Effect of the Thermodynamic Behavior of Selective Laser Melting on the Formation of In situ Oxide Dispersion-Strengthened Aluminum-Based Composites

Abstract

:1. Introduction

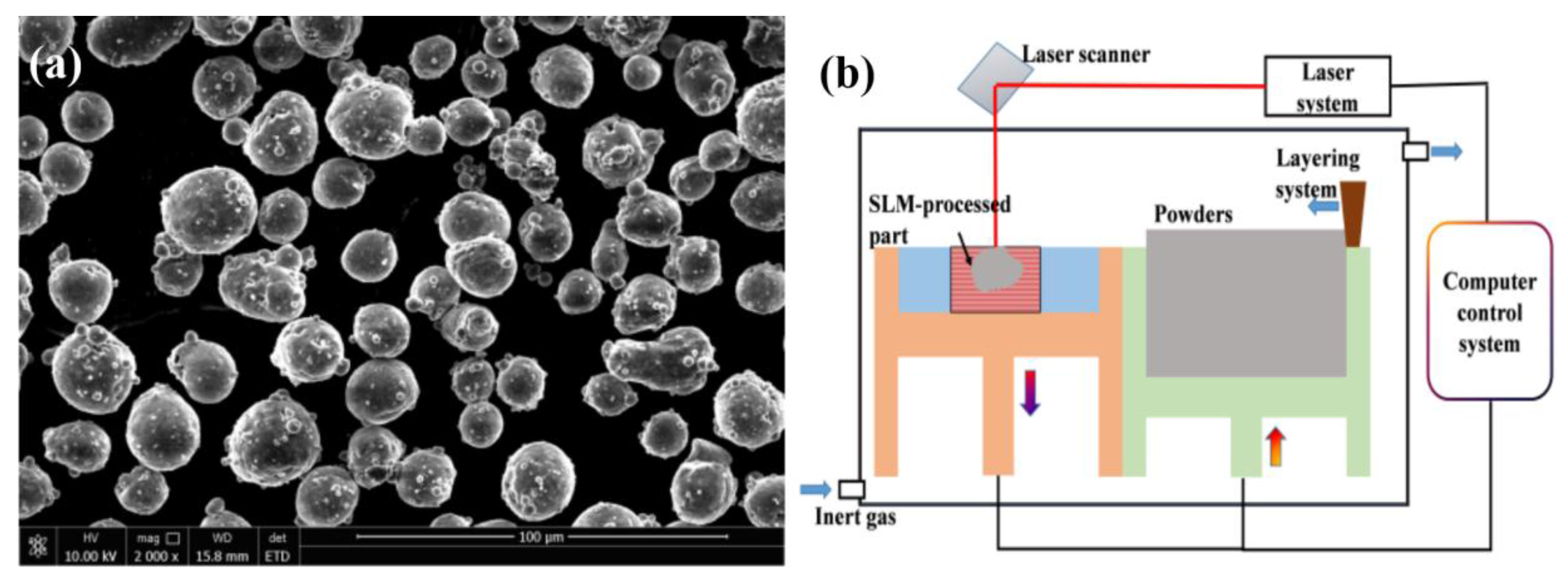

2. Materials and Methods

2.1. Preparation of Samples

2.2. Characterization of Composition

2.3. Numerical Simulation

- (1)

- The evaporation of molten liquid material was ignored when the maximum temperature of the molten material did not exceed the boiling temperature.

- (2)

- The reflectivity was regarded as a constant by varying the laser absorption of the aluminum alloy powder.

- (3)

- The conductivity and melt viscosity were considered to be time-dependent.

