Pore Structure and Migration Ability of Deep Shale Reservoirs in the Southern Sichuan Basin

Abstract

:1. Introduction

2. Geologic Background

3. Samples and Methods

3.1. Samples

3.2. Methods

3.2.1. Experimental Testing

3.2.2. Fractal Theory

3.2.3. Shale Gas Transport Capacity

4. Results

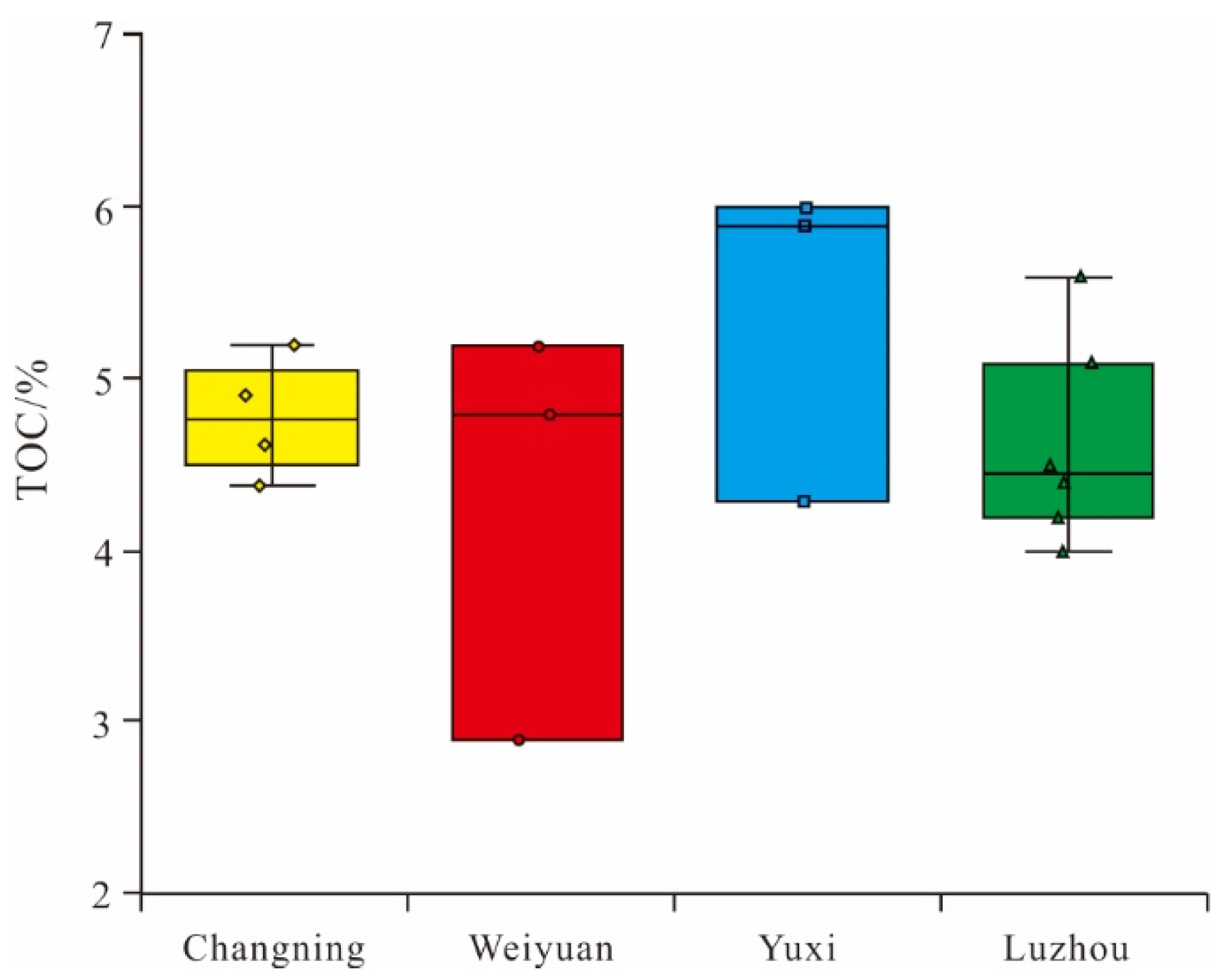

4.1. Total Organic Carbon

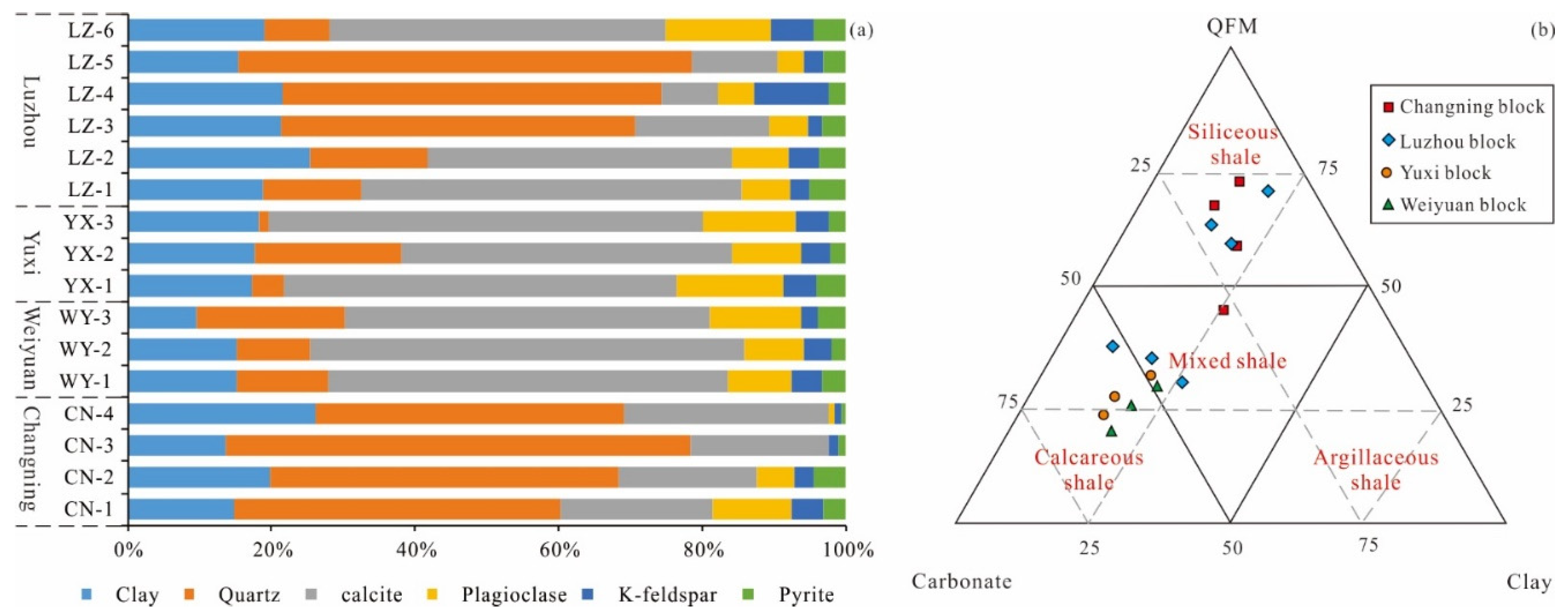

4.2. Mineralogy

4.3. Full Aperture Characterization

