Control of the Nano-Particle Weight Ratio in Stainless Steel Micro and Nano Powders by Radio Frequency Plasma Treatment

Abstract

:1. Introduction

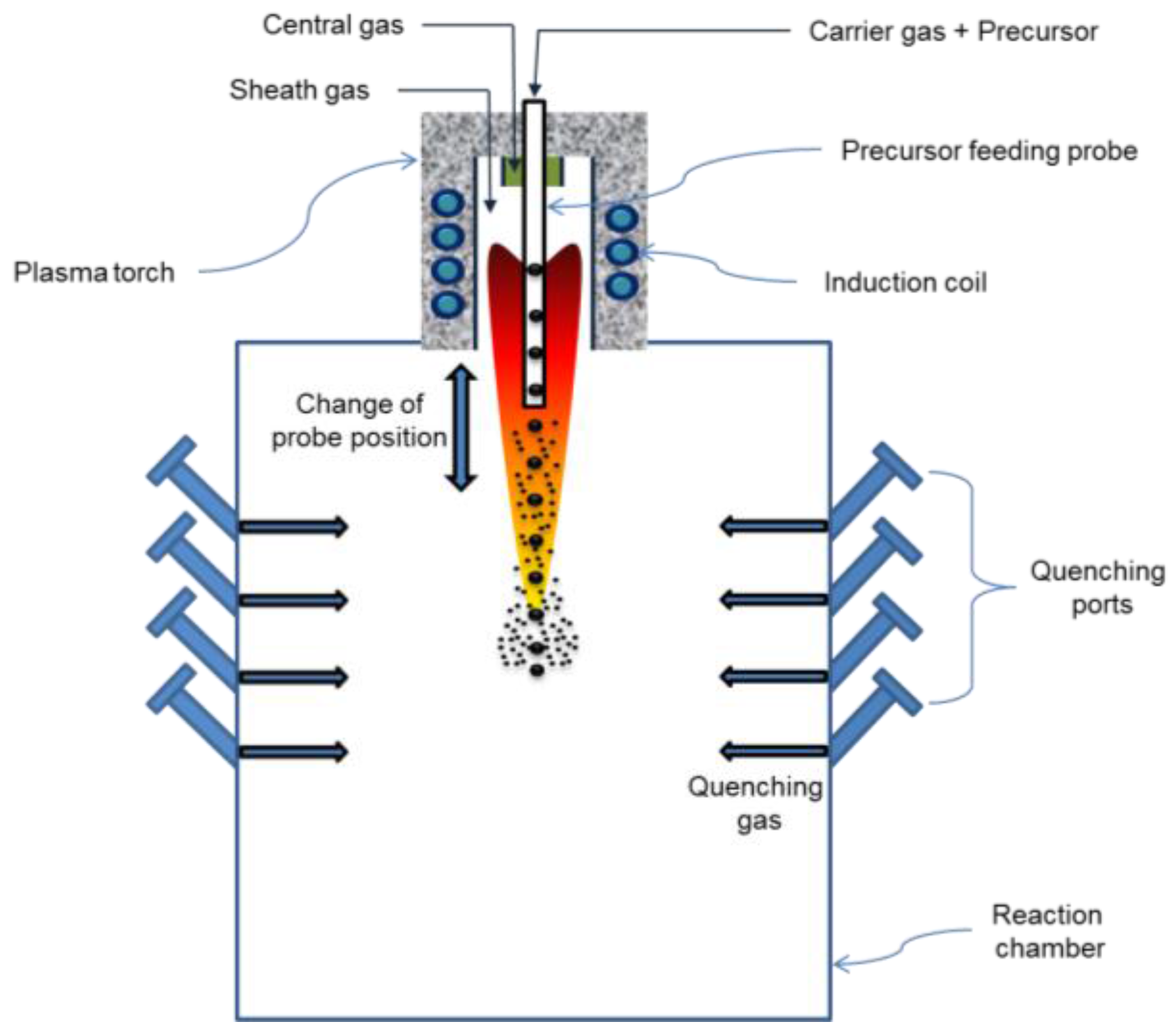

2. Methods

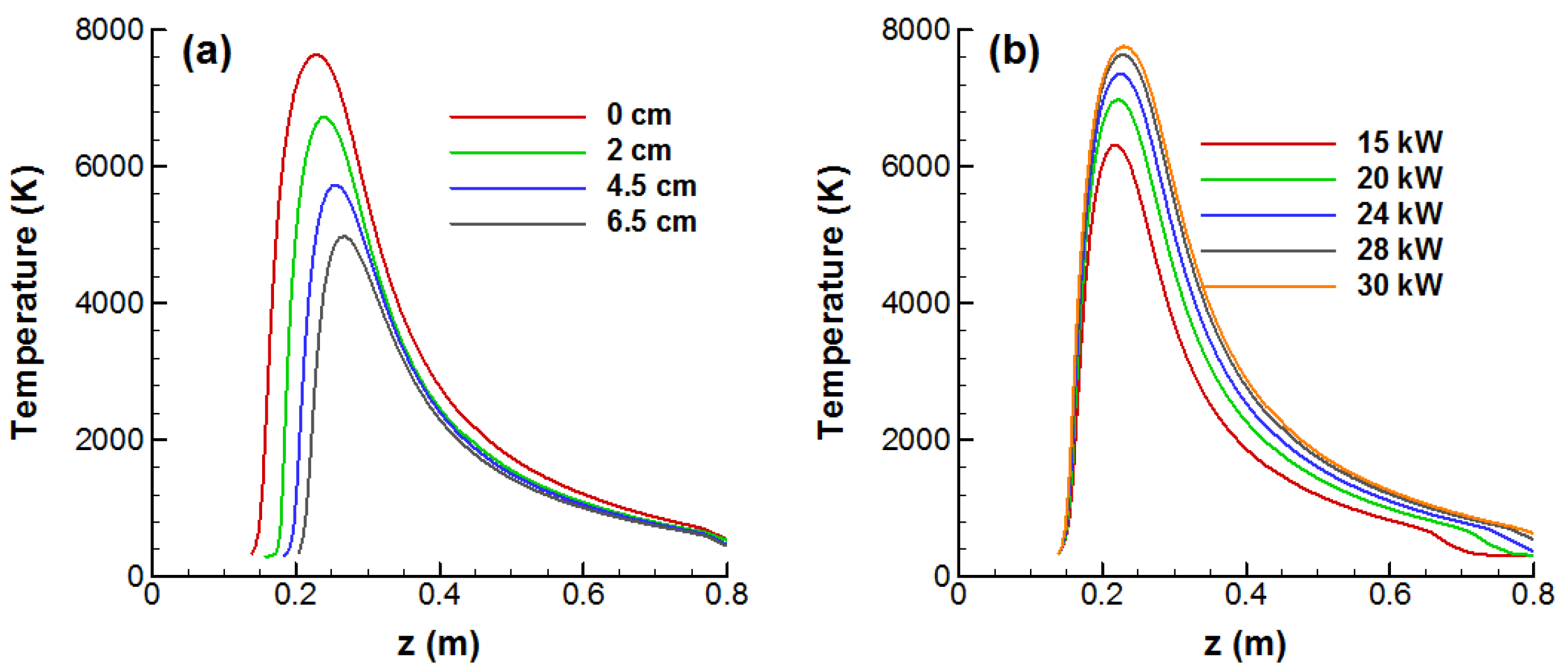

2.1. Simulation Methods

- (a)

- Axisymmetric at the cylindrical coordinate for 2D modeling.

- (b)

- Steady-state plasma flow.

- (c)

- The plasma is considered to be an incompressible fluid.

- (d)

- The pressure and viscous dissipation work are neglected in the conservation of energy.

- (e)

- The model of turbulence is adopted [23].

