Effect of Base Oil Type in Grease Composition on the Lubricating Film Formation in EHD Contacts †

Abstract

:1. Introduction

2. Methods and Lubricants

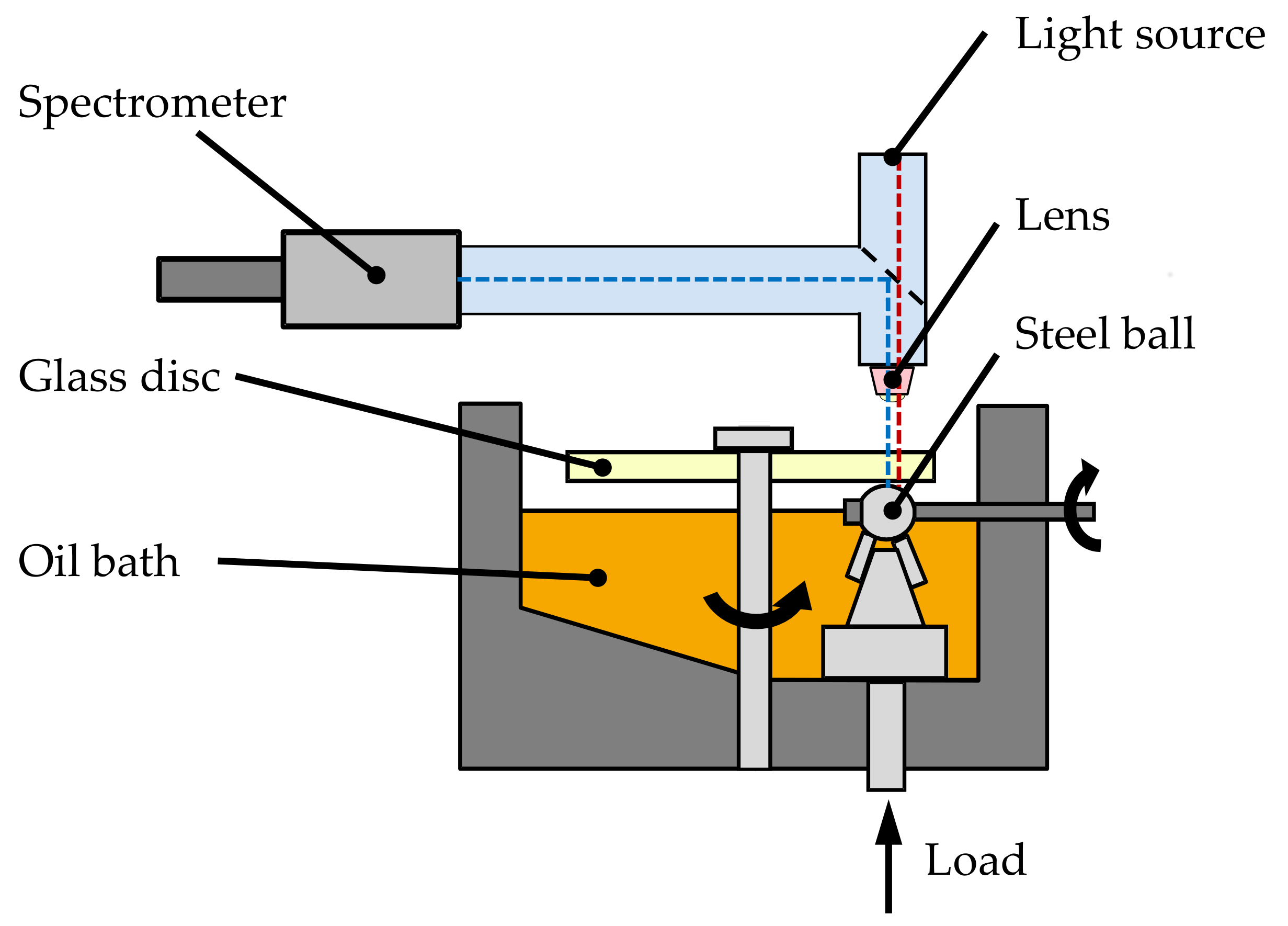

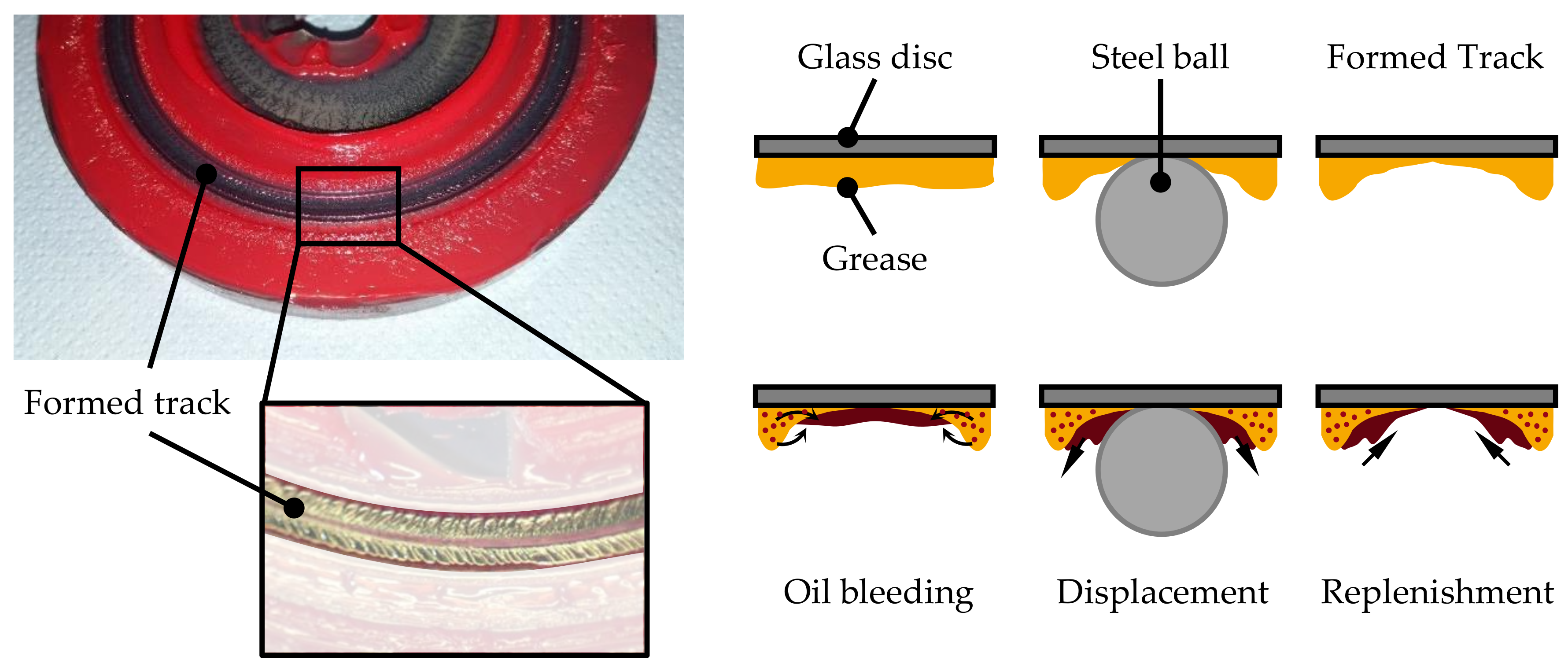

2.1. Film Thickness Measurements

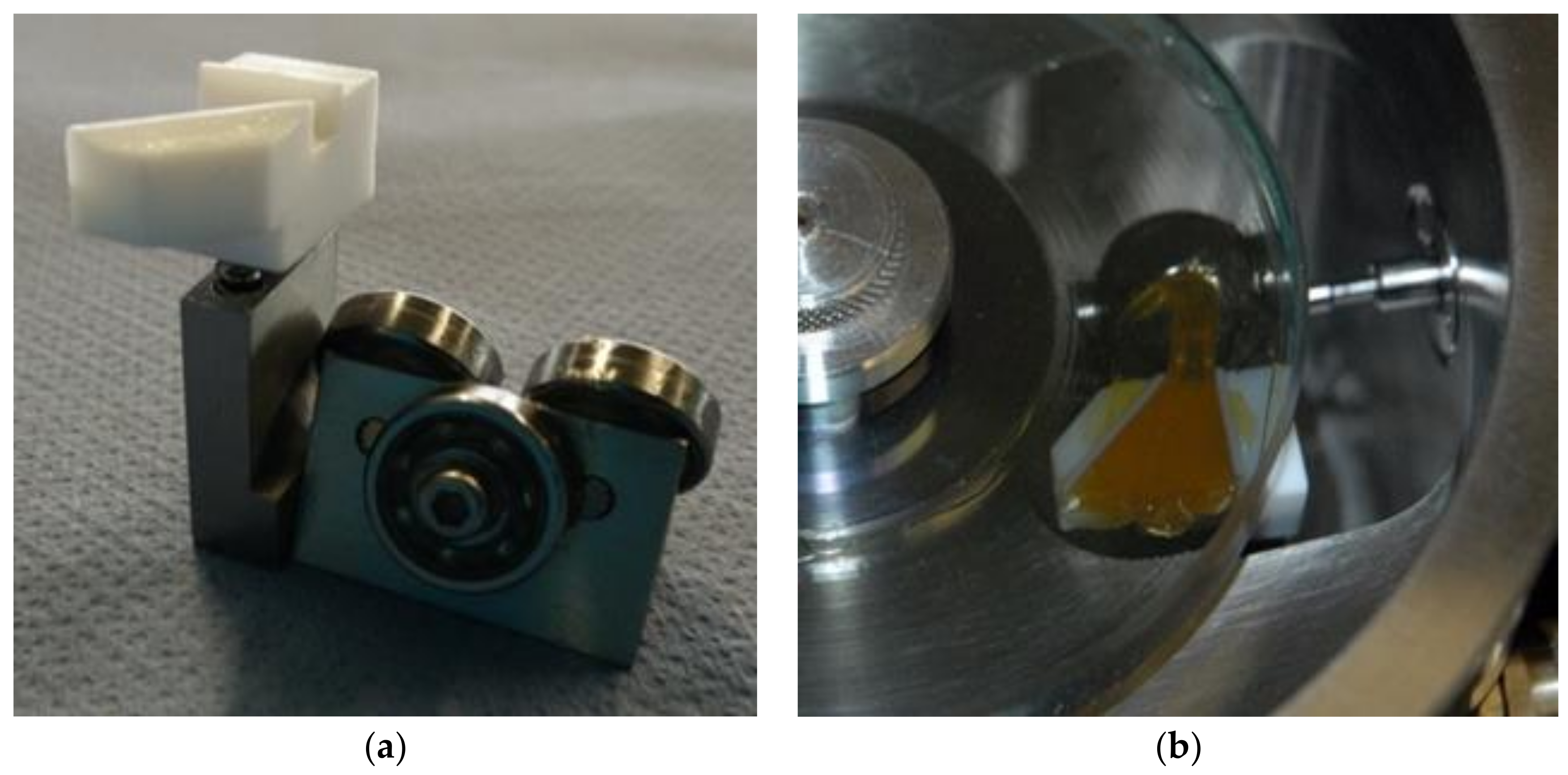

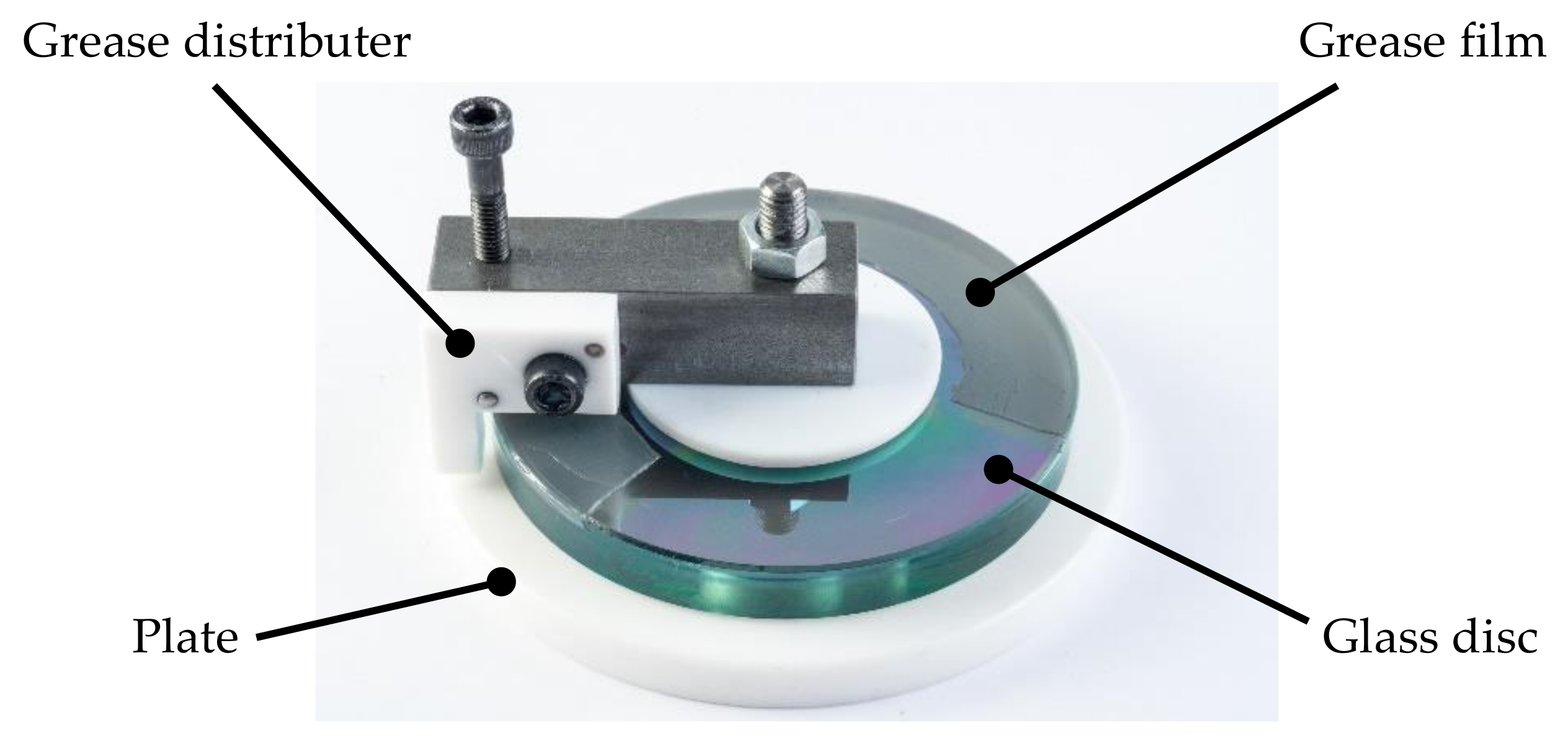

2.2. Preparation of Grease Lubricated Film Thickness Measurements

2.3. Lubricants

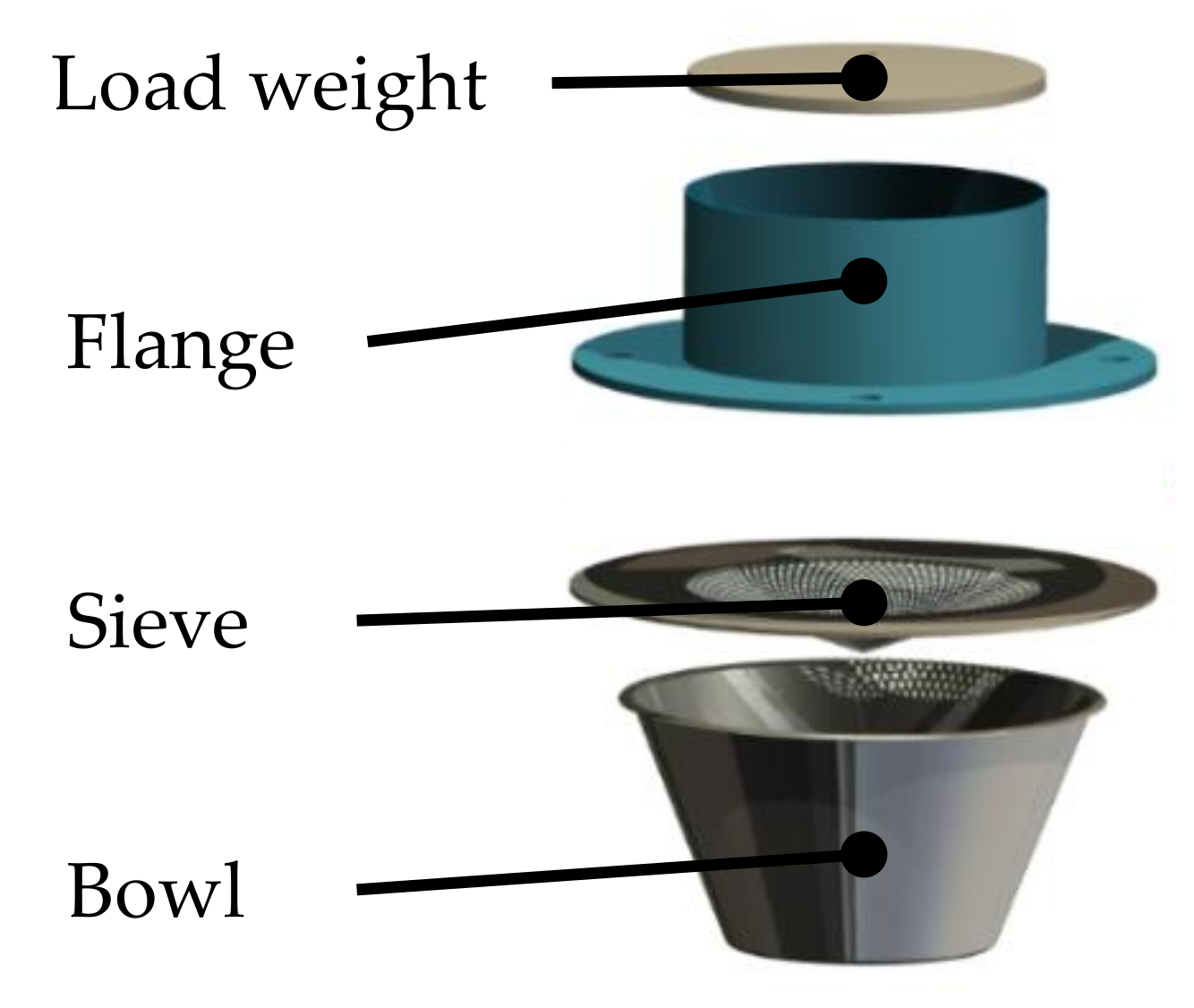

2.4. Extraction of Bleed Oil

3. Results

3.1. Results of the Bleeding Tests

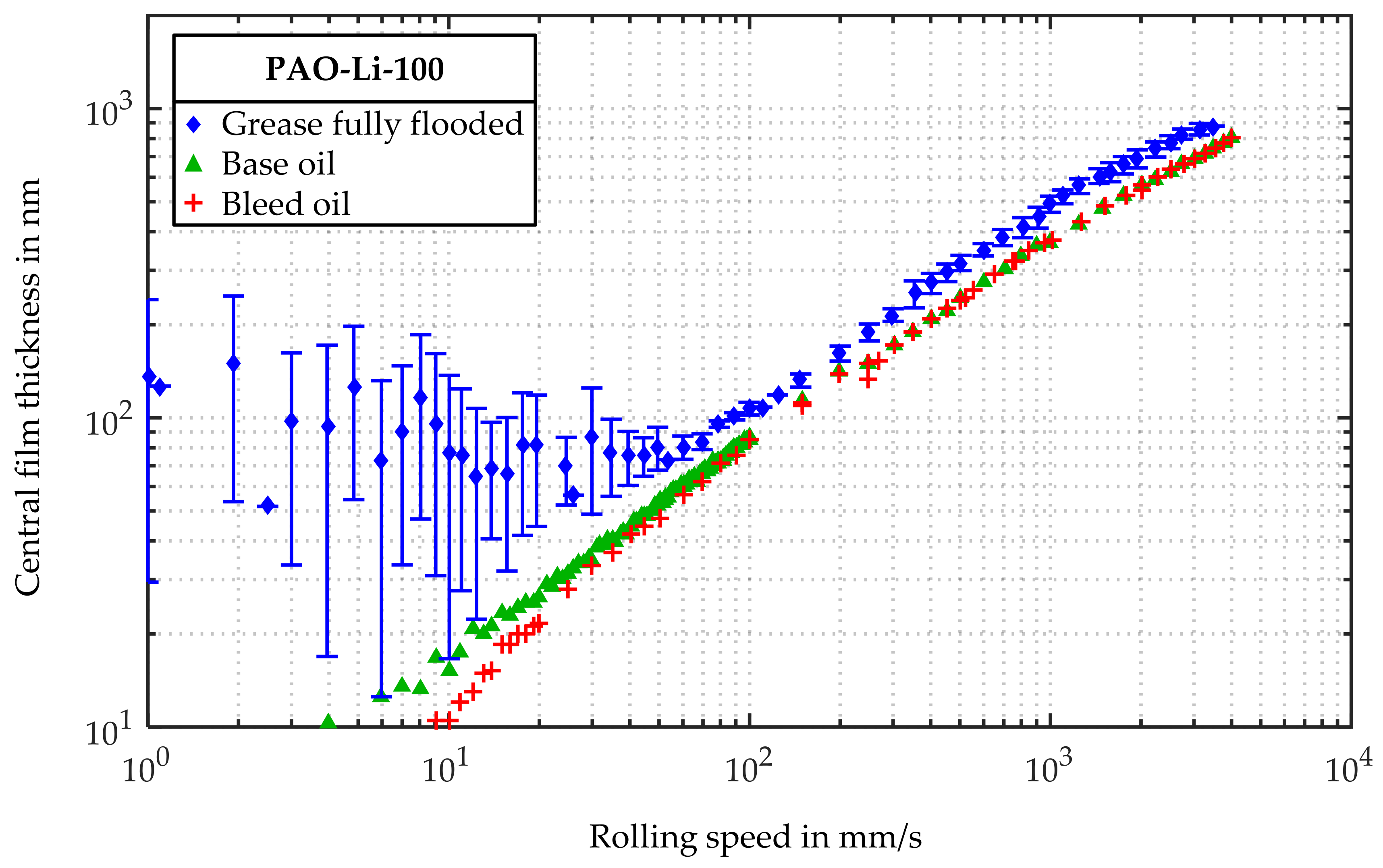

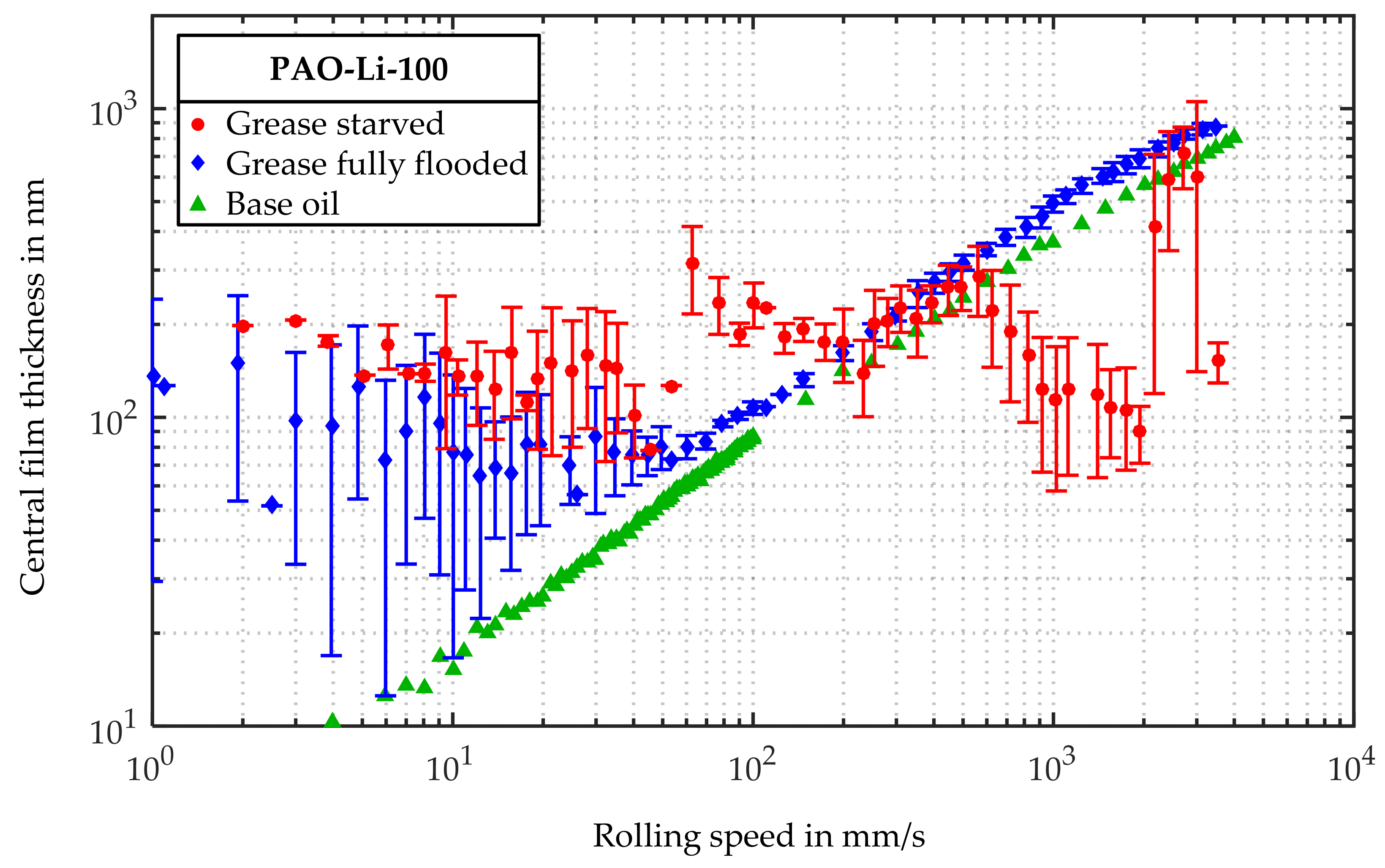

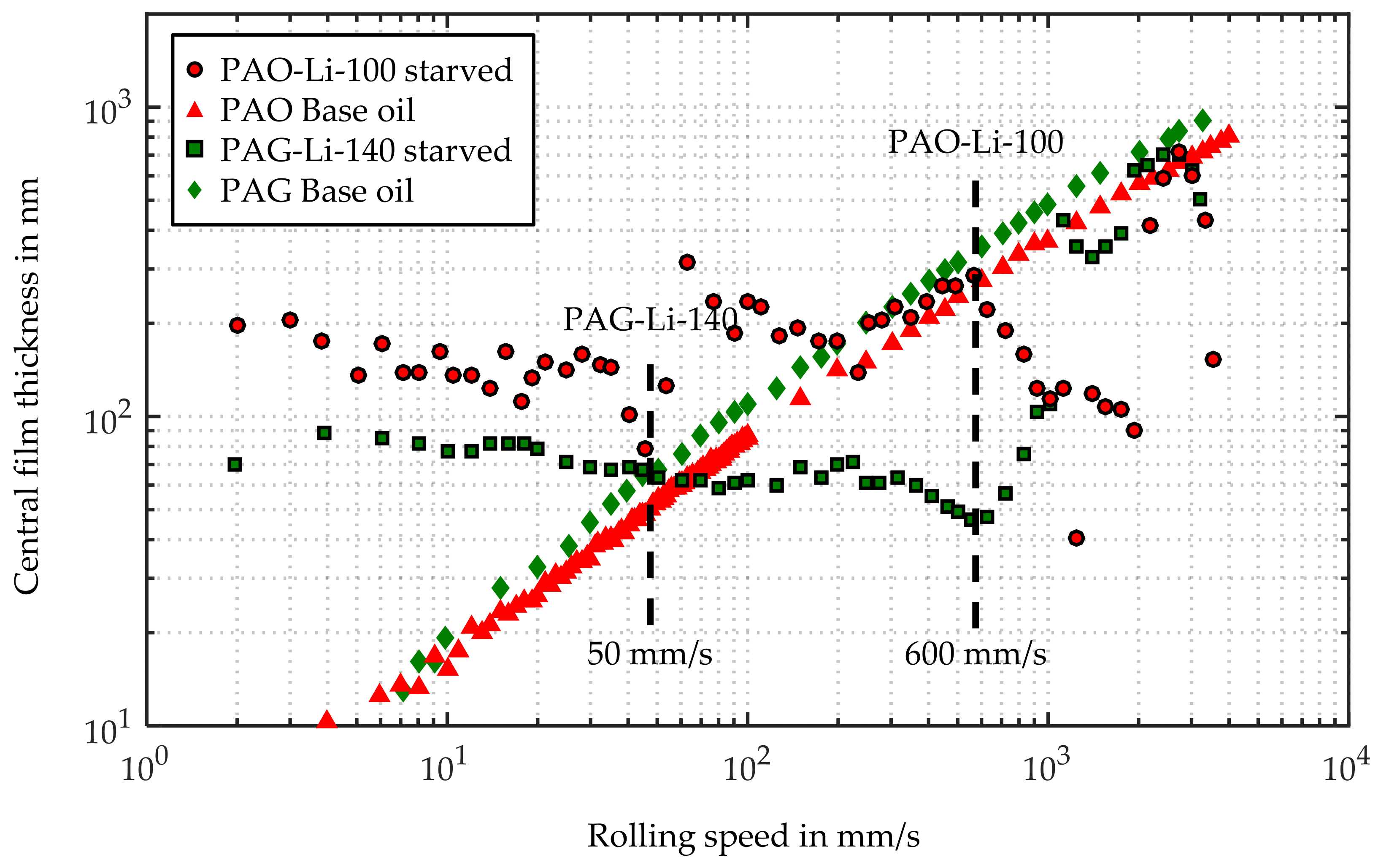

3.2. Measurement Results of PAO-Li-100

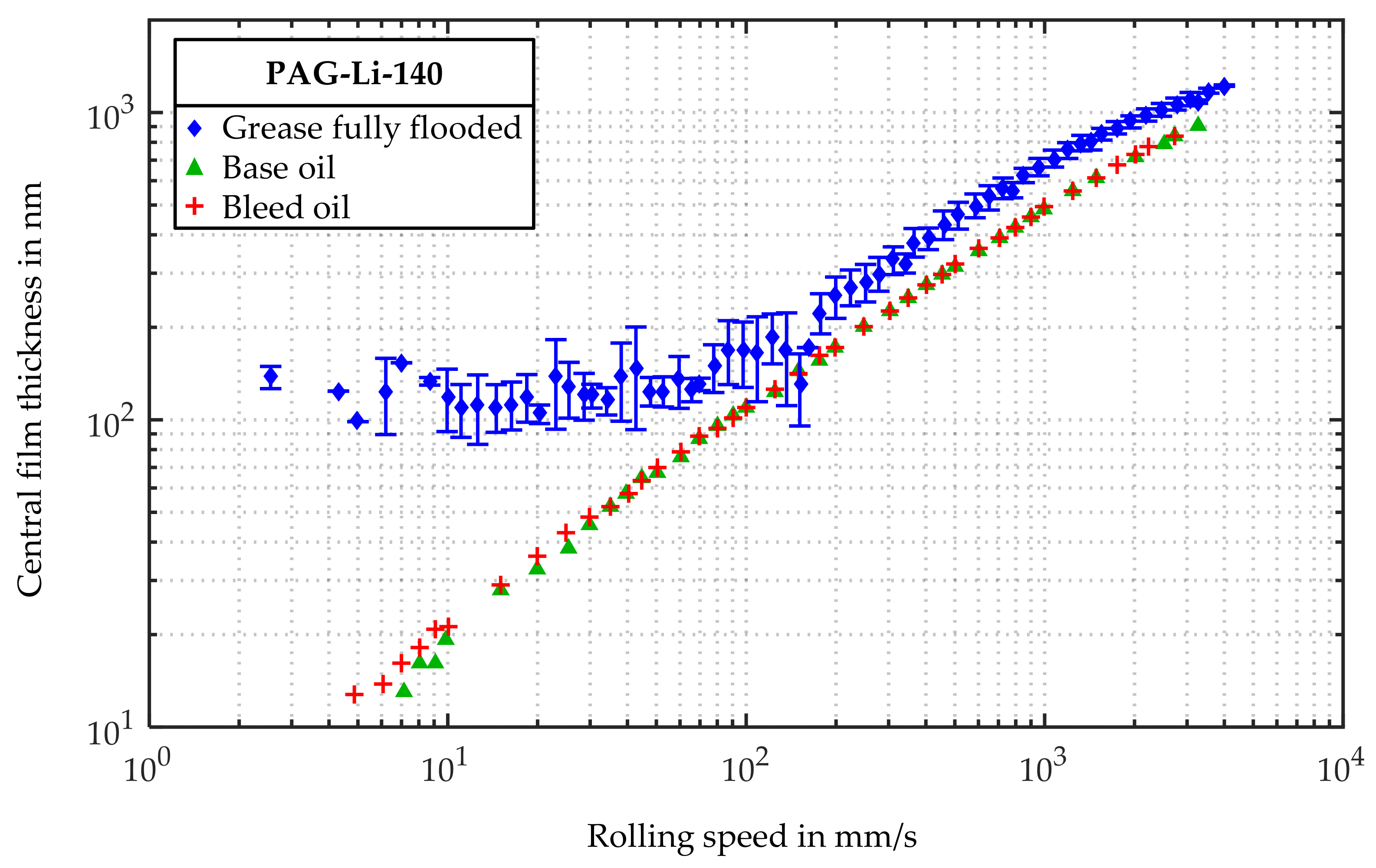