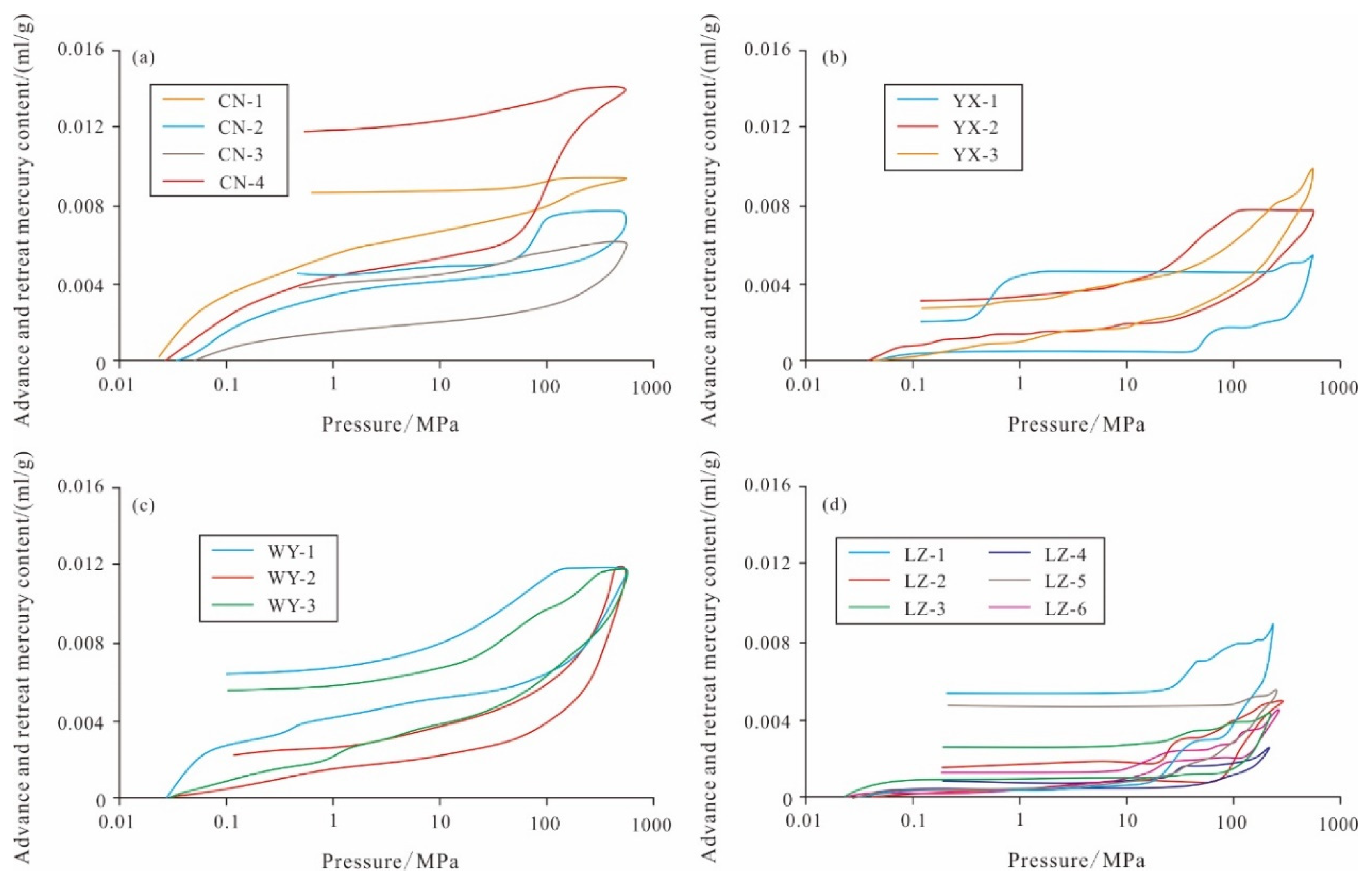

4.3.1. High-Pressure Mercury Injection

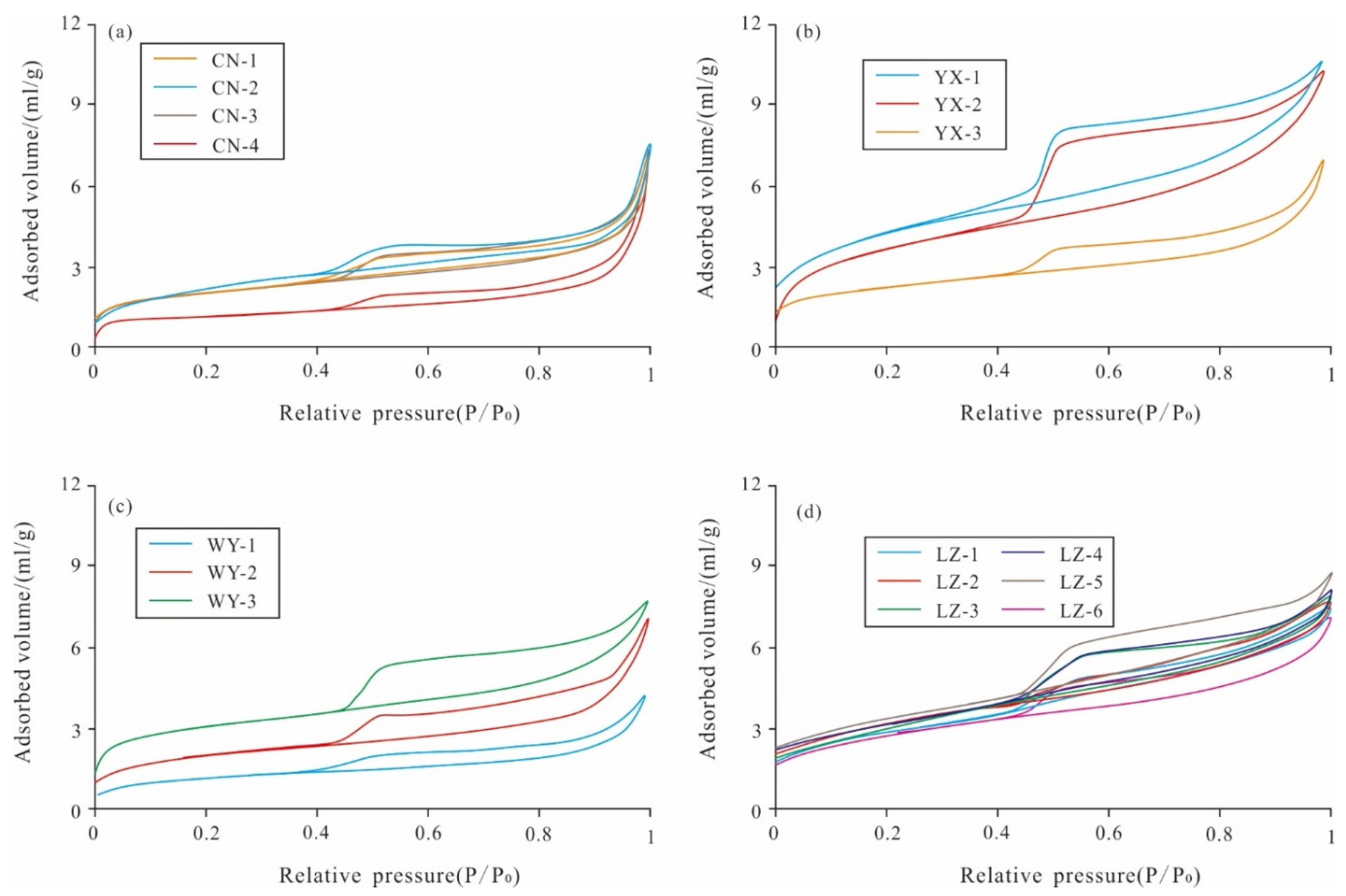

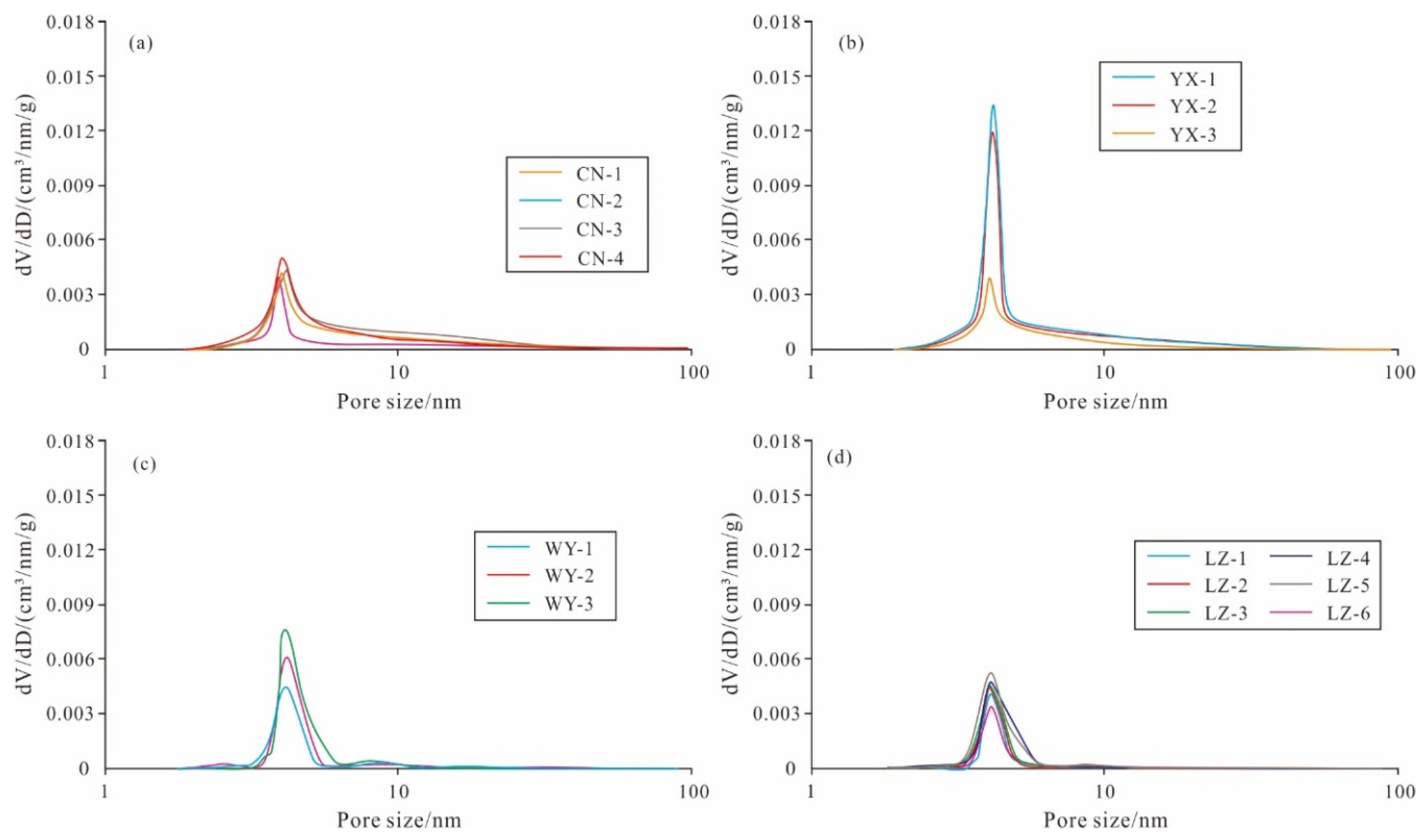

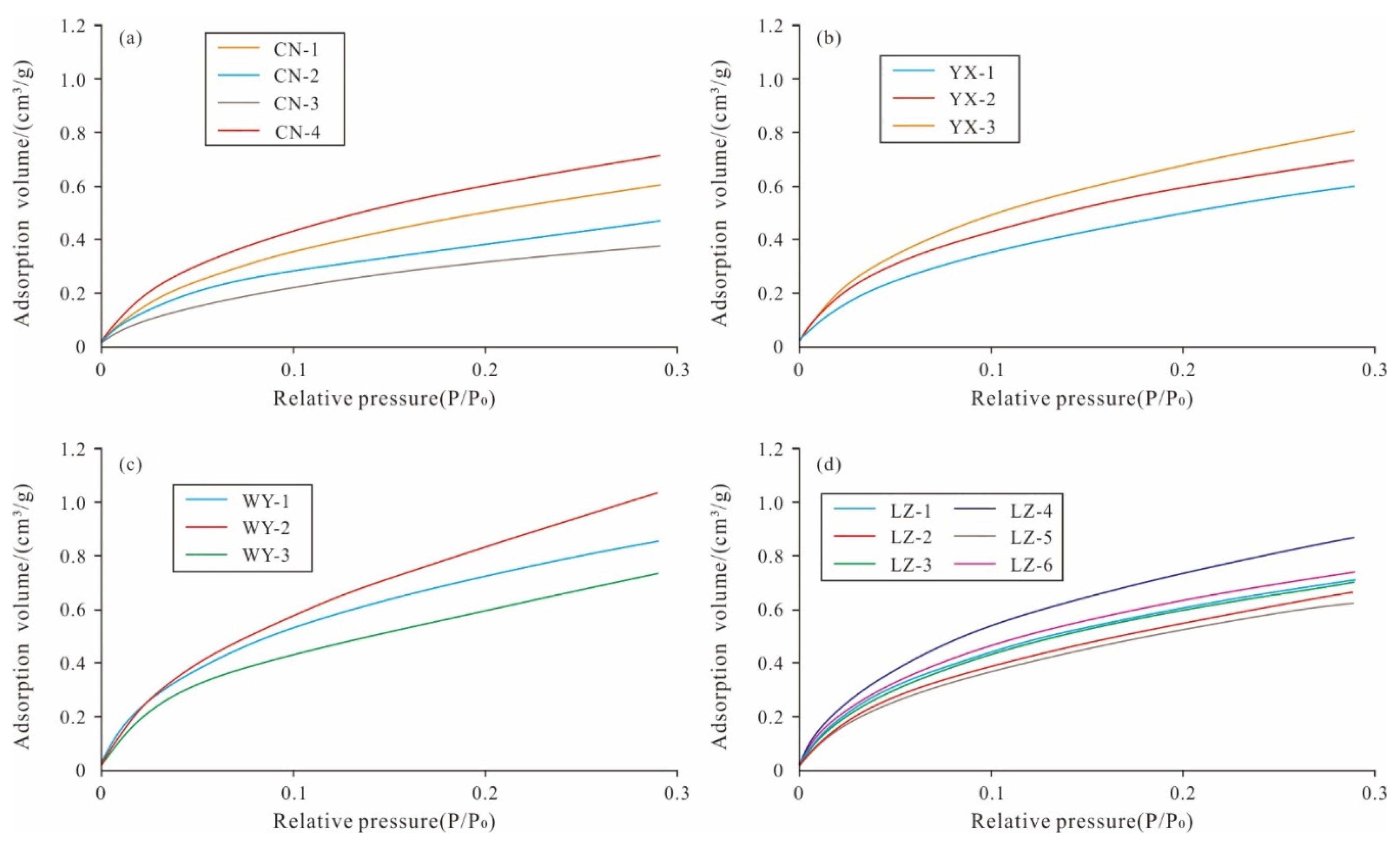

4.3.2. Low-Temperature N2 Adsorption

