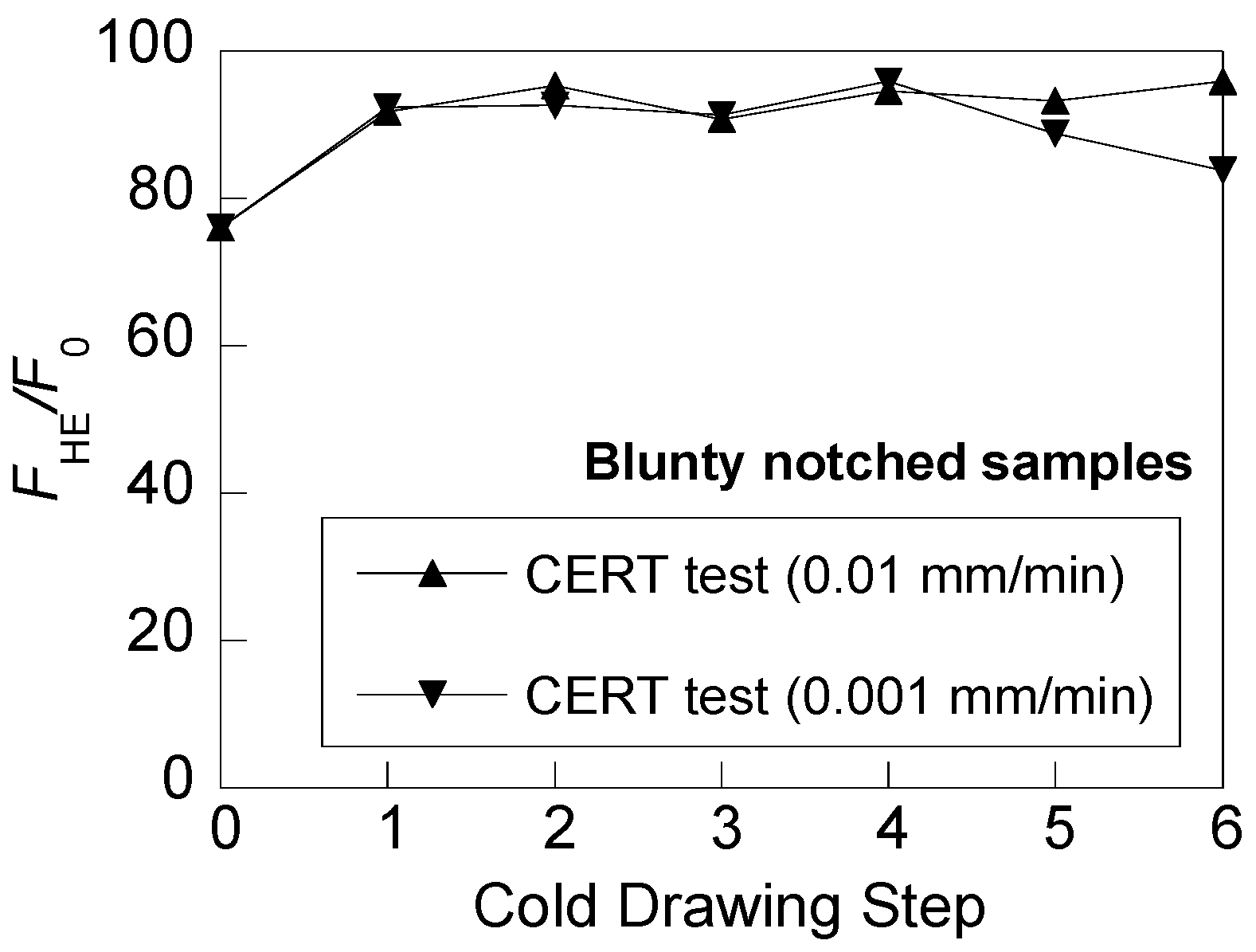

Influence of Loading Rate on the Hydrogen-Assisted Micro-Damage in Bluntly Notched Samples of Pearlitic Steel

