An Investigation of the Mechanical Properties of a Weldment of 7% Nickel Alloy Steels

Abstract

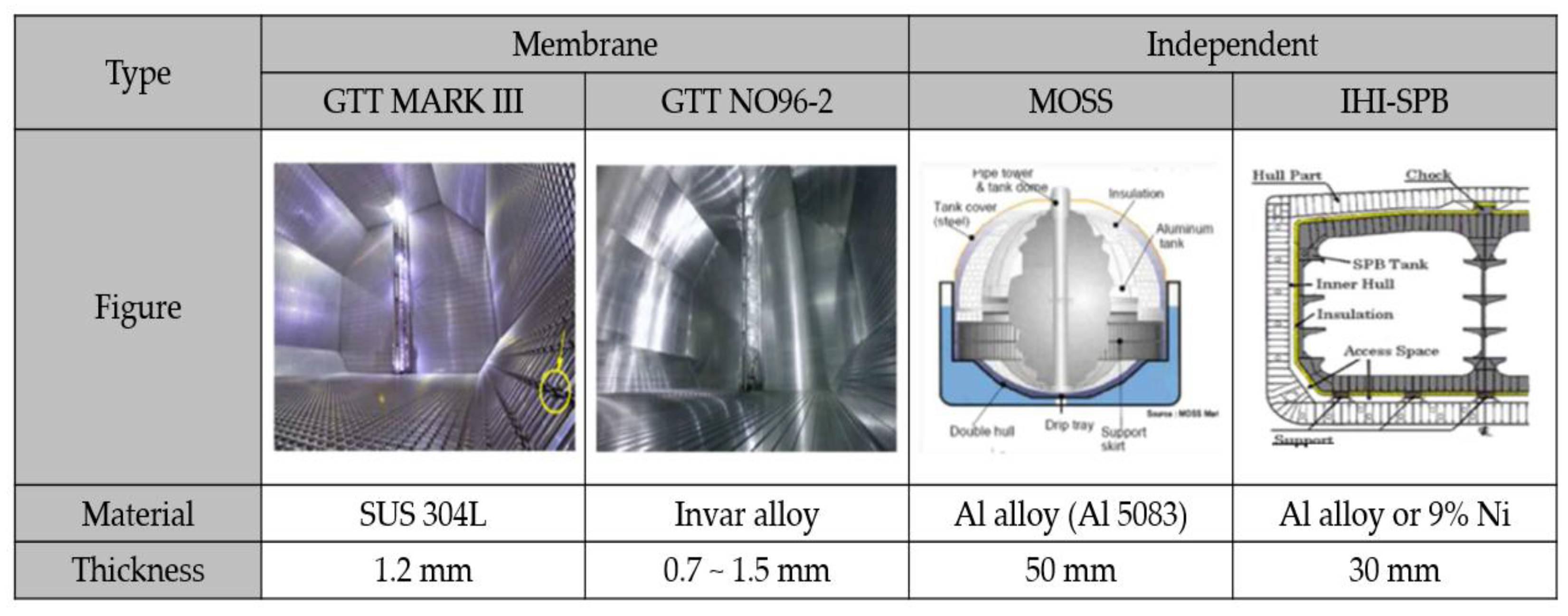

:1. Introduction

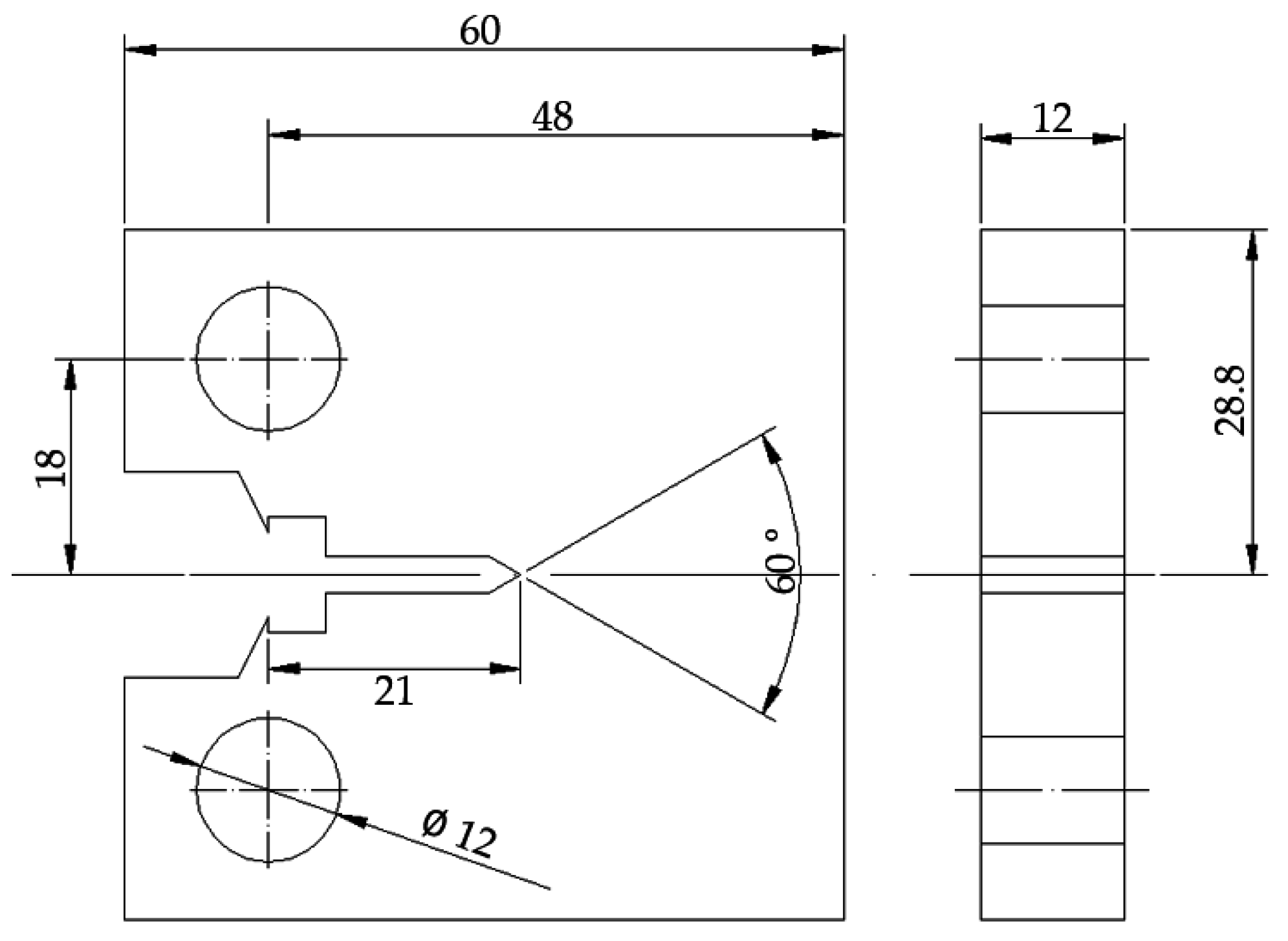

2. Materials and Methods

3. Test Results