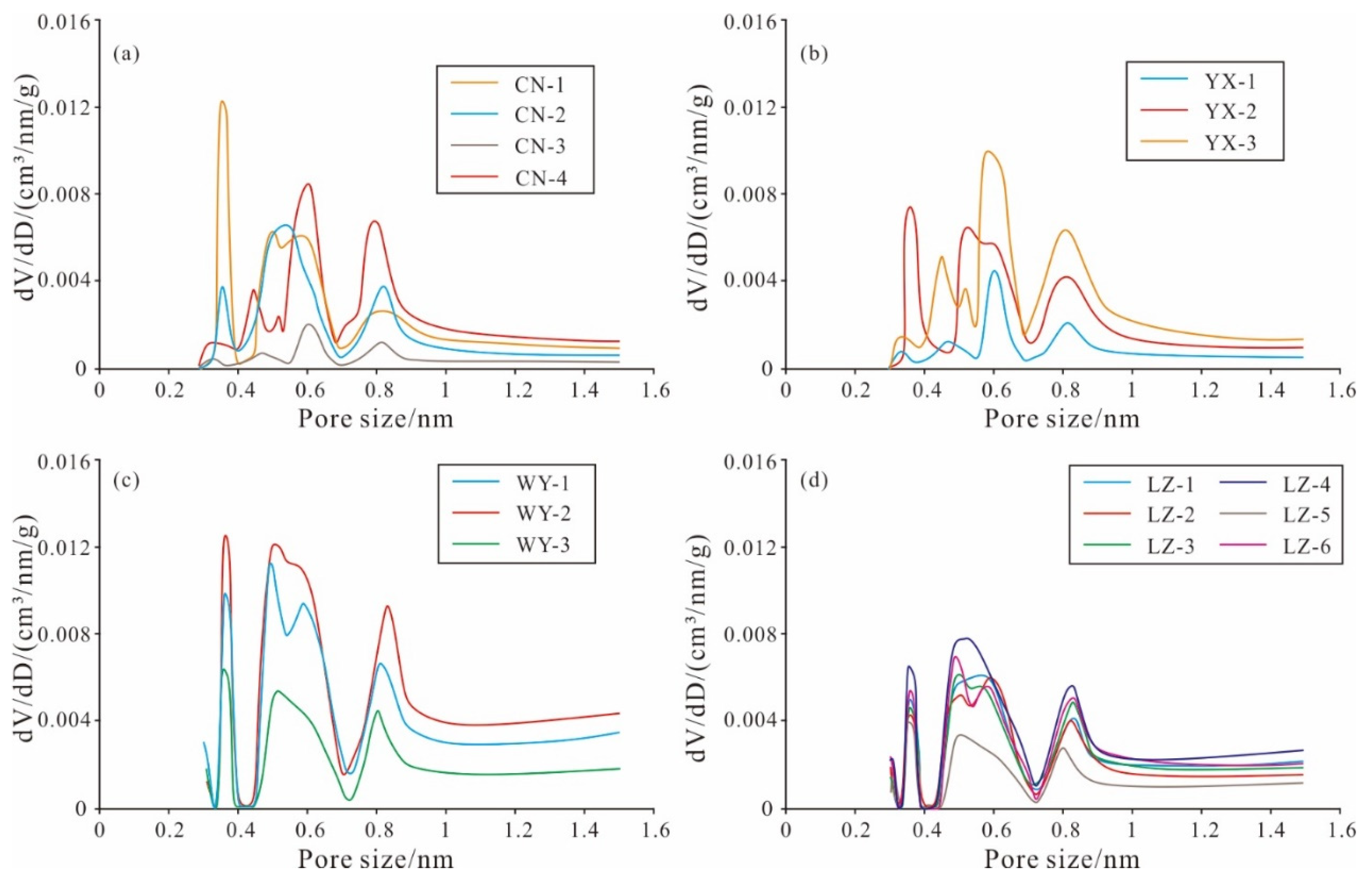

4.3.3. Low-Temperature CO2 Adsorption

4.3.4. Full Aperture Distribution

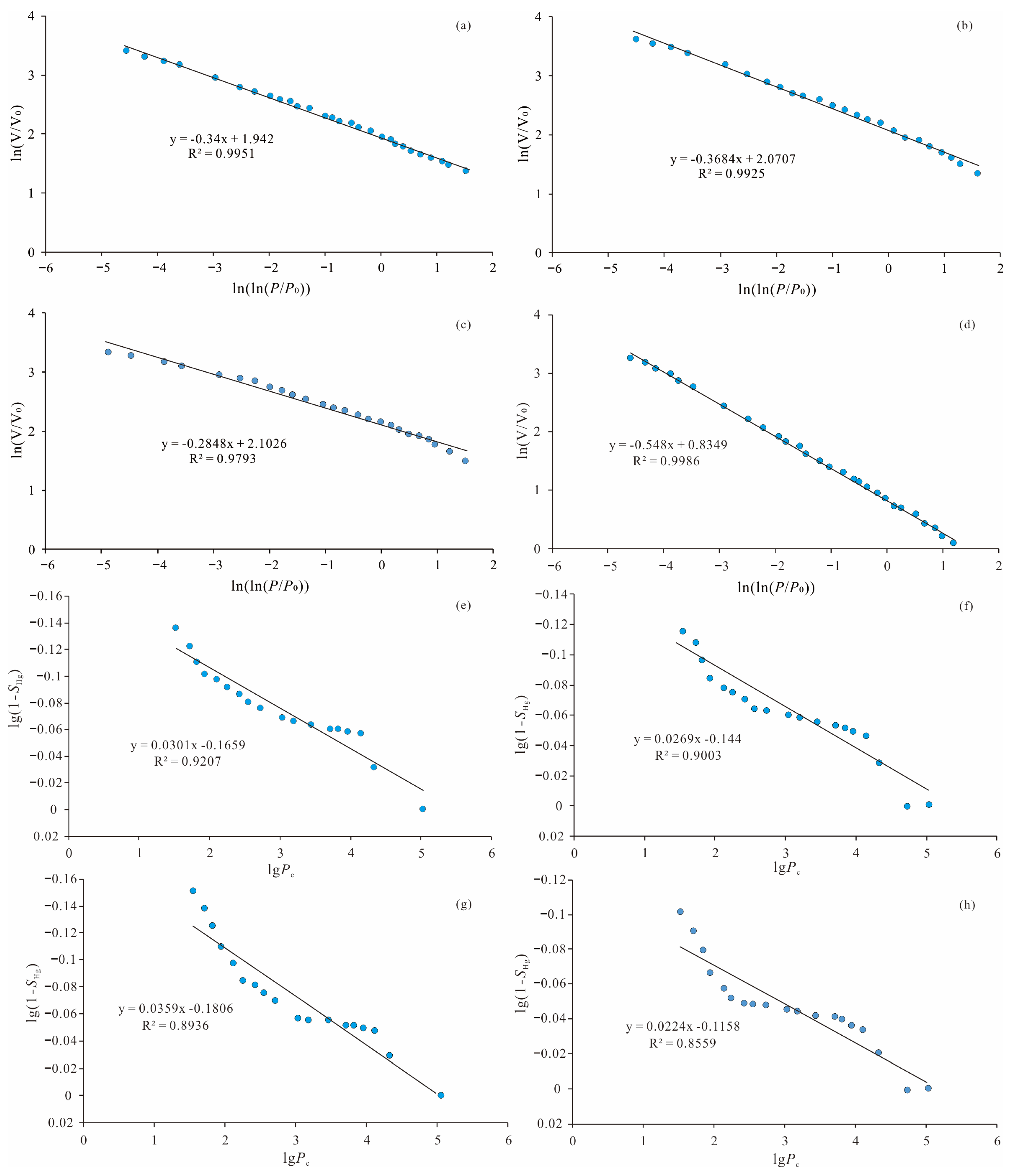

4.4. Fractal Characteristics

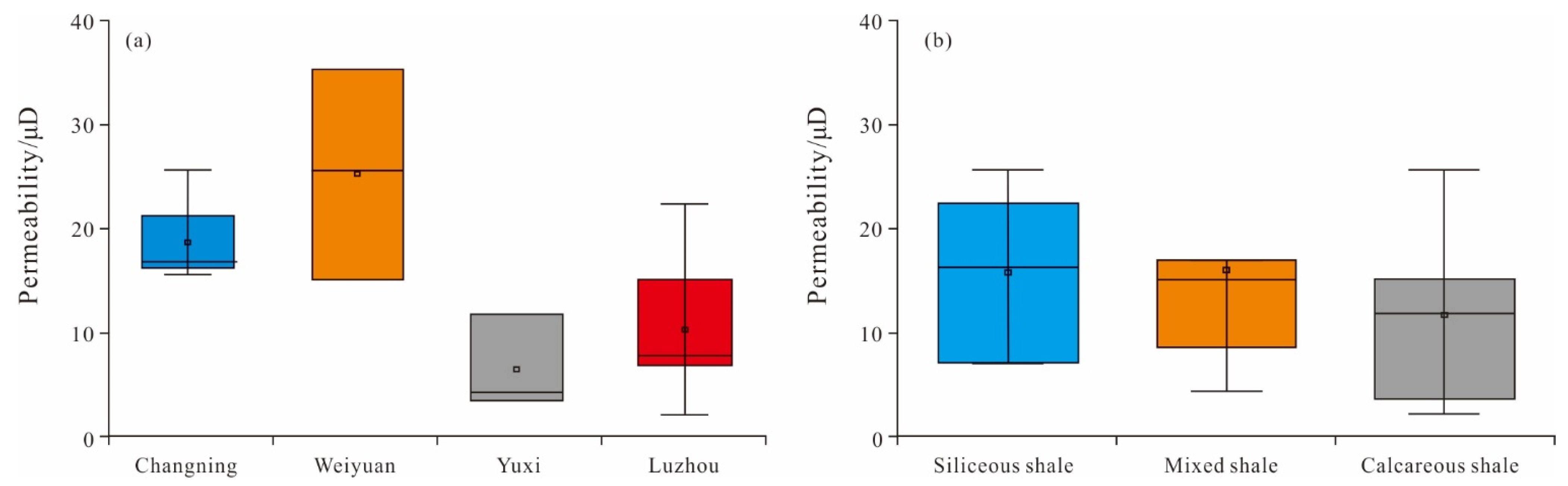

