Dynamic and Thermal Properties of Aluminum Alloy A356/Silicon Carbide Hollow Particle Syntactic Foams

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Quasi-Static Compression

2.3. High Strain Rate Compression

2.4. Failure Analysis

2.5. Dynamic Mechanical Analysis

2.6. Thermo-Mechanical Analysis

3. Results and Discussion

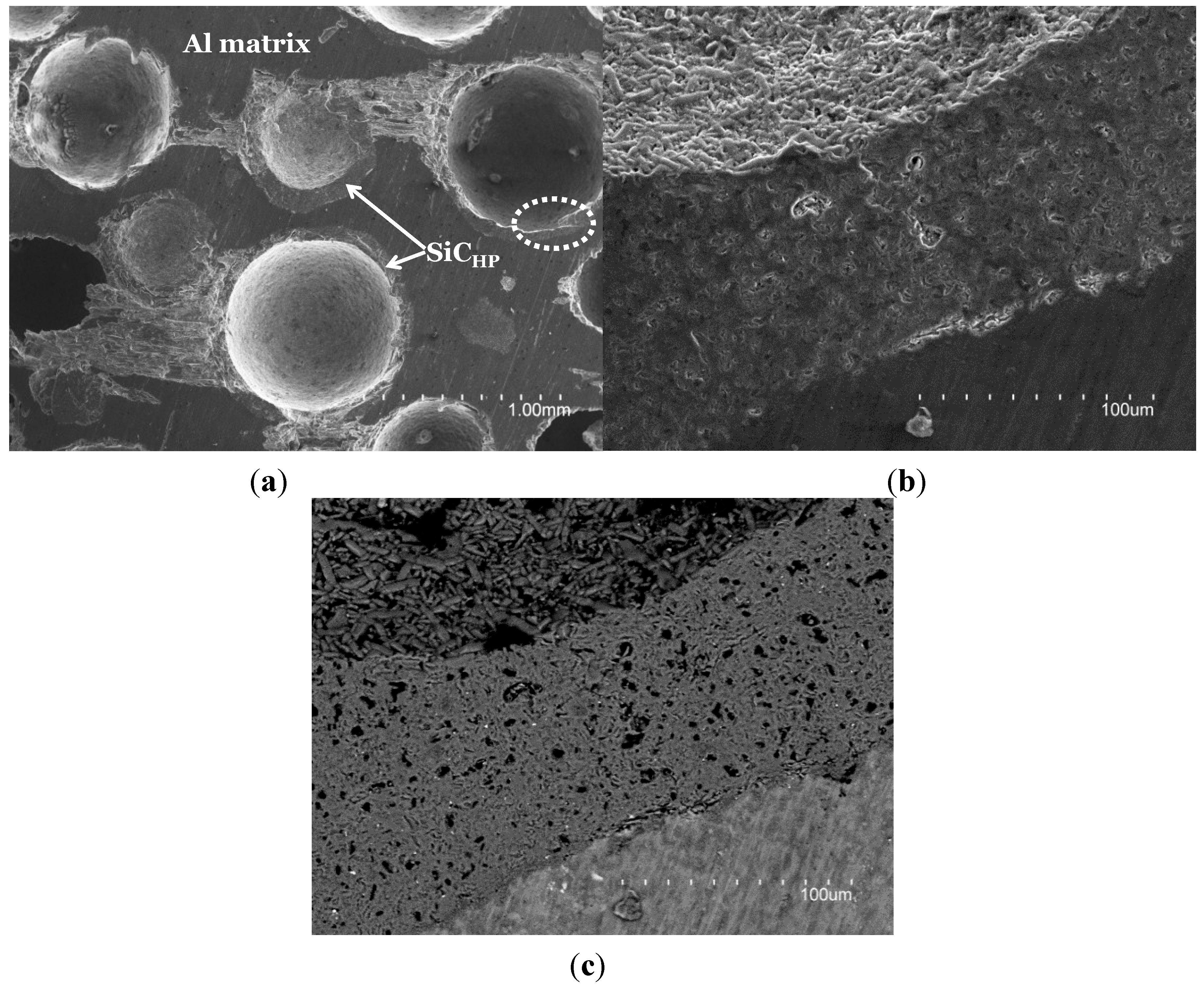

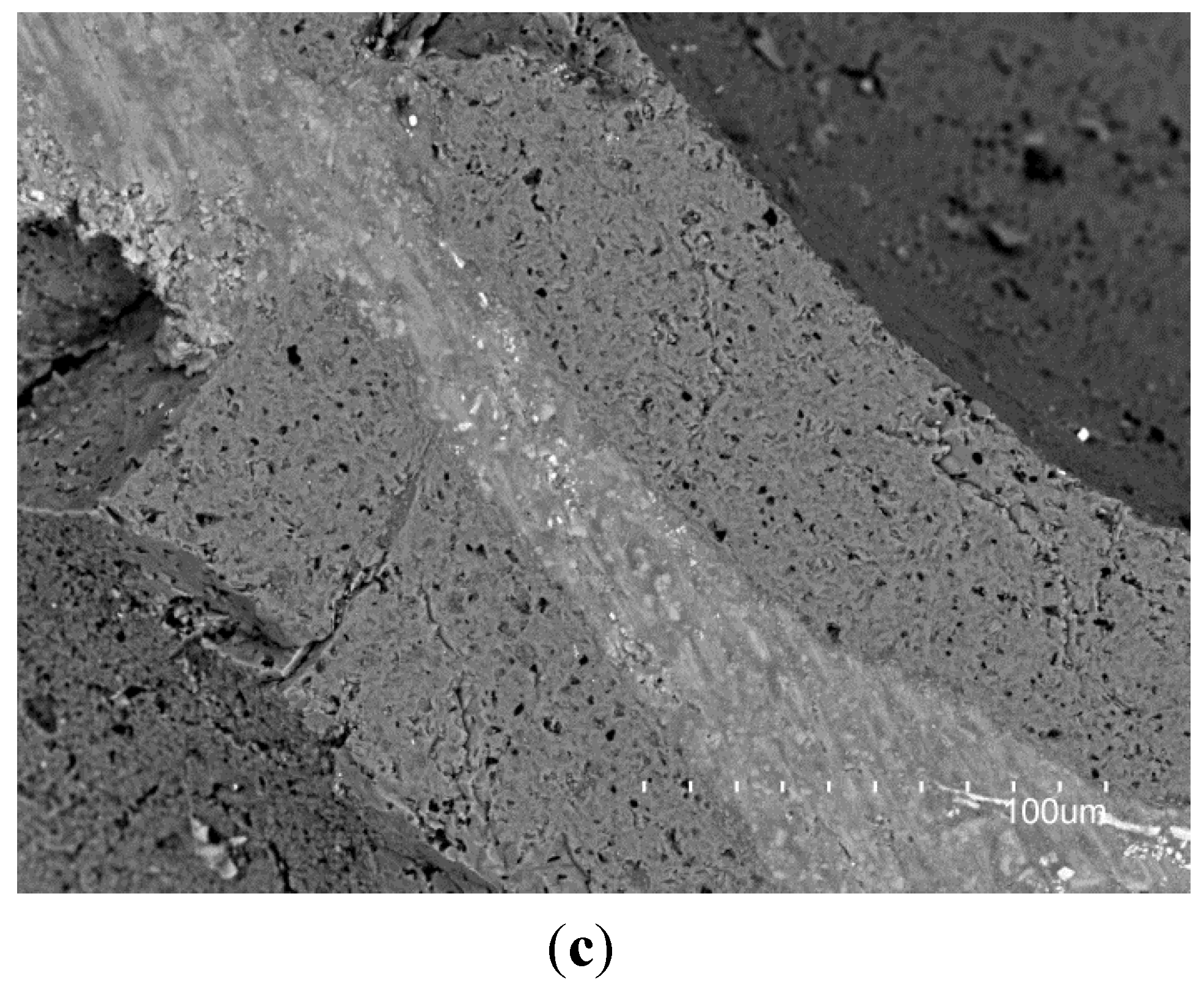

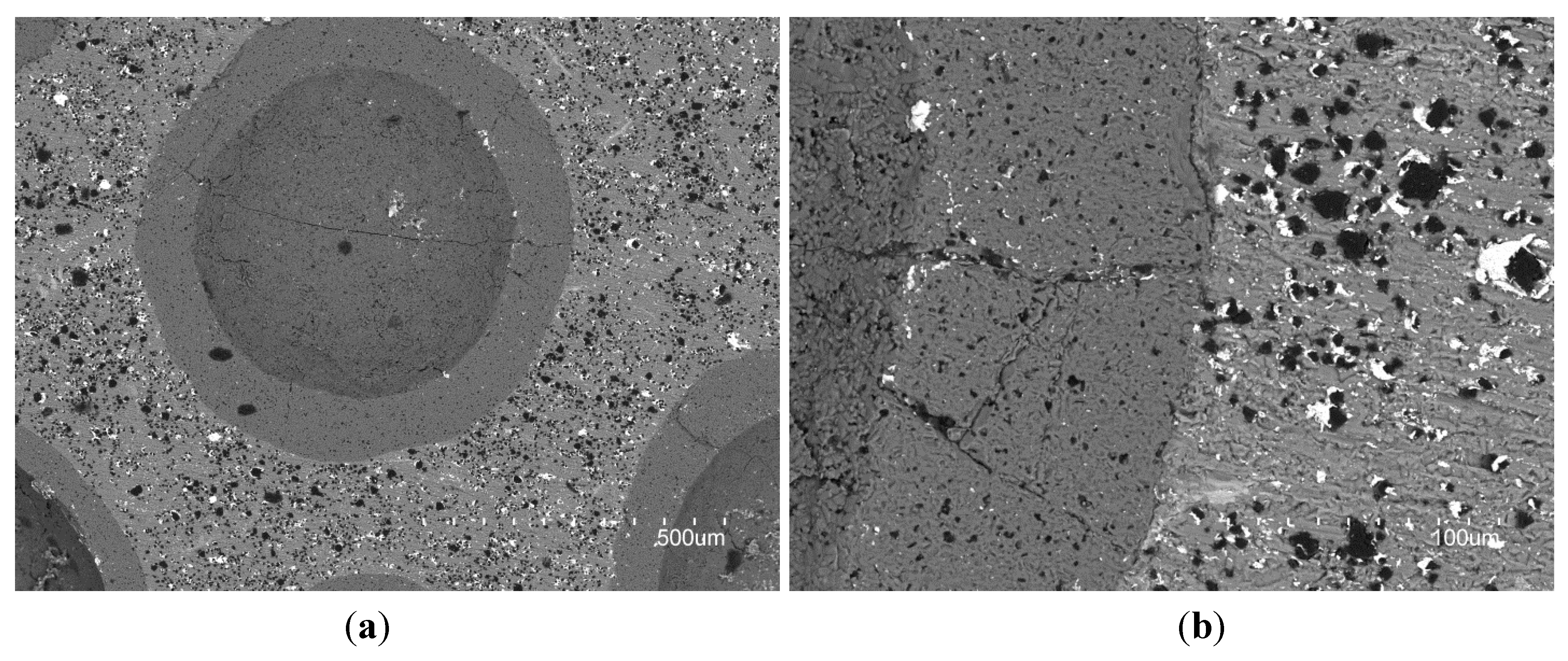

3.1. Microstructure

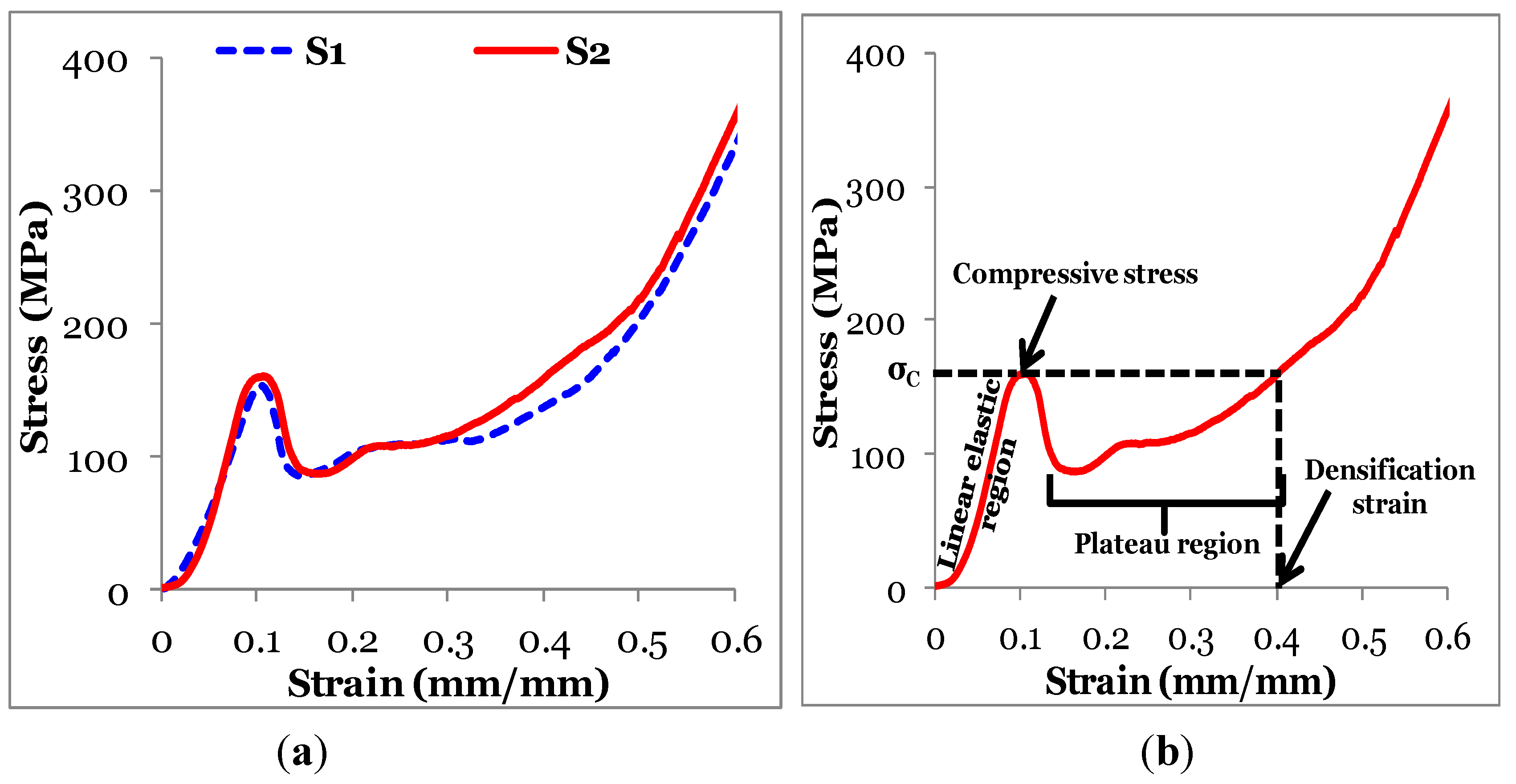

3.2. Quasi-Static Compression