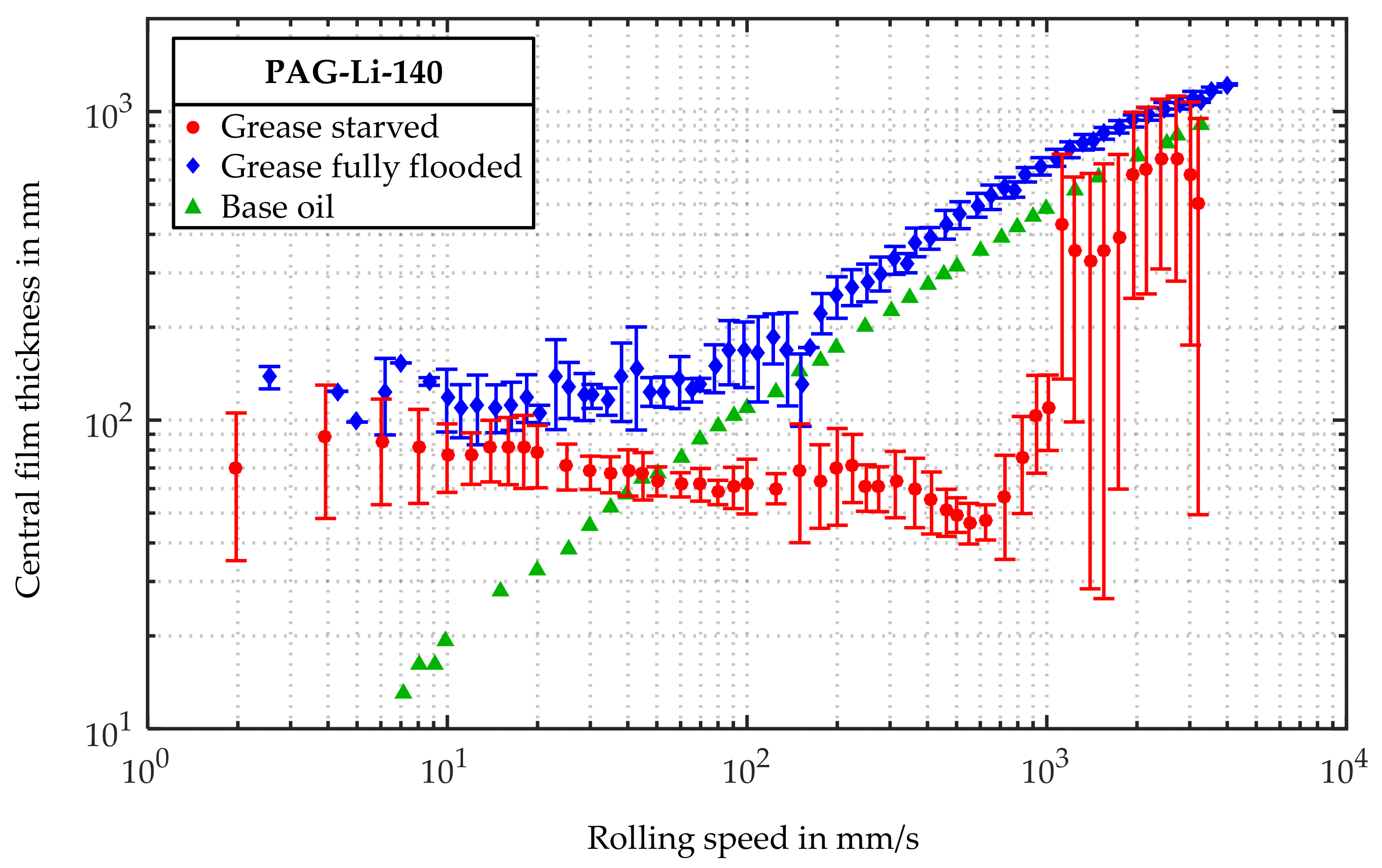

3.3. Measurement Results of PAG-Li-140

4. Discussion

5. Conclusions

- When comparing the investigated greases under fully flooded lubrication, it has been shown that in both cases, the film thickness is higher than the one of the base oil. This is probably encouraged by parts of the thickener, which enter the EHD contact area during operation.

- Since the viscosities at 40 °C of the pure base and bleed oils does not significantly differ, a formation of a higher film thickness by the bleed oil in comparison to the base oil could not be identified for the lubricants examined in this study. The bleed oil properties are probably depending on the grease composition and the oil extraction method.

