Microstructure and Mechanical Properties of Accumulative Roll-Bonded AA1050A/AA5005 Laminated Metal Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. The ARB Process

2.2. Microstructural Characterization

2.3. Mechanical Properties

3. Results and Discussion

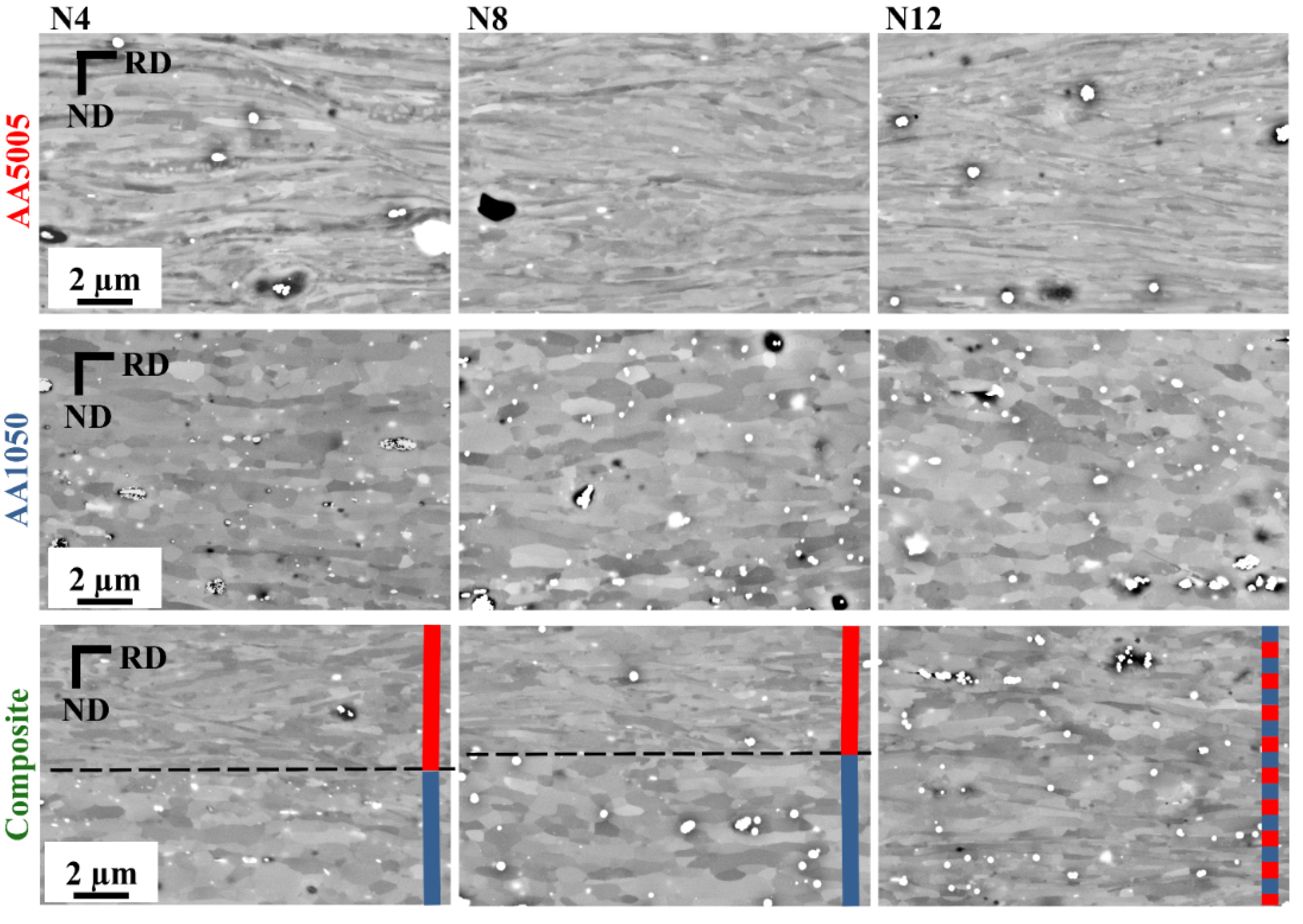

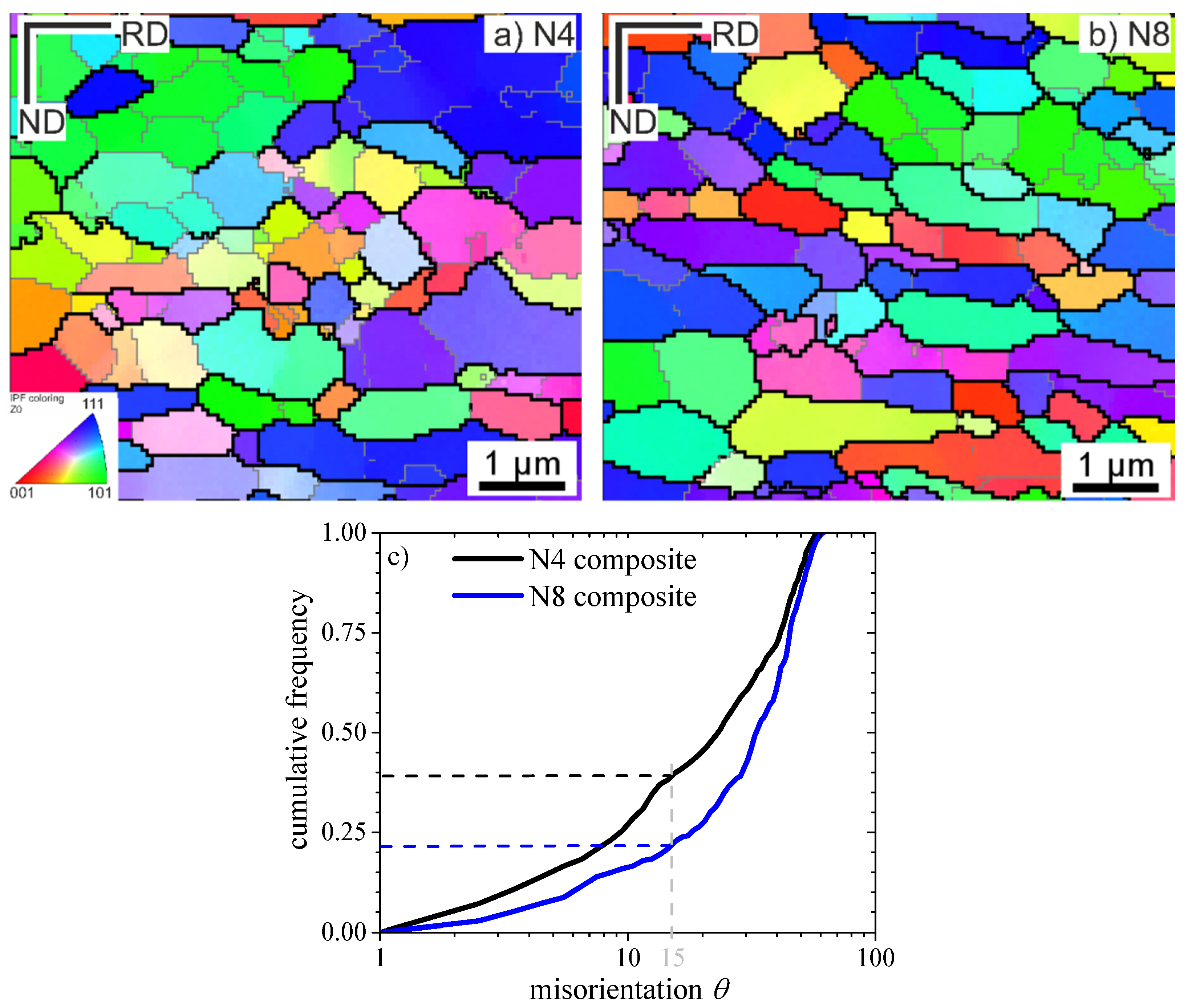

3.1. Microstructural Investigations

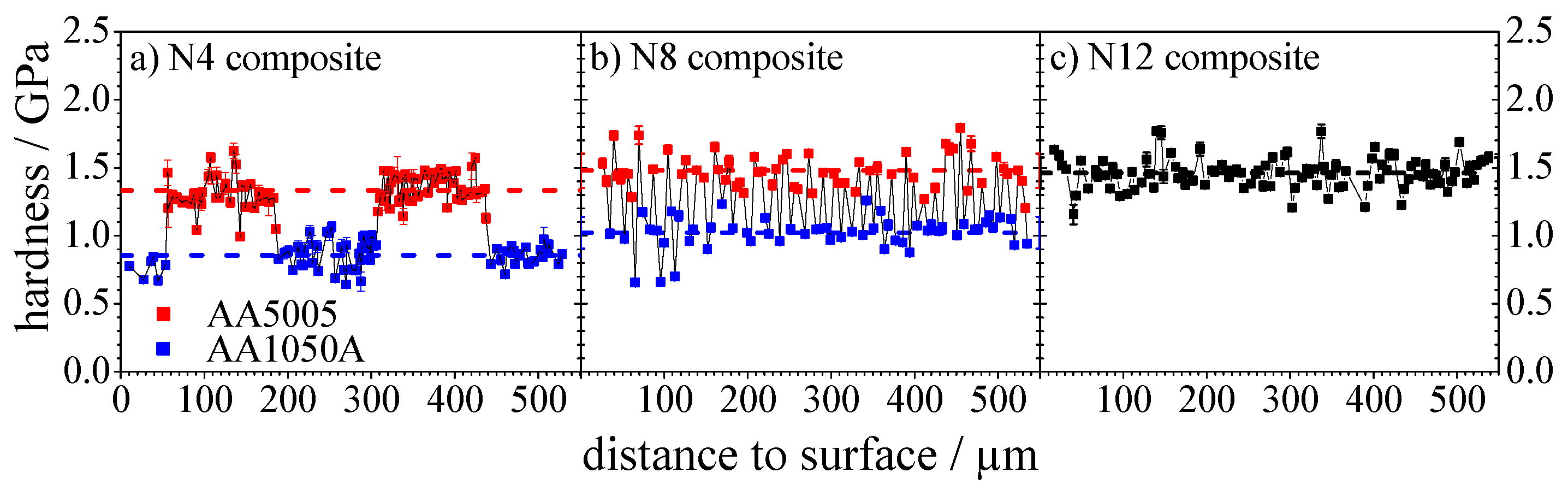

3.2. Nanoindentation Experiments

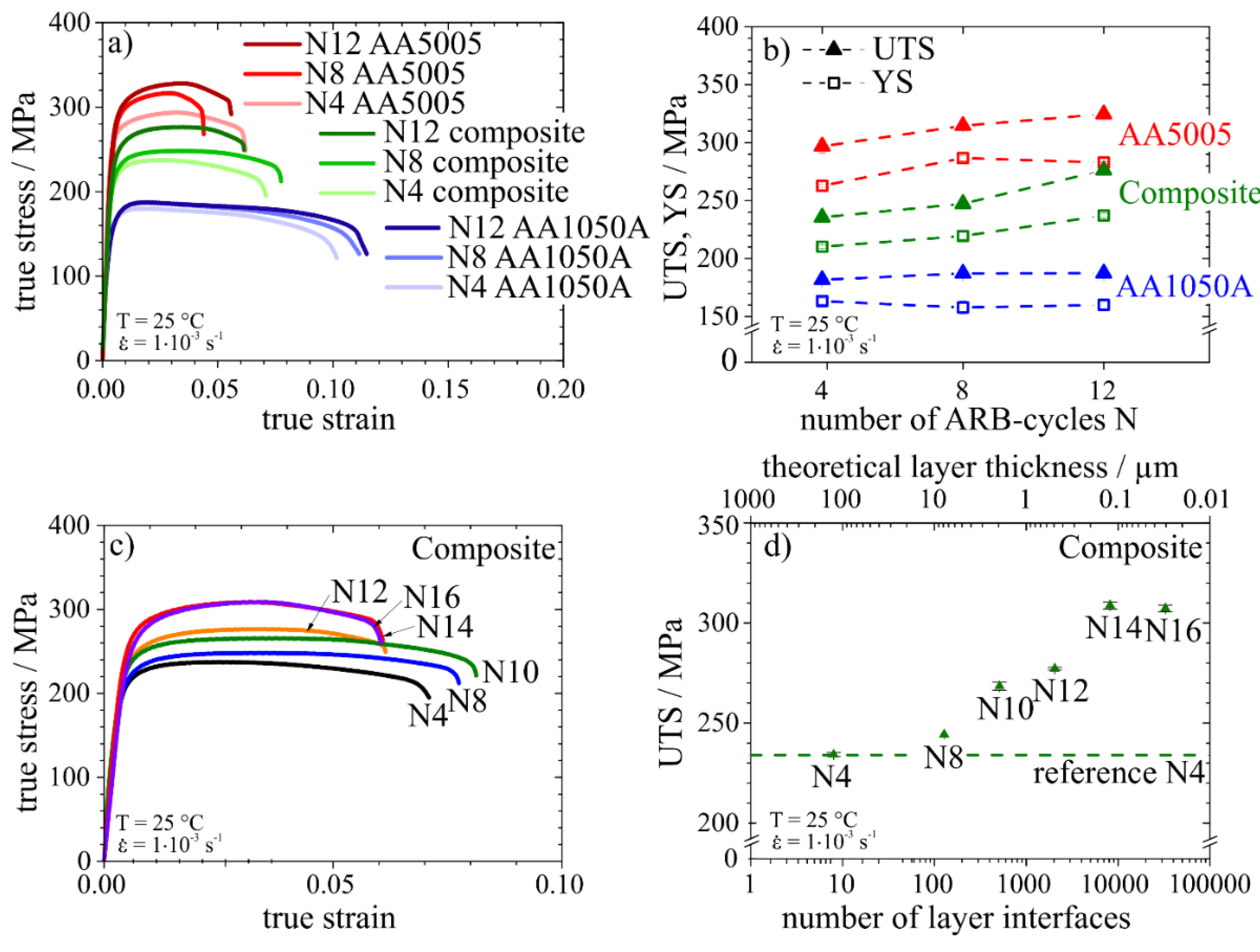

3.3. Mechanical Properties under Monotonic Loads

