Influence of the Overlapping Factor and Welding Speed on T-Joint Welding of Ti6Al4V and Inconel 600 Using Low-Power Fiber Laser

Abstract

:1. Introduction

2. Experimental Setup

2.1. Materials and Sample Preparation

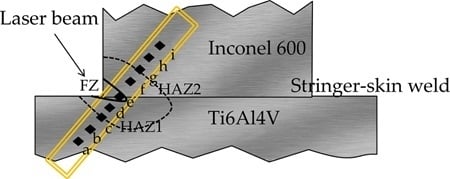

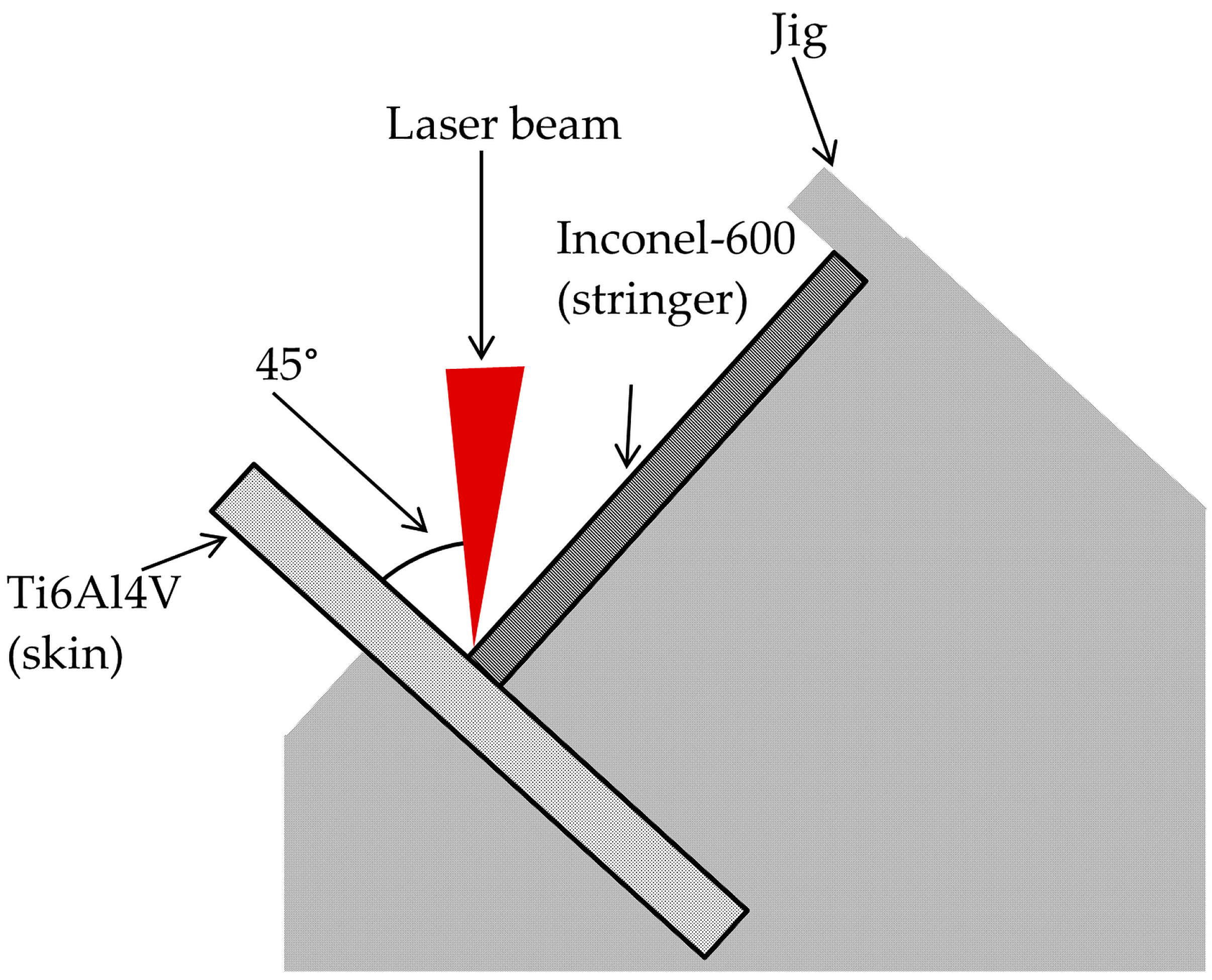

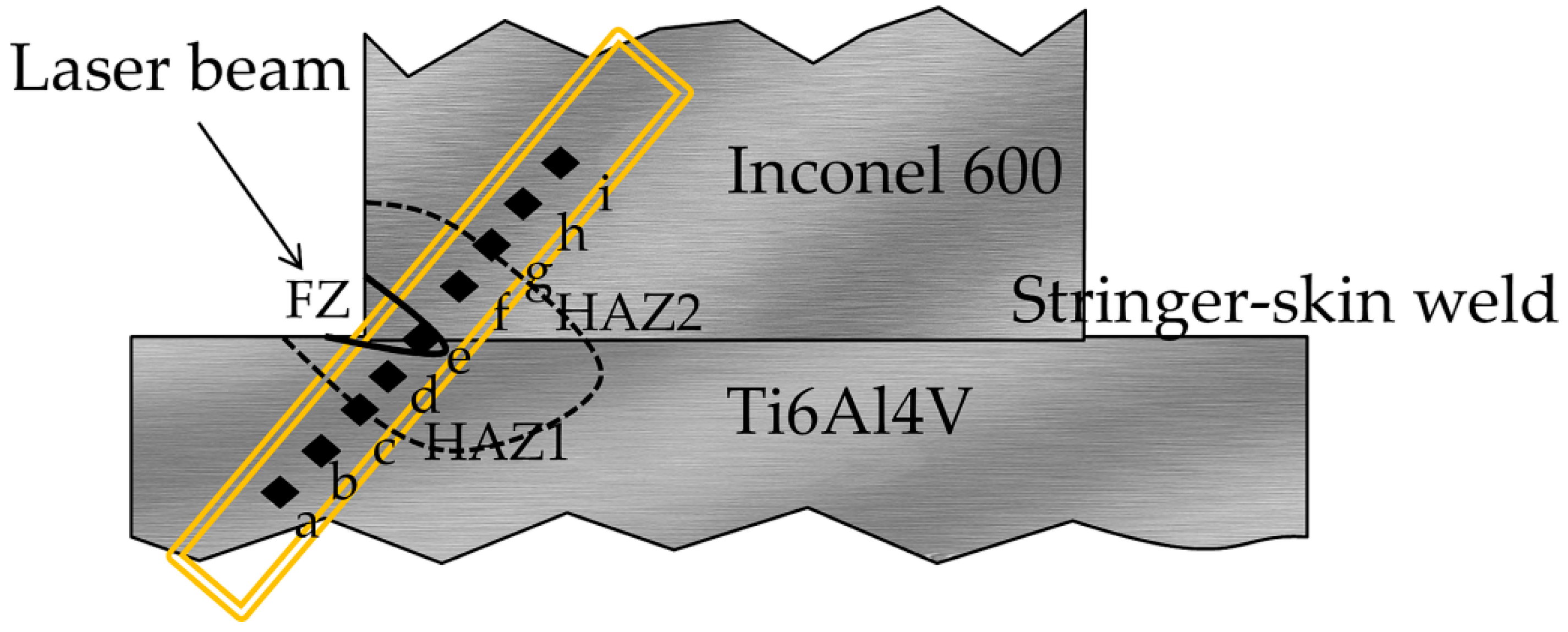

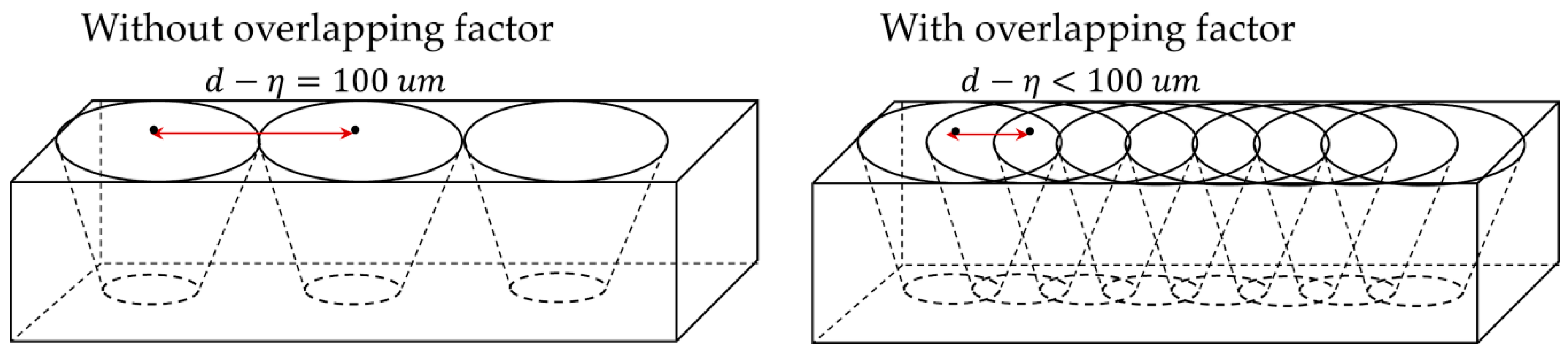

2.2. Laser Welding

2.3. Microstructural Characterization

