Feasibility of Recycling Ultrafine Leaching Residue by Backfill: Experimental and CFD Approaches

Abstract

:1. Introduction

2. Materials and Methods

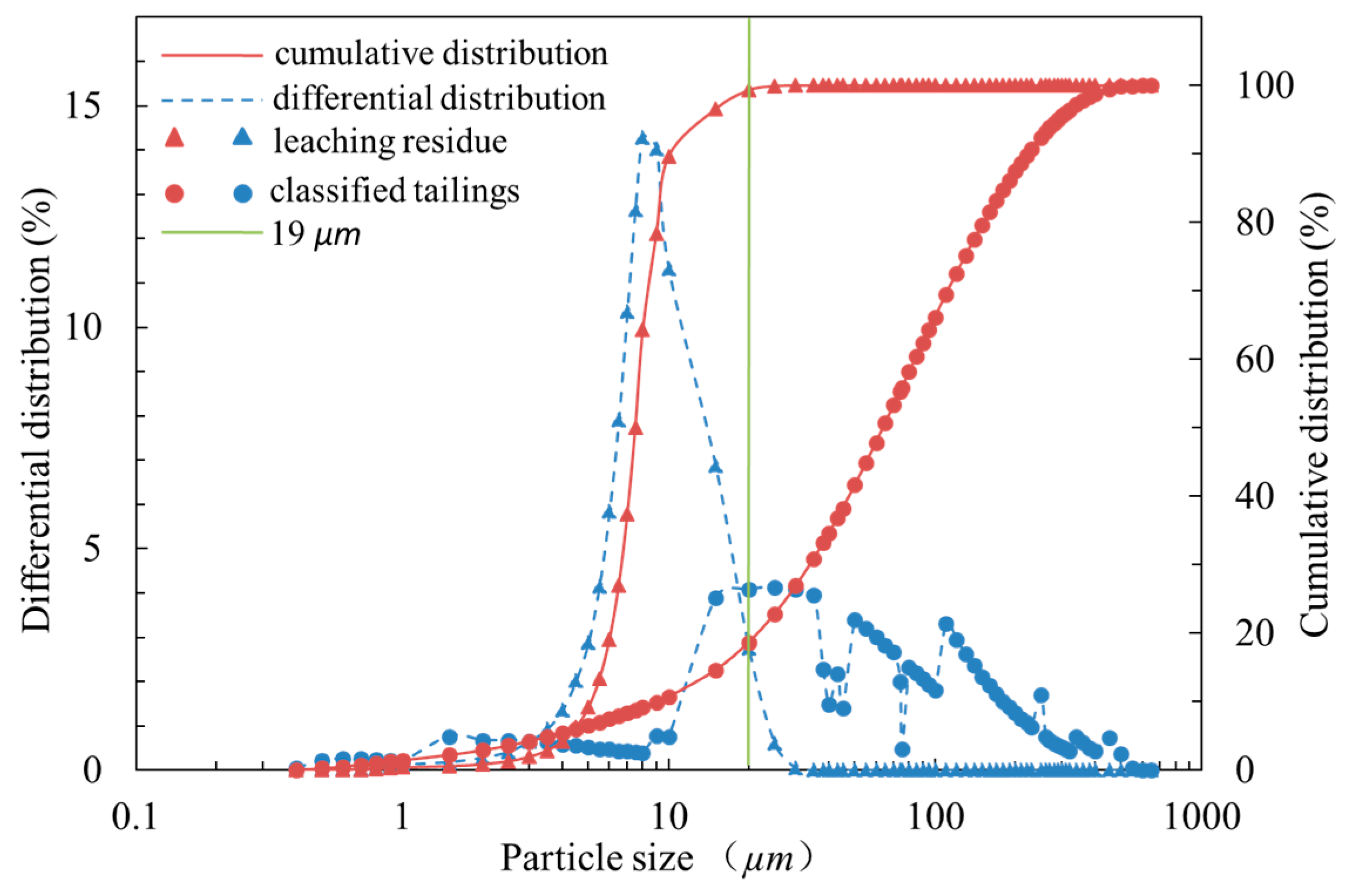

2.1. Physicochemical Properties

