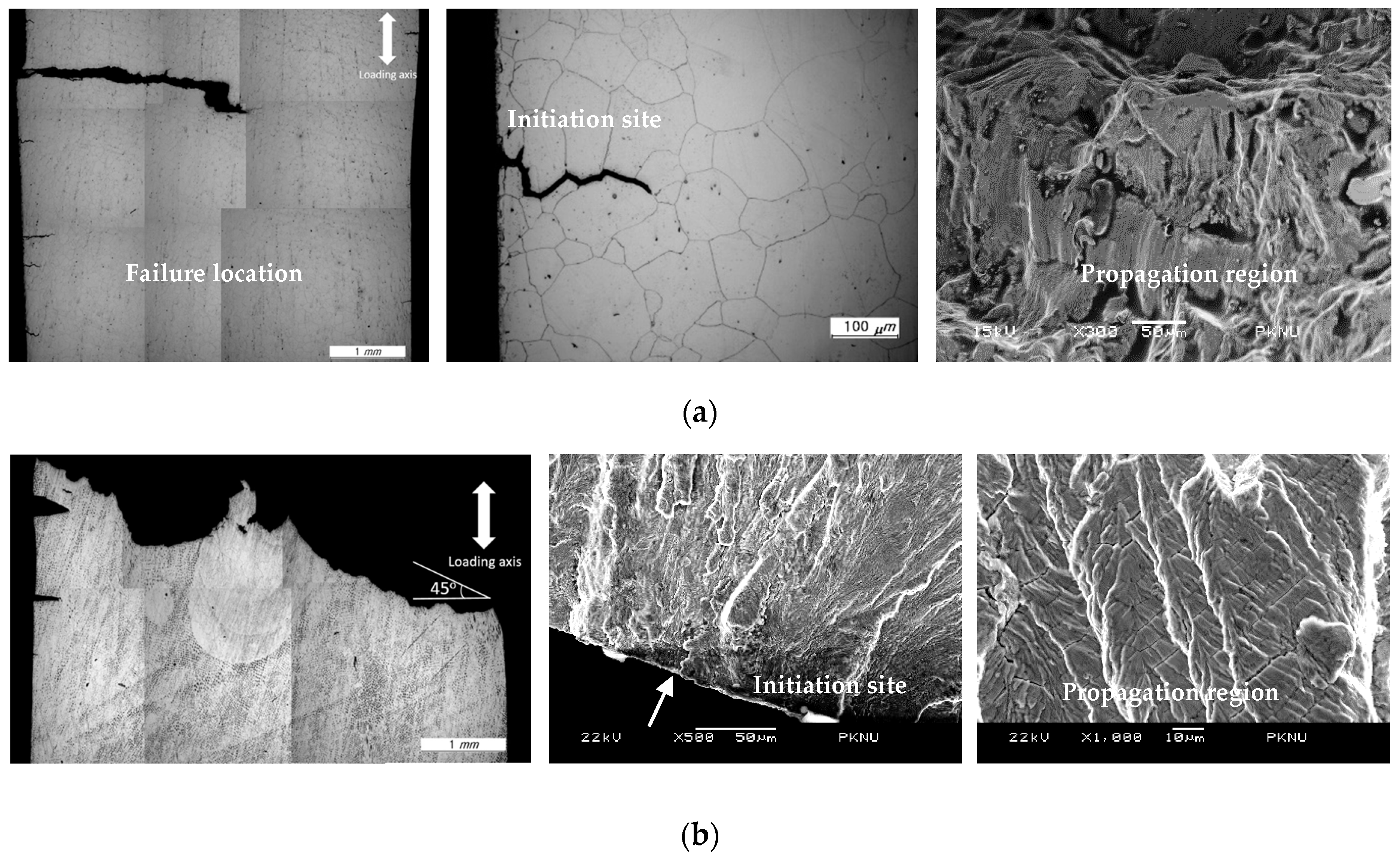

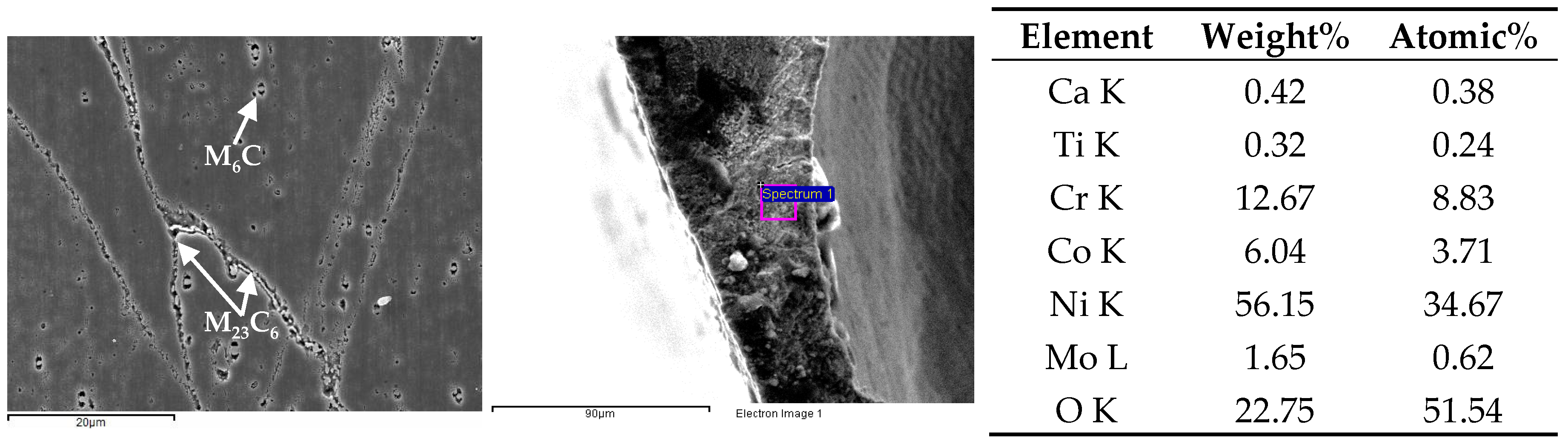

3.4. Fracture Surface Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dewa, R.T.; Kim, S.J.; Kim, W.G.; Kim, E.S. Low cycle fatigue behaviors of Alloy 617 (INCONEL 617) weldments for high temperature applications. Metals 2016, 6, 100. [Google Scholar] [CrossRef]

- Kim, S.J.; Dewa, R.T.; Kim, W.G.; Kim, M.H. Cyclic stress response and fracture behaviors of Alloy 617 base metal and weldments under LCF loading. Adv. Mater. Sci. Eng. 2015, 2015. [Google Scholar] [CrossRef]

- Lee, H.Y.; Kim, Y.W.; Song, K.N. Preliminary application of the draft code case for alloy 617 for a high temperature component. J. Mech. Sci. Technol. 2008, 22, 856–863. [Google Scholar] [CrossRef]

- Lee, G.G.; Jung, S.; Park, J.Y.; Kim, W.G.; Hong, S.D.; Kim, Y.W. Microstructural investigation of Alloy 617 creep-ruptured at high temperature in a helium environment. J. Mater. Sci. Technol. 2013, 29, 1177–1183. [Google Scholar] [CrossRef]

- Wright, J.K.; Carroll, L.J.; Cabet, C.; Lillo, T.M.; Benz, J.K.; Simpson, J.A.; Lloyd, W.R.; Chapman, J.A.; Wright, R.N. Characterization of elevated temperature properties of heat exchanger and steam generator alloys. Nucl. Eng. Des. 2012, 251, 252–260. [Google Scholar] [CrossRef]

- Wright, J.K.; Carroll, L.J.; Wright, R.N. Creep and creep-fatigue of Alloy 617 weldments. Available online: http://www.osti.gov/scitech/biblio/1168621 (accessed on 26 July 2016).

