1. Introduction

The use of aluminum foam as a filling for structural components is intended to improve their dynamic behavior, increase impact energy absorption,

etc. [

1]. In the machine tools field, the structures are generally designed by means of finite elements models (FEM) of the whole machine (basement, ram, spindle,

etc.) to obtain the desired dynamic behavior, the desired material savings and to avoid unwanted vibrations [

2]. If the virtual model is taken as a starting point (as in the work here described), the technological problems for the realization of the designed structure must be solved. In the realization of a ram with aluminum foam filling [

3], as an example, the component must be grinded and heat-treated. As the foaming process needs to take the ram to up to 650 °C, it is difficult to obtain the required tolerances. Therefore the use of aluminum foam fillings adds a degree of freedom to the structure design but also introduces some technological issues.

While it is well known in scientific literature that aluminum foam has a greater loss factor than its base bulk material [

1], there is, however, a lack of reports on the dynamic behavior of aluminum and Hybrid APM filled structures, as a function of hollow structure characteristics. In this paper attention is focused on foam filling of a simple structure (a portal) in order to obtain guidelines for the design of more complex components considering two important aspects: the dynamic behavior (experimental modal analysis) and the foaming temperature. A very promising material for the realization of filled structures with strict tolerances, is the hybrid APM foam [

4] which will be compared to aluminum foam prepared by powder metallurgical (PM) route. To manufacture hybrid APM foam, aluminium foam spheres are produced by foaming a granulated precursor material and subsequently coated with a thermally activated adhesive which contains a chemical foaming agent. The coated granules are then poured into the hollow structures which have to be filled. During a subsequent heat-treatment at moderate temperatures (e.g., 120 to 180 °C) the adhesive melts, foams up and cures. Thus, filling the hollow structures with hybrid APM foam is very easy and the thermal load applied to the structure is much less than in the traditional foam filling process.

Different types of foam fillings will be considered and compared to the original empty structure and then to each other, in order to evaluate their performances at different frequencies.

3. Results and Discussions

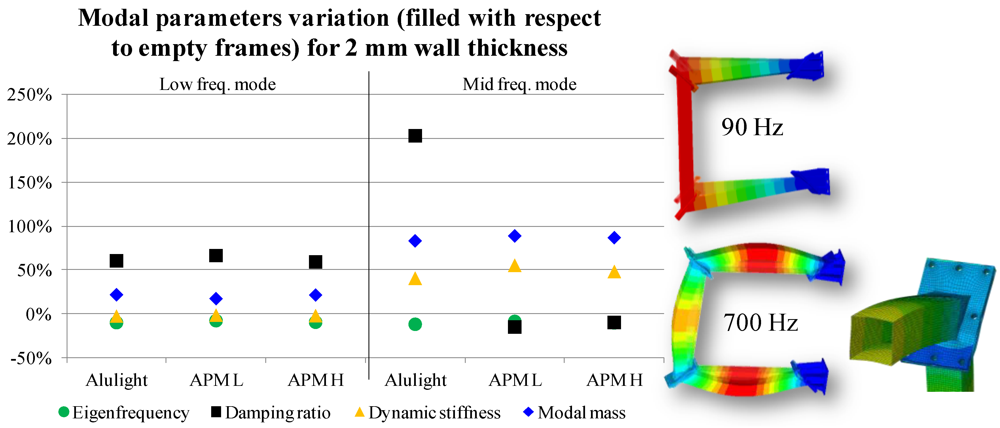

The analysis was carried out for each skin thickness and selected mode (low and mid frequency). As can be seen in

Figure 4, the three fillings have the same influence on the modal parameters of the low frequency mode for the 2 mm thickness tubes. The damping ratio increases of 60 to 65%, whereas the dynamic stiffness is slightly reduced. It is obvious that the modal mass increases as the filling is introduced. As a result, the eigenfrequency decreases.

In the mid-frequency mode for the same tubes thickness, it is possible to see that Alulight foam filling strongly increases the damping ratio, while hybrid APM (both low and high densities) reduce the ratio. It is possible to justify a reduction in the

damping ratio considering that it is defined as the ratio between the damping coefficient

c over the critical damping coefficient:

![Metals 02 00211 i001]()

. If the damping coefficient is unchanged and the mass increases, the damping ratio decreases.

Furthermore, it is important to note that the dynamic stiffness increases for the mid-frequency mode, whereas it is nearly unchanged at low frequency. Lastly, modal mass is nearly twice the corresponding empty structures for the mid-frequency mode.

The behavior of the damping ratio, modal mass and dynamic stiffness for the two modes can be explained by their shapes. The low frequency one is a straight line from the constraint to the free end (horizontal tubes in

Figure 3) whereas the second is a parabola starting and ending at near-zero deformation. The hybrid APM filling types are bonded (glued) to the skin whereas the aluminum foam is not bonded [

6]. If such a bonding is not present, a 700 Hz parabolic shape mode enables a great energy dissipation (friction) while mass and stiffness exhibit the same behavior. This is the most promising hypothesis for the explanation of +200% of damping ratio.