3.1. Mechanical Properties

3.2. Charpy-V Impact Test

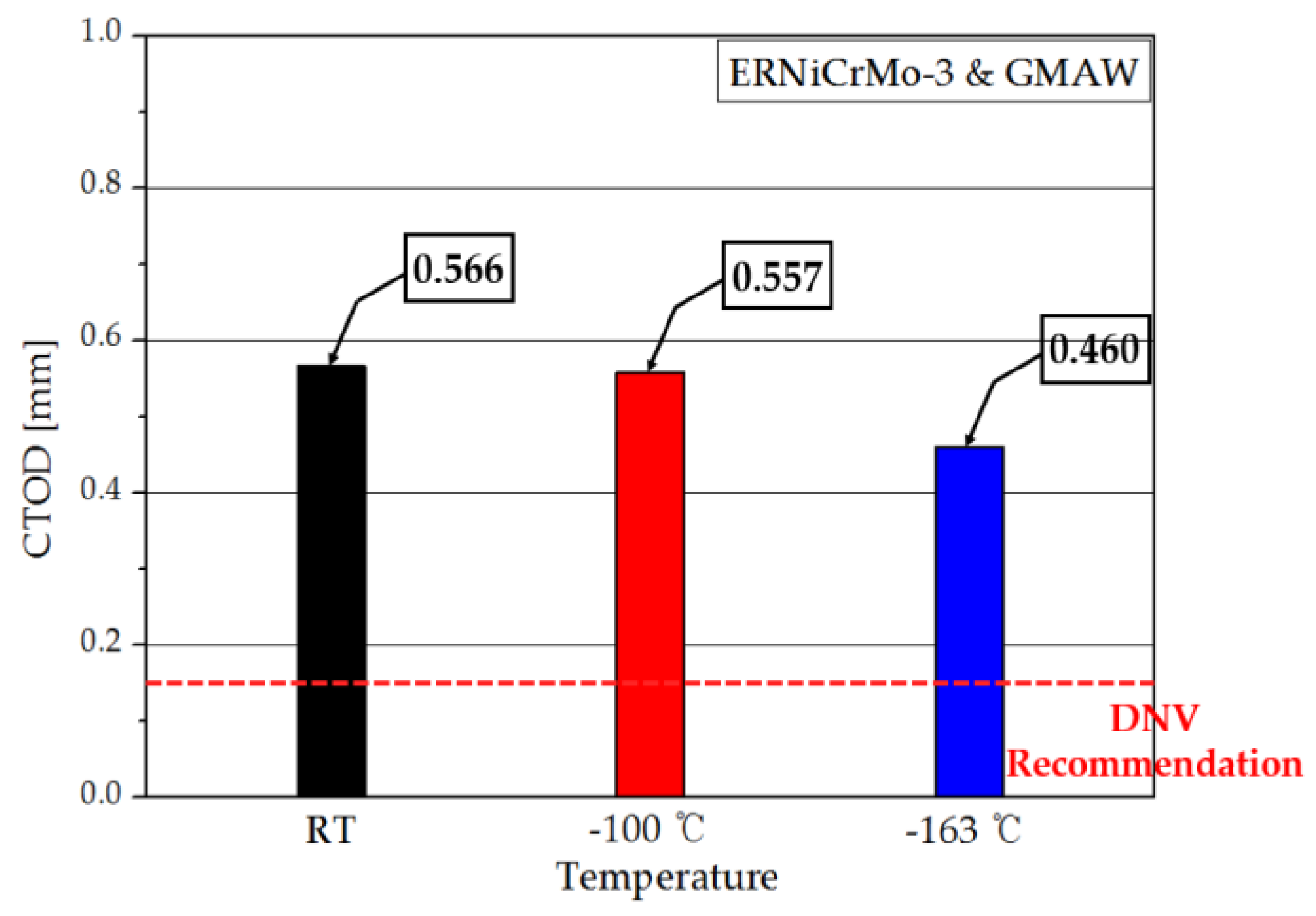

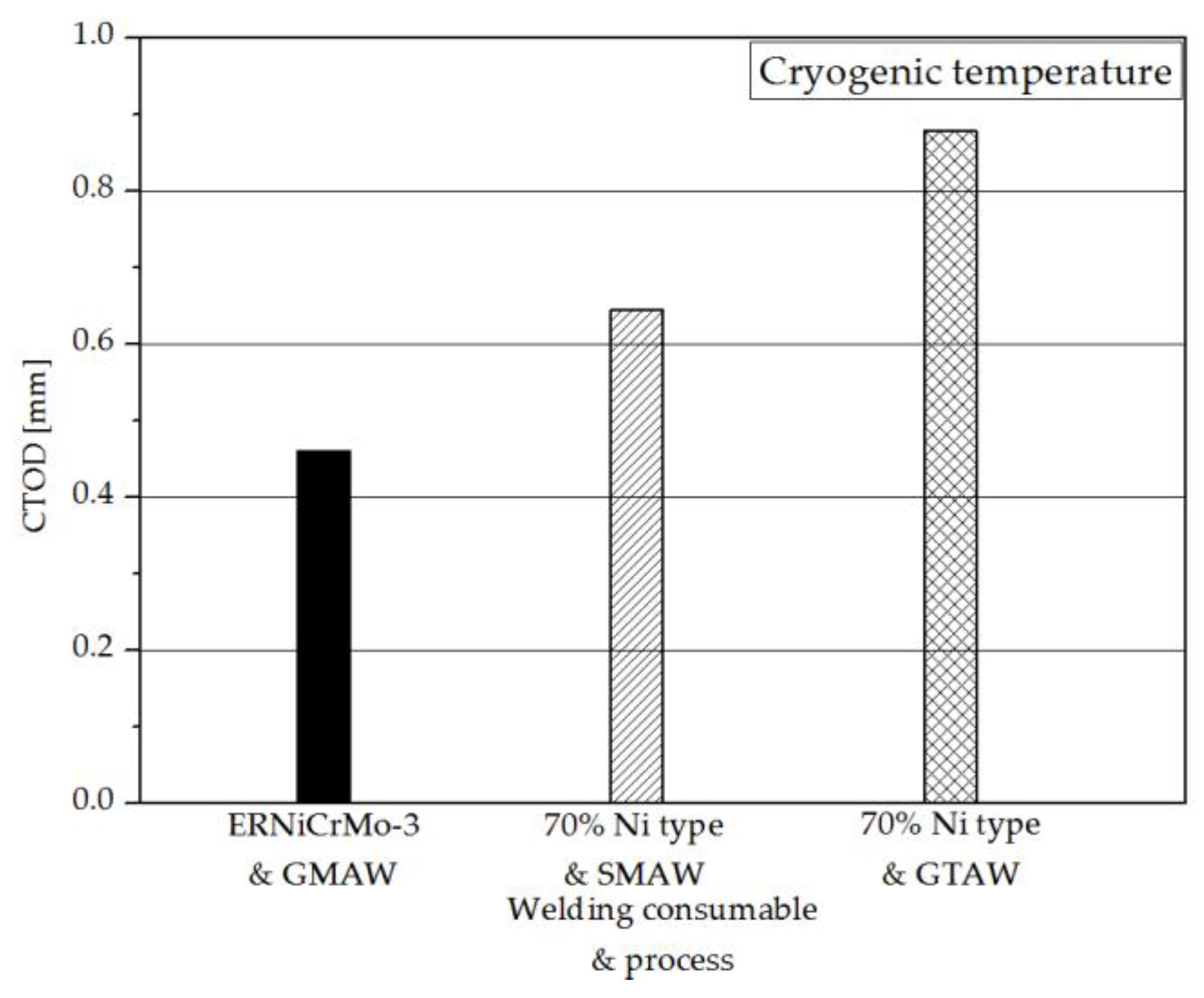

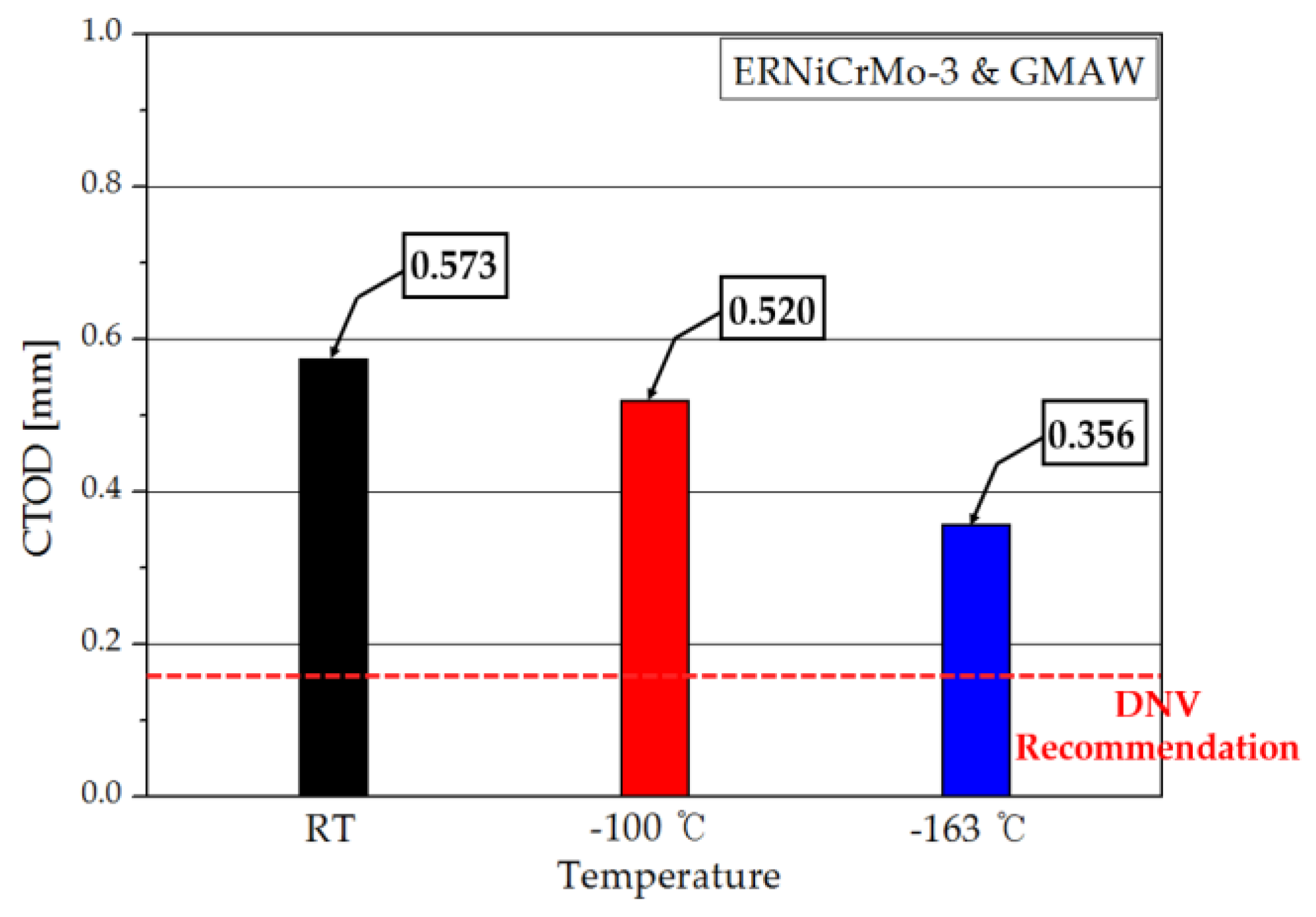

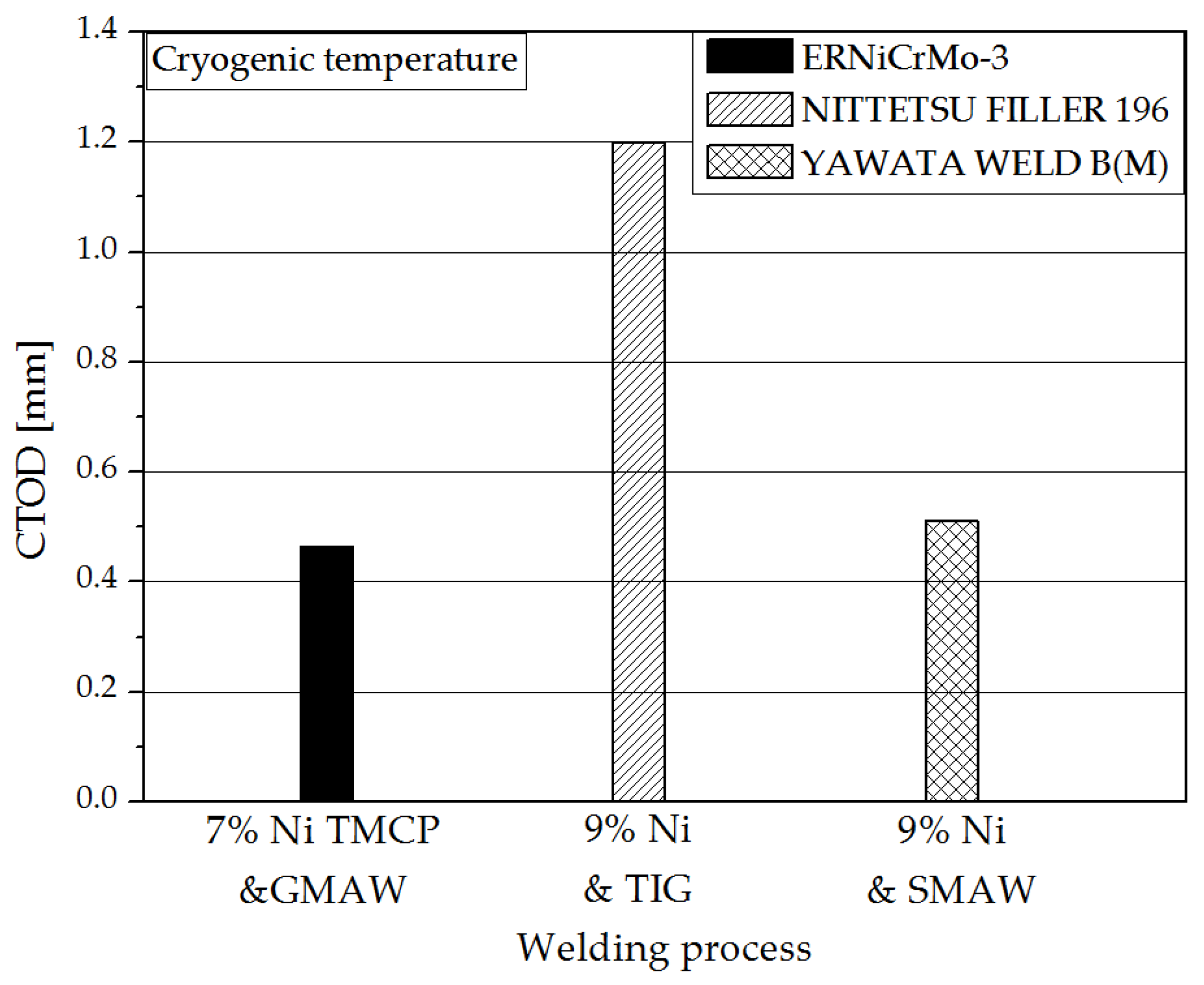

3.3. The CTOD Test

4. Discussion

5. Conclusions

- In the 7% nickel alloy steel, the weldment of ERNiCrMo-3 with FCAW had the highest yield and tensile strengths among other weldments. The mechanical properties of high manganese weldment with TIG did not satisfy the minimum requirements of BV and DNV. Therefore, the weldment of high manganese with TIG was determined to be unsuitable for 7% nickel alloy steel in terms of mechanical properties.

- The weldment of ERNiCrMo-3 with GMAW is about 2.3 and 1.05 times higher than that of ERNiCrMo-3 with FCAW and high manganese with TIG in terms of the absorbed energy at −196 °C, respectively. Based on the tensile and Charpy-V impact test results, the weldment of ERNiCrMo-3 with GMAW is the most appropriate for 7% nickel alloy steel.

- The weldment of ERNiCrMo-3 with GMAW exhibited the lowest CTOD values compared with other conventional weldments of 7% nickel alloy steel. It is estimated that the CTOD value of the weldment was affected by the nickel content of the welding consumables.