3. Results and Discussion

3.1. Phases and Composition Identification

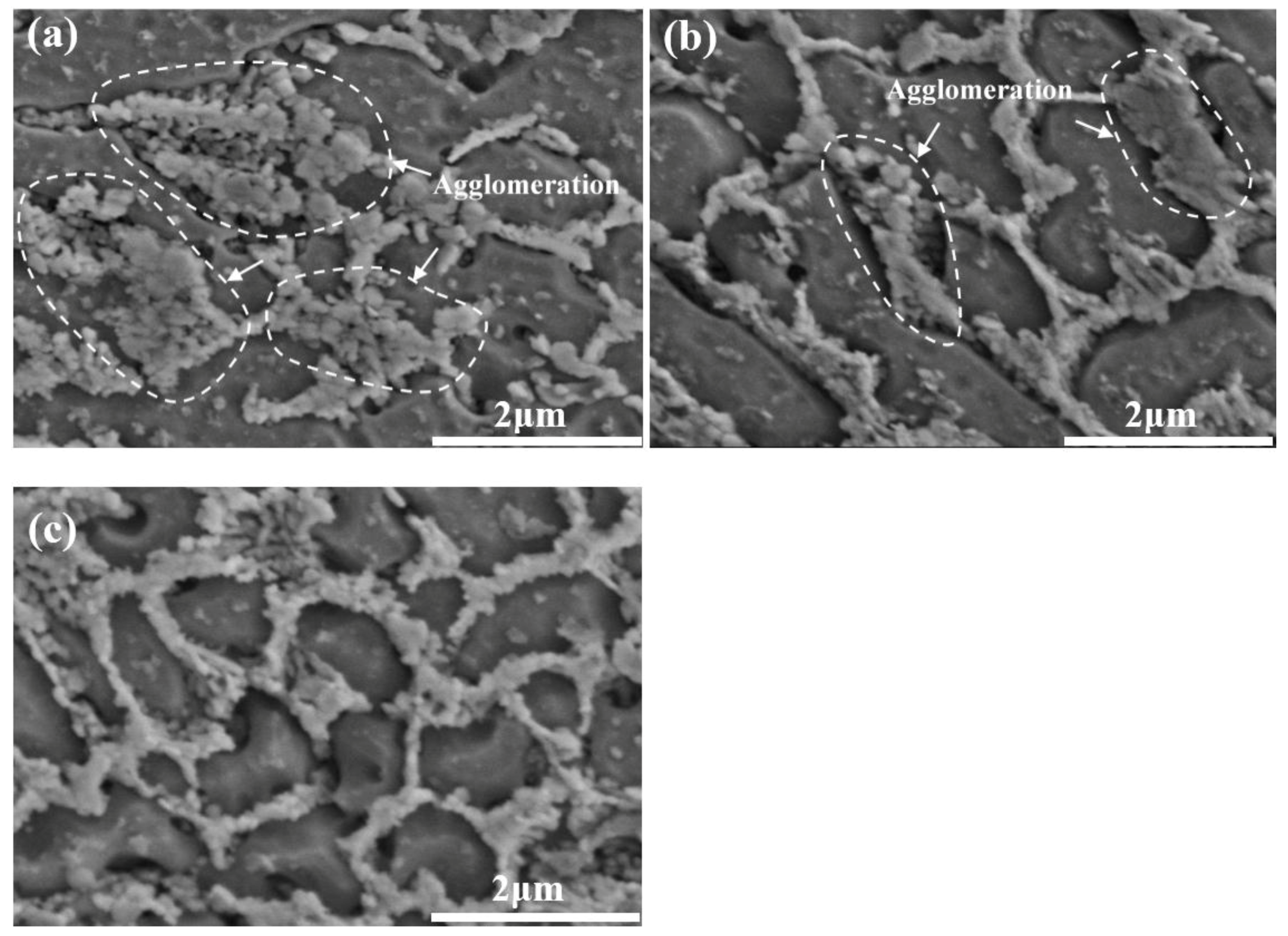

3.2. Microstructure Characterzation

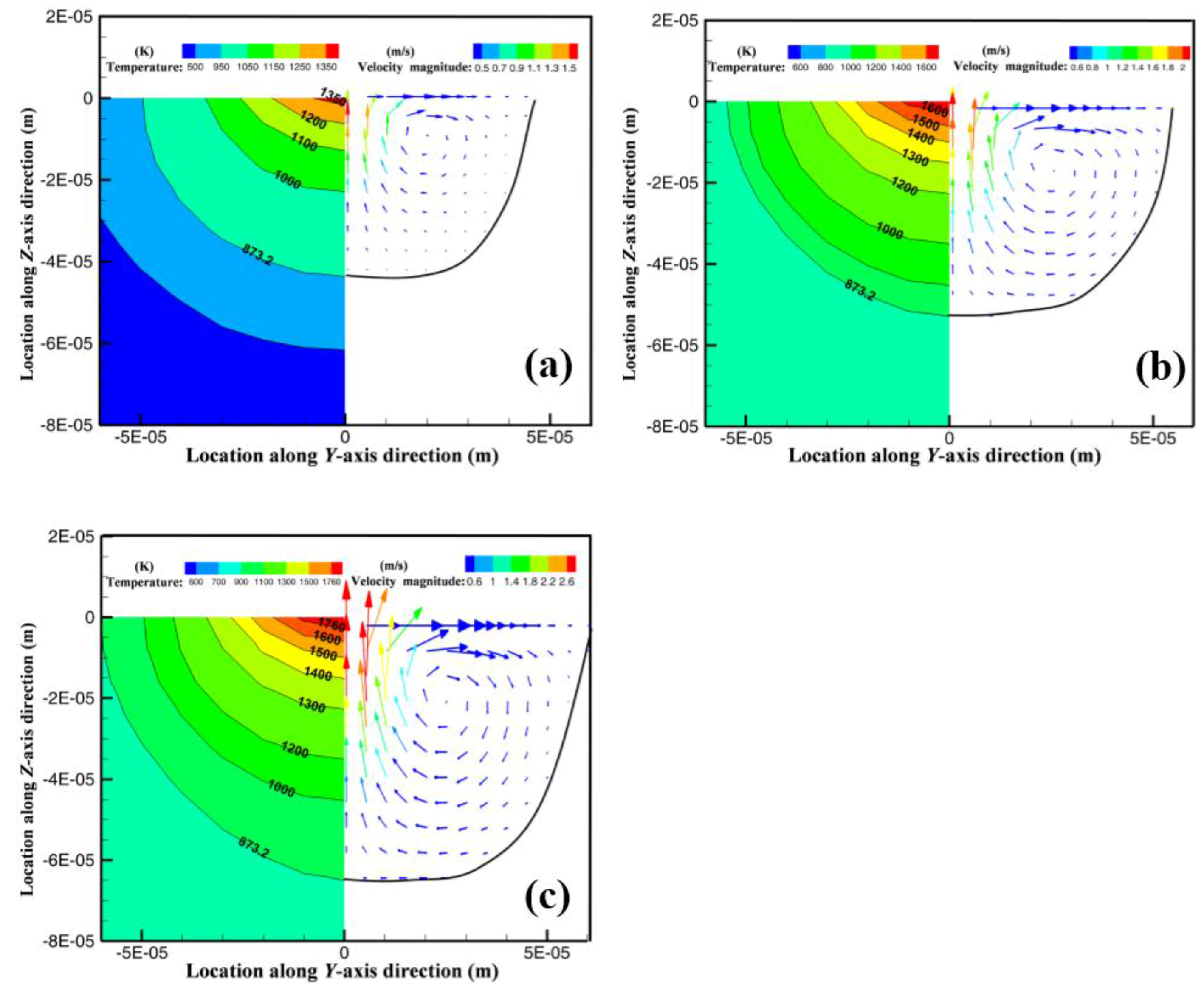

3.3. Thermodynamic Behavior of Molten Pool