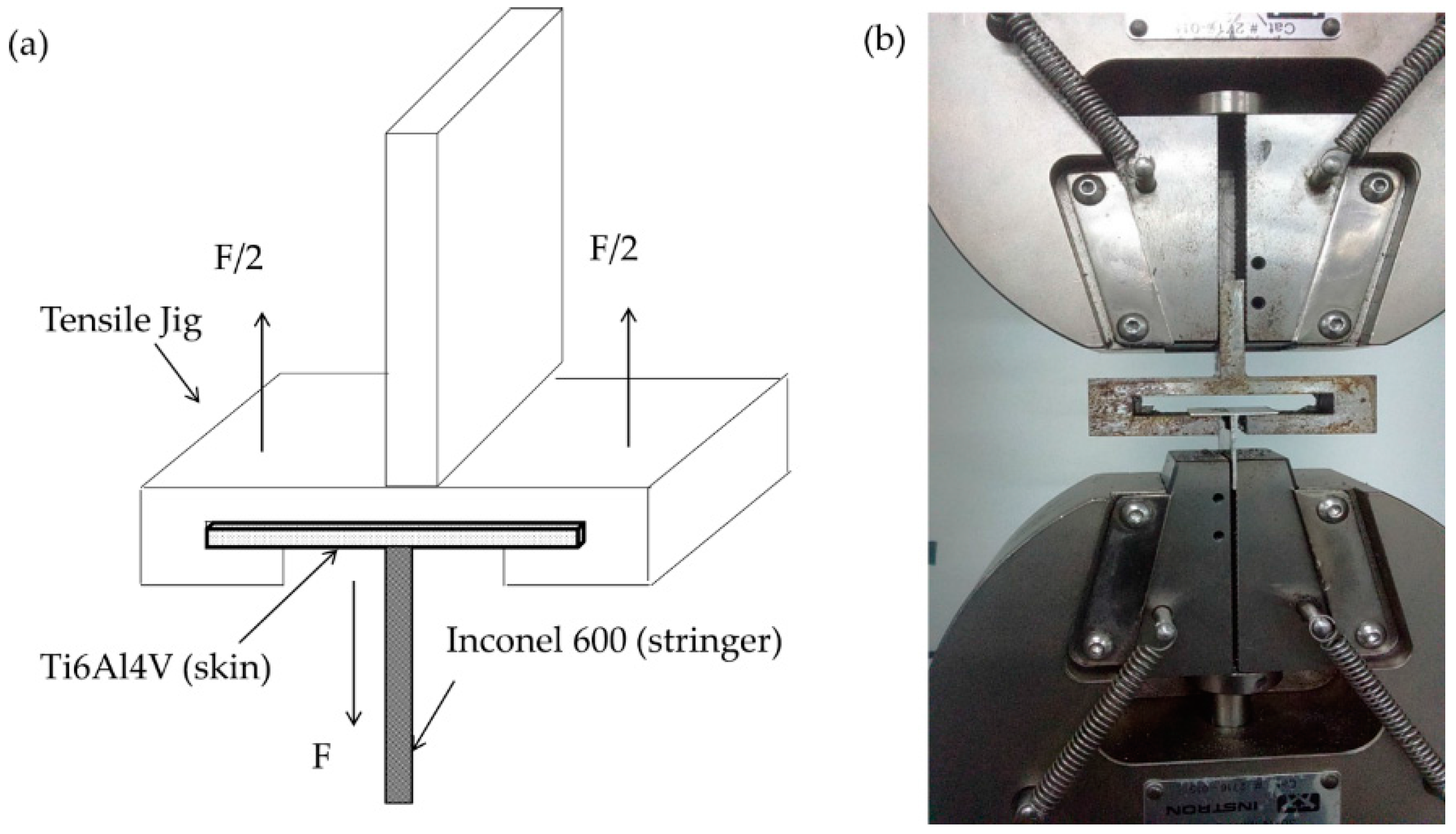

2.4. Pull Test Measurement

2.5. Vickers Microhardness Measurement

3. Results and Discussion

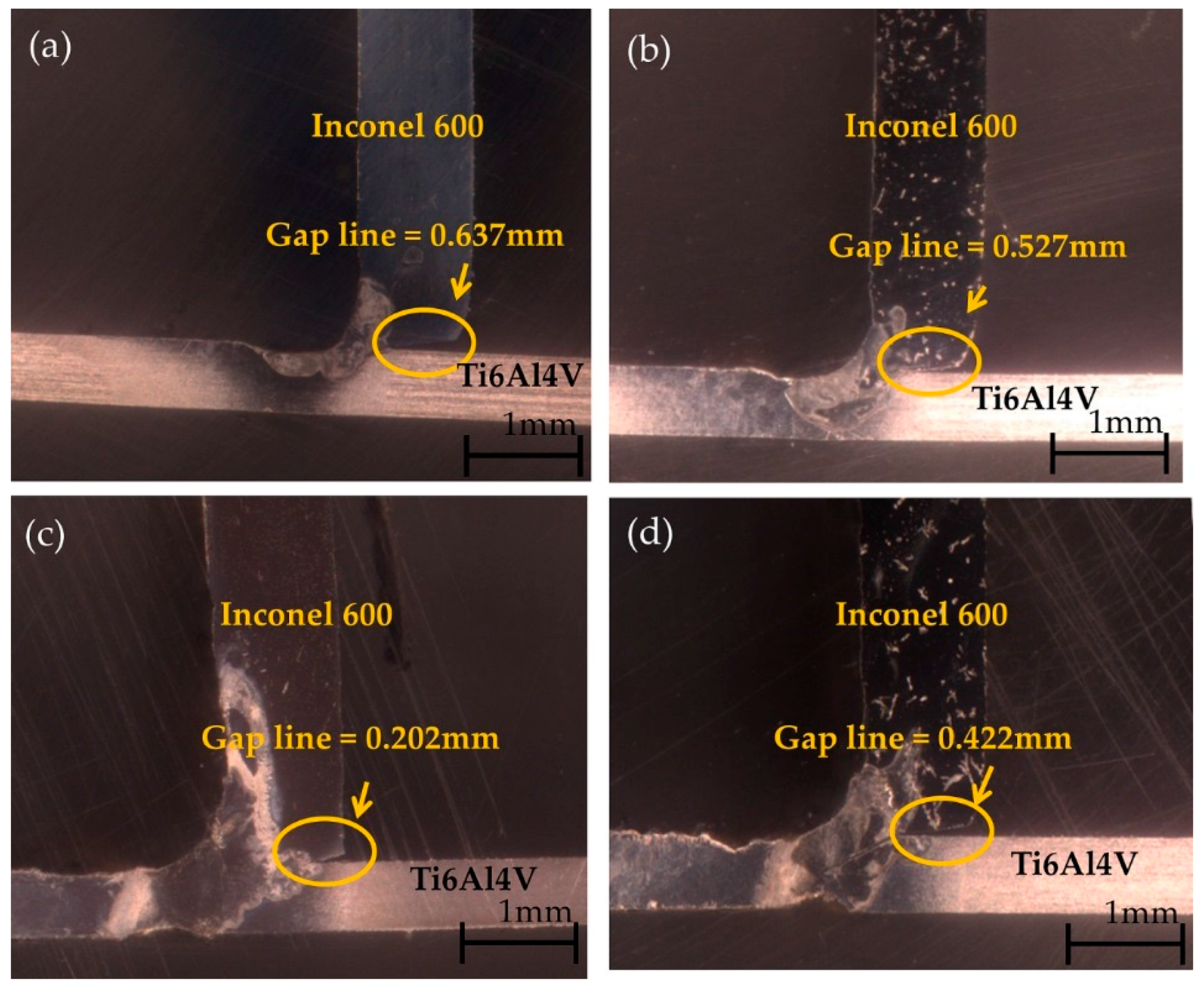

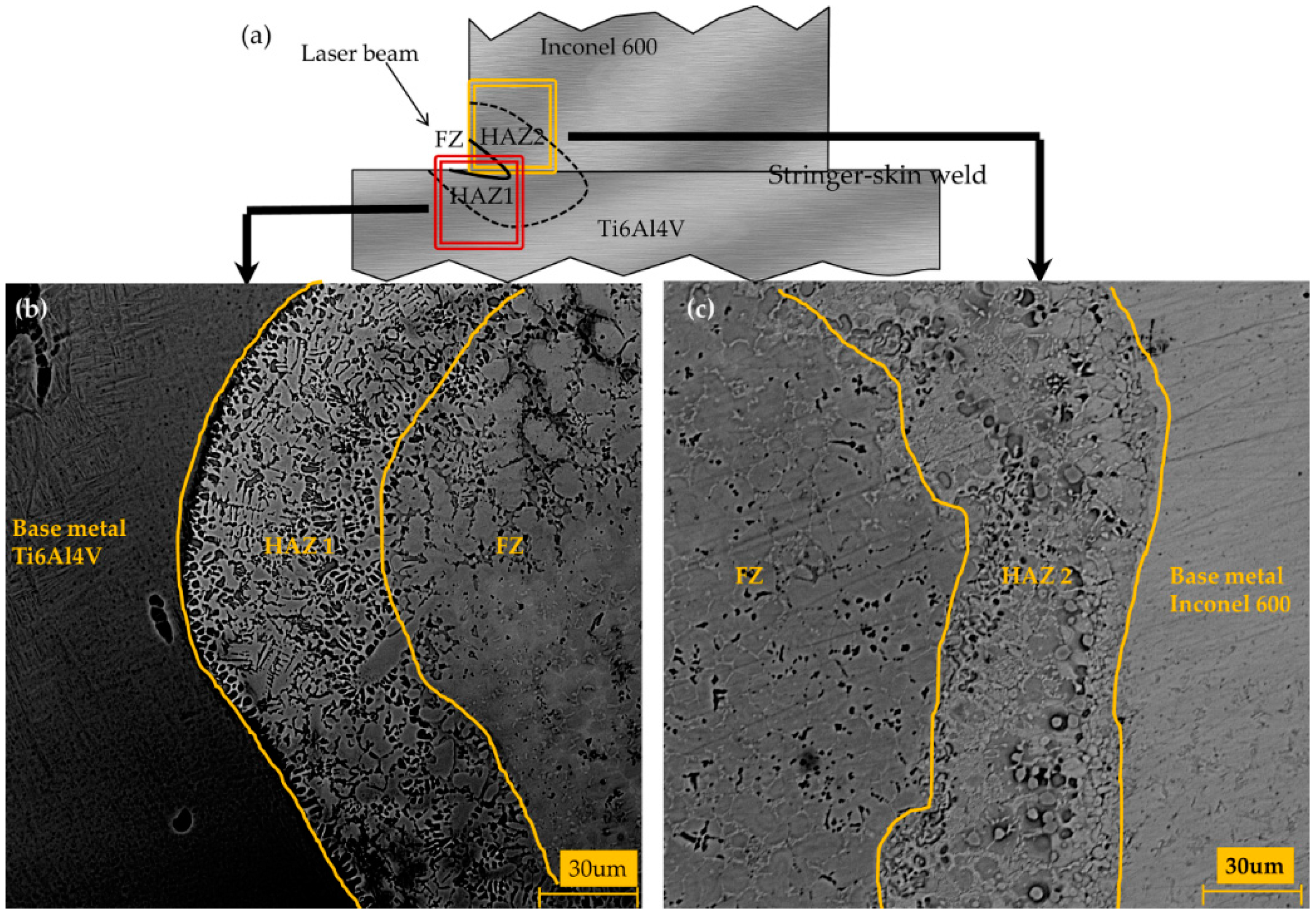