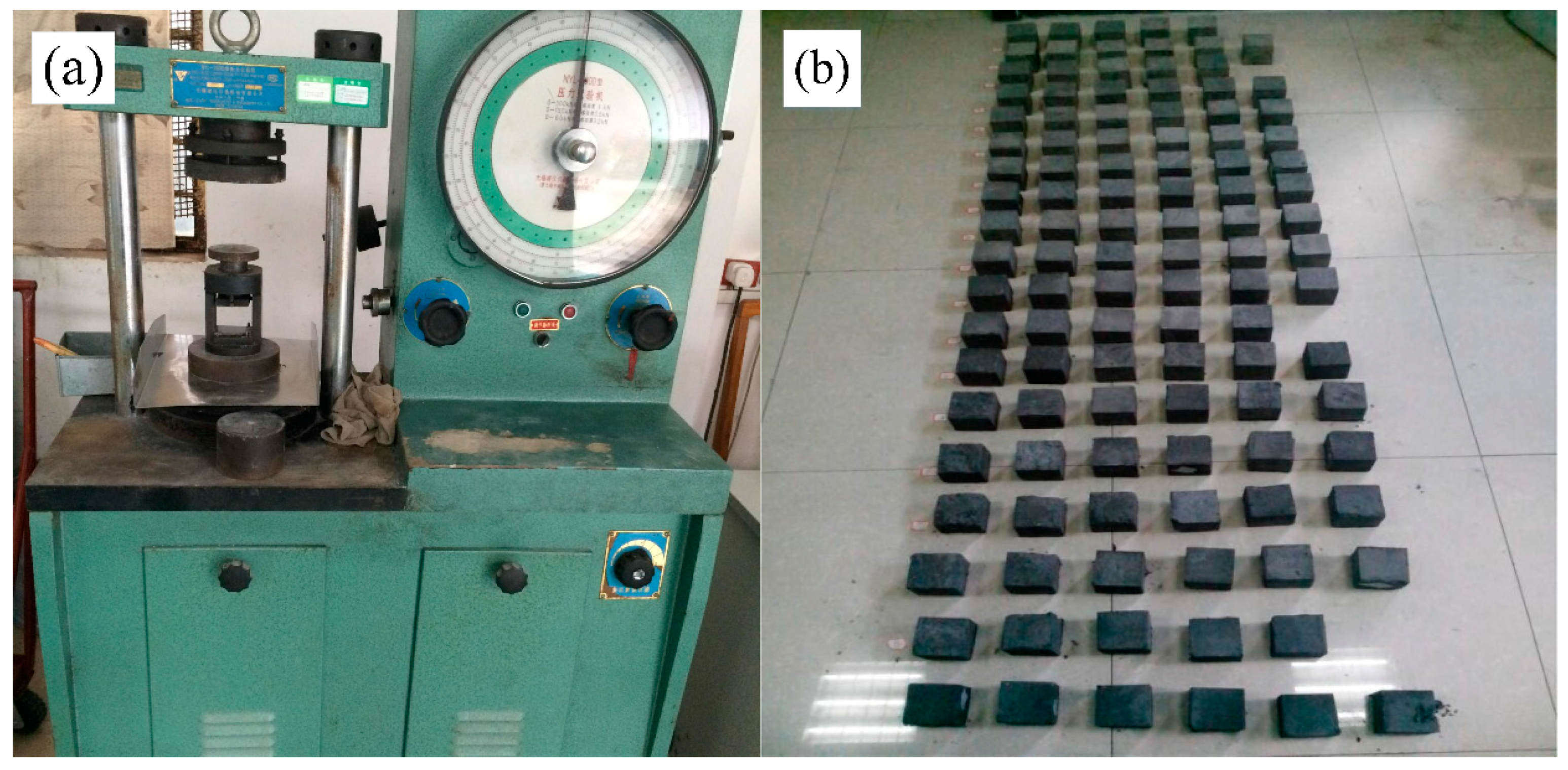

2.2. Strength Test

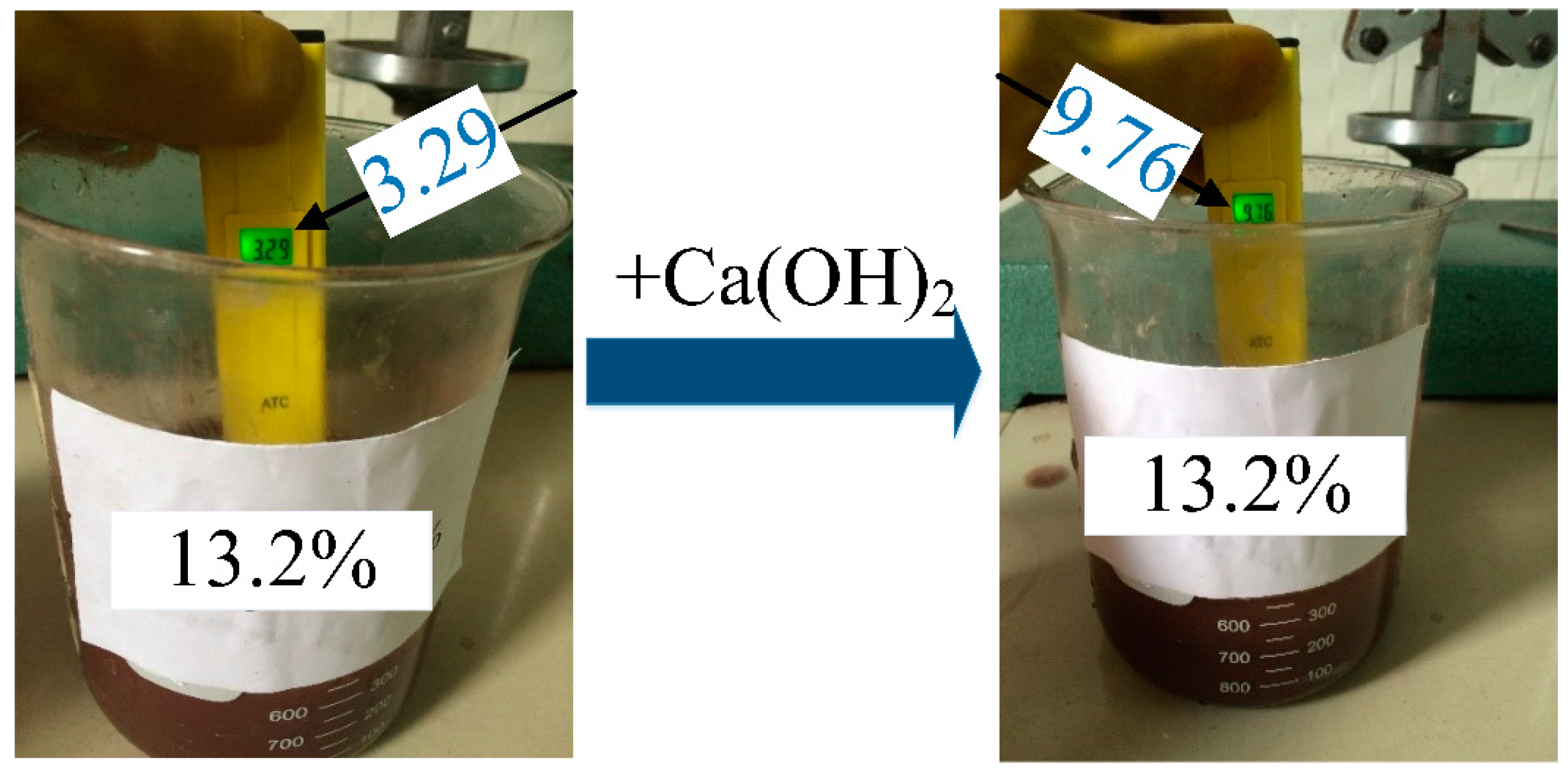

2.3. Rheological Properties

2.3.1. Diffusivity

2.3.2. CFD Simulations of Pipeline Transportation

- (1)

- At the walls, the standard wall function was used in all pipe segments.

- (2)

- At the pipe inlet, the velocity (v) function given below was used at the inlet face.

- (3)

- At the pipe outlet, the outflow function was used at the outlet face.