4.5. Permeability and Pores Satisfying Darcy Flow

5. Discussion

5.1. Factors Controlling Pore Complexity

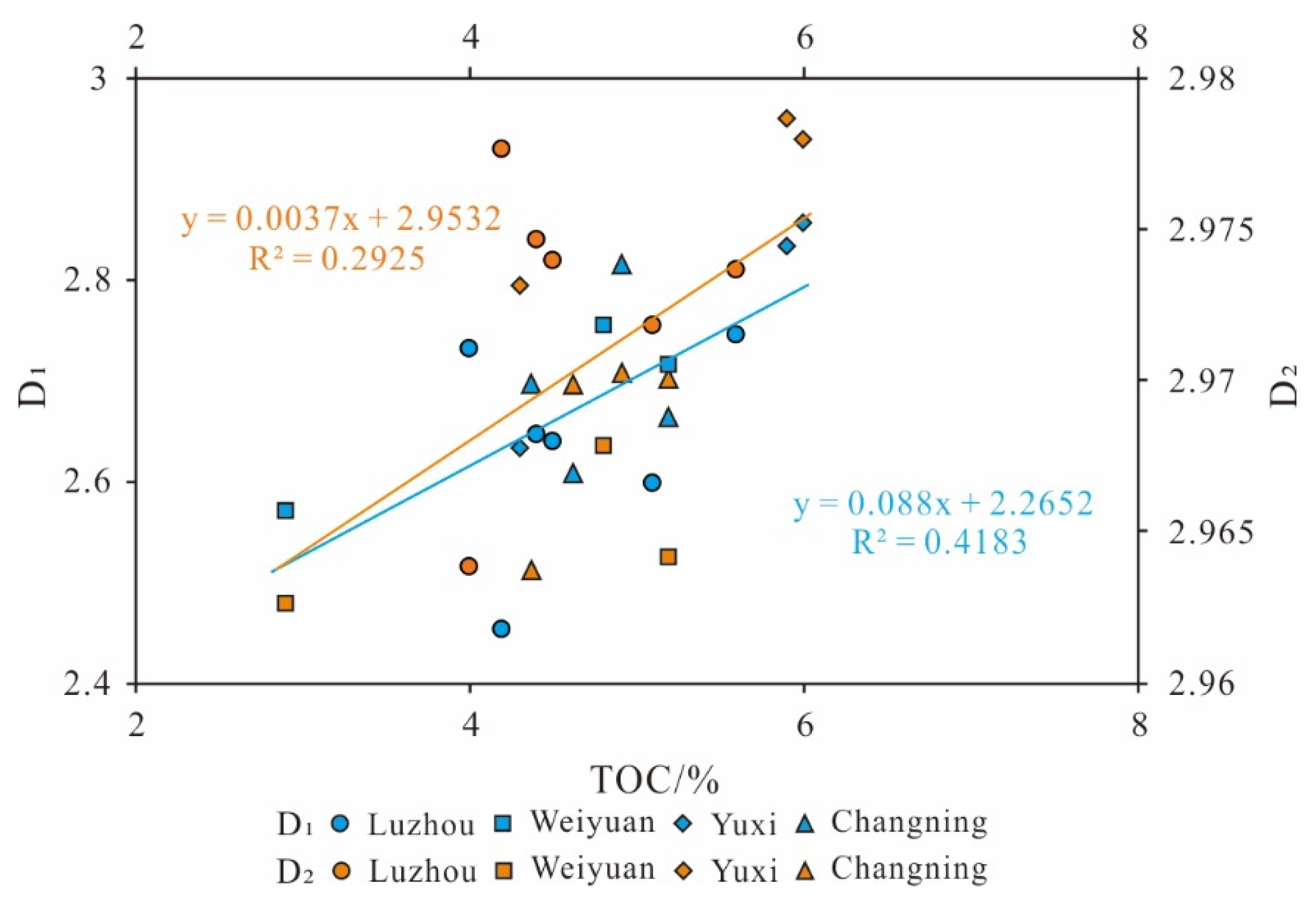

5.1.1. Influence of TOC on Pore Complexity