Abstract

:1. Introduction

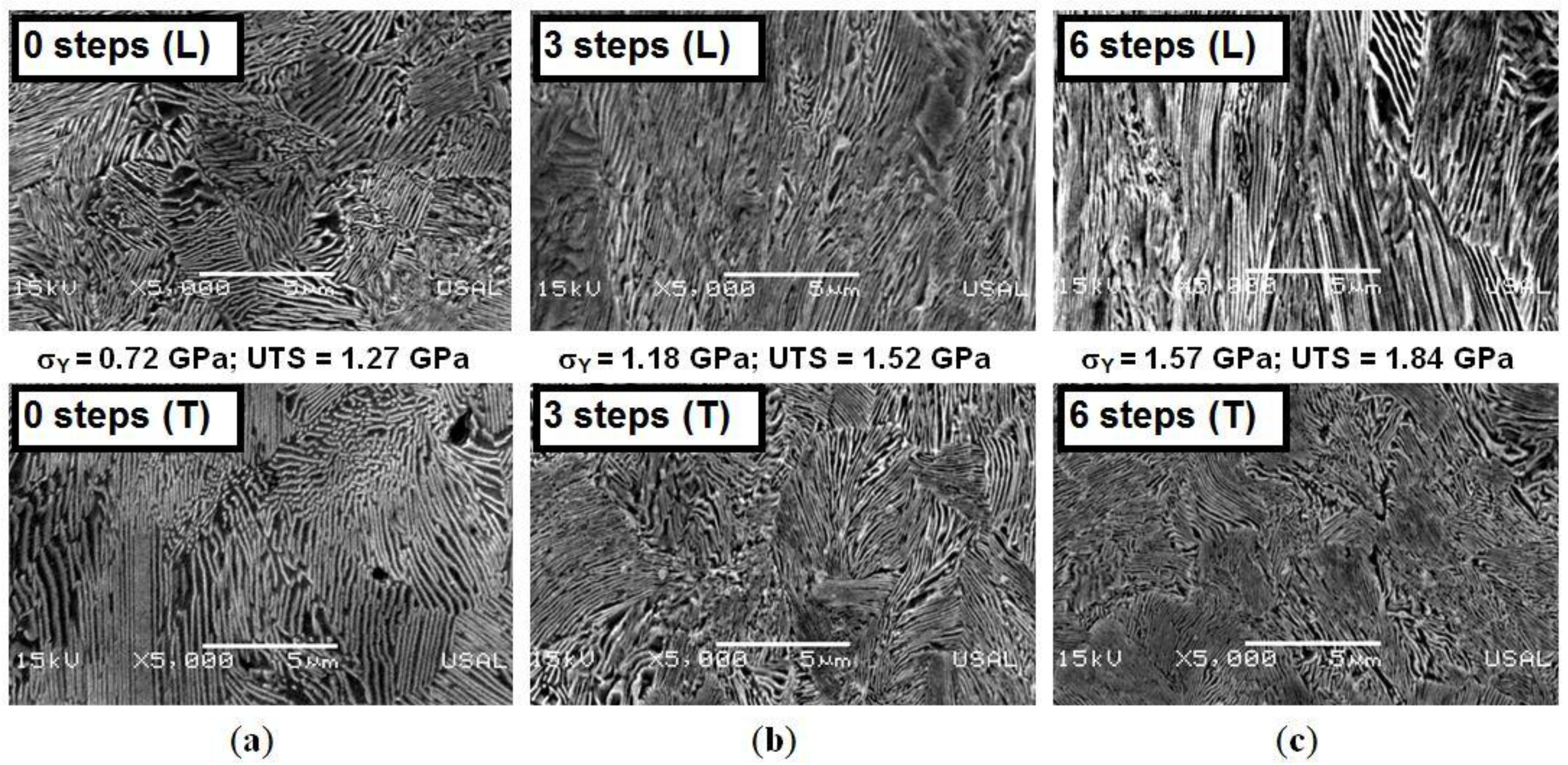

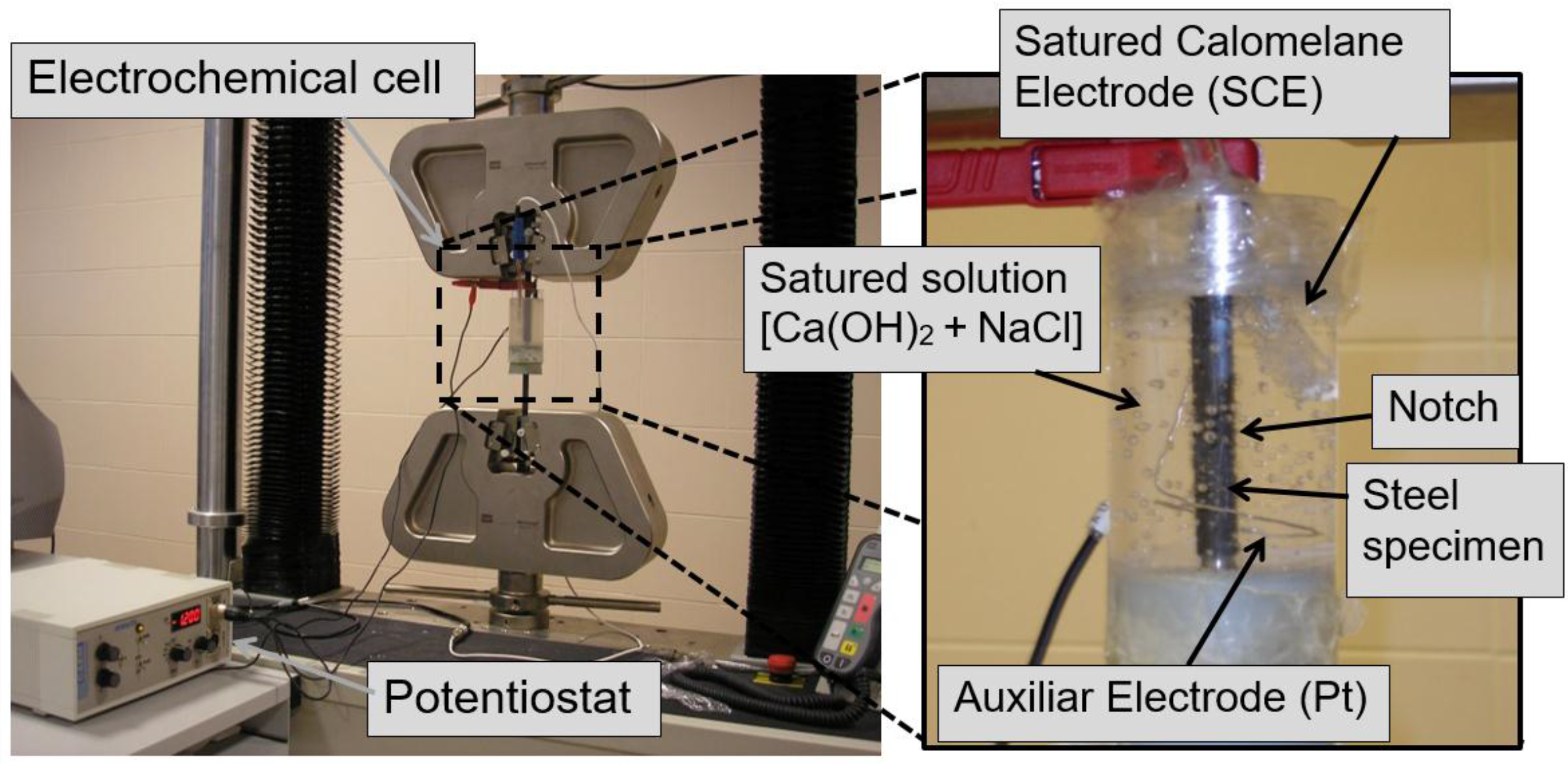