| Sample type | Measured density (g/cm3) | Compressive strength (MPa) | Specific compressive strength (MPa/(g/cm3)) | Plateau stress (MPa) | Densification strain (mm/mm) |

|---|---|---|---|---|---|

| S1 | 1.71 ± 0.06 | 152.4 ± 4.3 | 89.1 ± 2.0 | 103.0 ± 7.2 | 0.44 ± 0.01 |

| S2 | 1.84 ± 0.03 | 161.1 ± 7.8 | 87.4 ± 4.3 | 109.0 ± 4.1 | 0.41 ± 0.02 |

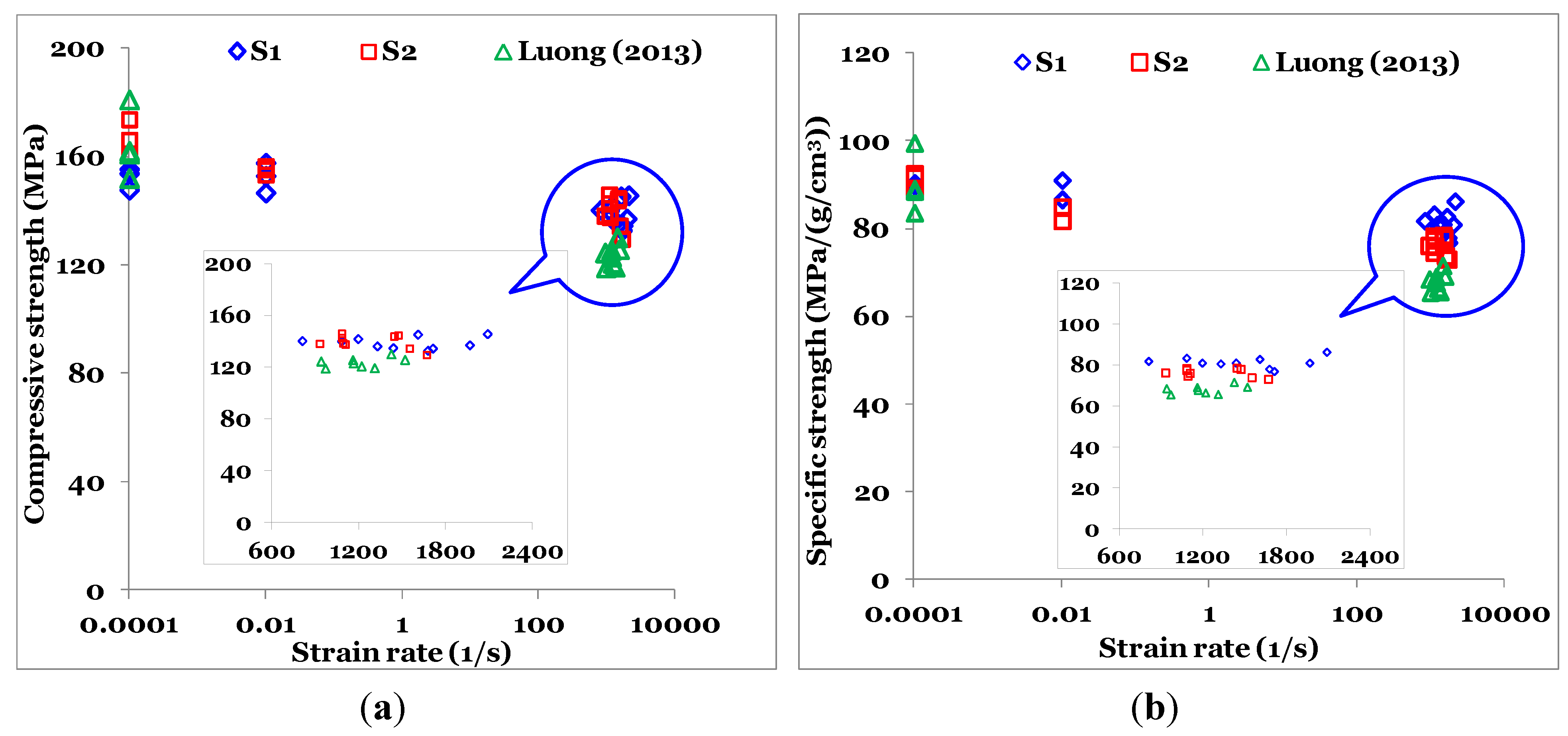

3.3. High Strain Rate Compression

3.4. Dynamic Mechanical Analysis

| Sample | Storage modulus (GPa) (50, 200, 400 °C) | Loss modulus (GPa) (50, 200, 400 °C) | tanδ (50, 200, 400 °C) |