5.1.2. The Influence of Mineral Composition on the Pore Complexity

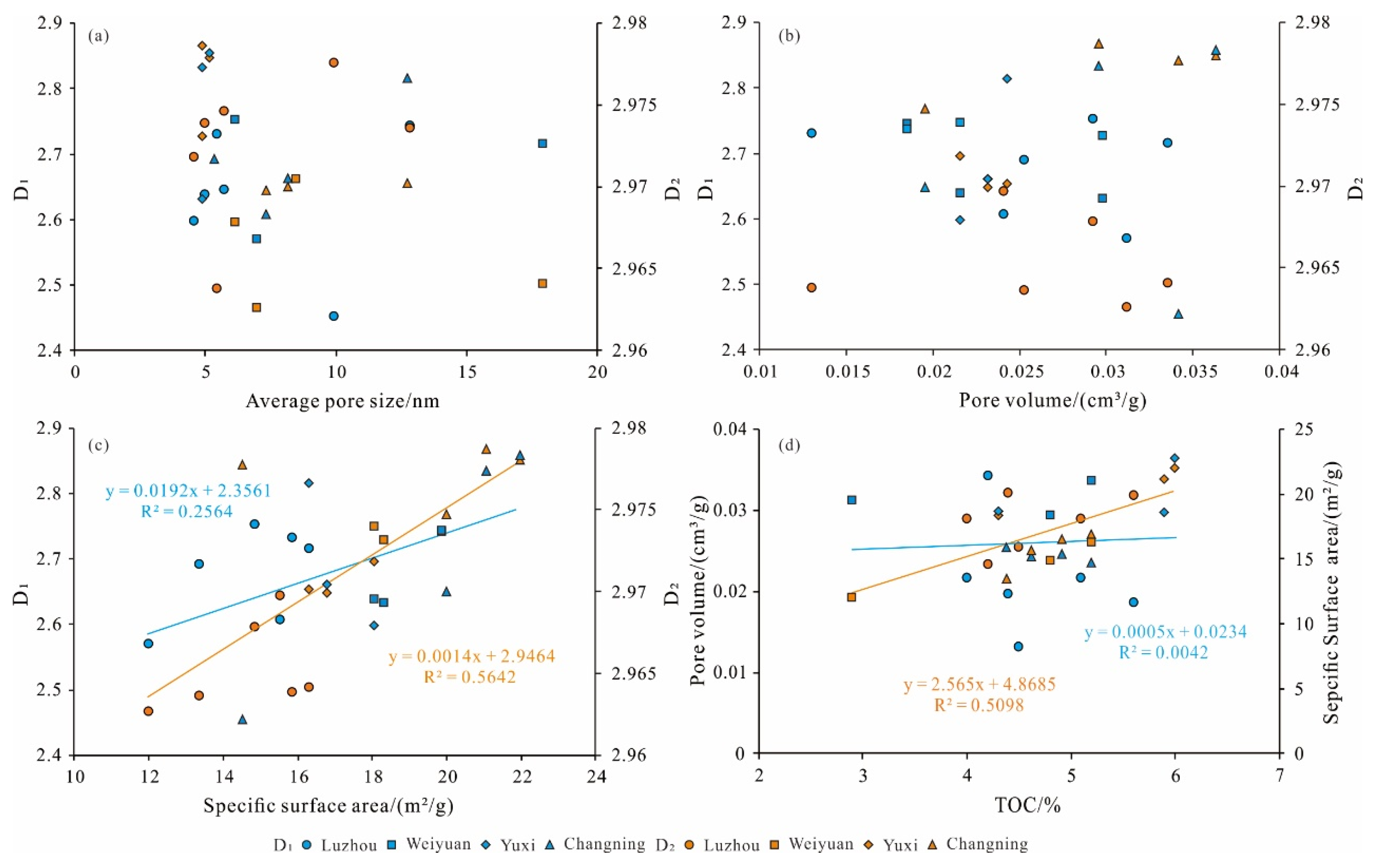

5.1.3. The Influence of Pore Structure on the Pore Complexity

5.2. Shale Gas Migration Capacity and Its Influencing Factors

6. Conclusions

- (1)