- (a)

- Conservation of mass:

- (b)

- Conservation of momentum:

- (c)

- Conservation of energy:

2.2. Experimental Methods

| Experimental parameter | Value |

|---|---|

| Central gas for plasma (L/min) | 15 (Ar) |

| Sheath gas for plasma (L/min) | 95 (Ar) |

| Precursor carrier gas (L/min) | 5 (Ar) |

| Quenching gas (L/min) | 200 (He) |

| Passivation gas (L/min) | 0.5 (O2) |

| Feeding rate (g/min) | 10–80 |

| Chamber pressure (MPa) | 0.1013 |

| Plate voltage (kV) | 5.32–7.16 |

| Plate current (A) | 2.83–4.22 |

| Power (kW) | 15–30 |

| Distance from plasma torch to feeding nozzle (cm) | 0–6.5 |

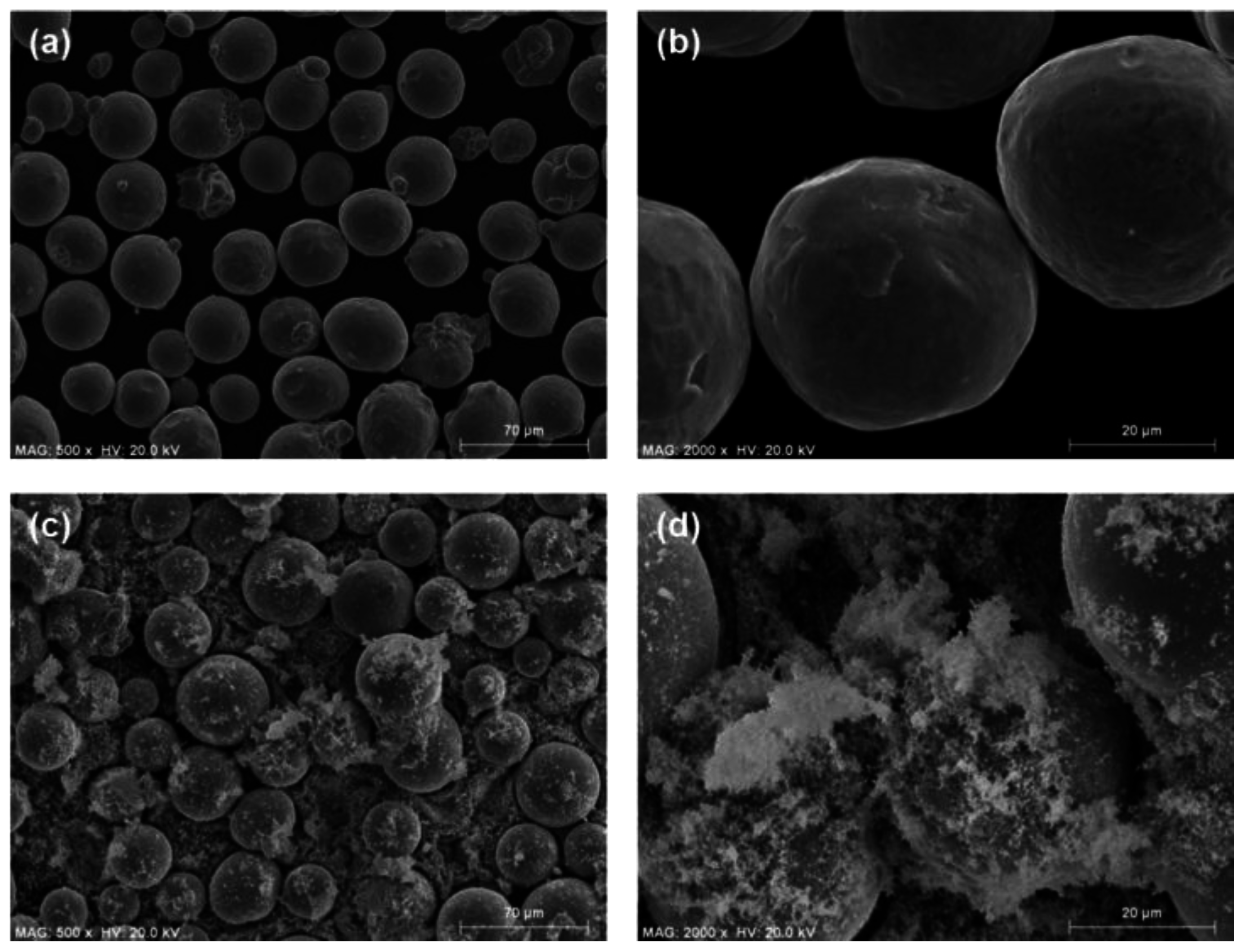

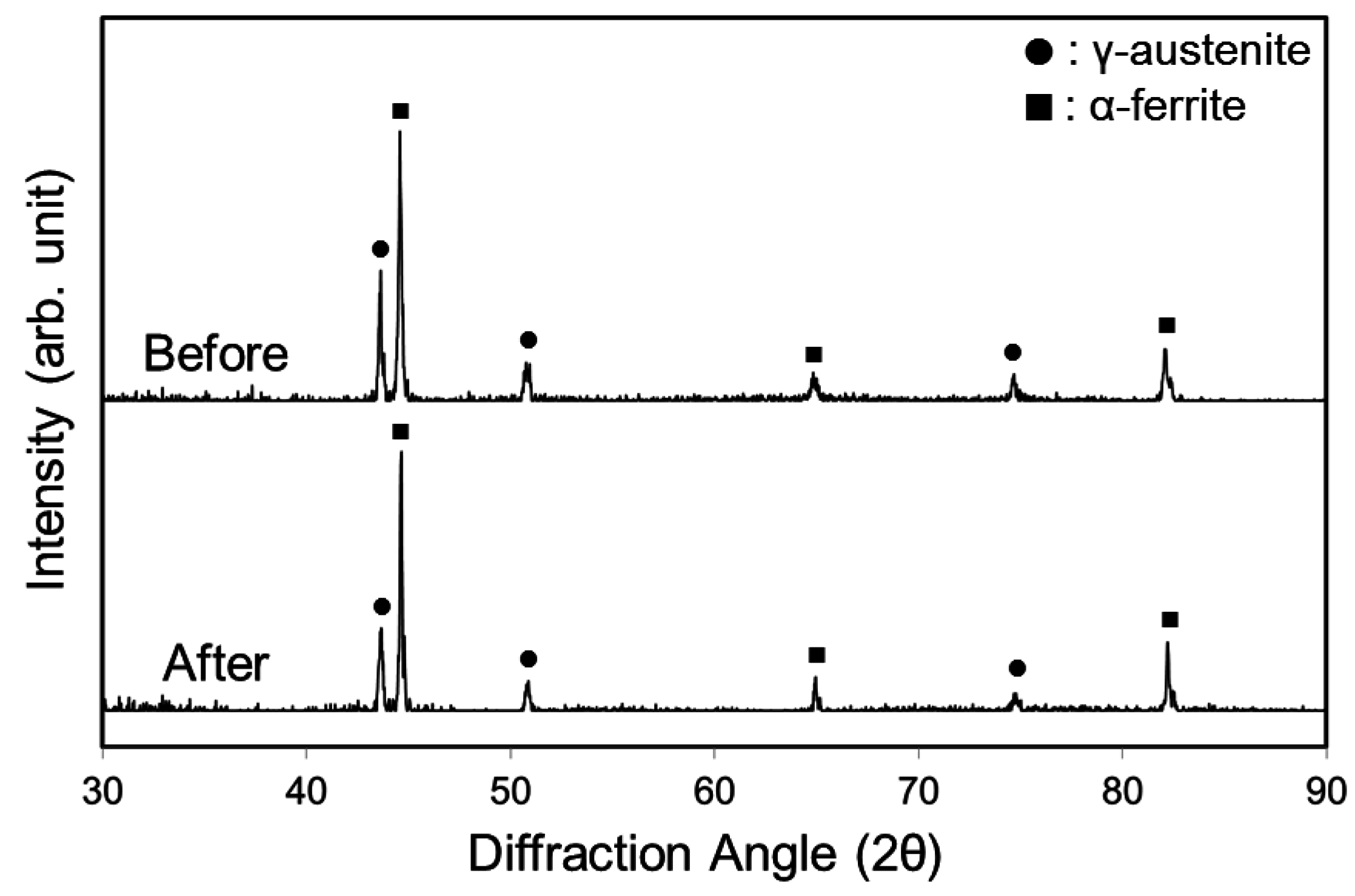

3. Results and Discussion

| Elements | Composition (wt. %) | ||||

|---|---|---|---|---|---|

| Reference (Stainless Steel 316L) | Atomization | Plasma Treated | |||

| Precursor | Micro Powder | Nano Powder | Mixture (Micro + Nano) | ||

| C | Max. 0.03 | 0.023 | 0.013 | 0.029 | 0.015 |

| Si | Max. 0.75 | 0.46 | 0.48 | 0.38 | 0.48 |

| Mn | Max. 2.00 | 1.18 | 0.67 | 1.95 | 1.05 |

| P | Max. 0.045 | 0.037 | 0.028 | 0.025 | 0.032 |

| S | Max. 0.03 | 0.013 | 0.009 | 0.023 | 0.011 |

| Ni | 10-14 | 10.28 | 12.12 | 9.05 | 10.5 |

| Cr | 16-18 | 16.94 | 16.43 | 19.06 | 16.6 |

| Mo | 2-3 | 2.03 | 2.68 | 0.65 | 2.28 |

| Fe | Balance | Balance | Balance | Balance | Balance |