2. Experimental Procedure

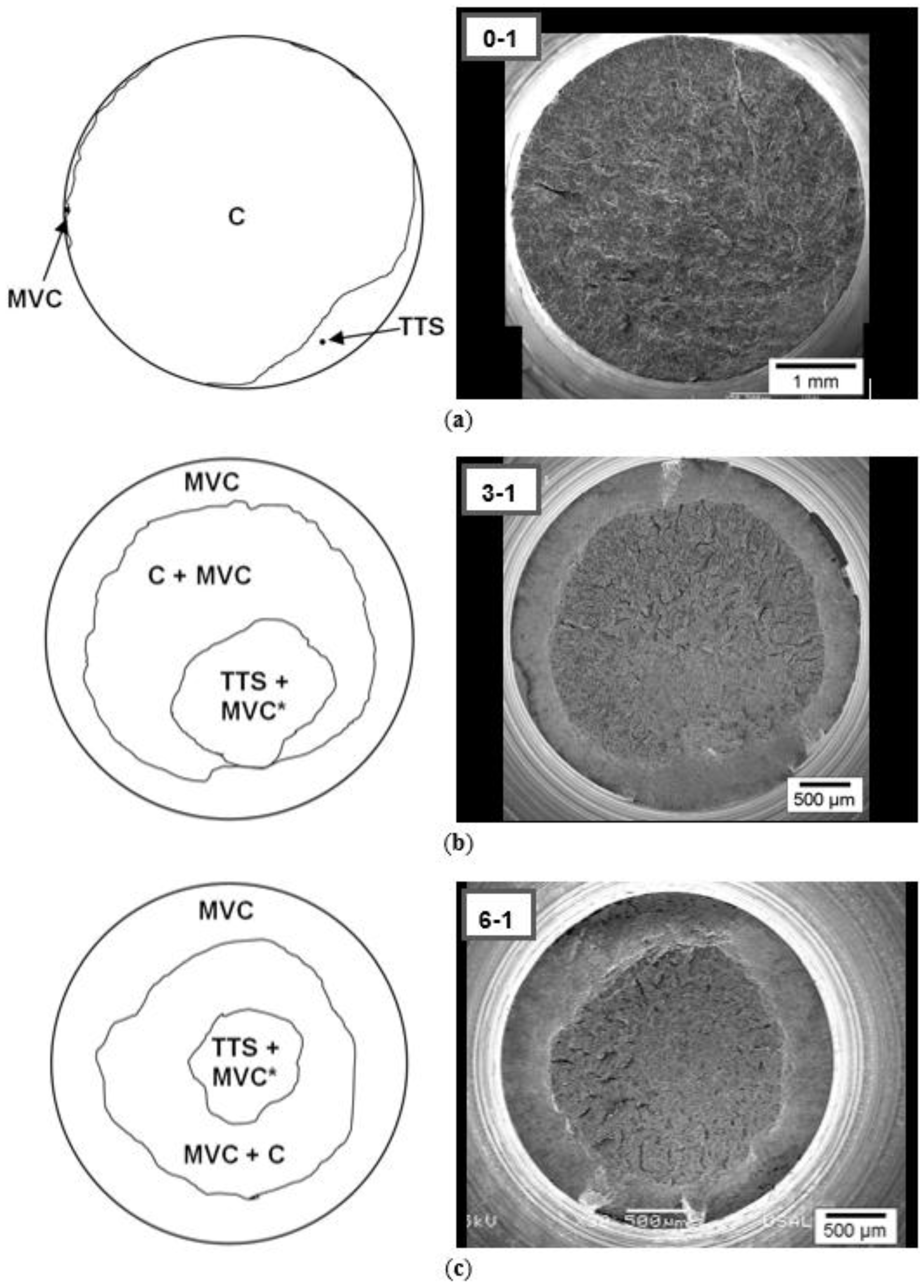

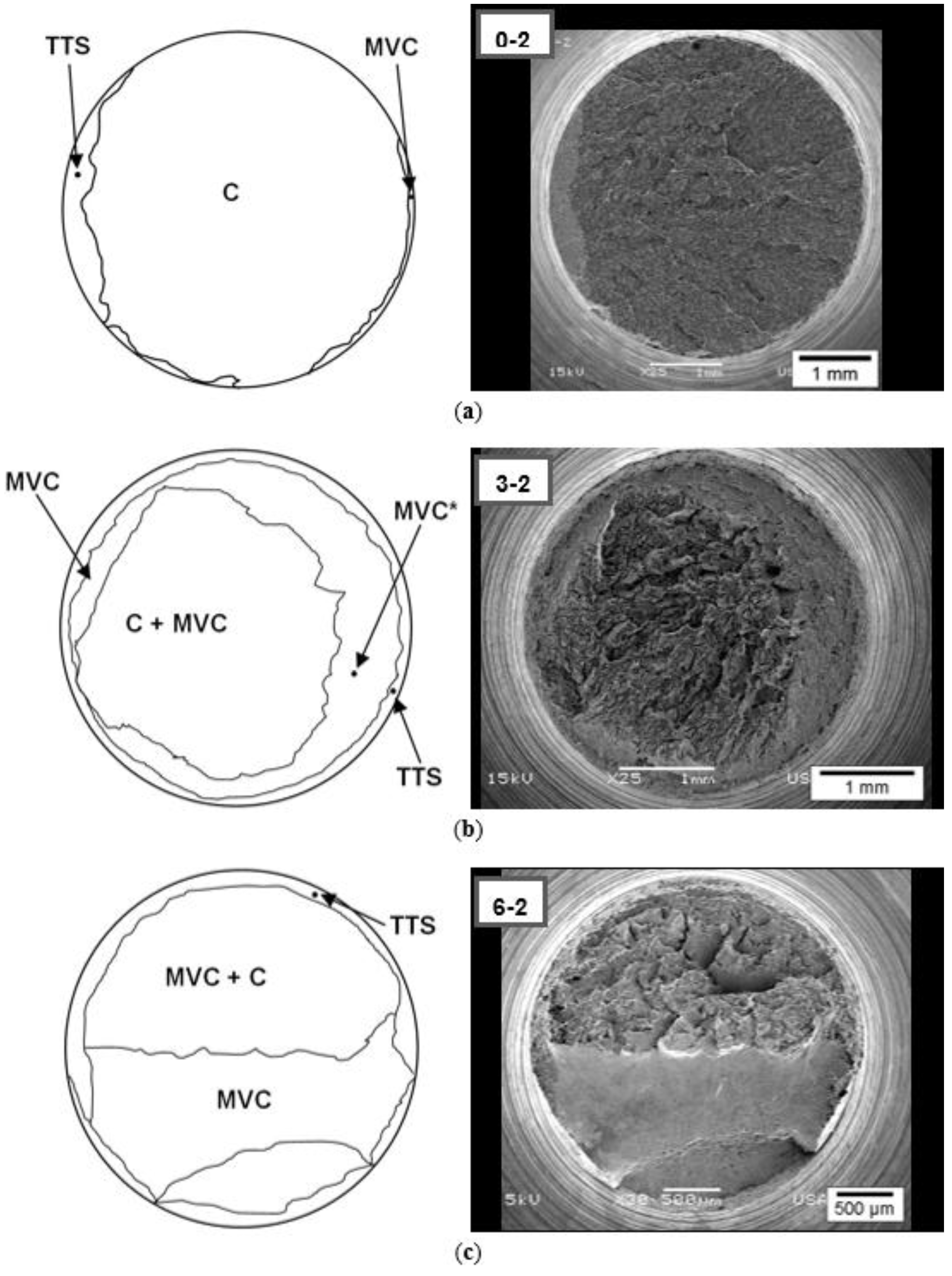

3. Fractography

| Loading Rate (Crosshead Speed) | Cold Drawing Step | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | |