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, L.; Nagai, K.; Yin, F. Progress in cold roll bonding of metals. Sci. Technol. Adv. Mater. 2008. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Höppel, H.W.; May, J.; Göken, M. Enhanced strength and ductility in ultrafine-grained aluminium produced by accumulative roll bonding. Adv. Eng. Mater. 2004, 6, 781–784. [Google Scholar] [CrossRef]

- Schmidt, C.W.; Knieke, C.; Maier, V.; Höppel, H.W.; Peukert, W.; Göken, M. Accelerated grain refinement during accumulative roll bonding by nanoparticle reinforcement. Scr. Mater. 2011, 64, 245–248. [Google Scholar] [CrossRef]

- Lesuer, D.R.; Syn, C.K.; Sherby, O.D.; Wadsworth, J.; Lewandowski, J.J.; Hunt, W.H., Jr. Mechanical behaviour of laminated metal composites. Int. Mater. Rev. 1996, 41, 169–197. [Google Scholar] [CrossRef]

- Eizadjou, M.; Talachi, A.K.; Manesh, H.D.; Shahabi, H.S.; Janghorban, K. Investigation of structure and mechanical properties of multi-layered Al/Cu composite produced by accumulative roll bonding (ARB) process. Compos. Sci. Technol. 2008, 68, 2003–2009. [Google Scholar] [CrossRef]

- Wu, K.; Chang, H.; Maawad, E.; Gan, W.M.; Brokmeier, H.G.; Zheng, M.Y. Microstructure and mechanical properties of the Mg/Al laminated composite fabricated by accumulative roll bonding (ARB). Mater. Sci. Eng. A 2010, 527, 3073–3078. [Google Scholar] [CrossRef]

- Kavarana, F.H.; Ravichandran, K.S.; Sahay, S.S. Nanoscale steel-brass multilayer laminates made by cold rolling: Microstructure and tensile properties. Scr. Mater. 2000, 42, 947–954. [Google Scholar] [CrossRef]

- Slámová, M.; Sláma, P.; Homola, P.; Uhlíř, J.; Cieslar, M. Multilayer composite Al99.99/AlMg3 sheets prepared by accumulative roll bonding. Int. J. Mater. Res. 2009, 100, 858–862. [Google Scholar] [CrossRef]