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Li, Y.; Li, L.; Khalil, K.A. Effect of powder loading on metal injection molding stainless steels. J. Mater. Process. Technol. 2007, 183, 432–439. [Google Scholar] [CrossRef]

- Ryan, G.E.; Pandit, A.S.; Apatsidis, D.P. Porous titanium scaffolds fabricated using a rapid prototyping and powder metallurgy technique. Biomaterials 2008, 29, 3625–3635. [Google Scholar] [CrossRef] [PubMed]

- Utela, B.; Storti, D.; Anderson, R.; Ganter, M. A review of process development steps for new material systems in three dimensional printing (3DP). J. Manuf. Process. 2008, 10, 96–104. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of metal matrix composites by metal injection molding. J. Mater. Process. Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef]

- Contreras, J.M.; Jimenez-Morales, A.; Torralba, J.M. Fabrication of bronze components by metal injection moulding using powders with different particle characteristics. J. Mater. Process. Technol. 2009, 209, 5618–5625. [Google Scholar] [CrossRef]

- Luo, T.G.; Qu, X.H.; Qin, M.L.; Ouyang, M.L. Dimension precision of metal injection molded pure tungsten. Int. J. Refract. Met. Hard Mater. 2009, 27, 615–620. [Google Scholar] [CrossRef]

- Ahsan, M.N.; Pinkerton, A.J.; Moat, R.J.; Shackleton, J. A comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti–6Al–4V powders. Mater. Sci. Eng. A 2011, 528, 7648–7657. [Google Scholar] [CrossRef]