3. Results and Discussion

3.1. Neutralization Method

3.2. Variance Analysis

3.2.1. Strength Analysis

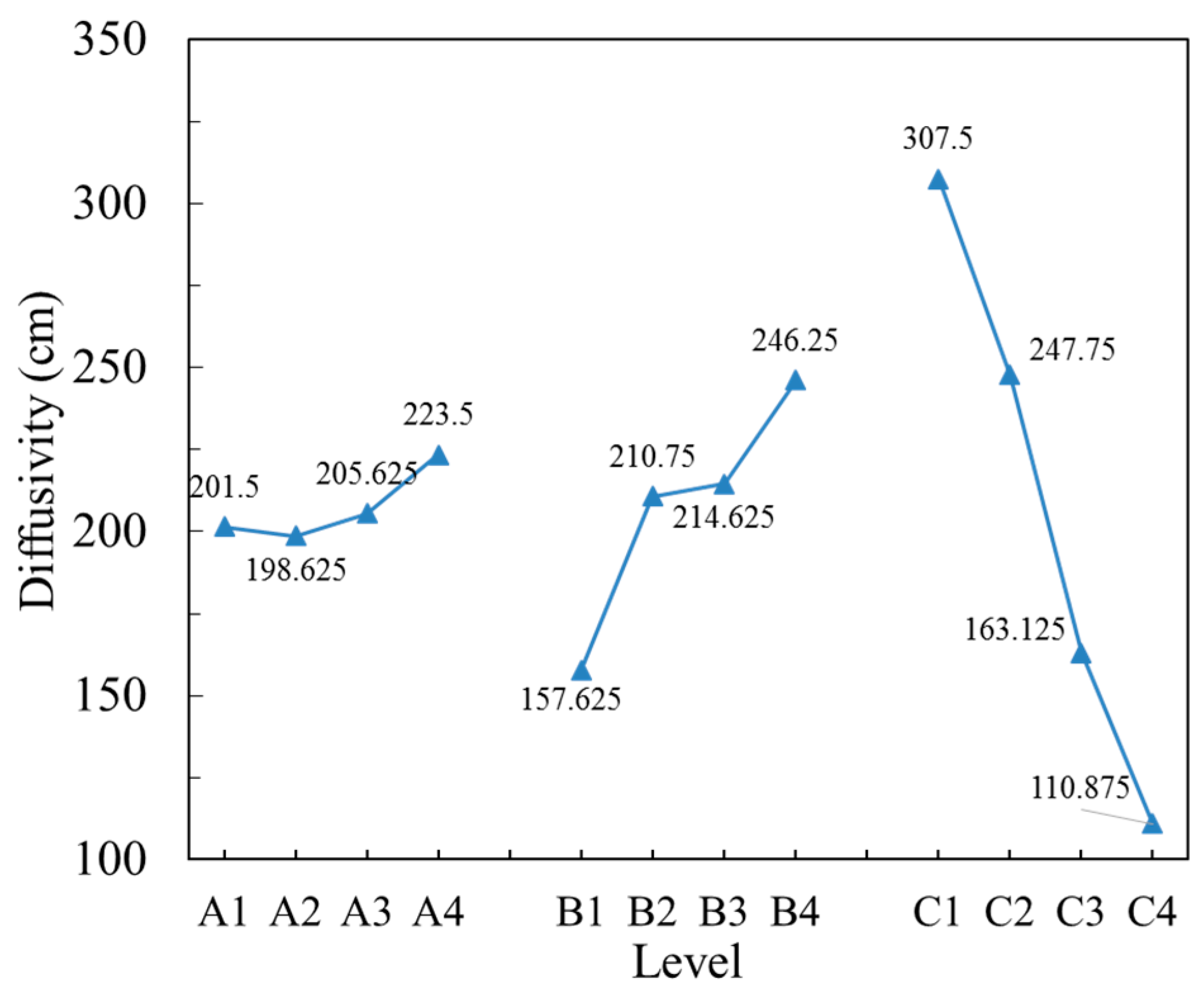

3.2.2. Diffusivity Analysis

3.2.3. Proportioning Scheme

- (1)

- room stopes: the cement:sand mass ratio is 1:6~1:8; 28 days compressive strength is greater than 4 MPa;

- (2)

- pillar stopes: the cement:sand mass ratio is above 1:12; 28 days compressive strength is 2–3 MPa;

- (3)

- artificial bottom, casting surface and first backfill layer: the cement:sand mass ratio is 1:3–1:4; 3 days compressive strength is greater than 1.5 MPa, and 28 days compressive strength is greater than 5 MPa.