- Totemeier, T.C.; Tian, H.; Clark, D.E.; Simpson, J.A. Microstructure and strength characteristics of Alloy 617 welds. Available online: https://inldigitallibrary.inl.gov/sti/3310959.pdf (accessed on 26 July 2016).

- Wright, J.K.; Carroll, L.J.; Simpson, J.A.; Wright, R.N. Low cycle fatigue of Alloy 617 at 850 °C and 950 °C. J. Eng. Mater. Technol. 2013, 135, 1–8. [Google Scholar] [CrossRef]

- Rao, K.B.S.; Meurer, H.P.; Schuster, H. Creep-fatigue interaction of lnconel 617 at 950 °C in simulated nuclear reactor helium. Mater. Sci. Eng. A 1988, 104, 37–51. [Google Scholar] [CrossRef]

- Ren, W.; Swindeman, R. A review on current status of Alloys 617 and 230 for Gen IV nuclear reactor internals and heat exchangers. J. Press. Vessel Technol. 2009, 131. [Google Scholar] [CrossRef]

- Rahman, M.S.; Priyadarshan, G.; Raja, K.S.; Nesbitt, C.; Misra, M. Characterization of high temperature deformation behavior of INCONEL 617. Mech. Mater. 2009, 41, 261–270. [Google Scholar] [CrossRef]

- Tian, D.D.; Liu, X.S.; He, G.Q.; Shen, Y.; Lv, S.Q.; Wang, Q.G. Low cycle fatigue behavior of casting A319 alloy under two different aging conditions. Mater. Sci. Eng. A 2016, 654, 60–68. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Zhao, P.; Huang, Y.; Yu, Z.; Fang, X. Low-cycle fatigue behaviors of a new type of 10% Cr martensitic steel and welded joint with Ni-based weld metal. Int. J. Fatigue 2016, 88, 78–87. [Google Scholar] [CrossRef]

- Jang, C.; Lee, D.; Kim, D. Oxidation behaviour of an Alloy 617 in very high-temperature air and helium environments. Int. J. Press. Vessels Pip. 2008, 85, 368–377. [Google Scholar] [CrossRef]

- Kim, W.G.; Park, J.Y.; Lee, G.G.; Hong, S.D.; Kim, Y.W. Temperature effect on the creep behavior of alloy 617 in air and helium environments. Nucl. Eng. Des. 2014, 271, 291–300. [Google Scholar] [CrossRef]

| Reference | εf’ | c | σf’ (MPa) | b | E (GPa) | n’ | K’ (MPa) |

|---|---|---|---|---|---|---|---|

| Base Metal | 6.527 | −1.040 | 212.4 | −0.017 | 149 | −0.048 | 142.5 |

| Weldments | 1.120 | −0.958 | 572.2 | −0.078 | 149 | 0.087 | 613.9 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dewa, R.T.; Kim, S.J.; Kim, W.G.; Kim, E.S. Understanding Low Cycle Fatigue Behavior of Alloy 617 Base Metal and Weldments at 900 °C. Metals 2016, 6, 178. https://doi.org/10.3390/met6080178

Dewa RT, Kim SJ, Kim WG, Kim ES. Understanding Low Cycle Fatigue Behavior of Alloy 617 Base Metal and Weldments at 900 °C. Metals. 2016; 6(8):178. https://doi.org/10.3390/met6080178

Chicago/Turabian StyleDewa, Rando Tungga, Seon Jin Kim, Woo Gon Kim, and Eung Seon Kim. 2016. "Understanding Low Cycle Fatigue Behavior of Alloy 617 Base Metal and Weldments at 900 °C" Metals 6, no. 8: 178. https://doi.org/10.3390/met6080178