- German, R.M. Powder Injection Molding; Metal Powder Industries Federation: Princeton, NJ, USA, 1990. [Google Scholar]

- German, R.M. Powder Metallurgy & Particulate Materials Processing; Metal Powder Industries Federation: Princeton, NJ, USA, 2005. [Google Scholar]

- Nishiyabu, K.; Kakishita, K.; Tanaka, S. Micro Metal Injection Molding Using Hybrid Micro/Nano Powders. Mater. Sci. Forum 2007, 534–536, 381–384. [Google Scholar] [CrossRef]

- You, W.-K.; Choi, J.-P.; Yoon, S.-M.; Lee, J.-S. Low temperature powder injection molding of iron micro-nano powder mixture. Powder Technol. 2012, 228, 199–205. [Google Scholar] [CrossRef]

- Han, C.; Choi, H.; Kim, B. Nano-Attached Tungsten Particle Synthesis and Sintering Behaviors. Met. Mater. Int. 2013, 19, 1035–1039. [Google Scholar] [CrossRef]

- Choi, J.-P.; Lyu, H.-G.; Lee, W.-S.; Lee, J.-S. Densification and microstructural development during sintering of powder injection molded Fe micro-nanopowder. Powder Technol. 2014, 253, 596–601. [Google Scholar] [CrossRef]

- Károly, Z.; Szépvölgyi, J. Plasma spheroidization of ceramic particles. Chem. Eng. Process. 2005, 44, 221–224. [Google Scholar] [CrossRef]

- Yang, C.-W.; Lui, T.-S. Effect of Crystallization on the Bonding Strength and Failures of Plasma-Sprayed Hydroxyapatite. Mater. Trans. 2007, 48, 211–218. [Google Scholar] [CrossRef]