3.3. Pipeline Transportation Properties

3.3.1. Pressure

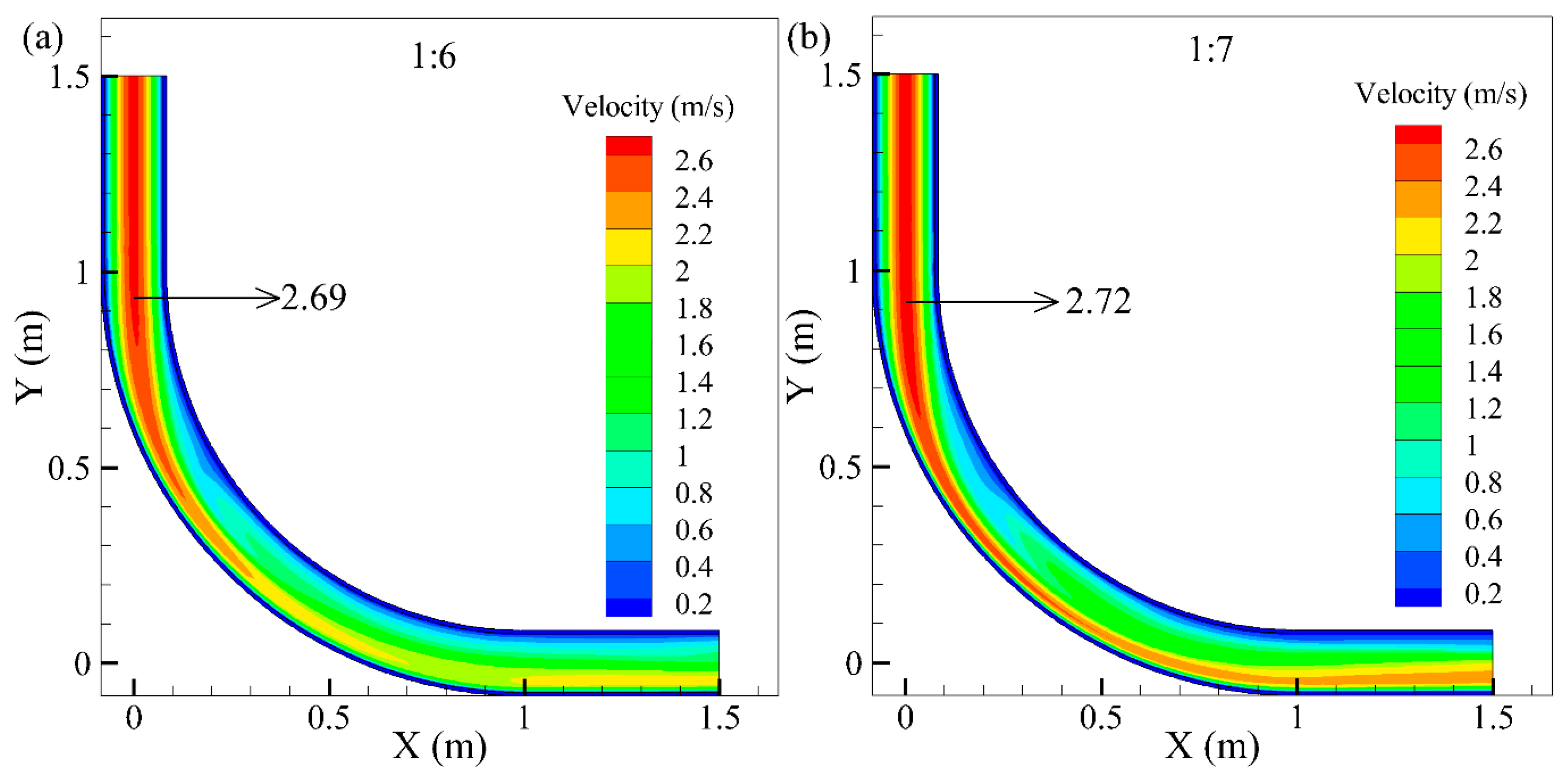

3.3.2. Velocity

3.4. Recoverability

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, B.J.; Jang, J.G.; Park, C.Y.; Han, O.H.; Kim, H.K. Recycling of arsenic-rich mine tailings in controlled low-strength materials. J. Clean. Prod. 2016, 118, 151–161. [Google Scholar] [CrossRef]

- Sivakugan, N.; Rankine, R.M.; Rankine, K.J.; Rankine, K.S. Geotechnical considerations in mine backfilling in Australia. J. Clean. Prod. 2006, 14, 1168–1175. [Google Scholar] [CrossRef]

- Li, B.C.; Wang, N.P.; Wan, J.H.; Xiong, S.Q.; Liu, H.T.; Li, S.J.; Zhao, R. In-situ gamma-ray survey of rare-earth tailings dams—A case study in Baotou and Bayan Obo Districts, China. J. Environ. Radioact. 2016, 151, 304–310. [Google Scholar] [CrossRef] [PubMed]

- Jackson, L.M.; Parbhakar-Fox, A. Mineralogical and geochemical characterization of the Old Tailings Dam, Australia: Evaluating the effectiveness of a water cover for long-term AMD control. Appl. Geochem. 2016, 68, 64–78. [Google Scholar] [CrossRef]

- Rico, M.; Benito, G.; Díez-Herrero, A. Floods from tailings dam failures. J. Hazard Mater. 2008, 154, 79–87. [Google Scholar] [CrossRef] [PubMed]

- Déjeant, A.; Galoisy, L.; Roy, R.; Calas, G.; Boekhout, F.; Phrommavanh, V.; Descostes, M. Evolution of uranium distribution and speciation in mill tailings, COMINAK Mine, Niger. Sci. Total Environ. 2016, 545, 340–352. [Google Scholar] [CrossRef] [PubMed]

- Fourie, A. Preventing catastrophic failures and mitigating environmental impacts of tailings storage facilities. Procedia Earth Planet. Sci. 2009, 9, 1067–1071. [Google Scholar] [CrossRef]