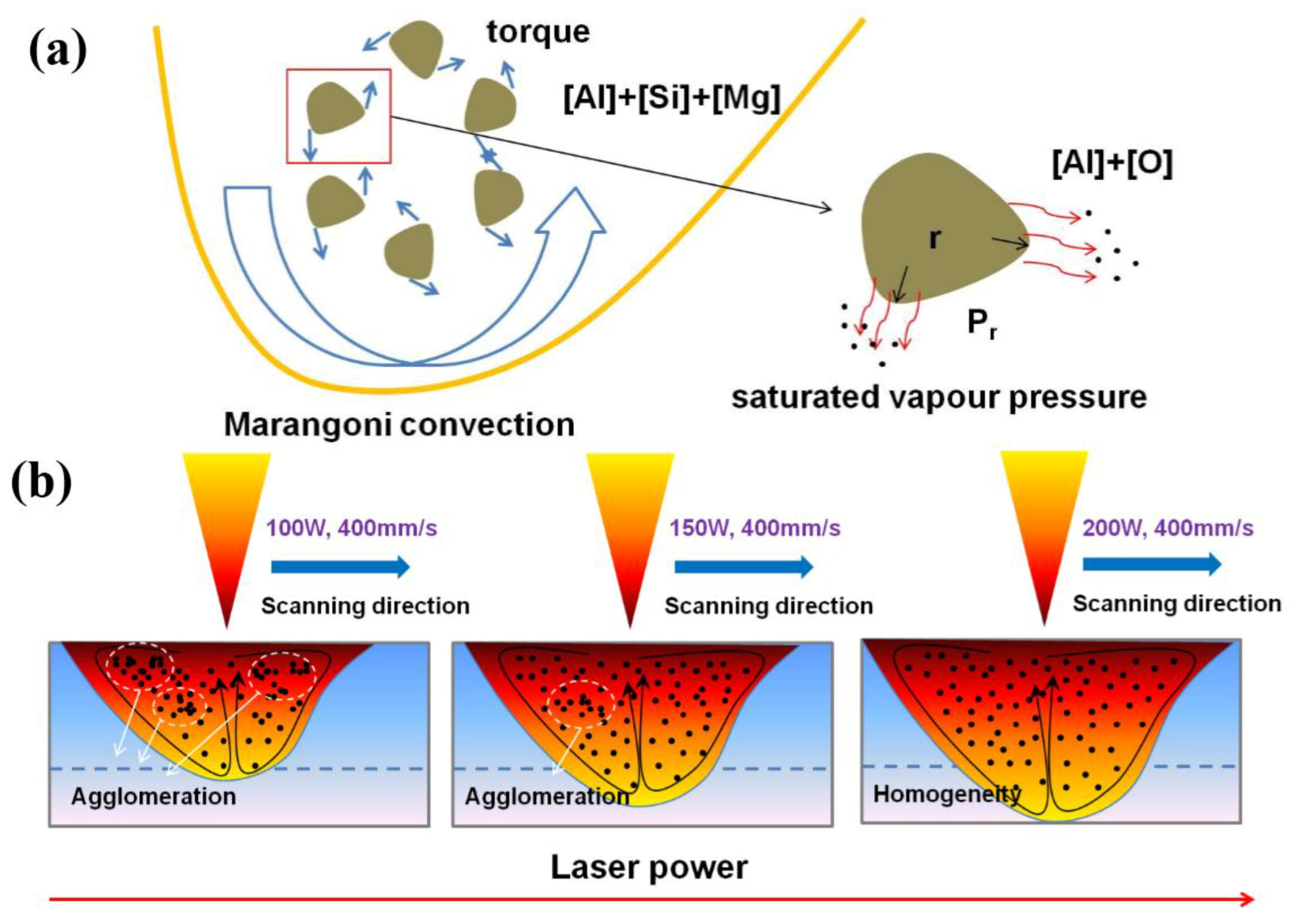

3.4. Formation Mechanism of SLM-Processed Composites

4. Conclusions

- (1)

- The in situ Al2Si4O10/Al composites were fabricated via SLM. The new silica-rich phase (aluminum silicate, i.e., Al2Si4O10) was identified via XRD spectrum and EDX analysis. The composites also presented a network microstructure, i.e., the Al2Si4O10 reinforcements aggregated around the aluminum matrix.