- Compared with the CTOD value of 9% nickel steel weldment, 7% nickel alloy steel weldment exhibits comparable CTOD values except the TIG welding process. Therefore, the weld metal of 7% nickel alloy steel is considered to be a viable alternative to 9% nickel steel from a cost-effective perspective.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chun, M.S.; Kim, M.H.; Kim, W.S.; Kim, S.H.; Lee, J.M. Experimental investigation on the impact behavior of membrane-type LNG carrier insulation system. J. Loss Prev. Process Ind. 2009, 22, 901–907. [Google Scholar] [CrossRef]

- Kim, M.H.; Lee, S.M.; Lee, J.M.; Noh, B.J.; Kim, W.S. Fatigue strength assessment of MARK-III LNG cargo containment system. Ocean Eng. 2010, 37, 1243–1252. [Google Scholar] [CrossRef]

- Ishimatu, J.; Kawabata, K.; Morita, H.; Ikkai, H.; Suetake, Y. Building of Advanced Large Sized Membrane Type LNG Carrier; Mitsubishi Heavy Industries, Ltd.: Tokyo, Japan, 2004. [Google Scholar]

- Oh, D.J.; Lee, J.M.; Noh, B.J.; Kim, W.S.; Ando, R.; Matsumoto, T.; Kim, M.H. Investigation of fatigue performance of low temperature alloys for liquefied natural gas storage tanks. J. Mech. Eng. Sci. 2015, 229, 1300–1314. [Google Scholar] [CrossRef]

- Saitoh, N.; Yamaba, R.; Muraoka, H.; Saeki, O. Development of Heavy 9% Nickel Steel Plates with Superior Low-Temperature Toughness for LNG Storage Tanks; Nippon Steel: Tokyo, Japan, 1993. [Google Scholar]

- Yoon, Y.K.; Kim, J.H.; Shim, K.T. Mechanical characteristics of 9% Ni steel welded joint for LNG storage tank at cryogenic. Int. J. Mod. Phys. Conf. Ser. 2012, 6, 355–360. [Google Scholar] [CrossRef]

- Khourshid, A.E.F.M.; Ghanem, M.A. The influence of welding parameters on brittle fracture of liquefied natural gas storage tank welded joint. Mater. Sci. Appl. 2013, 4, 198–204. [Google Scholar] [CrossRef]

- IA104E. International code for the construction and equipment of ships carrying liquefied gas in bulk. In ICG Code; IGC: London, UK, 2014; p. 99.

- Furuya, H.; Kawabata, T.; Takahashi, Y.; Kamo, T.; Inoue, T.; Okushima, M.; Ando, R.; Onishi, K. Development of Low-Nickel Steel for LNG Storage Tanks. In Proceedings of the 2013 International Conference & Exhibition on Liquefied Natural Gas, Houston, TX, USA, 16–19 April 2013.

- ASTM E8. Standard test methods for tension testing of metallic materials. In Annual Book of ASTM Standards; ASTM International: Baltimore, MD, USA, 2009.

- BS 7448-Part 2. Fracture mechanics toughness test. Method for determination of KIc, critical CTOD and critical J values of welds in metallic materials. In British Standard; British Standard Institution: London, UK, 1997.

- ASTM International. Standard test methods for notched bar impact testing of metallic materials. In Annual Book of ASTM Standards; ASTM International: Baltimore, MD, USA, 2007. [Google Scholar]

- Kim, M.H. JDP for Assessment of 7% Nickel Steel for Type-B LNG Tanks; Hyundai Heavy Industries: Busan, Korea, 2013. [Google Scholar]

- NR 216 DT R07 E. Rules on materials and welding for the classification of marine units. In Annual Book of BV Rule; BV: Courbevoie, France, 2014; p. 211.

- Rule for Ships Pt.2 Ch.3. Materials and welding. In Annual Book of DNV Rule; DNV: Oslo, Norway, 1996; p. 37.

- Kim, K.S.; Park, C.Y.; Kang, J.K. Availability evaluation of high Mn steel by comparison with current materials available in cryogenic environment. In Proceedings of the 2013 International Offshore and Polar Engineering, Anchorage, AK, USA, 30 June–5 July 2013.

- Nishigami, H. Development of 7% Ni-TMCP steel plate for LNG storage tanks. In Proceedings of the 2011 International Gas and Union Research Conference, Seoul, Korea, 19–21 October 2011.