- High scattering of the results at low rolling speeds for both greases under fully flooded and starved lubrication indicate a chaotic behaviour, which is probably due to the presence of thickener in the contact. Moreover, high scattering of the results at high rolling speed under starved lubrication is probably referred to centrifugal forces, which lead to a chaotic lubrication behaviour.

- When investigating the film thickness under starved lubrication, the onset of starvation for both greases could be determined at different rolling speeds. Thus, it has been emphasised, that the base oil type in the grease composition significantly affects the film formation in EHD contacts under starved lubrication. Furthermore, an early onset of starvation is likely due to a low oil release of the grease, which can be correlated to the results of the bleeding tests.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lugt, P.M. Grease Lubrication in Rolling Bearing; John Wiley & Sons, Ltd.: Chichester, UK, 2013; ISBN 978-1-118-35391-2. [Google Scholar]

- Cousseau, T.; Björling, M.; Graça, B.; Campos, A.; Seabra, J.; Larsson, R. Film thickness in a ball-on-disc contact lubricated with greases, bleed oils and base oils. Tribol. Int. 2012, 53, 53–60. [Google Scholar] [CrossRef]

- Cousseau, T.; Graça, B.; Campos, A.; Seabra, J. Grease aging effects on film formation under fully-flooded and starved lubrication. Lubricants 2015, 3, 197–221. [Google Scholar] [CrossRef]

