4. Experiments

Creep experiments were conducted on welded specimens at temperatures between 550 °C and 700 °C and stress levels between 80 and 200 MPa, by using an Applied Test Systems (ATS, Butler, PA, USA) lever arm (20:1) creep tester. Welded specimens were made of ASTM A387 Grade 91 CL2 steel (Grade 91) steel. The specimens were machined out of as-received plates, and were given a round cross-section with a diameter of 12.7 mm and gage length of 45 mm. The chemical composition of Grade 91 steel is indicated in

Table 1.

Table 1.

Chemical composition (wt. %) of modified 9Cr-1Mo steel.

| Elements | Nominal | Measured |

|---|

| Cr | 8.00–9.50 | 8.55 |

| Mo | 0.85–1.05 | 0.88 |

| V | 0.18–0.25 | 0.21 |

| Nb | 0.06–0.10 | 0.08 |

| C | 0.08–0.12 | 0.1 |

| Mn | 0.30–0.60 | 0.51 |

| Cu | 0.4 (max.) | 0.18 |

| Si | 0.20–0.50 | 0.32 |

| N | 0.03–0.07 | 0.035 |

| Ni | 0.40 (max.) | 0.15 |

| P | 0.02 (max.) | 0.012 |

| S | 0.01 (max.) | 0.005 |

| Ti | 0.01 (max.) | 0.002 |

| Al | 0.02 (max.) | 0.007 |

| Zr | 0.01 (max.) | 0.001 |

| Fe | Balance | Balance |

The as-received plates were delivered from hot rolled Grade 91, in normalized and tempered condition (

i.e., austenitized at 1038 °C for 240 min, followed by air cooling, and tempered at 788 °C for 43 min). The original dimensions of the as-received Grade 91 plate were 104 mm × 104 mm × 12.7 mm. The mechanical properties of the material are shown in

Table 2.

Table 2.

Mechanical properties of modified 9Cr-1Mo steel.

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation |

|---|

| Gage Length (mm) | % |

|---|

| 533 | 683 | 50.80 | 26.0 |

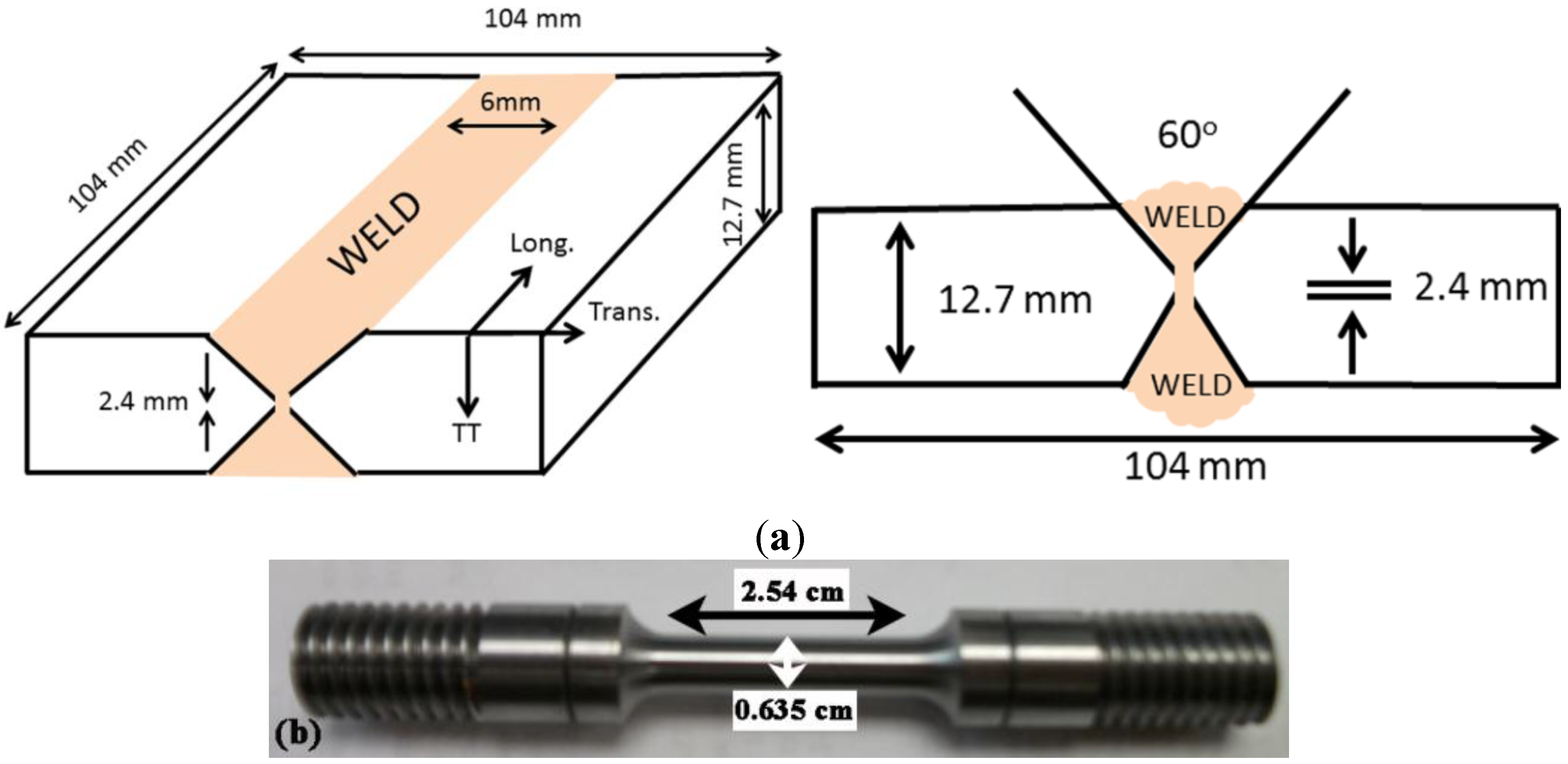

In order to machine the specimens, plates were cut into halves and tapered for double V welding joints, as shown in

Figure 2.