|---|---|---|---|

| S1 | 47.45, 37.69, 25.79 | 0.70, 1.04, 3.22 | 0.015, 0.028, 0.125 |

| S2 | 48.88, 32.57, 17.84 | 0.90, 1.39, 2.40 | 0.018, 0.043, 0.134 |

| A356 | 69.22, 63.42, 48.07 | 0.98, 1.19, 5.79 | 0.014, 0.019, 0.120 |

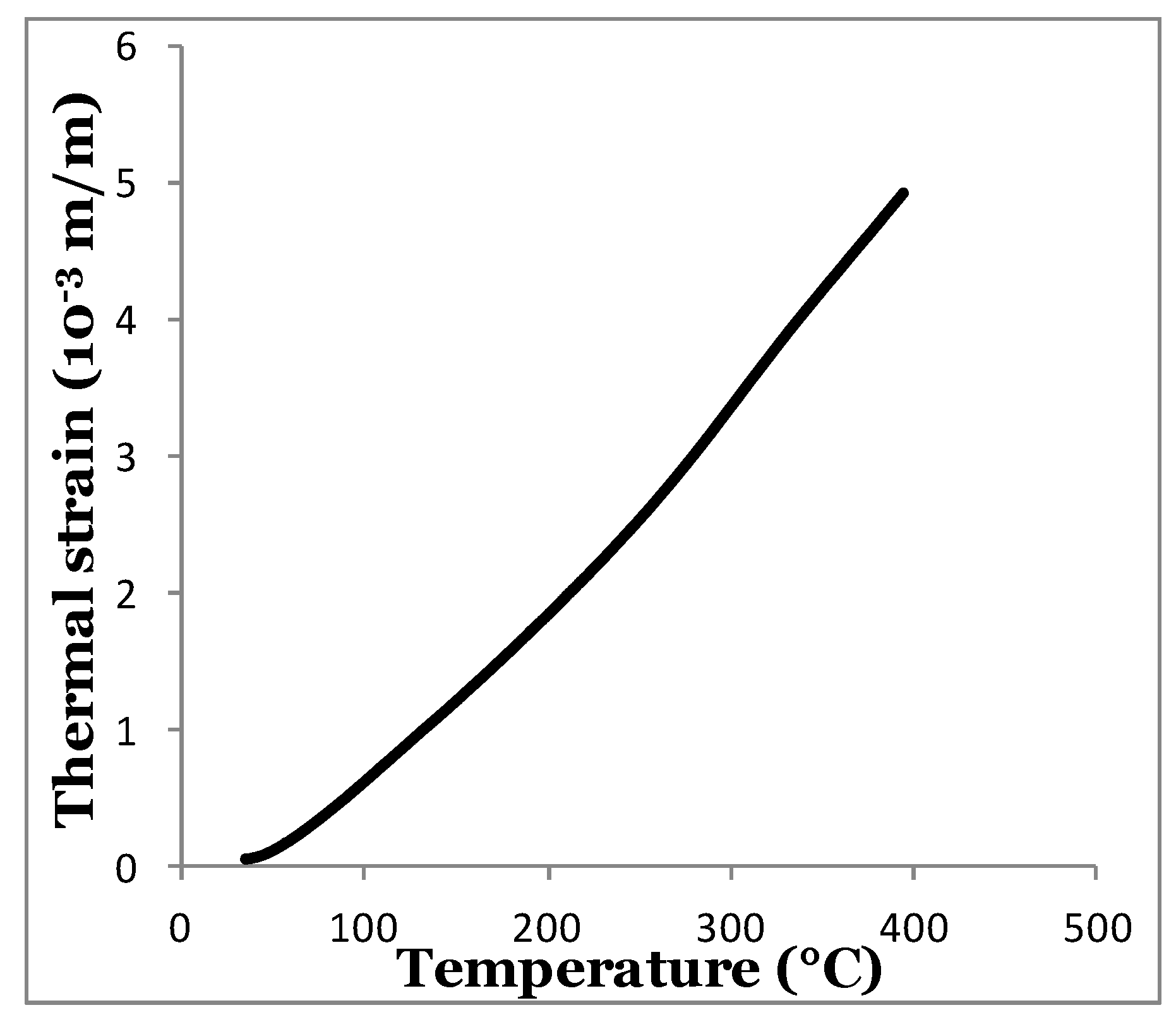

3.5. Thermomechanical Analysis

| Sample | CTE (100–200 °C) (μm/m°C) | CTE (300–400 °C) (μm/m°C) | Mean CTE (μm/m°C) |

|---|---|---|---|

| S1 | 11.67 ± 0.42 | 16.35 ± 0.66 | 14.60 ± 0.91 |

| S2 | 12.70 ± 0.36 | 17.61 ± 0.40 | 15.74 ± 0.74 |

4. Conclusions

- The S1 and S2 type specimens had average densities of 1.71 and 1.84 g/cm3, respectively. The compressive strength of higher density foam was higher. The compressive strength of S1 and S2 syntactic foams was measured as 152.4 and 161.1 MPa, respectively.