| Type 1 (0.001 mm/min) | I | II | IV | IV | IV | IV | IV |

| Type 2 (0.01 mm/min) | I | II | III | III | III | III | III |

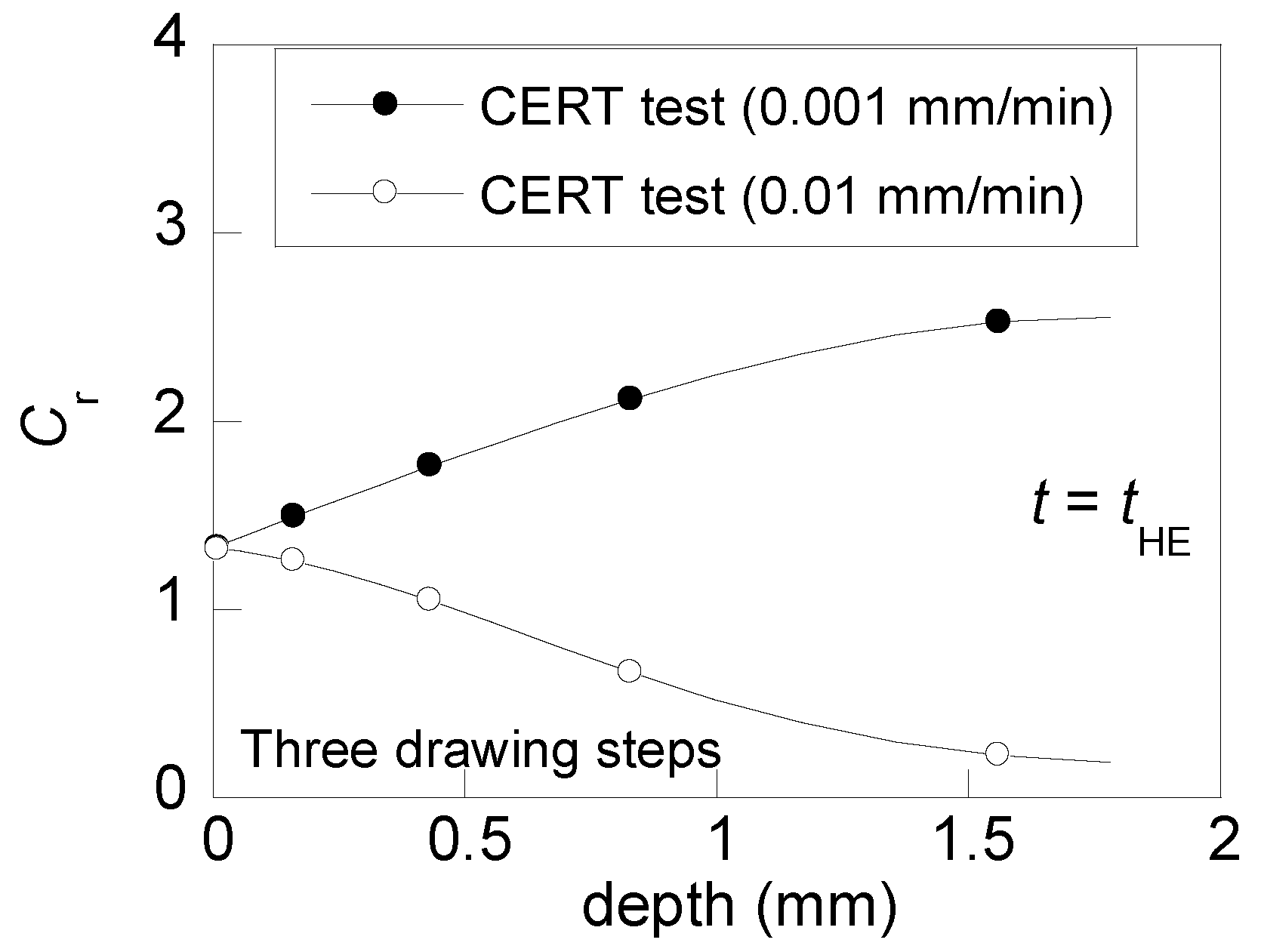

4. Hydrogen Diffusion

5. Conclusions

- (i)

- The fracture surfaces in bluntly notched samples of pearlitic steel subjected to constant extension rate tensile (CERT) tests in an environment promoting hydrogen embrittlement (HE) may be classified into four schematic micro-fracture maps (MFMs).

- (ii)

- In all MFMs the fracture process zone (FPZ) is associated either with tearing topography surface (TTS) or with an area resembling micro-void coalescence (MVC* or quasi-MVC), i.e., a candidate to TTS that is not fully hydrogenated.

- (iii)

- Cold drawing produces microstructural orientation in the pearlitic steel and therefore anisotropic fracture behavior under hydrogen environments, thus promoting axisymmetric shape of the FPZ (TTS alone or a mixture of TTS and MVC*).

- (iv)

- For low loading rates (slow HE tests) a special MFM appears in which hydrogen-assisted fracture (HAF) initiates in the central core of the cross-sectional area of the bluntly notched specimen of pearlitic steel.

- (v)

- For high loading rates (quick HE tests) all MFMs show experimental evidence of surface (peripherical) initiation of HAF due to the short time for hydrogen diffusion and penetration towards the inner zone.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Enos, D.G.; Williams, A.J.; Scully, J.R. Long-term effects of cathodic protection of prestressed concrete structures: Hydrogen embrittlement of prestressing steel. Corrosion 1997, 53, 891–908. [Google Scholar] [CrossRef]