- Hausöl, T.; Höppel, H.W.; Göken, M. Microstructure and mechanical properties of accumulative roll bonded AA6014/AA5754 aluminium laminates. Mater. Sci. Forum 2011, 667–669, 217–222. [Google Scholar] [CrossRef]

- Govindaraj, N.V.; Frydendahl, J.G.; Holmedal, B. Layer continuity in accumulative roll bonding of dissimilar material combinations. Mater. Des. 2013, 52, 905–915. [Google Scholar] [CrossRef]

- Göken, M.; Höppel, H.W.; Hausöl, T.; Bach, J.; Maier, V.; Schmidt, C.; Amberger, D. Grain Refinement and Deformation Mechanisms in Heterogeneous Ultrafine-Grained Materials Processed by Accumulative Roll Bonding. In Proceedings of the 33rd Riso International Symposium on Materials Science: Nanometals—Status and Perspective, Roskilde, Denmark, 3–7 September 2012; pp. 31–48.

- Kümmel, F.; Hausöl, T.; Höppel, H.W.; Göken, M. Enhanced fatigue life of accumulative roll bonded AA1050A/AA5005 laminated metal composites. Acta Mater submitted for publication. 2016. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hay, J.C.; Pharr, G.M. Instrumented Indentation Testing. ASM Handbook Volume 8: Mechanical Testing and Evaluation, 10th Ed. ed; ASM Int: Materials Park, OH, USA, 2000; pp. 232–243. [Google Scholar]

- May, J.; Dinkel, M.; Amberger, D.; Höppel, H.W.; Göken, M. Mechanical properties, dislocation density and grain structure of ultrafine-grained aluminum and aluminum-magnesium alloys. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 2007, 38A, 1941–1945. [Google Scholar] [CrossRef]

- Quadir, M.Z.; Ferry, M.; Al-Buhamad, O.; Munroe, P.R. Shear banding and recrystallization texture development in a multilayered Al alloy sheet produced by accumulative roll bonding. Acta Mater. 2009, 57, 29–40. [Google Scholar] [CrossRef]

- Tsuji, N. Fabrication of Bulk Nanostructured Materials by Accumulative Roll Bonding. In Bulk Nanostructured Materials; Zehetbauer, M.J., Zhu, Y.T., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2009; pp. 235–253. [Google Scholar]

- Huang, X.; Tsuji, N.; Hansen, N.; Minamino, Y. Microstructural evolution during accumulative roll-bonding of commercial purity aluminum. Mater. Sci. Eng. A 2003, 340, 265–271. [Google Scholar] [CrossRef]

- Torre, F.D.; Lapovok, R.; Sandlin, J.; Thomson, P.F.; Davies, C.H.J.; Pereloma, E.V. Microstructures and properties of copper processed by equal channel angular extrusion for 1–16 passes. Acta Mater. 2004, 52, 4819–4832. [Google Scholar] [CrossRef]

- Kamikawa, N.; Huang, X.; Tsuji, N.; Hansen, N. Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed. Acta Mater. 2009, 57, 4198–4208. [Google Scholar] [CrossRef]

- Su, L.; Lu, C.; Tieu, A.K.; Deng, G.; Sun, X. Ultrafine grained AA1050/AA6061 composite produced by accumulative roll bonding. Mater. Sci. Eng. A 2013, 559, 345–351. [Google Scholar] [CrossRef]

| Material | Chemical Composition (wt. %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Al | Each | Total | |

| AA1050A | <0.25 | <0.40 | <0.05 | <0.05 | <0.05 | <0.05 | <0.07 | bal. | <0.05 | - |

| AA5005 | <0.30 | <0.70 | <0.20 | <0.20 | 0.50-1.10 | <0.10 | <0.25 | bal. | <0.05 | 0.15 |

| ARB Cycle No. | Recrystallized after ARB Cycle No. | No. of Layer Interfaces | Layer Thickness/µm |