3.1. Metallurgical Characterization

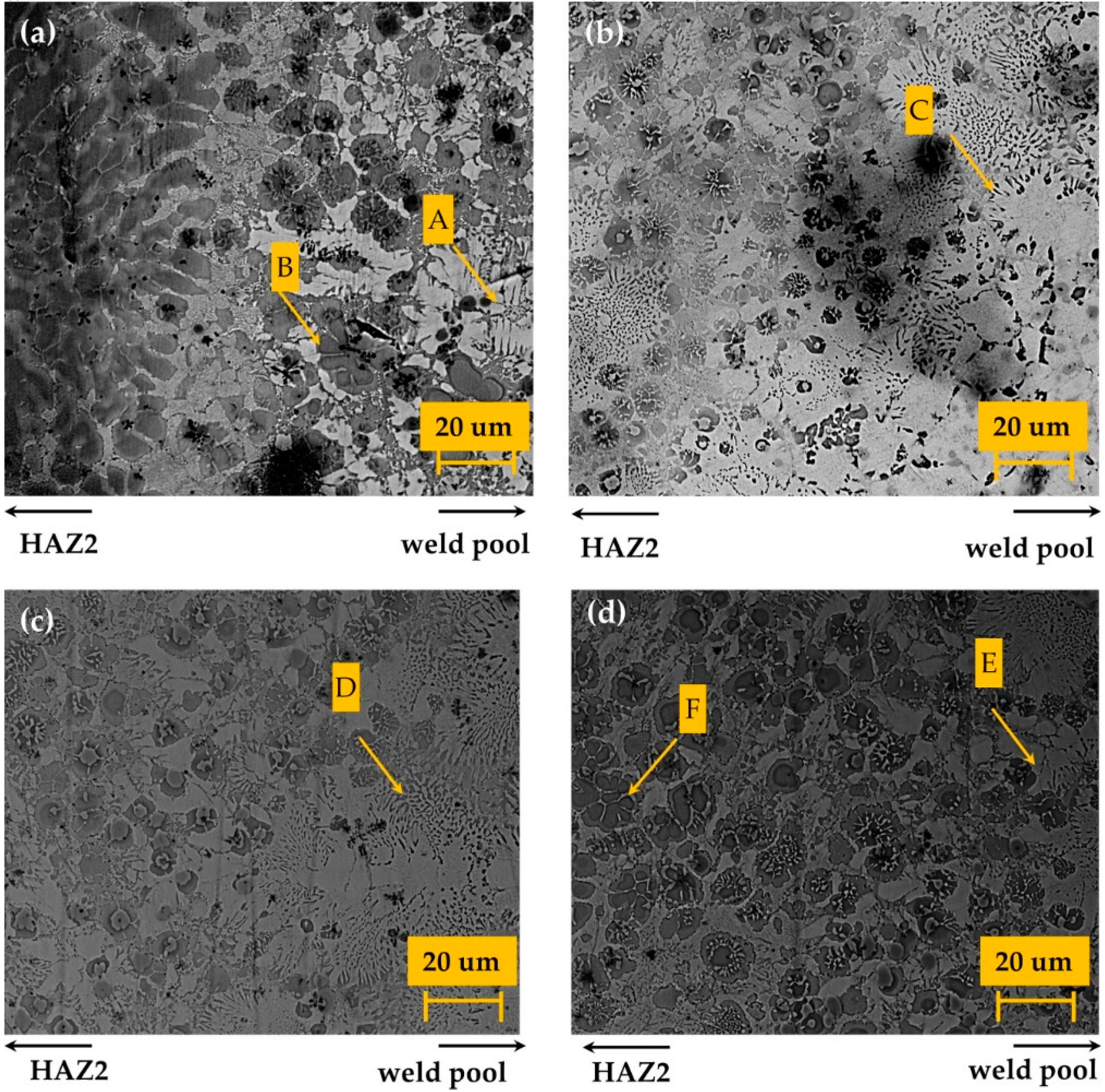

3.2. Microstructural Observation and Elemental Composition Analysis of the Weld Bead

3.3. Characterization of Mechanical Properties

4. Conclusions

- Single-sided laser welding was successfully performed on thin sheets of Ti6Al4V and Inconel 600 in a T-joint configuration using low-power Ytterbium-fiber laser with the influence of laser welding speed and the overlapping factor.