- A356/SiCHP syntactic foams did not show strain rate sensitivity in the range studied in the present work for both the S1 type and S2 type.

- The S1 and S2 type syntactic foams had specific quasi-static compressive strength of 89.1 and 87.4 MPa/(g/cm3), respectively, and a specific high strain rate compressive strength of 81.2 and 76.1 MPa/(g/cm3), respectively.

- The failure at high strain rate is initiated from the particle cracking and shear band formation in the matrix. A large compressive strain can be obtained in syntactic foams before densification because of a high volume fraction of porosity in the microstructure.

- The DMA testing showed that the storage modulus of syntactic foams is lower than that of the matrix alloy. It is also observed that the storage modulus of alloy decreases rapidly above a transition temperature, whereas the rate of decrease of storage modulus was nearly the same for syntactic foams in the test temperature range. Syntactic foams had a higher loss modulus than the matrix alloy at low temperatures. Due to the lack of viscoelasticity in metals, the storage modulus of the alloy was nearly the same as the elastic modulus and the loss modulus was comparatively negligible (two orders of magnitude lower).

- Syntactic foams had lower CTE compared to the matrix alloy. The syntactic foam demonstrated a higher CTE values at higher temperature.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ferguson, J.B.; Santa Maria, J.A.; Schultz, B.F.; Rohatgi, P.K. Al–Al2O3 syntactic foams—Part II: Predicting mechanical properties of metal matrix syntactic foams reinforced with ceramic spheres. Mater. Sci. Eng. A 2013, 582, 423–432. [Google Scholar] [CrossRef]

- Balch, D.K.; Dunand, D.C. Load partitioning in aluminum syntactic foams containing ceramic microspheres. Acta Mater. 2006, 54, 1501–1511. [Google Scholar] [CrossRef]

- Metal Matrix Syntactic Foams: Processing, Microstructure, Properties and Applications; Gupta, N.; Rohatgi, P.K. (Eds.) DEStech Publications: Lancaster, PA, USA, 2014.

- Bardella, L.; Genna, F. On the elastic behavior of syntactic foams. Int. J. Solids Struct. 2001, 38, 7235–7260. [Google Scholar]

- Bardella, L.; Sfreddo, A.; Ventura, C.; Porfiri, M.; Gupta, N. A critical evaluation of micromechanical models for syntactic foams. Mech. Mater. 2012, 50, 53–69. [Google Scholar] [CrossRef]

- Liu, J.A.; Yu, S.R.; Huang, Z.Q.; Ma, G.; Liu, Y. Microstructure and compressive property of in situ Mg2Si reinforced Mg-microballoon composites. J. Alloys Compd. 2012, 537, 12–18. [Google Scholar] [CrossRef]

- Balch, D.K.; O’Dwyer, J.G.; Davis, G.R.; Cady, C.M.; Gray, G.T., III; Dunand, D.C. Plasticity and damage in aluminum syntactic foams deformed under dynamic and quasi-static conditions. Mater. Sci. Eng. A 2005, 391, 408–417. [Google Scholar] [CrossRef]

- Goel, M.D.; Peroni, M.; Solomos, G.; Mondal, D.P.; Matsagar, V.A.; Gupta, A.K.; Larcher, M.; Marburg, S. Dynamic compression behavior of cenosphere aluminum alloy syntactic foam. Mater. Des. 2012, 42, 418–423. [Google Scholar] [CrossRef]

- Luong, D.D.; Strbik, O.M., III; Hammond, V.H.; Gupta, N.; Cho, K. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates. J. Alloys Compd. 2013, 550, 412–422. [Google Scholar] [CrossRef]

- Gupta, N.; Luong, D.D.; Cho, K. Magnesium matrix composite foams—density, mechanical properties, and applications. Metals 2012, 2, 238–252. [Google Scholar] [CrossRef]

- Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Lehmhus, D.; Weise, J.; Baumeister, J. Quasi-static and high strain rates compressive response of iron and Invar matrix syntactic foams. Mater. Des. 2015, 66 Part B, 516–531. [Google Scholar] [CrossRef]

- Peroni, L.; Scapin, M.; Avalle, M.; Weise, J.; Lehmhus, D. Dynamic mechanical behavior of syntactic iron foams with glass microspheres. Mater. Sci. Eng. A 2012, 552, 364–375. [Google Scholar] [CrossRef]