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled thermo-hydro-mechanical–chemical behaviour of cemented paste backfill in column experiments: Part II: Mechanical, chemical and microstructural processes and characteristics. Eng. Geol. 2014, 170, 11–23. [Google Scholar] [CrossRef]

- Koohestani, B.; Koubaa, A.; Belem, T.; Bussière, B.; Bouzahzah, H. Experimental investigation of mechanical and microstructural properties of cemented paste backfill containing maple-wood filler. Constr. Build Mater. 2016, 121, 222–228. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Bussière, B.; Demers, I.; Aubertin, M.; Fried, É.; Blier, A. Integrated mine tailings management by combining environmental desulphurization and cemented paste backfill: Application to mine Doyon, Quebec, Canada. Miner. Eng. 2008, 21, 330–340. [Google Scholar] [CrossRef]

- Deng, D.Q.; Liu, L.; Yao, Z.L.; Song, K.I.; Lao, Z.D. A practice of ultra-fine tailings disposal as filling material in a gold mine. J. Environ. Manag. 2017, 196, 100–109. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.S.; Zhang, Q.L.; Wang, X.M.; Xiao, C.C.; Hu, Q. A hydraulic gradient model of paste-like crude tailings backfill slurry transported by a pipeline system. Environ. Earth Sci. 2016, 75, 1099. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Chen, Q.S.; Wang, X.M. Cemented Backfilling Technology of Paste-Like Based on Aeolian Sand and Tailings. Minerals 2016, 6, 132. [Google Scholar] [CrossRef]

- Liu, G.S.; Li, L.; Yao, M.; Landry, D.; Malek, F.; Yang, X.C.; Guo, L.J. An Investigation of the Uniaxial Compressive Strength of a Cemented Hydraulic Backfill Made of Alluvial Sand. Minerals 2017, 7, 4. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Hu, G.; Wang, X.M. Hydraulic calculation of gravity transportation pipeline system for backfill slurry. J. Cent. South Univ. Technol. 2008, 15, 645–649. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.B.; Mitri, H.S. Classification of rockburst in undergroud projects: comparison of ten supervised learning methods. J. Comput. Civ. Eng. ASCE 2016, 30, 04016003. [Google Scholar] [CrossRef]

- Wang, X.M.; Zhao, J.W.; Xue, J.H.; Yu, G.F. Features of pipe transportation of paste-like backfilling in deep mine. J. Cent. South Univ. Technol. 2011, 18, 1413–1417. [Google Scholar] [CrossRef]

- An, H.; Li, A.; Sasmito, A.P.; Kurnia, J.C.; Jangam, S.V.; Mujumdar, A.S. Computational fluid dynamics (CFD) analysis of micro-reactor performance: Effect of various conFigureurations. Chem. Eng. Sci. 2012, 75, 85–95. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Mujumdar, A.S. Performance evaluation of a polymer electrolyte fuel cell with a dead-end anode: A computational fluid dynamic study. Int. J. Hydrog. Energy 2011, 36, 10917–10933. [Google Scholar] [CrossRef]

- Sun, W.; Wu, A.X.; Hou, K.P.; Yang, Y.; Liu, L.; Wen, Y.M. Experimental Study on the Microstructure Evolution of Mixed Disposal Paste in Surface Subsidence Areas. Minerals 2016, 6, 43. [Google Scholar] [CrossRef]

- Ke, X.; Zhou, X.; Wang, X.S.; Hou, H.B.; Zhou, M. Effect of tailings fineness on the pore structure development of cemented paste backfill. Constr. Build. Mater. 2016, 126, 345–350. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Miraz, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Panossian, Z.; de Almeida, N.L.; de Sousa, R.M.F.; de Souza Pimenta, G.; Marques, L.B.S. Corrosion of carbon steel pipes and tanks by concentrated sulfuric acid: A review. Corros. Sci. 2012, 58, 1–11. [Google Scholar] [CrossRef]

- Liu, Y.W.; Wu, R.J.; Yang, P.; Wang, T.G.; Liu, H.H.; Wang, L.H. Parameter study of the injection conFigureuration in a zero boil-off hydrogen storage tank using orthogonal test design. Appl. Therm. Eng. 2016, 109, 283–294. [Google Scholar] [CrossRef]

- China, E.P.A. Identification Standard for Hazardous Wastes-Identification for Extraction Procedure Toxicity; GB 5085. 3-2007; China Environmental Science Press: Beijing, China, 2007; Available online: http://kjs.mep.gov.cn/hjbhbz/bzwb/gthw/wxfwjbffbz/200705/W020120104532752182600.pdf?COLLCC=541750128& (accessed on 20 January 2017).