- Gonçalves, D.; Graça, B.; Campos, A.V.; Seabra, J.; Leckner, J.; Westbroek, R. On the film thickness behaviour of polymer greases at low and high speeds. Tribol. Int. 2015, 90, 435–444. [Google Scholar] [CrossRef]

- Gonçalves, D.; Vieira, A.; Carneiro, A.; Campos, V.A.; Seabra, H.J. Film thickness and friction relationship in grease lubricated rough contacts. Lubricants 2017, 5, 34. [Google Scholar] [CrossRef]

- De Laurentis, N.; Kadiric, A.; Lugt, P.M.; Cann, P.M. The influence of bearing grease composition on friction in rolling/sliding concentrated contacts. Tribol. Int. 2016, 94, 624–632. [Google Scholar] [CrossRef]

- De Laurentis, N.; Cann, P.M.; Lugt, P.M.; Kadiric, A. The influence of base oil properties on the friction behaviour of lithium grease in rolling/sliding concentrated contacts. Tribol. Lett. 2017, 65, 128. [Google Scholar] [CrossRef]

- Cen, H.; Lugt, P.M.; Morales-Espejel, G. Film thickness of mechanically worked lubricating grease at very low speeds. Tribol. Trans. 2014, 57, 1066–1071. [Google Scholar] [CrossRef]

- Cen, H.; Lugt, P.M.; Morales-Espejel, G. On the Film Thickness of Grease-Lubricated Contacts at Low Speeds. Tribol. Trans. 2014, 57, 668–678. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Lugt, P.M.; Pasaribu, H.R.; Cen, H. Film thickness in grease lubricated slow rotating rolling bearings. Tribol. Int. 2014, 74, 7–19. [Google Scholar] [CrossRef]

- Scarlett, N.A. Use of grease in rolling bearings. Proc. Inst. Mech. Eng. 1967, 1, 585–624. [Google Scholar] [CrossRef]

- Cann, P.M.; Spikes, H. Film thickness measurements of lubrication greases under normally starved conditions. NLGI Spokesm. 1992, 56, 21. [Google Scholar]

- Kaneta, M.; Ogata, T.; Takubo, Y.; Naka, M. Effects of a thickener structure on grease elastohydrodynamic lubrication films. Proc. Inst. Mech. Eng. 2000, 4, 327–336. [Google Scholar] [CrossRef]

- Cann, P.M. Grease lubrication of rolling element bearings—Role of the grease thickener. Lubr. Sci. 2007, 3, 183–196. [Google Scholar] [CrossRef]

- Cyriac, F.; Lugt, P.M.; Bosman, R.; Padberg, C.J.; Venner, C.H. Effect of thickener particle geometry and concentration on the grease EHL film thickness at medium speeds. Tribol. Lett. 2016, 60, 18. [Google Scholar] [CrossRef]