- Jha, N.; Mondal, D.P.; Goel, M.D.; Majumdar, J.D.; Das, S.; Modi, O.P. Titanium cenosphere syntactic foam with coarser cenosphere fabricated by powder metallurgy at lower compaction load. Trans. Nonferrous Metals Soc. China 2014, 24, 89–99. [Google Scholar] [CrossRef]

- Mondal, D.P.; Majumder, J.D.; Jha, N.; Badkul, A.; Das, S.; Patel, A.; Gupta, G. Titanium-cenosphere syntactic foam made through powder metallurgy route. Mater. Des. 2012, 34, 82–89. [Google Scholar] [CrossRef]

- Daoud, A. Effect of strain rate on compressive properties of novel Zn12Al based composite foams containing hybrid pores. Mater. Sci. Eng. A 2009, 525, 7–17. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Low-density expanded perlite–aluminium syntactic foam. Mater. Sci. Eng. A 2014, 604, 127–134. [Google Scholar] [CrossRef]

- Licitra, L.; Luong, D.D.; Strbik, O.M., III; Gupta, N. Dynamic properties of alumina hollow particle filled aluminum alloy A356 matrix syntactic foams. Mater. Des. 2015, 66, 504–515. [Google Scholar] [CrossRef]

- Goel, M.D.; Mondal, D.P.; Yadav, M.S.; Gupta, S.K. Effect of strain rate and relative density on compressive deformation behavior of aluminum cenosphere syntactic foam. Mater. Sci. Eng. A 2014, 590, 406–415. [Google Scholar] [CrossRef]

- Mondal, D.P.; Das, S.; Ramakrishnan, N.; Bhasker, K.U. Cenosphere filled aluminum syntactic foam made through stir-casting technique. Compos. Part A 2009, 40, 279–288. [Google Scholar] [CrossRef]

- Orbulov, I.N. Compressive properties of aluminium matrix syntactic foams. Mater. Sci. Eng. A 2012, 555, 52–56. [Google Scholar]

- Castro, G.; Nutt, S.R.; Wenchen, X. Compression and low-velocity impact behavior of aluminum syntactic foam. Mater. Sci. Eng. A 2013, 578, 222–229. [Google Scholar] [CrossRef]

- Maria, J.A.S.; Schultz, B.F.; Ferguson, J.B.; Rohatgi, P.K. Al–Al2O3 syntactic foams–Part I: Effect of matrix strength and hollow sphere size on the quasi-static properties of Al-A206/Al2O3 syntactic foams. Mater. Sci. Eng. A 2013, 582, 415–422. [Google Scholar] [CrossRef]

- Altenaiji, M.; Guan, Z.W.; Cantwell, W.J.; Zhao, Y.; Schleyer, G.K. Characterisation of aluminium matrix syntactic foams under drop weight impact. Mater. Des. 2014, 59, 296–302. [Google Scholar] [CrossRef]

- Zou, L.C.; Zhang, Q.; Pang, B.J.; Wu, G.H.; Jiang, L.T.; Su, H. Dynamic compressive behavior of aluminum matrix syntactic foam and its multilayer structure. Mater. Des. 2013, 45, 555–560. [Google Scholar]

- Rohatgi, P.K.; Gupta, N.; Alaraj, S. Thermal expansion of aluminum–fly ash cenosphere composites synthesized by pressure infiltration technique. J. Compos. Mater. 2006, 40, 1163–1174. [Google Scholar] [CrossRef]

- Liang, X.; Li, H.J.; Yu, W.; Jing, X. A numerical simulation on the coefficient of thermal expansion of hollow particle filled resin syntactic foam. Acta Metall Sinica 2013, 30, 233–239. [Google Scholar]

- Shunmugasamy, V.; Zeltmann, S.; Gupta, N.; Strbik, O., III. Compressive characterization of single porous SiC hollow particles. J. Miner. Metals Mater. Soc. 2014, 66, 892–897. [Google Scholar] [CrossRef]

- Gray, G.T., III. Mechanical Testing and Evaluation; ASM Handbook; ASM International: Materials Park, OH, USA, 2000; Volume 8. [Google Scholar]

- Gupta, N.; Luong, D.D.; Rohatgi, P.K. A method for intermediate strain rate compression testing and study of compressive failure mechanism of Mg-Al-Zn alloy. J. Appl. Phys. 2011, 109, 103512. [Google Scholar] [CrossRef]

- Labella, M.; Shunmugasamy, V.C.; Strbik, O.M., III; Gupta, N. Compressive and thermal characterization of syntactic foams containing hollow silicon carbide particles with porous shell. J. Appl. Polym. Sci. 2014, 131, 1–5. [Google Scholar] [CrossRef]