- (2)

- The characteristic microstructure of the in situ Al2Si4O10/Al composites via SLM tended to transfer from the irregular network structure to a nearly sphere-like network structure in regular forming by increasing the laser power.

- (3)

- As a high laser power was employed, a high peak temperature was acquired correspondingly, and the resultant Marangoni convection was generated with a high velocity, favoring the sufficient dispersion of the reinforcements within the molten pool.

- (4)

- The formation mechanism of in situ Al2Si4O10 and the distribution evolution of the reinforcement particles during the SLM processing of Al2O3/AlSi10Mg mixed powder were present. Formation of the in situ Al2Si4O10 phase could be attributed to the reaction among dissociative [Al], [O], and [Si] atoms, and the distribution of reinforcement particles was speculated to be influenced significantly by Marangoni convection and the viscosity of the molten material.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tjong, S.C. Novel Nanoparticle-Reinforced Metal Matrix Composites with Enhanced Mechanical Properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Gu, D.D.; Yuan, P.P. Thermal evolution behavior and fluid dynamics during laser additive manufacturing of Al-based nanocomposites: Underlying role of reinforcement weight fraction. J. Appl. Phys. 2015, 118, 233109. [Google Scholar] [CrossRef]

- Vijaya Ramnath, B.; Elanchezhian, C.; Jaivignesh, M.; Rajesh, S.; Parswajinan, C.; Siddique Ahmed Ghias, A. Evaluation of mechanical properties of aluminium alloy-alumina-boron carbide metal matrix composites. Mater. Des. 2014, 58, 332–338. [Google Scholar] [CrossRef]

- Yang, B.; Sun, M.; Gan, G.S.; Xu, C.G.; Huang, Z.J.; Zhang, H.B.; Fang, Z.Z. In situ Al2O3 particle-reinforced Al and Cu matrix composites synthesized by displacement reactions. J. Alloy. Compd. 2010, 494, 261–265. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L.; Jerrard, P.G.E.; Zhang, D.Z. Experimental investigation on selective laser melting behaviour and processing windows of in situ reacted Al/Fe2O3 powder mixture. Powder Technol. 2012, 231, 112–121. [Google Scholar] [CrossRef]

- Zawrah, M.F.; Aly, M.H. In situ formation of Al2O3-SiC-mullite from Al-matrix composites. Ceram. Int. 2006, 32, 21–28. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Löber, L.; Wang, P.; Attar, H.; Schimansky, F.P.; Pyczak, F.; Eckert, J. Processing of Al-12Si-TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Attar, H.; Löber, L.; Funk, A.; Calin, M.; Zhang, L.C.; Prashanth, K.G.; Scudino, S.; Zhang, Y.S.; Eckert, J. Mechanical behavior of porous commercially pure Ti and Ti–TiB composite materials manufactured by selective laser melting. Mater. Sci. Eng. A 2015, 625, 350–356. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Basu, D.; Bose, S.; Bandyopadhyay, A. Laser processing of SiC-particle-reinforced coating on titanium. Scr. Mater. 2010, 63, 438–441. [Google Scholar] [CrossRef]

- Gu, D.D. Laser Additive Manufacturing of High-Performance Materials; Springer: Berlin/Heidelberg, Germany, 2015; pp. 175–197. [Google Scholar]

- Dai, D.H.; Gu, D.D. Influence of thermodynamics within molten pool onmigration and distribution state of reinforcementduring selective laser melting of AlN/AlSi10Mg composites. Int. J. Mach. Tool. Manu. 2016, 100, 14–24. [Google Scholar] [CrossRef]