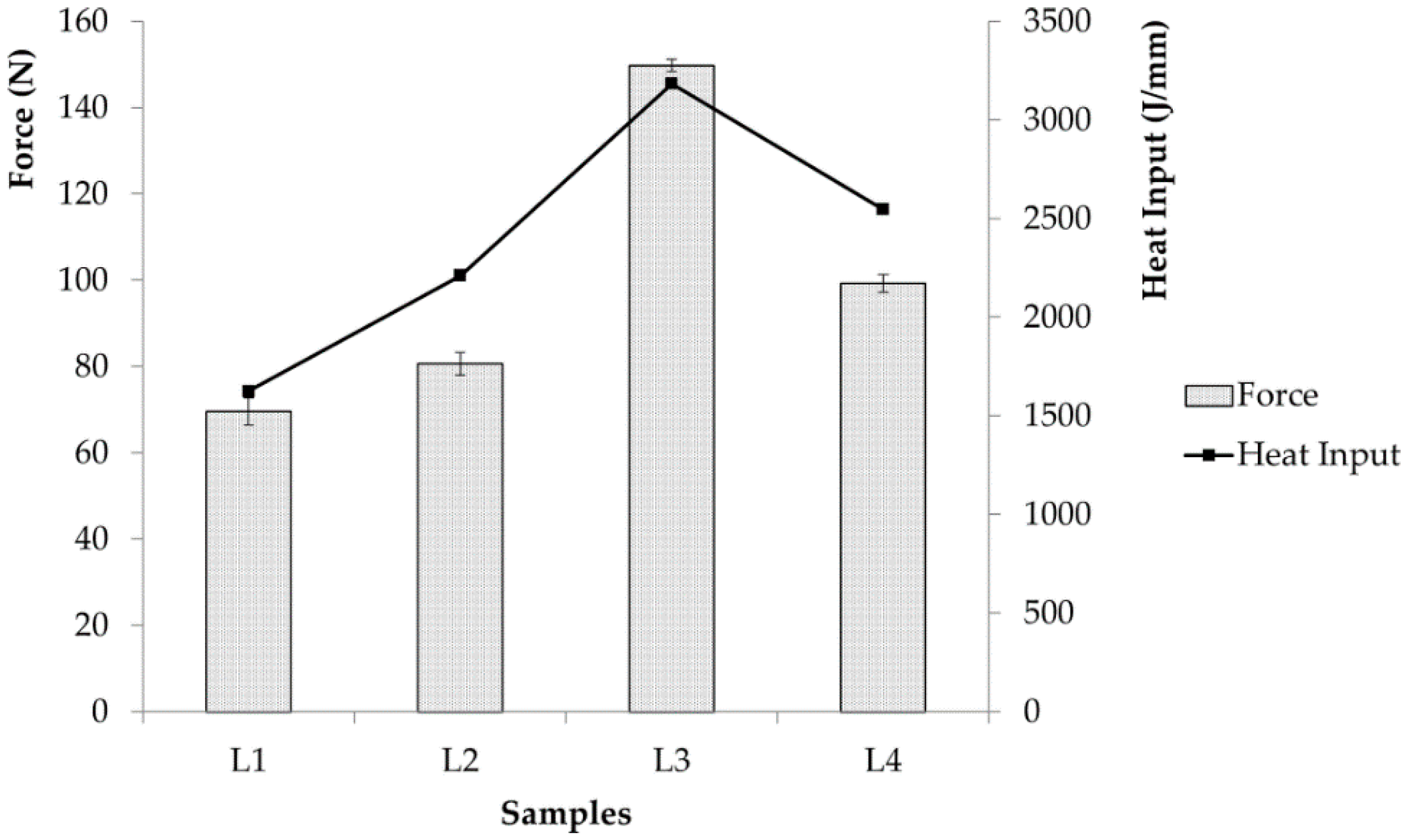

- The highest breaking force and hardness were obtained when the welding speed was 40 mm/s and the overlapping factor was 50% at laser power of 250 W, proving a sound joint was obtained because sufficient heat input was produced.

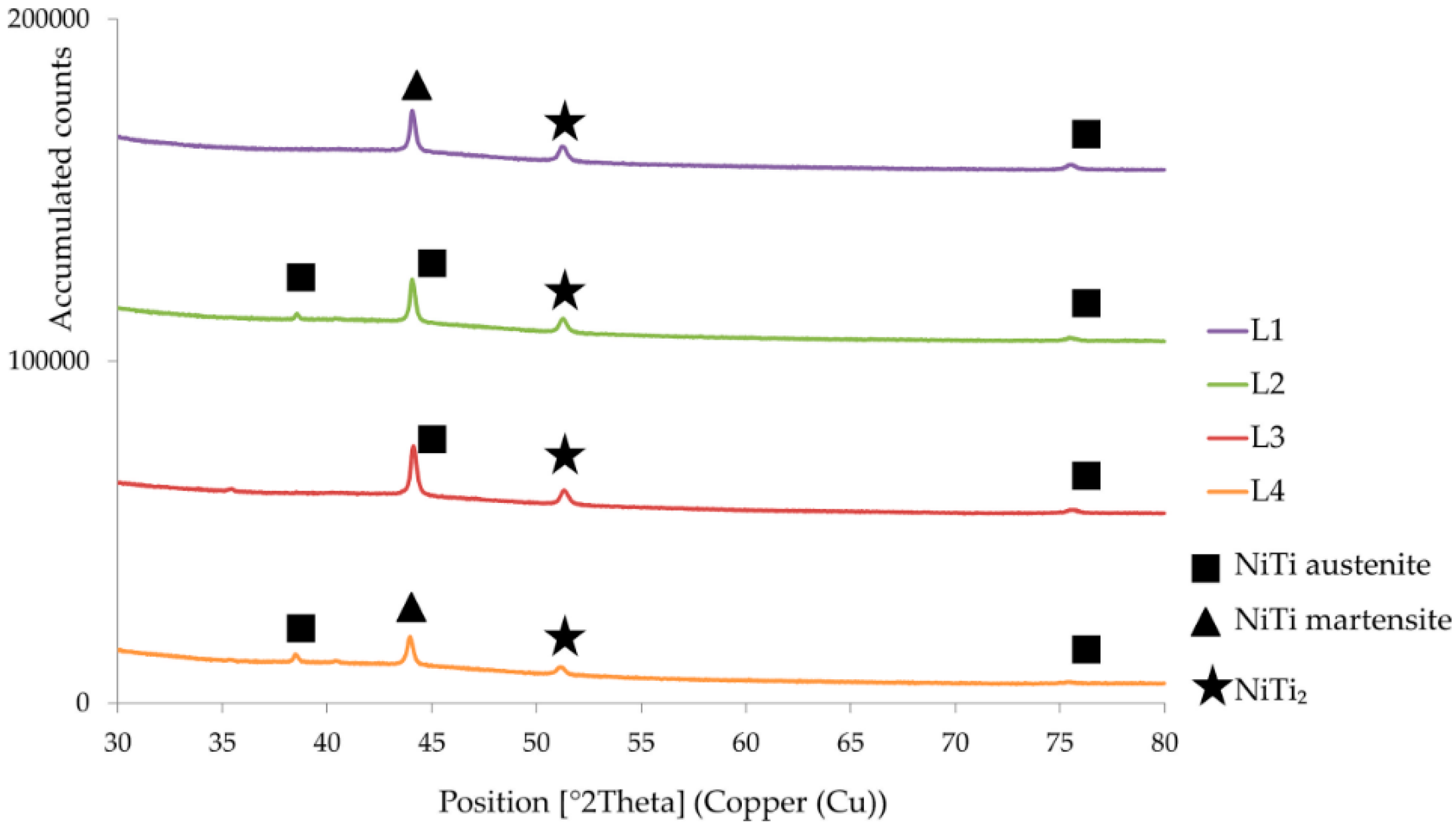

- NiTi and NiTi2 intermetallic layers formed in the FZ and HAZ regions due to crystallographic mismatch between Ni and Ti as well as the differences in thermo-physical properties of the materials.