- Vehovar, L.; Kuhar, V.; Vehovar, A. Hydrogen-assisted stress-corrosion of prestressing wires in a motorway viaduct. Eng. Fail. Anal. 1998, 5, 21–27. [Google Scholar] [CrossRef]

- Tkachov, V.I. Problems of hydrogen degradation of metals. Mater. Sci. 2000, 36, 481–488. [Google Scholar] [CrossRef]

- Perrin, M.; Gaillet, L.; Tessier, C.; Idrissi, H. Hydrogen embrittlement of prestressing cables. Corros. Sci. 2010, 52, 1915–1926. [Google Scholar] [CrossRef]

- Mallick, A.; Das, S.; Mathur, J.; Bhattacharyya, T.; Dey, A. Internal reversible hydrogen embrittlement leads to engineering failure of cold drawn wire. Case Stud. Eng. Fail. Anal. 2013, 1, 139–143. [Google Scholar] [CrossRef]

- Toribio, J.; Kharin, V.; Vergara, D.; Lorenzo, M. Optimization of the simulation of stress-assisted hydrogen diffusion for studies of hydrogen embrittlement of notched bars. Mater. Sci. 2011, 46, 819–833. [Google Scholar] [CrossRef]

- Toribio, J.; Elices, M. The role of local strain rate in the hydrogen embrittlement of round-notched samples. Corros. Sci. 1992, 33, 1387–1409. [Google Scholar] [CrossRef]

- Wang, M.; Akiyama, E.; Tsuzaki, K. Crosshead speed dependence of the notch tensile strength of a high strength steel in the presence of hydrogen. Scr. Mater. 2005, 53, 713–718. [Google Scholar] [CrossRef]