- Gao, J.; Yin, J.; Zhu, F.; Chen, X.; Tong, M.; Kang, W.Z.; Zhou, Y.B.; Lu, J. Orthogonal test design to optimize the operating parameters of CO2 desorption from a hybrid solvent MEA-Methanol in a packing stripper. J. Taiwan Inst. Chem. E. 2016, 64, 196–202. [Google Scholar] [CrossRef]

- Gopala, V.R.; à Nijeholt, J.A.L.; Bakker, P.; Haverkate, B. Development and validation of a CFD model predicting the backfill process of a nuclear waste gallery. Nucl. Eng. Des. 2011, 241, 2508–2518. [Google Scholar] [CrossRef]

- Fluent, A. 14.5 User’s Guide; Fluent Inc.: Lebanon, NH, USA, 2012. [Google Scholar]

- Chanteloup, V.; Mirade, P.S. Computational fluid dynamics (CFD) modelling of local mean age of air distribution in forced-ventilation food plants. J. Food Eng. 2009, 90, 90–103. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl. Math. Model. 2014, 38, 3467–3484. [Google Scholar] [CrossRef]

- Maric, M.; de Haan, E.; Hogendoorn, S.M.; Wolters, L.M.; Huizenga, H.M. Evaluating statistical and clinical significance of intervention effects in single-case experimental designs: An SPSS method to analyze univariate data. Behav. Ther. 2015, 46, 230–241. [Google Scholar] [CrossRef] [PubMed]

- Sabzi, S.; Javadikia, P.; Rabani, H.; Adelkhani, A. Mass modeling of Bam orange with ANFIS and SPSS methods for using in machine vision. Measurement 2013, 46, 3333–3341. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Liu, Q.; Zhao, J.W.; Liu, J.G. Pipeline transportation characteristics of filling paste-like slurry pipeline in deep mine. Chin. J. Nonferr. Met. 2015, 25, 3190–3195. (In Chinese) [Google Scholar]

- Beltrán, J.P.; Ceci, P.; Miguez, P.; Casali, P. Construction of slurry pipelines. Procedia Eng. 2016, 138, 27–130. [Google Scholar] [CrossRef]

| Tailings | Density (t/m3) | Average Unit Weight (kN/m3) | Porosity (wt %) | –19 µm Content (wt %) | () | Osmotic Coefficient (cm/h) | Slurry pH |

|---|---|---|---|---|---|---|---|

| leaching residue | 3.72 | 10.67 | 48.46 | 99.33 | 2.83 | 2.6 | 3.29–3.79 |

| classified tailings | 3.11 | 14.52 | 53.22 | 18.73 | 9.33 | 5.8 | 8.12–8.95 |

| Tailings | Zn | Pb | S | SiO2 | LOI | TiO2 | Al2O3 |

| leaching residue | 0.09 | 0.11 | 1.21 | 84.08 | 8.40 | 0.73 | 1.38 |

| classified tailings | 0.65 | 0.56 | 12.95 | 38.07 | 10.53 | 0.12 | 3.89 |

| Tailings | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 |

| leaching residue | 2.15 | 0.02 | 0.21 | 0.47 | <0.1 | 1.04 | 0.01 |

| classified tailings | 6.14 | 0.39 | 2.58 | 18.14 | 0.14 | 2.67 | 0.17 |

| Metallic Element | Cu | Zn | Cd | Pb | Cr | Cr(VI) | Hg | Ni | Ag |

|---|---|---|---|---|---|---|---|---|---|

| Content | 3.59 | 36.8 | 0.05 | 3.61 | 0.00 | 0.00 | 0.0020 | 1.99 | 0.11 |

| Limited Value [27] | 100 | 100 | 1 | 5 | 15 | 5 | 0.1 | 5 | 5 |

| Case | Factor | Compressive Strength (MPa) | Diffusivity (cm) | ||||

|---|---|---|---|---|---|---|---|

| Cement:Sand (Mass Ratio) (A) | Leaching Residue: Classified Tailings (Mass Ratio) (B) | Slurry Mass Concentration (C/wt %) | 3 Days | 7 Days | 28 Days | ||