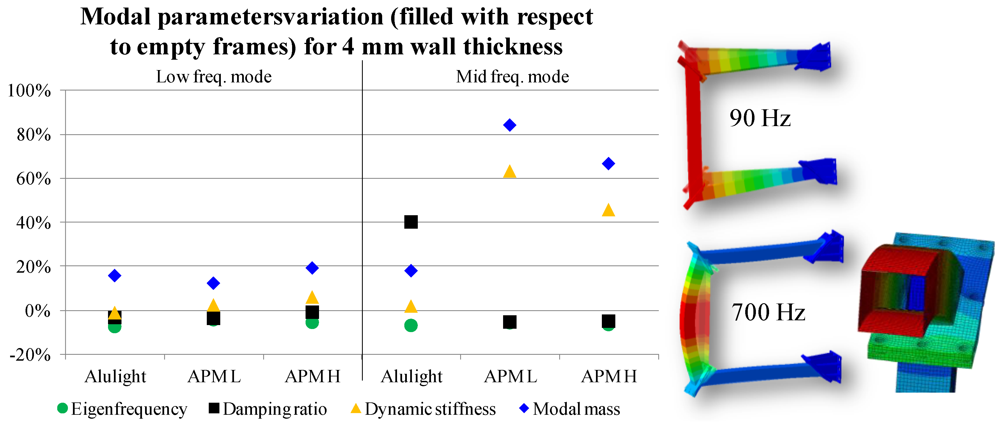

Considering the low frequency mode for the 4 mm thickness tubes, it can be seen (

Figure 5) that there is a slight reduction in both the eigenfrequency and damping ratio with an increase of about 15% in modal mass. The dynamic stiffness depends on the filling type: it is nearly unchanged for Alulight foam and increases with hybrid APM foam density even if change values are close to zero.

The mid-frequency mode (4 mm skin) exhibits, for hybrid APM, the same behavior reported in

Figure 4, whereas Alulight foam increases the damping ratio of about 40%. The latter could also be explained by the lack of bonding as for the 2 mm tubes structure. The main difference between the mid frequency modes shape for 2 and 4 mm tubes, is that the former exhibits skin rounding, and the latter does not. As Alulight foam fillings are not bonded to the skin, a greater effect of filling on modal parameters in the 2 mm case is expected. As can be seen when comparing

Figure 4 and

Figure 5, the dynamic mass and stiffness for hybrid APM are the same for the two wall thicknesses, while Alulight foam exhibits a scaled performance (of about one fifth).

Finally, the dynamic behavior of the empty structures is characterized by a little number of modes from 1500 Hz up that involve only the tube skin (called membrane modes). These modes disappear when any of the three types of filling is introduced in the tubes.

FEA analysis performed on the structures shows a good agreement with measured low-frequency modes (errors are within ±5%) in terms of modal shape and frequency. As mode frequency increases, the FEM prediction is not reliable, as local deformations are not well predicted in FEM analysis due to geometry and material simplifications.

4. Conclusions

The lack of documentation on the design of structural components in order to maximize the effect of foam filling was the pivotal reason for this work. The most important conclusion (revealed in hindsight) is that it is not possible to define a general procedure as the modes shape have a great influence on the performance of the filling. In the case considered in this study, the three foam fillings tested have the same influence on modal parameters only if vibration amplitudes are great or mode shape involve the filling itself (i.e., skin rounding). A partially unproven hypothesis is that the bonding of the filling has a great influence on the damping ratio of high frequency modes, whereas the nature of the filling influences all modal parameters.

Hybrid APM exhibits stable results in terms of modal parameters, whereas unbonded Alulight foam needs a mode shape that involves the whole filling to maximize the performance. As noted above, if no bonding is present and the mode shape does not involve the filling, damping ratio is increased while the other parameters remain almost unchanged.

Another important result is that both foam fillings (Alulight or hybrid APM) were able to suppress the membrane modes. This expected phenomenon results in a reduction of environmental noise and an increase in performance of the component.

Finally, the foaming temperature must be considered. In certain applications, the mechanical component has tolerances that must be respected after the foaming process. In this way hybrid APM has a great advantage as the foaming temperature is 120–180 °C, whereas Alulight precursor must be heated to up to the melting point of the precursor material, usually about 650 °C. A heat treatment involving a fast heating ramp up to 650 °C and a subsequent cooling phase can produce severe thermal deformations unacceptable in applications characterized by narrow tolerances such as the one described in [

2]. In these types of applications, hybrid APM fillings can be considered an attractive alternative, because the low temperature foaming phase is easily controllable and nearly deformation free.

. If the damping coefficient is unchanged and the mass increases, the damping ratio decreases.

. If the damping coefficient is unchanged and the mass increases, the damping ratio decreases.