- Merson, E.D.; Krishtal, M.M.; Merson, D.L.; Eremichev, A.A.; Vinogradov, A. Effect of strain rate on acoustic emission during hydrogen assisted cracking in high carbon steel. Mater. Sci. Eng. A 2012, 550, 408–417. [Google Scholar] [CrossRef]

- Raykar, N.R.; Raman, R.K.S.; Maiti, S.K.; Choudhary, L. Investigation of hydrogen assisted cracking of a high strength steel using circumferentially notched tensile test. Mater. Sci. Eng. A 2012, 547, 86–92. [Google Scholar] [CrossRef]

- Toribio, J.; Vergara, D. Role of microstructural anisotropy in the hydrogen-assisted fracture of pearlitic steel notched bars. Int. J. Fract. 2013, 182, 149–156. [Google Scholar] [CrossRef]

- Smith, E. The elastic stress distribution near a circular cylindrical notch due to external dislocations. Int. J. Eng. Sci. 2004, 42, 1841–1846. [Google Scholar] [CrossRef]

- Sanyal, G.; Das, A.; Singh, J.B.; Chakravartty, J.K. Effect of notch geometry on fracture features. Mater. Sci. Eng. A 2015, 641, 210–214. [Google Scholar] [CrossRef]

- Toribio, J.; Lorenzo, M.; Vergara, D.; Kharin, V. Hydrogen degradation of cold-drawn wires: A numerical analysis of drawing-induced residual stresses and strains. Corrosion 2011, 67, 075001:1–075001:8. [Google Scholar] [CrossRef]

- Nam, W.J.; Bae, C.M. Void initiation and microstructural changes during wire drawing of pearlitic steels. Mater. Sci. Eng. A 1995, 203, 278–285. [Google Scholar] [CrossRef]

- Zelin, M. Microstructure evolution in pearlitic steels during wire drawing. Acta. Mater. 2002, 50, 4431–4447. [Google Scholar] [CrossRef]

- Sauvage, X.; Guelton, N.; Blavette, D. Microstructure evolutions during drawing of a pearlitic steel containing 0.7 at. % copper. Scri. Mater. 2002, 46, 459–464. [Google Scholar] [CrossRef]

- Guo, N.; Luan, B.; Wang, B.; Liu, Q. Microstructure and texture evolution in fully pearlitic steel during wire drawing. Sci. China Technol. Sci. 2013, 56, 1139–1146. [Google Scholar] [CrossRef]

- Guo, N.; Luan, B.; Wang, B.; Liu, Q. Deformation bands in fully pearlitic steel during wire drawing. Sci. China Technol. Sci. 2014, 57, 796–803. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Microstructure evolution in a pearlitic steel subjected to progressive plastic deformation. Mater. Sci. Eng. A 1997, 234–236, 579–582. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Microstructure orientation in a pearlitic steel subjected to progressive plastic deformation. J. Mater. Sci. Lett. 1998, 17, 1037–1040. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Effect of cumulative cold drawing on the pearlite interlamellar spacing in eutectoid steel. Scr. Mater. 1998, 39, 323–328. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Effect of cold drawing on microstructure and corrosion performance of high-strength steel. Mech. Time-Depend. Mater. 1998, 1, 307–319. [Google Scholar] [CrossRef]

- Dua, X.S.; Caoa, W.B.; Wanga, C.D.; Lib, S.J.; Zhao, J.Y.; Sun, Y.F. Effect of microstructures and inclusions on hydrogen-induced cracking and blistering of A537 steel. Mater. Sci. Eng. A 2015, 646, 181–186. [Google Scholar] [CrossRef]

- Inés, M.N.; Asmus, C.A.; Mansilla, G.A. Influence of total strain amplitude on hydrogen embrittlement of high strength steel. Procedia Mater. Sci. 2015, 8, 1039–1046. [Google Scholar] [CrossRef]

- Parkins, R.N.; Elices, M.; Sánchez-Gálvez, V.; Caballero, L. Environment sensitive cracking of pre-stressing steels. Corros. Sci. 1982, 22, 379–405. [Google Scholar] [CrossRef]

- Thompson, A.W.; Chesnutt, J.C. Identification of a fracture mode: the tearing topography surface. Metall. Trans. 1979, 10A, 1193–1196. [Google Scholar] [CrossRef]

- Costa, J.E.; Thompson, A.W. Hydrogen cracking in nominally pearlitic 1045 steel. Metall. Trans. 1982, 13A, 1315–1318. [Google Scholar] [CrossRef]