- Lugt, P.M. A review on grease lubrication in rolling bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Cann, P.; Chevalier, F.; Lubrecht, A.A. Track depletion and replenishment in a grease lubricated point contact: A quantitative analysis. Tribol. Ser. 1997, 32, 405–413. [Google Scholar] [CrossRef]

- Couronné, I.; Vergne, P.; Mazuyer, D.; Truong-Dinh, N.; Girodin, D. Effects of grease composition and structure on film thickness in rolling contact. Tribol. Trans. 2003, 46, 31–36. [Google Scholar] [CrossRef]

- Couronné, I.; Vergne, P.; Mazuyer, D.; Truong-Dinh, N.; Girodin, D. Nature and properties of the lubricating phase in grease lubricated contact. Tribol. Trans. 2003, 46, 37–43. [Google Scholar] [CrossRef]

- Nagata, Y.; Kalogiannis, K.; Glovnea, R. Track Replenishment by Lateral Vibrations in Grease-Lubricated EHD Contacts. Tribol. Trans. 2012, 55, 91–98. [Google Scholar] [CrossRef]

- Chen, J.; Tanaka, H.; Sugimura, J. Experimental study of starvation and flow behavior in grease-lubricated ehd contact. Tribol. Online 2015, 1, 48–55. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Kuhn, M.; Rankl, M.; Spallek, R. Film forming behavior of greases under starved and fully flooded EHL conditions. Tribol. Trans. 2016, 59, 62–71. [Google Scholar] [CrossRef]

- Wilson, A.R. The Relative thickness of grease and oil films in rolling bearings. Proc. Inst. Mech. Eng. 1979, 193, 185–192. [Google Scholar] [CrossRef]

- Cann, P.M. Starvation and reflow in a grease-lubricated elastohydrodynamic contact. Tribol. Trans. 1996, 39, 698–704. [Google Scholar] [CrossRef]

- Chiu, Y.P. An analysis and prediction of lubricant film starvation in rolling contact systems. ASLE Trans. 1974, 17, 22–35. [Google Scholar] [CrossRef]

- Jacod, B.; Pubilier, F.; Cann, P.M.; Lubrecht, A.A. An analysis of track replenishment mechanisms in the starved regime. Tribol. Ser. 1999, 36, 483–492. [Google Scholar] [CrossRef]

- Baart, P.; van der Vorst, B.; Lugt, P.M.; van Ostayen, R.A. Oil-bleeding model for lubricating grease based on viscous flow through a porous microstructure. Tribol. Trans. 2010, 53, 340–348. [Google Scholar] [CrossRef]

- Testing of Lubricants—Determination of Oil Separation from Greases under Static Conditions; Beuth Verlag: Berlin, Germany, 2014; DIN-51817.

- Johnston, G.J.; Wayte, R.; Spikes, H.A. The measurement and study of very thin lubricant films in concentrated contacts. Tribol. Trans. 1991, 34, 187–194. [Google Scholar] [CrossRef]

- Lugt, P.M.; Velickov, S.; Tripp, J.H. On the chaotic behavior of grease lubrication in rolling bearings. Tribol. Trans. 2009, 52, 581–590. [Google Scholar] [CrossRef]

- Kanazawa, Y.; Sayles, R.S.; Kadiric, A. Film formation and friction in grease lubricated rolling-sliding non-conformal contacts. Tribol. Int. 2017, 109, 505–518. [Google Scholar] [CrossRef]

- Gonçalves, D.; Graça, B.; Campos, A.V.; Seabra, J.; Leckner, J.; Westbroek, R. Formulation, rheology and thermal ageing of polymer greases—Part I: Influence of the thickener content. Tribol. Int. 2015, 87, 160–170. [Google Scholar] [CrossRef]

- Salomonsson, L.; Stang, G.; Zhmud, B. Oil/thickener interactions and rheology of lubricating greases. Tribol. Trans. 2007, 50, 302–309. [Google Scholar] [CrossRef]

- Saatchi, A.; Shiller, P.J.; Eghtesadi, S.A.; Liu, T.; Doll, G.L. A fundamental study of oil release mechanism in soap and non-soap thickened greases. Tribol. Int. 2017, 110, 333–340. [Google Scholar] [CrossRef]

- Sakai, K.; Tokumo, Y.; Ayame, Y.; Shitara, Y.; Tanaka, H.; Sugimura, J. Effect of Formulation of Li Greases on Their Flow and Ball Bearing Torque. Tribol. Online 2016, 11, 168–173. [Google Scholar] [CrossRef]

| Thickener | Base Oil | Viscosity 40 °C | Viscosity 80 °C | Designation |

|---|---|---|---|---|

| 22 wt % Lithium Complex | PAO | 98.01 mm2/s | 22.14 mm2/s | PAO-Li-100 |

| 26 wt % Lithium Complex | PAG | 141.71 mm2/s | 40.64 mm2/s | PAG-Li-140 |

| Grease | Bleed Oil Release at 80 °C | Bleed oil Viscosity 40 °C | Bleed Oil Viscosity 80 °C |

|---|---|---|---|

| PAO-Li-100 | 4.14 wt % | 93.26 mm2/s | 21.57 mm2/s |

| PAG-Li-140 | 2.20 wt % | 140.61 mm2/s | 39.25 mm2/s |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fischer, D.; Jacobs, G.; Stratmann, A.; Burghardt, G. Effect of Base Oil Type in Grease Composition on the Lubricating Film Formation in EHD Contacts. Lubricants 2018, 6, 32. https://doi.org/10.3390/lubricants6020032

Fischer D, Jacobs G, Stratmann A, Burghardt G. Effect of Base Oil Type in Grease Composition on the Lubricating Film Formation in EHD Contacts. Lubricants. 2018; 6(2):32. https://doi.org/10.3390/lubricants6020032

Chicago/Turabian StyleFischer, Dennis, Georg Jacobs, Andreas Stratmann, and Gero Burghardt. 2018. "Effect of Base Oil Type in Grease Composition on the Lubricating Film Formation in EHD Contacts" Lubricants 6, no. 2: 32. https://doi.org/10.3390/lubricants6020032