Figure 2.

(a) Schematic representation of the double V-butt welded plate; and (b) specimen used for creep testing. The specimen is cut from the plate, and the central portion of the specimen matches the weld zone.

In this figure, Long, Trans, and TT are the longitudinal, the transversal and the through-thickness directions, respectively. The Metrode 2.4 mm diameter 9CrMoV-N TIG filler wire, which is well known for low residual stresses, was used for welding. The plates were preheated at 260 °C before welding. To prevent overheating, the steel plates were placed on an aluminum plate during welding. The welding was completed in three successive passes with a current of 130 A and voltage of 15 V. The post-weld heat treatment (PWHT) was conducted at 750 °C for 2 h.

As it was mentioned earlier, the microstructure of the welding heat affected zone will undergo changes due to the temperature gradient during welding. The microstructure of the as-welded and post-weld heat-treated specimens exhibits three different zones, i.e., the unaffected base material, the heat affected zone and the weld material. A typical heat affected zone presents two distinct microstructures: the fine grain heat affected zone (FGHAZ), and the coarse grain heat affected zone (CGHAZ). It has been widely reported that type IV cracks initiate in the HAZ, being caused by the non-uniform structure of the HAZ. The non-uniform structure of HAZ is caused by the partial transformation of austenite into martensite, the presence of retained austenite, the formation of delta-ferrite, and differential migration of interstitial and precipitate forming elements through the heat affected zone which creates a complex microstructure prone to failure.

The hardness of Grade 91 steel in the as-received and PWHT condition was measured using a Vickers microhardness tester (LECO, St. Joseph, MI, USA). The hardness of the as-welded material increased across the weld but decreased in the HAZ, as shown in

Figure 3a. The as-welded specimen had a maximum hardness of 474 VHN in the weld, while HAZ exhibited the lowest hardness of 200 VHN. The base material had a hardness of approximately 225 VHN. The HAZ was symmetric on either side of the weld. The hardness profile of specimen PWHT at 750 °C for 2 h was similar to the as-welded specimen, but the hardness magnitudes were lower. The maximum hardness of 304 VHN was observed in the weld, while the lowest hardness of 174 VHN was observed in the HAZ. The hardness of steels can be correlated with the yield stress, thus the yield stress profile of the as-welded and PWHT specimens is similar to the hardness profile, as illustrated in

Figure 3b.

Figure 3.

Vickers microhardness (a); and yield strength profile (b) of welded Grade 91 steel. Position “0” indicates the center of the weld.

5. Results and Discussion

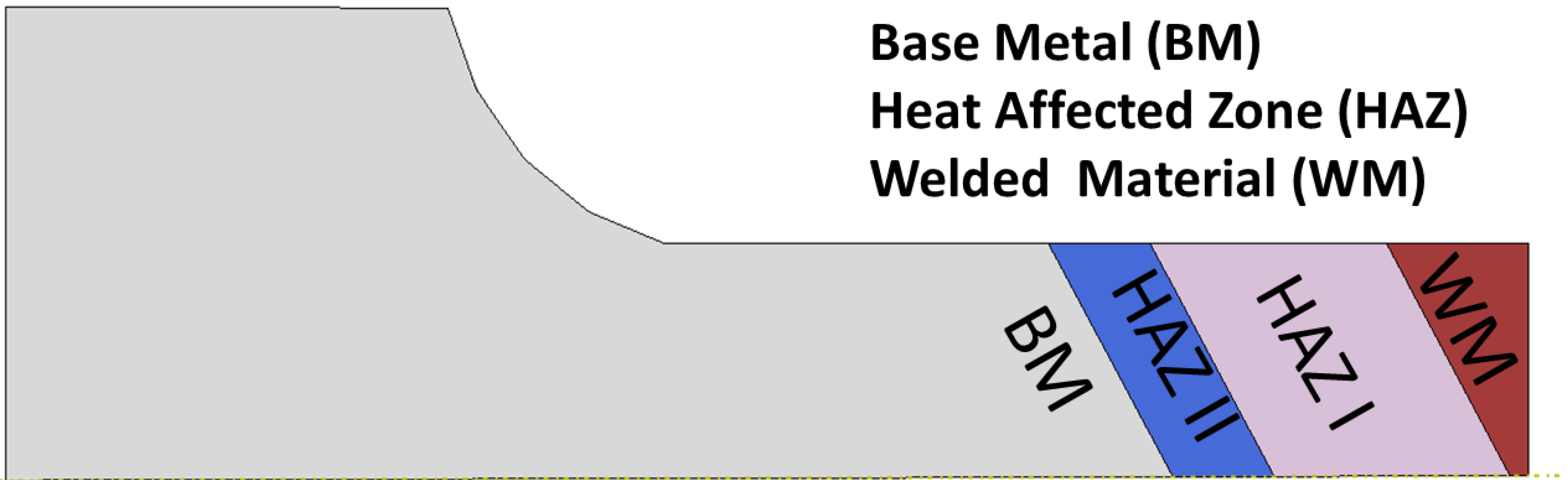

To perform a finite element analysis on the welded specimen, one needs to obtain accurate material constants in the constitutive model for each distinct region of the specimen. In general, it is reasonable to divide the specimen into four regions, the BM, FGHAZ (HAZ II), CGHAZ (HAZ I) and the welded material (WM). Although the HAZ microstructure changes gradually from the WM to the BM, for simplicity, in this study the HAZ was considered as divided into two separate and homogeneous zones (HAZ I and HAZ II). In a study by Gaffard

et al. [

3], it was shown that the WM and BM demonstrate similar steady state creep behaviors. Hence, the same material properties were considered for the BM and WM regions in the finite element model. Simulations were performed on a model with three materials, the BM and two HAZ regions. The HAZ segment was divided into HAZ I and HAZ II.