- The principal lithogenic minerals in the Longmaxi Formation shale in the study area consist of quartz and calcite, resulting in the classification of siliceous shale, calcareous shale, and mixed shale.

- (2)

- The pore structure of the Longmaxi Formation shale in the study area is complex, with an average pore size ranging from 4.55 to 17.92 nm, pore volume ranging from 0.0131 to 0.0364 cm3/g, and specific surface area ranging from 12.01 to 21.99 m2/g. The fractal dimensions (D1) of the mesopores range from 2.452 to 2.8548, and the fractal dimensions (D2) of the macropores range from 2.9626 to 2.9786.

- (3)

- Fractal dimensions of shale are influenced by organic matter, inorganic minerals, and pore structure parameters. Both D1 and D2 exhibit positive correlations with TOC, clay mineral content, and specific surface area, while showing negative correlations with quartz. However, correlations with calcite content, pore volume, and average pore size are not statistically significant.

- (4)

- Macropores emerge as the primary contributors to the migration capability of shale reservoirs, with the permeability of shale being influenced by D2, specific surface area, and the connectivity of macropores.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Samples | Depth/m | Blocks | TOC/% | Mineral Content/% | Fractal Dimension | Lithofacies | Permeability /μD | Pore Volume /(cm3/g) | BET Surface Area/(m2/g) | Average Pore Size/nm | Proportion/% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clay | Quartz | Calcite | Plagioclase | K-Feldspar | Pyrite | D1 | D2 | ||||||||||

| CN-1 | 2520.4 | Changning | 4.62 | 14.73 | 45.49 | 21.29 | 11 | 4.32 | 3.17 | 2.6064 | 2.9697 | Siliceous shale | 16.85 | 0.0241 | 15.53 | 7.35 | 9.56 |

| CN-2 | 3148.4 | 4.38 | 19.91 | 48.42 | 19.4 | 5.06 | 2.68 | 4.53 | 2.6902 | 2.9636 | Siliceous shale | 25.63 | 0.0253 | 13.36 | 5.37 | 6.86 | |

| CN-3 | 3166.9 | 5.2 | 13.58 | 64.9 | 19.19 | 0 | 1.27 | 1.06 | 2.66 | 2.9699 | Siliceous shale | 15.64 | 0.02321 | 16.78 | 8.17 | 6.83 | |

| CN-4 | 2349.5 | 4.91 | 26.22 | 42.85 | 28.53 | 0.8 | 0.9 | 0.7 | 2.8135 | 2.9701 | Mixed shale | 16.85 | 0.02431 | 16.31 | 12.76 | 5.00 | |

| WY-1 | 2569 | Weiyuan | 5.2 | 15.13 | 12.71 | 55.75 | 8.9 | 4.22 | 3.29 | 2.7152 | 2.9641 | Calcareous shale | 15.08 | 0.0336 | 16.3 | 17.92 | 4.72 |

| WY-2 | 3116.74 | 4.8 | 15.25 | 10.22 | 60.39 | 8.26 | 3.86 | 2.02 | 2.7523 | 2.9678 | Calcareous shale | 25.63 | 0.0293 | 14.84 | 6.14 | 6.73 | |

| WY-3 | 3784.96 | 2.9 | 9.38 | 20.04 | 49.26 | 12.36 | 2.36 | 3.7 | 2.5693 | 2.9626 | Mixed shale | 35.22 | 0.0312 | 12.01 | 6.98 | 5.84 | |

| YX-1 | 4077.1 | Yuxi | 5.9 | 17.36 | 4.41 | 54.61 | 14.96 | 4.56 | 4.1 | 2.8315 | 2.9786 | Mixed shale | 4.26 | 0.0296 | 21.06 | 4.89 | 7.25 |

| YX-2 | 3754 | 6 | 17.8 | 20.4 | 45.9 | 9.7 | 4 | 2.2 | 2.8548 | 2.9779 | Calcareous shale | 11.79 | 0.0364 | 21.99 | 5.16 | 5.40 | |

| YX-3 | 3345 | 4.3 | 18.32 | 1.25 | 60.65 | 12.93 | 4.65 | 2.3 | 2.6316 | 2.9731 | Calcareous shale | 3.52 | 0.0298 | 18.31 | 4.89 | 6.05 | |

| LZ-1 | 4039 | Luzhou | 5.6 | 18.8 | 13.8 | 52.9 | 6.7 | 2.7 | 5.1 | 2.7432 | 2.9736 | Calcareous shale | 2.13 | 0.0186 | 19.87 | 12.86 | 11.79 |

| LZ-2 | 3839.7 | 5.1 | 25.5 | 16.3 | 42.3 | 7.99 | 4.31 | 3.6 | 2.5976 | 2.9718 | Mixed shale | 15.03 | 0.0216 | 18.06 | 4.55 | 4.00 | |

| LZ-3 | 4926.8 | 4.4 | 21.4 | 49.2 | 18.7 | 5.5 | 1.9 | 3.3 | 2.6458 | 2.9746 | Siliceous shale | 7.05 | 0.0196 | 20.01 | 5.73 | 7.58 | |

| LZ-4 | 4086.4 | 4.5 | 21.5 | 52.8 | 7.9 | 5.1 | 10.4 | 2.3 | 2.6375 | 2.9739 | Siliceous shale | 6.89 | 0.0131 | 15.84 | 4.98 | 6.76 | |

| LZ-5 | 4918 | 4 | 15.4 | 63.2 | 11.9 | 3.7 | 2.6 | 3.2 | 2.7312 | 2.9638 | Siliceous shale | 22.45 | 0.0216 | 18.06 | 5.43 | 7.99 | |

| LZ-6 | 4031.3 | 4.2 | 19.1 | 9.1 | 46.7 | 14.64 | 5.96 | 4.5 | 2.452 | 2.9776 | Mixed shale | 8.54 | 0.0342 | 14.53 | 9.93 | 3.73 | |