- Chang, F.; Gu, D.D.; Dai, D.H.; Yuan, P.P. Selective laser melting of in situ Al4SiC4 + SiC hybrid reinforced Al matrix composites: Influence of starting SiC particle size. Surf. Coat. Tech. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Gu, D.D.; Shen, Y.F. WC-Co particulate reinforcing Cu matrix composites produced by direct laser sintering. Mater Lett. 2006, 60, 3664–3668. [Google Scholar] [CrossRef]

- Yuan, P.P.; Gu, D.D.; Dai, D.H. Particulate migration behavior and its mechanism during selective laser melting of TiC reinforced Al matrix nanocomposites. Mater. Design. 2015, 82, 46–55. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Moataz, M.A. Selective laser melting of AlSi10Mg alloy: Process optimization and mechanical properties development. Mater. Design. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Zhang, B.C.; Bi, G.J.; Nai, S.; Sun, C.N.; Wei, J. Microhardness and microstructure evolution of TiB2 reinforced Inconel 625/TiB2 composite produced by selective laser melting. Opt. Laser Technol. 2016, 80, 186–195. [Google Scholar] [CrossRef]

- Wang, D.; Song, C.H.; Yang, Y.Q.; Bai, Y.C. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater. Design. 2016, 100, 291–299. [Google Scholar] [CrossRef]

- Gu, D.D.; Shen, Y.F.; Wu, X.J. Formation of a novel W-rim/Cu-core structure during direct laser sintering of W-Cu composite system. Mater. Lett. 2008, 62, 1765–1768. [Google Scholar] [CrossRef]

- Gu, D.D.; Wang, H.Q.; Dai, D.H. Rapid fabrication of Al-based bulk-form nanocomposites with novel reinforcement and enhanced performance by selective laser melting. Scr. Mater. 2015, 96, 25–28. [Google Scholar] [CrossRef]

- Kurt, H.I.; Oduncuoglu, M. Formulation of the Effect of Different Alloying Elements on the Tensile Strength of the in situ Al-Mg2Si Composites. Metals 2015, 5, 371–382. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Subramanian, J.; Seetharaman, S.; Gupta, M. Processing and Properties of Aluminum and Magnesium Based Composites Containing Amorphous Reinforcement: A Review. Metals 2015, 5, 743–762. [Google Scholar] [CrossRef]

| Position | Elements (at. %) | |||

|---|---|---|---|---|

| Al | Si | O | Mg | |

| Point 1 | 89.1 | 5.75 | 4.74 | 0.41 |

| Point 2 | 12.56 | 24.98 | 62.46 | - |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Jue, J.; Xia, M.; Guo, L.; Yan, B.; Gu, D. Effect of the Thermodynamic Behavior of Selective Laser Melting on the Formation of In situ Oxide Dispersion-Strengthened Aluminum-Based Composites. Metals 2016, 6, 286. https://doi.org/10.3390/met6110286

Wang L, Jue J, Xia M, Guo L, Yan B, Gu D. Effect of the Thermodynamic Behavior of Selective Laser Melting on the Formation of In situ Oxide Dispersion-Strengthened Aluminum-Based Composites. Metals. 2016; 6(11):286. https://doi.org/10.3390/met6110286

Chicago/Turabian StyleWang, Lianfeng, Jiubin Jue, Mujian Xia, Lijie Guo, Biao Yan, and Dongdong Gu. 2016. "Effect of the Thermodynamic Behavior of Selective Laser Melting on the Formation of In situ Oxide Dispersion-Strengthened Aluminum-Based Composites" Metals 6, no. 11: 286. https://doi.org/10.3390/met6110286

APA StyleWang, L., Jue, J., Xia, M., Guo, L., Yan, B., & Gu, D. (2016). Effect of the Thermodynamic Behavior of Selective Laser Melting on the Formation of In situ Oxide Dispersion-Strengthened Aluminum-Based Composites. Metals, 6(11), 286. https://doi.org/10.3390/met6110286