Figure 4 shows a schematic of each segment of the welded specimen.

Figure 4.

Schematic representation of the welded specimen, showing the Base Metal (BM), Heat Affected Zone I and II (HAZ I and II), and the Welded Material (WM).

Given such a configuration of the specimen, the steady state creep rate is computed using the following equation

where,

,

,

and

are the steady state creep strain rates of the welded specimen SS, BM, WM, and HAZ, respectively.

(=45 mm) is the total gage length of the specimen,

,

(

+

= 39 mm) represent the length of BM, WM zones, and

(=6 mm) is the length of HAZ zone. If the steady state creep test data for both welded specimen and BM are available, the material properties for HAZ can be obtained. Considering the same material properties for the steady state creep rate of the welded specimen in the WM and BM, Equation (32) is used to compute the creep rate developed in the HAZ as

As discussed before, the model requires a number of material constants. Some of them depend on temperature and applied stress, while others are independent of stress and temperature. The material properties independent of the testing conditions are

,

,

,

, and

. Two key material parameters for the second stage creep are

and

. While it is not straightforward to measure the dislocation density

, it has been showed by [

14] that if the initial dislocation density is in a realistic range (

i.e., between 0.2 × 10

14 and 2.0 × 10

14 m

−2), the results will converge to approximately the same value [

14]. The values for

may be determined by performing simulations for the minimum creep rate in the welded and BM specimens, and by employing Equation (33). Furthermore,

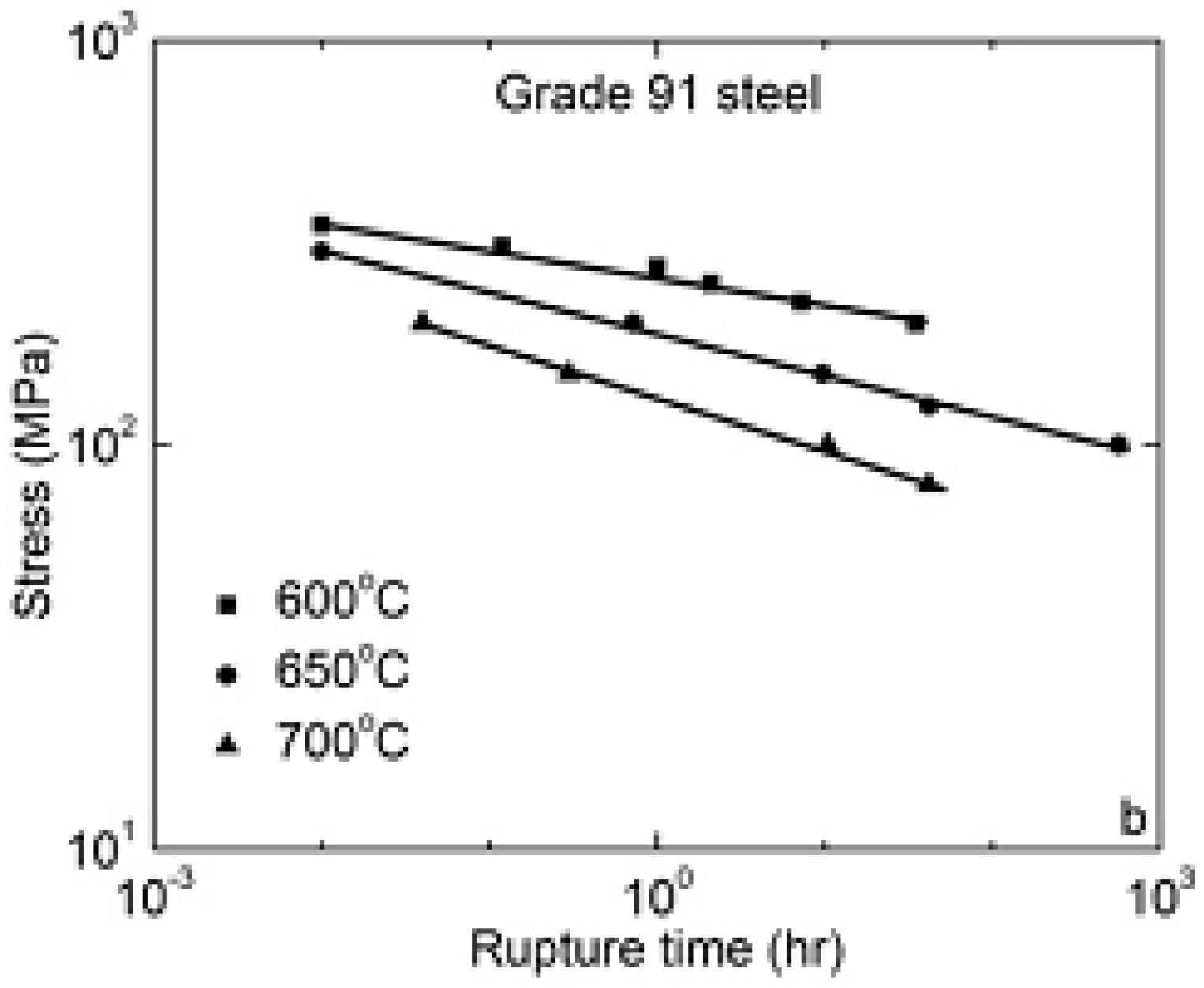

for different loading conditions has been obtained from experiments, and is illustrated in

Figure 1. Values for the remaining material constants used in this study are presented in

Table 3.