- The extent of skin-stringer penetration was related to the heat input, which was manipulated by varying the laser welding speed and overlapping factor.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| SEM | Scanning electron microscopy |

| XRD | X-ray diffraction |

| LBW | Laser beam welding |

| BM | Base metal |

| CW | Continuous wave |

| FZ | Fusion zone |

| HAZ | Heat-affected zone |

| TIG | Tungsten inert gas |

| MIG | Metal inert gas |

| Ti | Titanium |

| Ni | Nickel |

| Yb | Ytterbium |

| HNO3 | Nitric acid |

| HF | Hydrofluoric acid |

| OM | Optical microscope |

| EDX | Energy dispersive X-ray |

References

- Shokrani, A.; Dhokia, V.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tool. Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.C.; Pinkerton, A.J.; Li, L. Fibre laser welding of dissimilar alloys of Ti–6Al–4V and inconel 718 for aerospace applications. Int. J. Adv. Manuf. Technol. 2011, 52, 977–987. [Google Scholar] [CrossRef]

- Mavrigian, M. Performance Exhaust Systems: How to Design, Fabricate, and Install; CarTech Inc.: North Branch MN, USA, 2014; p. 144. [Google Scholar]

- Shen, Y.; Liu, Y.; Sun, W.; Dong, H.; Zhang, Y.; Wang, X.; Zheng, C.; Ji, R. High-speed dry compound machining of Ti6Al4V. J. Mater. Process. Technol. 2015, 224, 200–207. [Google Scholar] [CrossRef]

- Warwick Manufacturing Group. Off to the races. Met. Powder Rep. 2012, 67, 22–24. [Google Scholar]

- Welding exhaust systems—part 1. Available online: http://www.burnsstainless.com/weldingarticle1.aspx (accessed on 12 April 2016).

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Kurakake, Y.; Farazila, Y.; Miyashita, Y.; Otsuka, Y.; Mutoh, Y. Effect of molten pool shape on tensile shear strength of dissimilar materials laser spot joint between plastic and metal. J. Laser Micro Nanoeng. 2013, 8, 161–164. [Google Scholar] [CrossRef]

- Chatterjee, S.; Abinandanan, T.A.; Chattopadhyay, K. Phase formation in Ti/Ni dissimilar welds. Mater. Sci. Eng. A 2008, 490, 7–15. [Google Scholar] [CrossRef]

- Schubert, E.; Klassen, M.; Zerner, I.; Walz, C.; Sepold, G. Light-weight structures produced by laser beam joining for future applications in automobile and aerospace industry. J. Mater. Process. Technol. 2001, 115, 2–8. [Google Scholar] [CrossRef]

- Seretsky, J.; Ryba, E. Laser-welding of dissimilar metals—Titanium to nickel. Weld. J. 1976, 55, 208–211. [Google Scholar]

- Chatterjee, S.; Abinandanan, T.A.; Chattopadhyay, K. Microstructure development during dissimilar welding: Case of laser welding of Ti with Ni involving intermetallic phase formation. J. Mater. Sci. 2006, 41, 643–652. [Google Scholar] [CrossRef]

- Carpinteri, A.; Brighenti, R.; Huth, H.J.; Vantadori, S. Fatigue growth of a surface crack in a welded T-joint. Int. J. Fatigue 2004, 27, 59–69. [Google Scholar] [CrossRef]

- Padovani, C.; Fratini, L.; Squillace, A.; Bellucci, F.E. Electrochemical analysis on friction stir welded and laser welded 6xxx aluminium alloys t-joints. Corros. Rev. 2007, 25, 475–489. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Panton, B.; Zeng, Z.; Andrei, C.M.; Zhou, Y.; Miranda, R.M.; Fernandes, F.M.B. Laser joining of niti to Ti6Al4V using a niobium interlayer. Acta Mater. 2016, 105, 9–15. [Google Scholar] [CrossRef]

- Miranda, R.M.; Assunção, E.; Silva, R.J.C.; Oliveira, J.P.; Quintino, L. Fiber laser welding of NiTi to Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 2015, 81, 1533–1538. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. Influence of material characteristics on plastomechanics of the fsw process for T-joints. Mater. Des. 2009, 30, 2435–2445. [Google Scholar] [CrossRef]

- Rebak, R.B.; Crook, P. Nickel alloys for corrosive environments. Adv. Mater. Process. 2000, 157, 37. [Google Scholar]

- Badini, C.; Pavese, M.; Fino, P.; Biamino, S. Laser beam welding of dissimilar aluminium alloys of 2000 and 7000 series: Effect of post-welding thermal treatments on T joint strength. Sci. Technol. Weld. Join. 2009, 14, 484–492. [Google Scholar] [CrossRef]

- Enz, J.; Khomenko, V.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Single-sided laser beam welding of a dissimilar AA2024-AA7050 T-joint. Mater. Des. 2015, 76, 110–116. [Google Scholar] [CrossRef]