- Gai, G.; Yang, Y.; Jin, L.; Zou, X.; Wu, Y. Particle shape modification and related property improvements. Powder Technol. 2008, 183, 115–121. [Google Scholar] [CrossRef]

- Harbec, D.; Gitzhofer, F.; Tagnit-Hamou, A. Induction plasma synthesis of nanometric spheroidized glass powder for use in cementitious materials. Powder Technol. 2011, 214, 356–364. [Google Scholar] [CrossRef]

- Yang, S.; Gwak, J.-N.; Lim, T.-S.; Kim, Y.-J.; Yun, J.-Y. Preparation of Spherical Titanium Powders from Polygonal Titanium Hydride Powders by Radio Frequency Plasma Treatment. Mater. Trans. 2013, 54, 2313–2316. [Google Scholar] [CrossRef]

- Park, J.H.; Hong, S.H. Optimization Analysis of an Inductively Coupled Plasma Torch for Material Processing by Using Local Thermal Equilibrium Numerical Models. J. Korean Phys. Soc. 1997, 31, 753–763. [Google Scholar]

- Park, J.M.; Hur, M.; Hong, S.H. Numerical analysis on effects of various cathode and nozzle geometries on plasma characteristics of transferred arc torches for waste treatment. In Proceedings of the 28th IEEE International Conference on Plasma Science and 13th International Pulsed Power Conference, Las Vegas, NV, USA, 17–22 June 2001.

- Jackson, J.D. Classical Electrodynamics, 3rd ed.; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Bernardi, D.; Colombo, V.; Ghedini, E.; Mentrelli, A. Comparison of different techniques for the FLUENT-based treatment of the electromagnetic field in inductively coupled plasma torches. Eur. Phys. J. D 2003, 27, 55–72. [Google Scholar] [CrossRef]

- Hur, M.; Hong, S.H. Comparative analysis of turbulent effects on thermal plasma characteristics inside the plasma torches with rod- and well-type cathodes. J. Phys. D 2002, 35, 1946–1954. [Google Scholar] [CrossRef]

- Yoshida, T.; Akashi, K. Preparation of Ultrafine Iron Particles using a RF Plasma. Trans. Jpn. Inst. Met. 1981, 22, 371–378. [Google Scholar] [CrossRef]

- Kobayashi, N.; Kawakami, Y.; Kamada, K.; Li, J.-G.; Ye, R.; Watanabe, T.; Ishigaki, T. Spherical submicron-size copper powders coagulated from a vapor phase in RF induction thermal plasma. Thin Solid Films 2008, 516, 4402–4406. [Google Scholar] [CrossRef]

- Shin, J.W.; Miyazoe, H.; Leparoux, M.; Siegmann, S.; Dorier, J.L.; Hollenstein, C. The influence of process parameters on precursor evaporation for alumina nanopowder synthesis in an inductively coupled RF thermal plasma. Plasma Sources Sci. Technol. 2006, 15, 441–449. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.-Y.; Kim, Y.; Hur, M.Y.; Lee, H.J.; Kim, Y.-J.; Lim, T.-S.; Kim, K.-B.; Yang, S. Control of the Nano-Particle Weight Ratio in Stainless Steel Micro and Nano Powders by Radio Frequency Plasma Treatment. Metals 2015, 5, 2058-2069. https://doi.org/10.3390/met5042058

Yang D-Y, Kim Y, Hur MY, Lee HJ, Kim Y-J, Lim T-S, Kim K-B, Yang S. Control of the Nano-Particle Weight Ratio in Stainless Steel Micro and Nano Powders by Radio Frequency Plasma Treatment. Metals. 2015; 5(4):2058-2069. https://doi.org/10.3390/met5042058

Chicago/Turabian StyleYang, Dong-Yeol, Youngja Kim, Min Young Hur, Hae June Lee, Yong-Jin Kim, Tae-Soo Lim, Ki-Bong Kim, and Sangsun Yang. 2015. "Control of the Nano-Particle Weight Ratio in Stainless Steel Micro and Nano Powders by Radio Frequency Plasma Treatment" Metals 5, no. 4: 2058-2069. https://doi.org/10.3390/met5042058