Table 3.

Material constants used in the constitutive model.

| Material | Temperatures | Constant | σ = 100 MPa | σ = 150 MPa | σ =200 MPa |

|---|

| BM & WM | 600 °C | kλ | 1 × 104 | 550 | 90 |

| HAZ I | 650 °C | 300 | 25.5 | 12 |

| HAZ II | 700 °C | 100 | 14 | 9 |

| HAZ I | 600 °C | Ks | - | 5.6 × 10−9 | 2.7 × 10−6 |

| 650 °C | 0.8 × 10−4 | 5.5 × 10−9 | 0.8 × 10−4 |

| 700 °C | - | 0.8 × 10−4 | 0.8 × 10−4 |

| HAZ II | 600 °C | Kp | - | 1.9 × 10−6 | 1.9 × 10−6 |

| 650 °C | 0.1 × 10−5 | 0.2 × 10−6 | 0.6 × 10−3 |

| 700 °C | - | 0.1 × 10−5 | 0.1 × 10−5 |

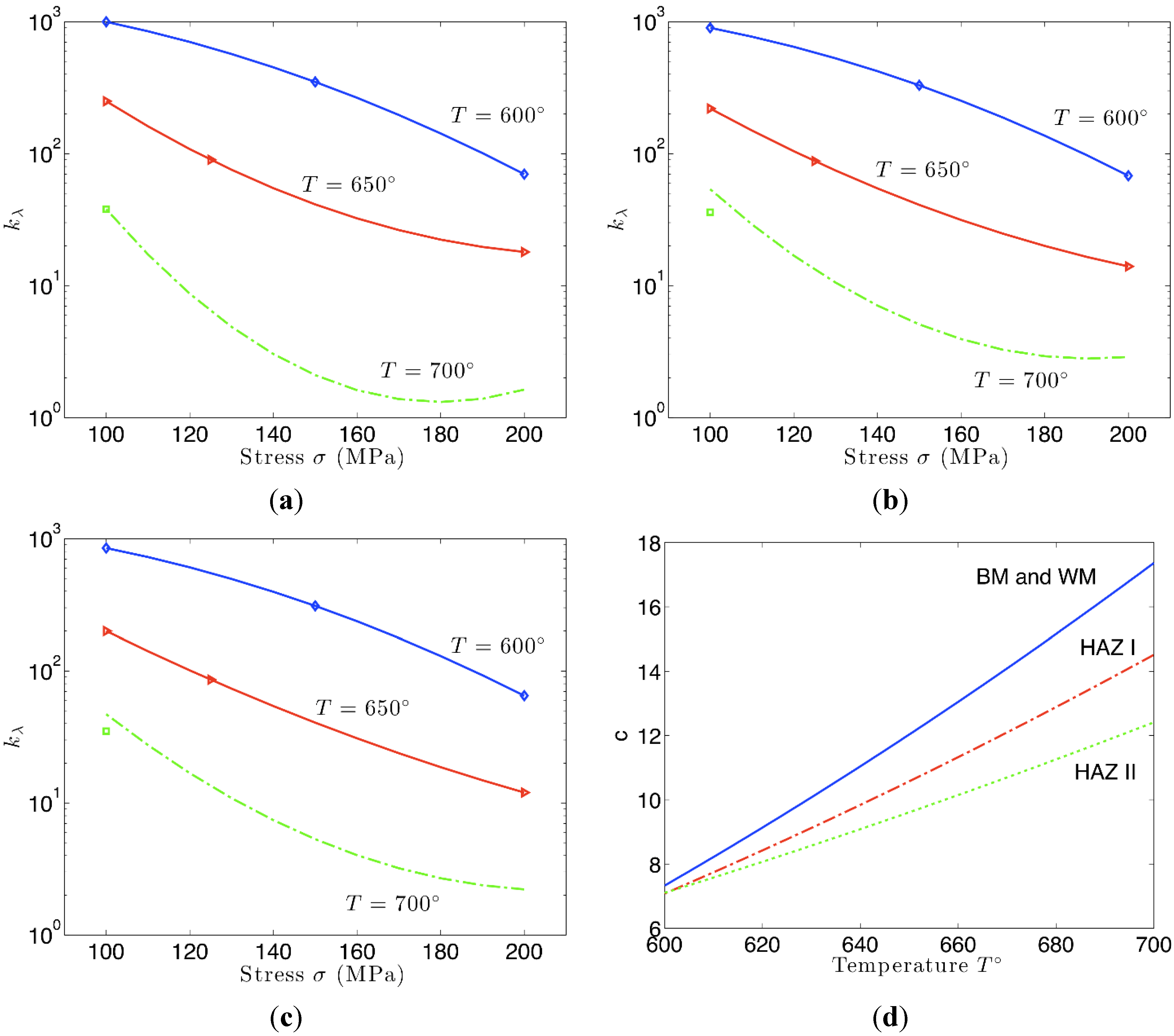

To perform predictions at temperatures different than those that have been tested in this study, it is useful to perform curve-fitting of material parameters

versus temperature. For example,

kλ is chosen because it is a key material constant in this model. By studying the values of

kλ in

Table 3, which were obtained from numerical simulations for each specimen microstructure (BM and WM, HAZ I and HAZ II), it is proposed that ln