- Toribio, J.; Lancha, A.M.; Elices, M. The tearing topography surface as the zone associated with hydrogen embrittlement processes in pearlitic steel. Metall. Trans. 1992, 23A, 1573–1584. [Google Scholar] [CrossRef]

- Toribio, J.; Vasseur, E. Hydrogen-assisted micro-damage evolution in pearlitic steel. J. Mater. Sci. Lett. 1997, 16, 1345–1348. [Google Scholar] [CrossRef]

- Gamboa, E.; Atrens, A. Environmental influence on the stress corrosion cracking of rock bolts. Eng. Fail. Anal. 2003, 10, 521–558. [Google Scholar] [CrossRef]

- Toribio, J.; Vergara, D.; Lorenzo, M. Role of microstructural anisotropy of prestressing steel on the fractographic appearance of hydrogen-assisted micro-damage. In Proceedings of the Corrosion 2011, Houston, TX, USA, 13–17 March 2011; NACE International: Houston, TX, USA; pp. 2759–2767.

- Toribio, J. Role of hydrostatic stress in hydrogen diffusion in pearlitic steel. J. Mater. Sci. 1993, 28, 2289–2298. [Google Scholar] [CrossRef]

- Panasyuk, V.V.; Ivanyts’kyi, Y.L.; Hembara, O.V.; Boiko, V.M. Influence of the stress-strain state on the distribution of hydrogen concentration in the process zone. Mater. Sci. 2014, 50, 315–323. [Google Scholar] [CrossRef]

- Raykar, N.R.; Maiti, S.K.; Raman, R.K.S. Influence of hydrostatic stress distribution on the modelling of hydrogen assisted stress corrosion crack growth. Blucher Mech. Eng. Proc. 2014, 1, 1–15. [Google Scholar]

- Toribio, J.; Kharin, V.; Vergara, D.; Lorenzo, M. Two-dimensional numerical modelling of hydrogen diffusion in metals assisted by both stress and strain. Adv. Mater. Res. 2010, 138, 117–126. [Google Scholar] [CrossRef]

- Toribio, J.; Kharin, V.; Vergara, D.; Lorenzo, M. Hydrogen diffusion in metals assisted by stress: 2D Numercal Modelling and Analysis of Directionality. Solid State Phenom. 2015, 225, 33–38. [Google Scholar] [CrossRef]

- Hirth, J.P. Effects of hydrogen on the properties of iron and steel. Metall. Trans. 1980, 11A, 861–890. [Google Scholar] [CrossRef]

- Toribio, J.; Kharin, V.; Lorenzo, M.; Vergara, D. Role of drawing-induced residual stresses and strains in the hydrogen embrittlement susceptibility of prestressing steels. Corros. Sci. 2011, 53, 3346–3355. [Google Scholar] [CrossRef]

- Lillard, R.S.; Enos, D.G.; Scully, J.R. Calcium hydroxide as a promoter of hydrogen absorption in 99.5% Fe and a fully pearlitic 0.8% C steel during electrochemical reduction of water. Corros. Sci. 2000, 56, 1119–1132. [Google Scholar] [CrossRef]

- Toribio, J.; Elices, M. Influence of residual stresses on hydrogen embrittlement susceptibility of prestressing steels. Inter. J. Solids Struct. 1991, 25, 791–803. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toribio, J.; Vergara, D.; Lorenzo, M. Influence of Loading Rate on the Hydrogen-Assisted Micro-Damage in Bluntly Notched Samples of Pearlitic Steel. Metals 2016, 6, 11. https://doi.org/10.3390/met6010011

Toribio J, Vergara D, Lorenzo M. Influence of Loading Rate on the Hydrogen-Assisted Micro-Damage in Bluntly Notched Samples of Pearlitic Steel. Metals. 2016; 6(1):11. https://doi.org/10.3390/met6010011

Chicago/Turabian StyleToribio, Jesús, Diego Vergara, and Miguel Lorenzo. 2016. "Influence of Loading Rate on the Hydrogen-Assisted Micro-Damage in Bluntly Notched Samples of Pearlitic Steel" Metals 6, no. 1: 11. https://doi.org/10.3390/met6010011

APA StyleToribio, J., Vergara, D., & Lorenzo, M. (2016). Influence of Loading Rate on the Hydrogen-Assisted Micro-Damage in Bluntly Notched Samples of Pearlitic Steel. Metals, 6(1), 11. https://doi.org/10.3390/met6010011