| 1 | 1:3 | 1:4 | 67 | 1.06 | 2.35 | 6.11 | 246.50 |

| 2 | 1:4 | 1:4 | 69 | 1.26 | 2.87 | 6.30 | 188.50 |

| 3 | 1:5 | 1:4 | 71 | 1.75 | 3.56 | 6.92 | 105.00 |

| 4 | 1:6 | 1:4 | 73 | 3.25 | 4.23 | 7.30 | 90.50 |

| 5 | 1:3 | 1:5 | 69 | 1.39 | 2.96 | 5.29 | 256.50 |

| 6 | 1:4 | 1:5 | 67 | 0.61 | 1.53 | 3.30 | 297.50 |

| 7 | 1:5 | 1:5 | 73 | 2.07 | 4.02 | 5.77 | 104.00 |

| 8 | 1:6 | 1:5 | 71 | 1.33 | 2.53 | 5.57 | 185.00 |

| 9 | 1:3 | 1:6 | 71 | 2.37 | 4.28 | 7.85 | 163.50 |

| 10 | 1:4 | 1:6 | 73 | 2.27 | 4.79 | 7.97 | 109.50 |

| 11 | 1:5 | 1:6 | 67 | 0.73 | 1.03 | 2.59 | 326.50 |

| 12 | 1:6 | 1:6 | 69 | 0.67 | 1.35 | 2.92 | 259.00 |

| 13 | 1:3 | 1:7 | 73 | 3.71 | 5.94 | 9.60 | 139.50 |

| 14 | 1:4 | 1:7 | 71 | 1.54 | 2.71 | 5.32 | 199.00 |

| 15 | 1:5 | 1:7 | 69 | 0.69 | 1.54 | 3.47 | 287.00 |

| 16 | 1:6 | 1:7 | 67 | 0.38 | 1.07 | 1.91 | 359.50 |

| Factor | Dependent Variable (Compression Strength) | Sum of Class III Squares | Freedom | Mean Square Deviation | F | Significance |

|---|---|---|---|---|---|---|

| A | 3 days strength | 1.878 | 3 | 0.626 | 5.039 | 0.044 |

| 7 days strength | 5.865 | 3 | 1.955 | 11.376 | 0.007 | |

| 28 days strength | 19.178 | 3 | 6.393 | 12.984 | 0.005 | |

| diffusivity | 1496.562 | 3 | 498.854 | 3.438 | 0.092 | |

| B | 3 days strength | 0.521 | 3 | 0.174 | 1.399 | 0.332 |

| 7 days strength | 0.602 | 3 | 0.201 | 1.167 | 0.397 | |

| 28 days strength | 7.259 | 3 | 2.420 | 4.914 | 0.047 | |

| diffusivity | 16,201.062 | 3 | 5400.453 | 37.222 | 0.000 | |

| C | 3 days strength | 11.243 | 3 | 3.748 | 30.165 | 0.001 |

| 7 days strength | 24.125 | 3 | 8.042 | 46.791 | 0.000 | |

| 28 days strength | 42.412 | 3 | 14.137 | 28.714 | 0.001 | |

| diffusivity | 91,701.812 | 3 | 30,567.271 | 210.688 | 0.000 |

| Case | Factor | Inlet Pressure (Pin/MPa) | Outlet Pressure (Pout/MPa) | Resistance (hf/MPa) | Gravitational Potential Energy (P/MPa) | Self-Flowing Transportation | ||

|---|---|---|---|---|---|---|---|---|

| Cement:Sand (Mass Ratio) (A) | Leaching Residue: Classified Tailings (Mass Ratio) (B) | Slurry Mass Concentration (C/wt %) | ||||||

| 1 | 1:3 | 1:6 | 71 | 0.0022 | 3.1776 | 3.1754 | 3.7965 | Yes |

| 2 | 1:3 | 1:7 | 71 | 0.0022 | 3.2497 | 3.2475 | 3.7984 | Yes |

| Material | Cement (ton) | Leaching Residue (ton) | Classified Tailings (ton) | Water (ton) | The Output of Leaching Residue (ton) | Recovery Ratio (wt %) |

|---|---|---|---|---|---|---|

| Content | 36.4 | 15.6 | 93.6 | 59.5 | 80.0 | 19.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Yang, C. Feasibility of Recycling Ultrafine Leaching Residue by Backfill: Experimental and CFD Approaches. Minerals 2017, 7, 54. https://doi.org/10.3390/min7040054

Chen X, Shi X, Zhou J, Chen Q, Yang C. Feasibility of Recycling Ultrafine Leaching Residue by Backfill: Experimental and CFD Approaches. Minerals. 2017; 7(4):54. https://doi.org/10.3390/min7040054

Chicago/Turabian StyleChen, Xin, Xiuzhi Shi, Jian Zhou, Qiusong Chen, and Chao Yang. 2017. "Feasibility of Recycling Ultrafine Leaching Residue by Backfill: Experimental and CFD Approaches" Minerals 7, no. 4: 54. https://doi.org/10.3390/min7040054