(kλ) can be modeled as a quadratic function of σ with coefficients

a, b, and

c dependent on temperature

T, namely

where

a(

T),

b(

T), and

c(

T) are different for each zone of the material and they need to be determined. Three values of

kλ are available at three values of stress σ at temperatures

T = 600 °C and

T = 650 °C, and only one value is known at

T = 700 °C, due to the available experimental data. The results of fitting ln

(kλ) to a quadratic polynomial for

T = 600 °C and

T = 650 °C are shown in

Figure 5a,b using solid lines, while the symbols represent values from the simulations.

Figure 5.

Logarithmic plot of kλ as a function of stress for T = 600 °C, 650 °C and 700 °C for (a) BM and WM, (b) HAZ I and (c) and HAZ II. (d) Quadratic curve-fitting of coefficient c. Solid curves represent fitted lines, while dash-dotted curve is the extrapolation for temperature T = 700 °C.

Thus, we know

a(

T),

b(

T), and

c(

T) at

T = 600 °C and

T = 650 °C. To find the coefficients

a, b and

c at

T = 700 °C and describe

kλ as a function of temperature, we assume that

a, b and

c depend quadratically on

T as well,

i.e.,

Requiring that

a,

b and

c assume the computed values at

T = 600 °C and

T = 650 °C as well as using the table value of

kλ at σ = 100 MPa and

T = 700 °C in Equation (34) produces a linear 10 × 12 underdetermined system for unknowns α

i, β

i, γ

i,

i = 1, 2, 3 and

a(

T),

b(

T),

c(

T) at

T = 700 °C. The system was solved in a least squares sense using the truncated singular value decomposition (SVD) method because of ill-conditioning of the coefficient matrix. As an example, in

Figure 5d coefficient

c is shown as a quadratic function of

T for different zones of the welded specimen. It was found that

c = 17.366 at

T = 700 °C for BM and WM,

c = 14.517 for HAZ I and

c = 12.414 for HAZ II. Coefficients

a and

b are much smaller (

a 10

−4,

a 10

−1) and they can be approximated at

T = 700 °C in a similar manner. With

a,

b and

c known at

T = 700 °C,

kλ at

T = 700 °C can be reconstructed using Equation (34). The results of such reconstruction for each material are shown with a dashed line in

Figure 5. These approximated curves provide an excellent agreement with a value of

kλ available at

T = 700 °C and σ = 100 MPa.