- Wu, G.H.; Dou, Z.Y.; Sun, D.L.; Jiang, L.T.; Ding, B.S.; He, B.F. Compression behaviors of cenosphere–pure aluminum syntactic foams. Scr. Mater. 2007, 56, 221–224. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Kim, J.K.; Gupta, N.; Alaraj, S.; Daoud, A. Compressive characteristics of A356/fly ash cenosphere composites synthesized by pressure infiltration technique. Compos. Part A 2006, 37, 430–437. [Google Scholar] [CrossRef]

- Májlinger, K.; Orbulov, I.N. Characteristic compressive properties of hybrid metal matrix syntactic foams. Mater. Sci. Eng. A 2014, 606, 248–256. [Google Scholar] [CrossRef] [Green Version]

- Rivero, G.A.R.; Schultz, B.F.; Ferguson, J.B.; Gupta, N.; Rohatgi, P.K. Compressive properties of Al-A206/SiC and Mg-AZ91/SiC syntactic foams. J. Mater. Res. 2013, 28, 2426–2435. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Májlinger, K. Description of the compressive response of metal matrix syntactic foams. Mater. Des. 2013, 49, 1–9. [Google Scholar] [CrossRef]

- Surappa, M.K. Synthesis of fly ash particle reinforced A356 Al composites and their characterization. Mater. Sci. Eng. A 2008, 480, 117–124. [Google Scholar] [CrossRef]

- Daoud, A.; Abou El-khair, M.T.; Abdel-Aziz, M.; Rohatgi, P. Fabrication, microstructure and compressive behavior of ZC63 Mg–microballoon foam composites. Compos. Sci. Technol. 2007, 67, 1842–1853. [Google Scholar] [CrossRef]

- Huang, Z.; Yu, S.; Li, M. Microstructures and compressive properties of AZ91D/fly-ash cenospheres composites. Trans. Nonferrous Metals Soc. China 2010, 20 (Suppl. 2), s458–s462. [Google Scholar]

- Guo, R.Q.; Rohatgi, P.K.; Nath, D. Preparation of aluminium-fly ash particulate composite by powder metallurgy technique. J. Mater. Sci. 1997, 32, 3971–3974. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Daoud, A.; Schultz, B.F.; Puri, T. Microstructure and mechanical behavior of die casting AZ91D-Fly ash cenosphere composites. Compos. Part A 2009, 40, 883–896. [Google Scholar] [CrossRef]

- Dou, Z.Y.; Jiang, L.T.; Wu, G.H.; Zhang, Q.; Xiu, Z.Y.; Chen, G.Q. High strain rate compression of cenosphere-pure aluminum syntactic foams. Scr. Mater. 2007, 57, 945–948. [Google Scholar] [CrossRef]

- Das, T.; Bandyopadhyay, S.; Blairs, S. DSC and DMA studies of participate reinforced metal matrix composites. J. Mater. Sci. 1994, 29, 5680–5688. [Google Scholar] [CrossRef]

- Zhang, J.; Perez, R.J.; Lavernia, E.J. Effect of SiC and graphite particulates on the damping behavior of metal matrix composites. Acta Metall. Mater. 1994, 42, 395–409. [Google Scholar] [CrossRef]

- Zhang, J.; Perez, R.J.; Gupta, M.; Lavernia, E.J. Damping behavior of particulate reinforced 2519 Al metal matrix composites. Scr. Metall. Mater. 1993, 28, 91–96. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM Specialty Handbook; ASM International: Materials Park, OH, USA, 1993; pp. 1–784. [Google Scholar]

- Labella, M.; Zeltmann, S.E.; Shunmugasamy, V.C.; Gupta, N.; Rohatgi, P.K. Mechanical and thermal properties of fly ash/vinyl ester syntactic foams. Fuel 2014, 121, 240–249. [Google Scholar] [CrossRef]

- Elomari, S.; Boukhili, R.; Lloyd, D.J. Thermal expansion studies of prestrained Al2O3/Al metal matrix composite. Acta Mater. 1996, 44, 1873–1882. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cox, J.; Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Strbik, O.M., III; Cho, K. Dynamic and Thermal Properties of Aluminum Alloy A356/Silicon Carbide Hollow Particle Syntactic Foams. Metals 2014, 4, 530-548. https://doi.org/10.3390/met4040530

Cox J, Luong DD, Shunmugasamy VC, Gupta N, Strbik OM III, Cho K. Dynamic and Thermal Properties of Aluminum Alloy A356/Silicon Carbide Hollow Particle Syntactic Foams. Metals. 2014; 4(4):530-548. https://doi.org/10.3390/met4040530

Chicago/Turabian StyleCox, James, Dung D. Luong, Vasanth Chakravarthy Shunmugasamy, Nikhil Gupta, Oliver M. Strbik, III, and Kyu Cho. 2014. "Dynamic and Thermal Properties of Aluminum Alloy A356/Silicon Carbide Hollow Particle Syntactic Foams" Metals 4, no. 4: 530-548. https://doi.org/10.3390/met4040530