- Shin, Y.T.; Kang, S.W.; Kim, M.H. Evaluation of fracture toughness and microstructure on FCA weldment according to heat input. J. Weld. Join. 2008, 26, 51–60. [Google Scholar] [CrossRef]

- Scheid, A.; Felix, L.M.; Martinazzi, D.; Renck, T.; Kwietniewski, C.E.F. The microstructure effect on the fracture toughness of ferritic Ni-alloyed steels. Mater. Sci. Eng. A 2016, 661, 96–104. [Google Scholar] [CrossRef]

| Minimum Design Temperature (°C) | Chemical Composition and Heat Treatment | Application |

|---|---|---|

| −60 | 1.5% nickel steel—normalizded | Liquefied Propane Gas |

| −65 | 2.25% nickel steel—normalized or normalized and tempered | |

| −90 | 3.5% nickel steel—normalized or normalized and tempered | Liquefied Ethane Gas |

| −105 | 5% nickel steel—normalized or normalized and tempered | |

| −165 | 9% nickel steel—double nomalized and tempered or quenched and temperd | Liquefied Natural Gas |

| Material | C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| 7% nickel alloy steel | 0.04 | 0.06 | 0.78 | 0.002 | 0.004 | 0.46 | 7.13 | 0.09 |

| Welding Consumable | C | Si | S | Mn | Ni | Cr | Mo | Co | Nb | N |

|---|---|---|---|---|---|---|---|---|---|---|

| High manganese | 0.01 | - | 0.41 | 7.25 | 15.77 | 20.59 | 2.9 | 0.13 | 0.06 | 0.16 |

| ERNiCrMo-3 | 0.018 | 0.47 | 0.001 | 0.36 | 62.91 | 22.51 | 9.01 | - | 3.65 | - |

| Classification | YS (Mpa) | TS (Mpa) | E.L. (%) |

|---|---|---|---|

| High manganese & TIG | 473 | 614 | 36 |

| ERNiCrMo-3 & FCAW | 509 | 781 | 68.7 |

| ERNiCrMo-3 & GMAW | 506 | 753 | 75.0 |

| BV requirement [14] | 480 | 670 | 22 |

| DNV requirement [15] | 490 | 640 | 25 |

| Classification | Test Temp. (°C) | Charpy-V Impact Test (J) | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | ||

| High manganese & TIG | −196 | 91 | 105 | 89 | 95 |

| ERNiCrMo-3 & FCAW | 47 | 39 | 41 | 42 | |

| ERNiCrMo-3 & GMAW | 104 | 100 | 96 | 100 | |

| BV requirement [14] | - | - | - | 34 | |

| DNV requirement [15] | - | - | - | ||

| Welding Consumable | C | Si | S | Mn | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| ERNiCrMo-3 | 0.018 | 0.47 | 0.001 | 0.36 | 62.91 | 22.51 | 9.01 |

| 70% Ni type | - | - | - | - | 70 | - | - |

| Welding Consumable | C | Si | Mn | Ni | Cr | Mo | W | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|

| NITTETSU FILLER 196 (9% Ni & TIG) | 0.04 | 0.40 | 0.45 | 72.5 | - | 19.0 | 2.91 | - | 3.5 |

| YAWATA WELD B(M) (9% Ni & SMAW) | 0.09 | 0.20 | 3.22 | 65.1 | 15.8 | 3.35 | - | 1.60 | 10.2 |

| ERNiCrMo-3 (7% TMCP Ni & GMAW) | 0.018 | 0.47 | 0.36 | 62.91 | 22.51 | 9.01 | - | 3.65 | - |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.Y.; Lee, J.M.; Kim, M.H. An Investigation of the Mechanical Properties of a Weldment of 7% Nickel Alloy Steels. Metals 2016, 6, 285. https://doi.org/10.3390/met6110285

Park JY, Lee JM, Kim MH. An Investigation of the Mechanical Properties of a Weldment of 7% Nickel Alloy Steels. Metals. 2016; 6(11):285. https://doi.org/10.3390/met6110285

Chicago/Turabian StylePark, Jeong Yeol, Jae Myung Lee, and Myung Hyun Kim. 2016. "An Investigation of the Mechanical Properties of a Weldment of 7% Nickel Alloy Steels" Metals 6, no. 11: 285. https://doi.org/10.3390/met6110285