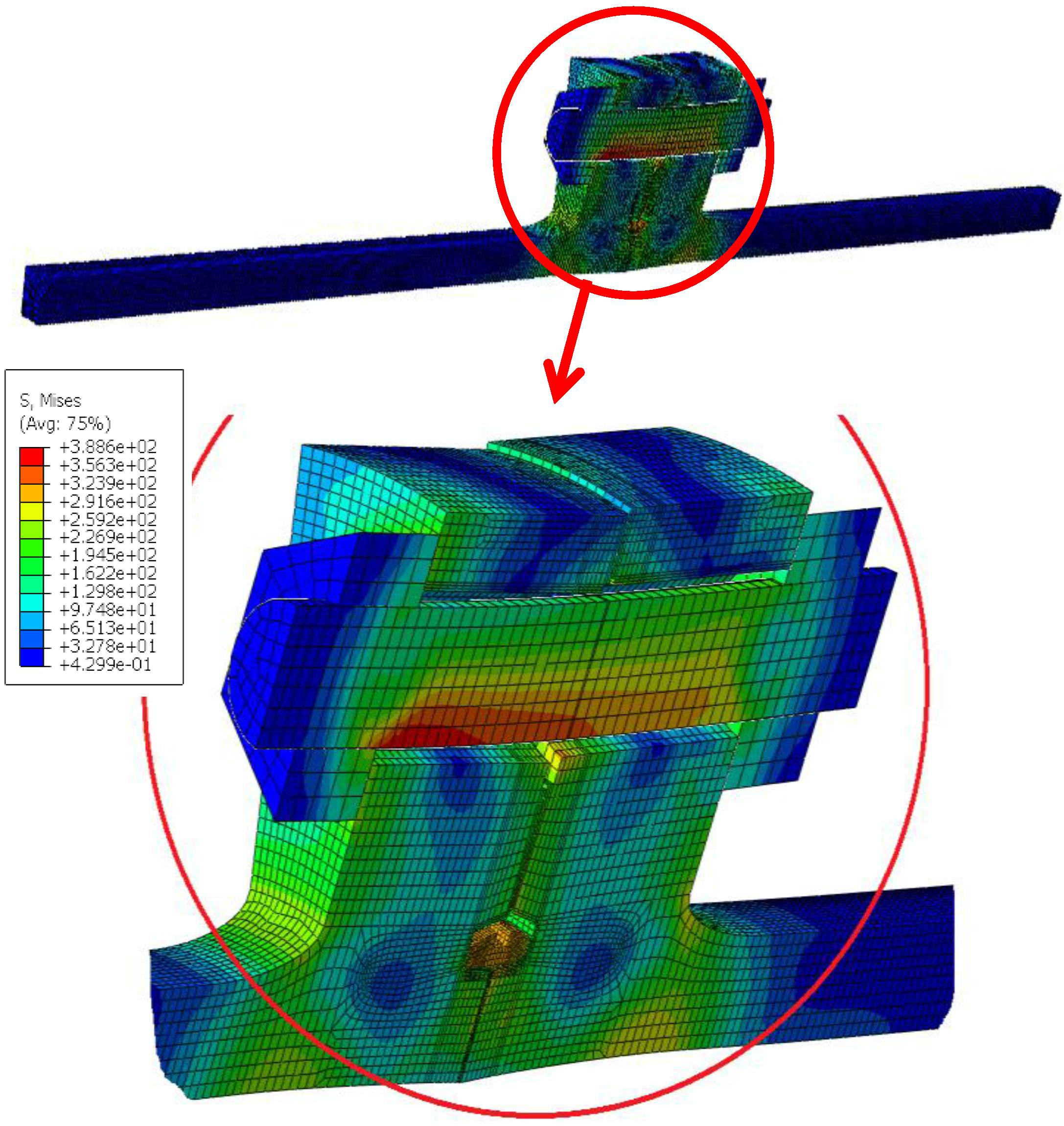

Finite element simulations have been performed in ABAQUS for a range of stresses and temperatures.

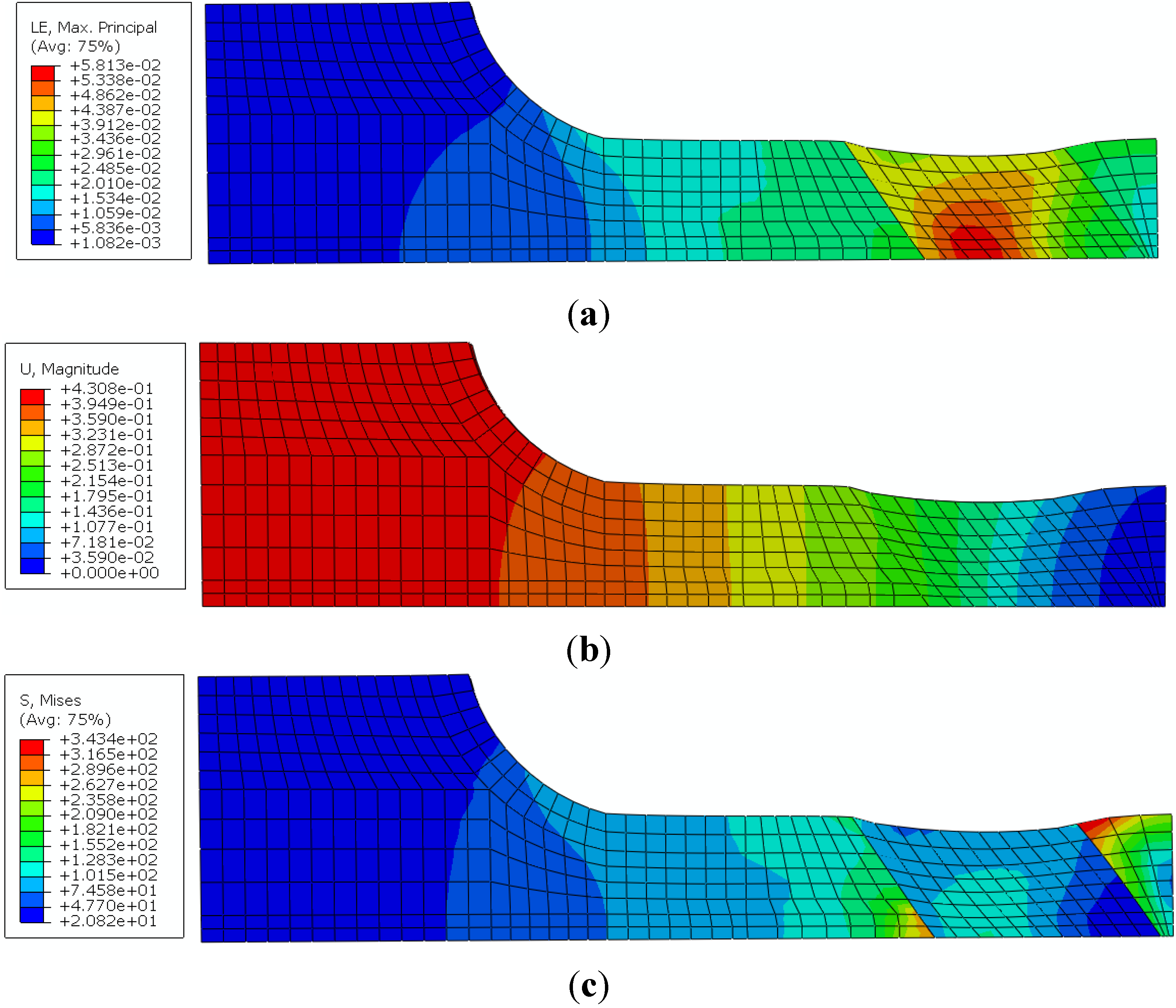

Figure 6a–d show the displacement along the axis of the specimen, the maximum principal strain, and the von-Mises stress on a cross-section and at the surface of the specimen, respectively.

Figure 6.

Finite element simulations of creep in a welded 9Cr-1Mo specimen subjected to an applied stress of 200 MPa and at a temperature of 600 °C: (a) maximum principal strain; (b) displacement along the axis of the specimen; (c) von-Mises stress in the cross section of the specimen; and (d) the stress distribution at the surface of the specimen.