|---|---|---|---|

| N | N | (2N/2) | (1000 × 2/2N) |

| 4 | - | 8 | 125.0 |

| 8 | 4 | 128 | 8.0 |

| 10 | 4 + 6 | 512 | 2.0 |

| 12 | 4 + 8 | 2048 | 0.5 |

| 14 | 4 + 8 + 10 | 8192 | 0.1 |

| 16 | 4 + 8 + 12 | 22,768 | 0.03 |

| Mono-Material | AA1050A | AA5005 | ||||

| N | ND | RD | a | ND | RD | a |

| 0 | 40.54 ± 3.53 | 67.75 ± 8.97 | 1.67 | 12.71 ± 1.34 | 16.04 ± 2.18 | 1.26 |

| 4 | 0.324 ± 0.019 | 0.895 ± 0.102 | 2.76 | 0.210 ± 0.010 | 0.924 ± 0.115 | 4.41 |

| 8 | 0.365 ± 0.022 | 0.962 ± 0.111 | 2.63 | 0.198 ± 0.010 | 1.057 ± 0.148 | 5.82 |

| 12 | 0.385 ± 0.025 | 1.048 ± 0.090 | 2.73 | 0.190 ± 0.011 | 1.105 ± 0.150 | 5.80 |

| Composite | AA1050A | AA5005 | ||||

| N | ND | RD | a | ND | RD | a |

| 4r | 13.95 ± 1.31 | 18.24 ± 2.36 | 1.20 | 15.15 ± 1.35 | 16.47 ± 1.71 | 1.18 |

| 4 | 0.333 ± 0.026 | 0.800 ± 0.089 | 2.40 | 0.183 ± 0.017 | 0.733 ± 0.108 | 4.00 |

| 8 | 0.362 ± 0.025 | 0.876 ± 0.121 | 2.42 | 0.178 ± 0.015 | 0.767 ± 0.117 | 4.31 |

| No Distinction of the Two Materials is Possible for ARB Cycles ≥ 10 | ||||||

| 10 | 0.246 ± 0.028 | 1.029 ± 0.101 | 4.19 | - | - | - |

| 12 | 0.210 ± 0.013 | 0.962 ± 0.071 | 4.59 | - | - | - |

| 14 | 0.198 ± 0.012 | 0.864 ± 0.074 | 4.38 | - | - | - |

| 16 | 0.197 ± 0.008 | 0.713 ± 0.095 | 3.39 | - | - | - |

| Material | Median of Misorientation/° | Fraction of LAGB/% | Fraction of HAGB/% |

|---|---|---|---|

| AA1050A N4 Composite | 22.5 | 38 | 62 |

| AA1050A N8 Composite | 32.5 | 21 | 79 |

| No. of ARB Cycles N | Mono-Material | Composite | ||

|---|---|---|---|---|

| AA1050A | AA5005 | AA1050A | A5005 | |

| Mean Hardness/GPa | ||||

| 4 | 0.83 ± 0.10 | 1.30 ± 0.15 | 0.85 ± 0.10 | 1.33 ± 0.11 |

| 8 | 1.00 ± 0.07 | 1.61 ± 0.08 | 1.02 ± 0.12 | 1.53 ± 0.13 |

| 12 | 1.02 ± 0.07 | 1.63 ± 0.09 | 1.46 ± 0.11 * | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kümmel, F.; Kreuz, M.; Hausöl, T.; Höppel, H.W.; Göken, M. Microstructure and Mechanical Properties of Accumulative Roll-Bonded AA1050A/AA5005 Laminated Metal Composites. Metals 2016, 6, 56. https://doi.org/10.3390/met6030056

Kümmel F, Kreuz M, Hausöl T, Höppel HW, Göken M. Microstructure and Mechanical Properties of Accumulative Roll-Bonded AA1050A/AA5005 Laminated Metal Composites. Metals. 2016; 6(3):56. https://doi.org/10.3390/met6030056

Chicago/Turabian StyleKümmel, Frank, Michael Kreuz, Tina Hausöl, Heinz Werner Höppel, and Mathias Göken. 2016. "Microstructure and Mechanical Properties of Accumulative Roll-Bonded AA1050A/AA5005 Laminated Metal Composites" Metals 6, no. 3: 56. https://doi.org/10.3390/met6030056

APA StyleKümmel, F., Kreuz, M., Hausöl, T., Höppel, H. W., & Göken, M. (2016). Microstructure and Mechanical Properties of Accumulative Roll-Bonded AA1050A/AA5005 Laminated Metal Composites. Metals, 6(3), 56. https://doi.org/10.3390/met6030056