- Unt, A.; Salminen, A. Effect of welding parameters and the heat input on weld bead profile of laser welded T-joint in structural steel. J. Laser Appl. 2015, 27. [Google Scholar] [CrossRef]

- Ribic, B.; Palmer, T.A.; DebRoy, T. Problems and issues in laser-arc hybrid welding. Int. Mater. Rev. 2009, 54, 223–244. [Google Scholar] [CrossRef]

- Gao, X.L.; Liu, J.; Zhang, L.J.; Zhang, J.X. Effect of the overlapping factor on the microstructure and mechanical properties of pulsed Nd:Yag laser welded Ti6Al4V sheets. Mater. Character. 2014, 93, 136–149. [Google Scholar] [CrossRef]

- Norris, J.T.; Robino, C.V.; Hirschfeld, D.A.; Perricone, M.J. Effects of laser parameters on porosity formation: Investigating millimeter scale continuous wave Nd:Yag laser welds. Weld. J. 2011, 90, 198. [Google Scholar]

- Donachie, M.J. Titanium: A Technical Guide; ASM International: Novelty, OH, USA, 2000; p. 381. [Google Scholar]

- Sudarshan, T.S. Surface Modification Technologies: Proceedings of the 20th International Conference on Surface Modification Technologies; ASM International: Vienna, Austria, 2007. [Google Scholar]

- Hiraga, H.; Inoue, T.; Shimura, H.; Matsunawa, A. Cavitation erosion mechanism of niti coatings made by laser plasma hybrid spraying. Wear 1999, 231, 272–278. [Google Scholar] [CrossRef]

- Richman, R.H.; Rao, A.S.; Kung, D. Cavitation erosion of NiTi explosively welded to steel. Wear 1995, 181–183, 80–85. [Google Scholar] [CrossRef]

- Kocich, R.; Szurman, I.; Kursa, M. The methods of preparation of Ti–Ni–X alloys and their forming. In Shape Memory Alloys-Processing, Characterization and Applications; Fernandes, F.M.B., Ed.; Press: Ostrava, Czech Republic, 2013. [Google Scholar]

- Brantley, W.A.; Eliades, T. Orthodontic Materials: Scientific and Clinical Aspects; Thieme: Stuttgart, Germany, 2011. [Google Scholar]

- Atabaki, M.M.; Nikodinovski, M.; Chenier, P.; Ma, J.; Liu, W.; Kovacevic, R. Experimental and numerical investigations of hybrid laser arc welding of aluminum alloys in the thick T-joint configuration. Opt. Laser Technol. 2014, 59, 68–92. [Google Scholar] [CrossRef]

| Element | Ti6Al4V | Inconel 600 |

|---|---|---|

| Ni | - | 72 min |

| Cr | - | 14.0–17.0 |

| Cu | - | 0.5 max |

| S | - | 0.015 max |

| Si | - | 0.5 max |

| C | 0–0.08 | 0.05–0.10 |

| Fe | 0–0.4 | 6.0–10.0 |

| Ti | Balance | - |

| Al | 5.5–6.75 | - |

| V | 3.5–4.5 | - |

| Sample | Power (W) P | Welding Speed (mm/s) v | Overlapping Factor (%) η |

|---|---|---|---|

| L1 | 250 | 40 | 30 |

| L2 | 250 | 40 | 40 |

| L3 | 250 | 40 | 50 |

| L4 | 250 | 50 | 50 |

| Point | Ni (at. %) | Ti (at. %) | V (at %) | Al (at. %) | Cr (at. %) | Fe (at. %) | Total (%) | Phase |

|---|---|---|---|---|---|---|---|---|

| A | 39.5 | 40.5 | 3.4 | 5.4 | 7.7 | 3.5 | 100.0 | NiTi |

| B | 28.4 | 56.4 | 3.3 | 5.3 | 3.6 | 3.0 | 100.0 | NiTi2 |

| C | 42.1 | 38.9 | 3.2 | 4.0 | 8.3 | 3.5 | 100.0 | NiTi |

| D | 40.5 | 40.9 | 3.5 | 3.9 | 8.1 | 3.1 | 100.0 | NiTi |

| E | 39.4 | 40.6 | 3.3 | 4.4 | 7.6 | 4.7 | 100.0 | NiTi |

| F | 29.1 | 55.4 | 3.5 | 6.0 | 3.3 | 2.7 | 100.0 | NiTi2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janasekaran, S.; Tan, A.W.; Yusof, F.; Abdul Shukor, M.H. Influence of the Overlapping Factor and Welding Speed on T-Joint Welding of Ti6Al4V and Inconel 600 Using Low-Power Fiber Laser. Metals 2016, 6, 134. https://doi.org/10.3390/met6060134

Janasekaran S, Tan AW, Yusof F, Abdul Shukor MH. Influence of the Overlapping Factor and Welding Speed on T-Joint Welding of Ti6Al4V and Inconel 600 Using Low-Power Fiber Laser. Metals. 2016; 6(6):134. https://doi.org/10.3390/met6060134

Chicago/Turabian StyleJanasekaran, Shamini, Ai Wen Tan, Farazila Yusof, and Mohd Hamdi Abdul Shukor. 2016. "Influence of the Overlapping Factor and Welding Speed on T-Joint Welding of Ti6Al4V and Inconel 600 Using Low-Power Fiber Laser" Metals 6, no. 6: 134. https://doi.org/10.3390/met6060134