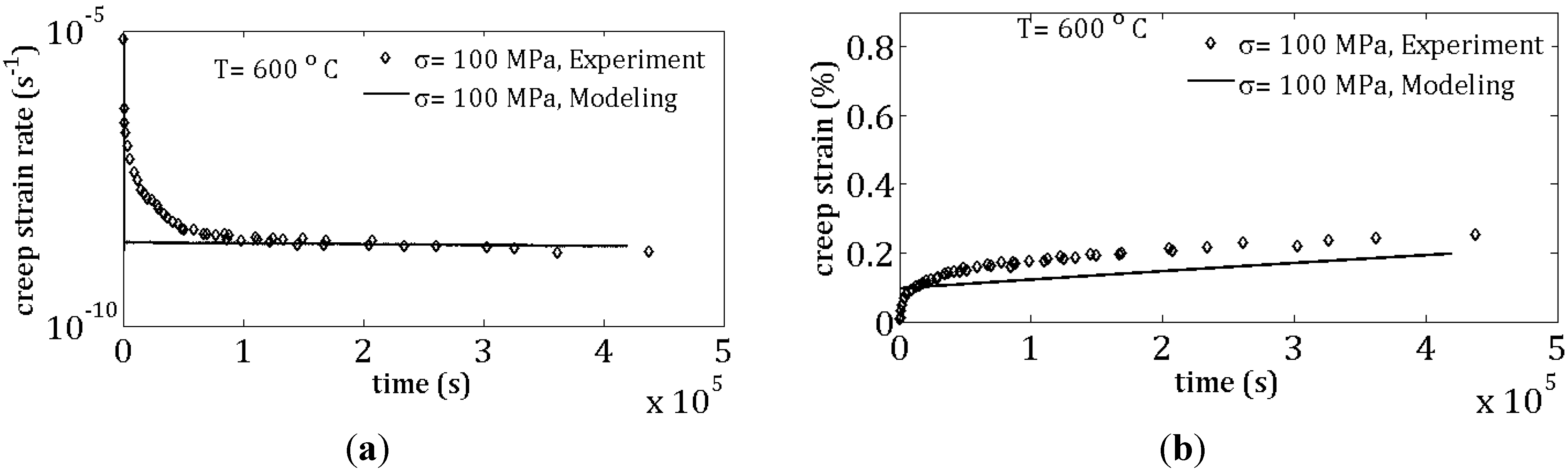

Figure 7 shows the comparison of the experimental result to the model simulation for 100 MPa and 600 °C.

Figure 7a shows the rate of creep strain

versus time, and

Figure 7b shows the true creep strain

versus time.

Figure 7.

Creep results from experiments and finite element simulation for 100 MPa and 600 °C: (a) creep strain rate versus time; and (b) true creep strain versus time.

Figure 8.

Creep results from experiments and finite element simulation for 150 MPa and 600 °C: (a) creep strain rate versus time; and (b) true creep strain versus time.

The simulation and experimental results comparison for 150 MPa at 600 °C have been shown in

Figure 8. Again,

Figure 8a is the creep strain rate

versus time and

Figure 8b is the true creep strain

versus time.

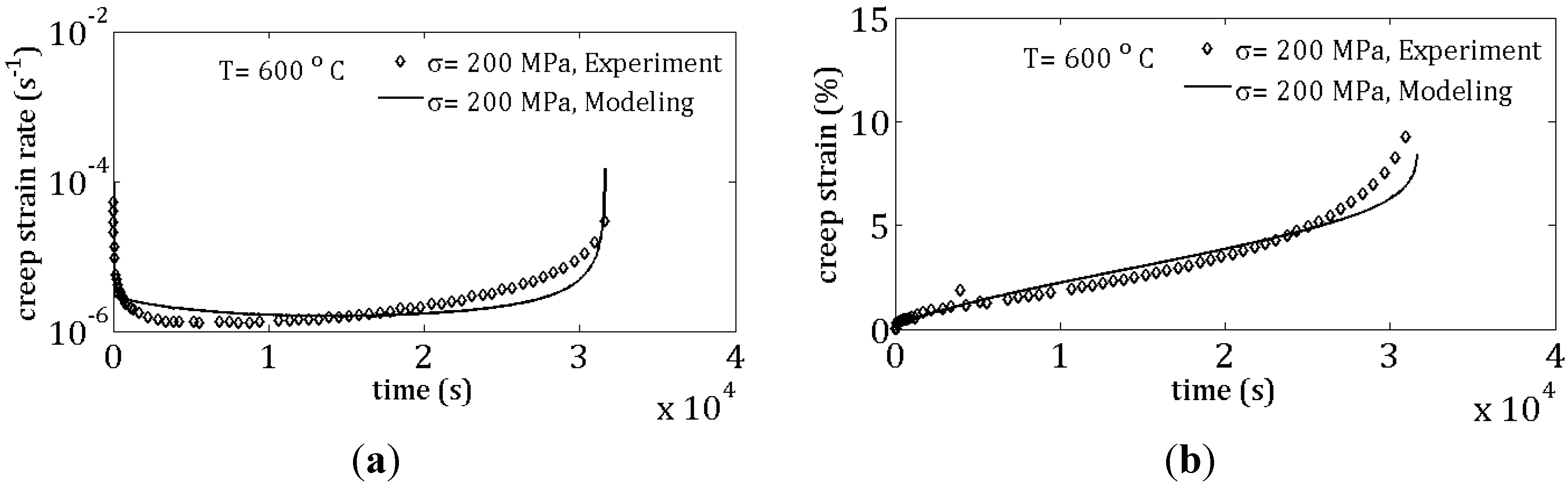

For specimen crept at 200 MPa and 600 °C

Figure 9a,b, respectively, show the creep strain rate

versus time and the true creep strain

versus time.

The comparisons of the modeling

versus experiments at 650 °C and applied stresses of 100 MPa, 125 MPa and 200 MPa are shown in

Figure 10,

Figure 11 amd

Figure 12, respectively.

Figure 9.

Creep results from experiments and finite element simulation for 200 MPa and 600 °C: (a) creep strain rate versus time; and (b) true creep strain versus time.

Figure 10.

Creep results from experiments and finite element simulation for 100 MPa and 650 °C: (a) creep strain rate versus time; and (b) true creep strain versus time.

Figure 11.

Creep results from experiments and finite element simulation for 125 MPa and 650 °C: (a) creep strain rate versus time; and (b) true creep strain versus time.

Figure 12.

Creep results from experiments and finite element simulation for 200 MPa and 650 °C: (a) creep strain rate versus time; and (b) true creep strain versus time.

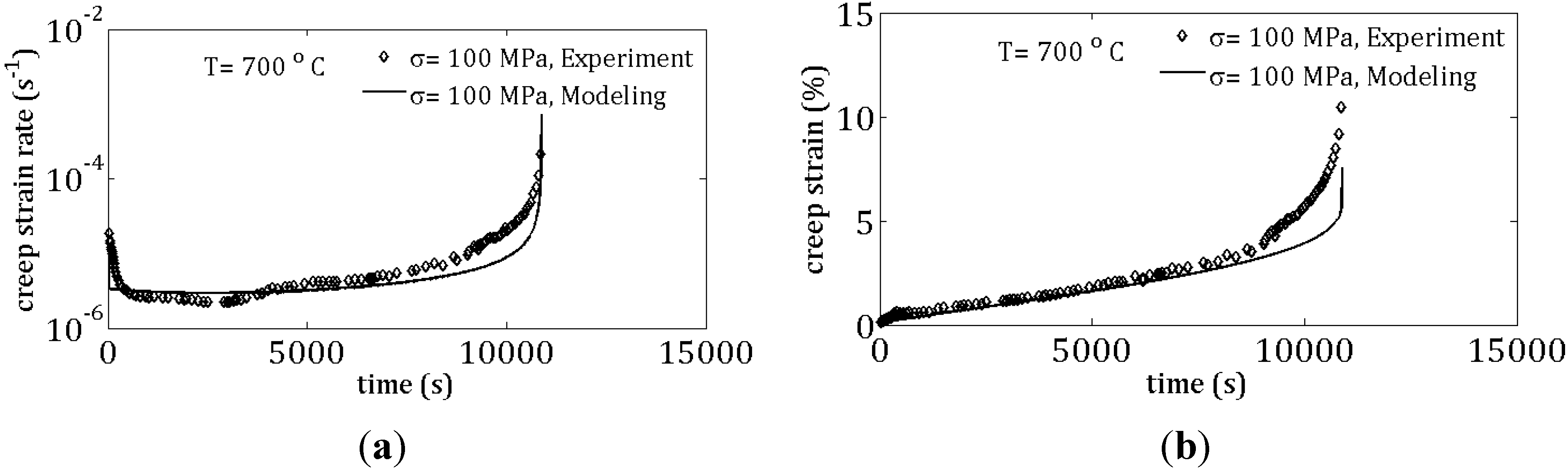

Figure 13a,b show the comparison of creep strain rate

versus time and true creep strain

versus time at 700 °C and applied stress of 100 MPa.

Figure 13.

Creep results from experiments and finite element simulation for 100 MPa and 700 °C, (a) creep strain rate versus time; and (b) true creep strain versus time.

In general, the model predicts well the evolution of the total creep strain and the creep strain rate with time, as measured experimentally. This agreement is particularly true for the stage II creep in most of the loading conditions, while a slight disagreement between experimental and simulation data is recorded at the transition between successive stages of creep. The model under-predicts the accumulation of the creep strain with time for the 150 MPa and 600 °C, but this is mainly due to its inability to capture well the transition in the creep strain rate between the creep stage I and II. An overall assessment of the models leads to the conclusion that it can be used successfully to predict the deformation and fracture in modified 9Cr-1Mo welded steels for the large majority of testing conditions.

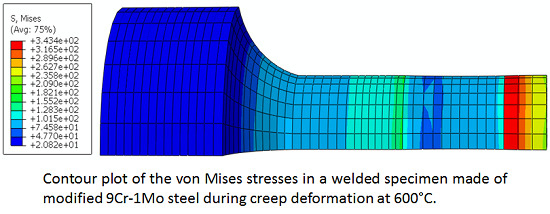

To exemplify the applicability of the constitutive model to three dimensional geometries, a creep simulation was performed for a pipe joined by a bolted connection to a flange. The pipe material was modified 9Cr-1Mo steel, while the flange material was Inconel X625. The operating temperature is 575 °C, and the internal pressure is 17 MPa. The bolt has been tightened down with a force equal to 7500 N and the simulation has been run for 100 h under these operating conditions. Due to symmetry, only a sector of the overall geometry was modeled in ABAQUS, and axisymmetric boundary conditions were used. As an illustration, the von Mises stress distribution developed after 100 h of creep in this bolted joint is plotted in

Figure 14 on the deformed shape of the connection.

Figure 14.

Example of a finite element simulation of creep stress distribution in a 9Cr-1Mo steel pipe connected to an Inconel X625 flange under thermo-mechanical loading. The operating temperature is 575 °C, and the internal pressure is 17 MPa.