References

- Guo, X.S.; Li, Y.P.; Li, J.L.; Feng, M.G.; Duan, H. Shale Discovery of Fuling Shale Gas Field and its prospects. Front. Energy 2019, 13, 354–366. [Google Scholar] [CrossRef]

- Ma, Y.S.; Cai, X.Y.; Zhao, P.R. China’s shale gas exploration and development: Understanding and practice. Pet. Exp. Dev. 2018, 45, 589–603. [Google Scholar] [CrossRef]

- Zou, C.N.; Zhu, R.K.; Chen, Z.Q.; Chen, Z.Q.; Ogg, J.G.; Wu, S.T.; Dong, D.Z.; Qiu, Z.; Wang, Y.M.; Wang, L.; et al. Organic-matter-rich shales of China. Earth. Sci. Rev. 2019, 189, 51–78. [Google Scholar] [CrossRef]

- Ma, X.H.; Zhang, X.W.; Xiong, W.; Liu, Y.Y.; Gao, J.L.; Yu, R.Z.; Sun, Y.P.; Wu, J.; Kang, L.X.; Zhao, S.P. Prospects and challenges of shale gas development in China. Pet. Sci. Bul. 2023, 4, 491–501. [Google Scholar]

- Gong, X.; Ma, X.H.; Liu, Y.Y.; Li, G.F. Advances in Hydraulic Fracture Propagation Research in Shale Reservoirs. Minerals 2022, 12, 1438. [Google Scholar] [CrossRef]

- Nie, H.K.; Li, P.; Dang, W.; Ding, J.H.; Sun, C.X.; Liu, M.; Wang, J.; Du, W.; Zhang, P.X.; Li, D.H.; et al. Enrichment characteristics and research directions of deep shale gas: A case study of the Ordovician Wufeng-Silurian Longmaxi shale in the Sichuan Basin and its surrounding areas, China. Pet. Exp. Dev. 2022, 49, 648–659. [Google Scholar]

- Chen, L.; Zuo, L.; Jiang, Z.X.; Jiang, S.; Liu, K.Y.; Tan, J.Q.; Zhang, L.C. Mechanisms of shale gas adsorption: Evidence from thermodynamics and kinetics study of methane adsorption on shale. Chem. Eng. J. 2019, 361, 559–570. [Google Scholar] [CrossRef]

- Fan, C.H.; Li, H.; Qin, Q.R.; He, S.; Zhong, C. Geological conditions and exploration potential of shale gas reservoir in Wufeng and Longmaxi Formation of southeastern Sichuan Basin, China. J. Pet. Sci. Eng. 2020, 191, 107138. [Google Scholar] [CrossRef]

- Shi, X.W.; Wu, W.; Wu, Q.Z.; Zhong, K.S.; Jiang, Z.X.; Miao, H. Controlling Factors and Forming Types of Deep Shale Gas Enrichment in Sichuan Basin, China. Energies 2022, 15, 7023. [Google Scholar] [CrossRef]

- Guo, X.S.; Hu, D.F.; Li, Y.P.; Wei, Z.H.; Wei, X.F.; Liu, Z.J. Geological factors controlling shale gas enrichment and high production in Fuling shale gas field. Pet. Exp. Dev. 2017, 44, 513–523. [Google Scholar] [CrossRef]

- Sun, C.X.; Nie, H.K.; Dang, W.; Chen, Q.; Zhang, G.R.; Li, W.P.; Lu, Z.Y. Shale Gas Exploration and Development in China: Current Status, Geological Challenges, and Future Directions. Energy Fuels 2021, 35, 6359–6379. [Google Scholar] [CrossRef]

- Nie, H.K.; Jin, Z.J.; Li, P.; Katz, B.J.; Dang, W.; Liu, Q.Y.; Ding, J.H.; Jiang, S.; Li, D.H. Deep shale gas in the Ordovician-Silurian Wufeng–Longmaxi formations of the Sichuan Basin, SW China: Insights from reservoir characteristics, preservation conditions and development strategies. J. Asian. Earth Sci. 2023, 244, 105521. [Google Scholar] [CrossRef]

- Jin, Z.J.; Nie, H.K. Evolution History of Overpressured and Normally Pressured Shale Gas Reservoirs in Wufeng Formation-Longmaxi Formation, Sichuan Basin, China: An Analysis from the Perspective of Source and Seal Coupling Mechanism. Energy Fuels 2022, 36, 10870–10885. [Google Scholar] [CrossRef]

- Jiang, Z.X.; Song, Y.; Tang, X.L.; Li, Z.; Wang, X.M.; Wang, G.Z.; Xue, Z.X.; Li, X.; Zhang, K.; Chang, J.Q.; et al. Controlling factors of marine shale gas differential enrichment in southern China. Pet. Exp. Dev. 2020, 47, 617–628. [Google Scholar] [CrossRef]

- Zhang, X.L.; Xiao, L.Z.; Guo, L.; Xie, Q.M. Investigation of shale gas microflow with the Lattice Boltzmann method. Pet. Sci. 2015, 12, 96–103. [Google Scholar] [CrossRef]

- Li, Y.Z.; Li, Y.M.; Luo, P.; Zhao, K.Z. Study on seepage mechanism and productivity of shale gas. Fault-Block Oil Gas Field 2013, 20, 186–190. [Google Scholar]

- Sun, L.; Qiu, Z.; Zhu, R.K.; Guo, Q.L. Occurrence and Migration Mechanism and Application Models of Tight and Shale Hydrocarbon. Bul. Geol. Sci. Technol. 2015, 34, 115–122. [Google Scholar]

- Javadpour, F. Nanopores and Apparent Permeability of Gas Flowin Mudrocks (Shales and Siltstone). J. Can. Pet. Technol. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Soeder, D.J. Porosity and permeability of eastern devonian gas shale. SPE Form. Eval. 1998, 3, 116–124. [Google Scholar] [CrossRef]

- Wang, G.Z. Differential Enrichment Mechanism of Shale Gas in the Southern Marine Longmaxi Formation. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2022; pp. 1–141. [Google Scholar]

- Miao, H.; Jiang, Z.X.; Tang, X.L.; Wang, G.Z.; Wu, Q.Z.; Fan, W.L.; Zheng, H.Y. Strata Uplift Controlled Deep Shale Gas Accumulation Modes: A Case Study from the Weiyuan Block, Sichuan Basin. Energy Fuels 2023, 37, 12889–12904. [Google Scholar] [CrossRef]

- Wang, G.Z.; Jiang, Z.X.; Gong, H.J.; Shi, Y.G.; He, S.J.; Miao, H. A Novel Method for Calculating Diffusion Coefficient of Shale Gas Reservoirs: A Case Study of Longmaxi Formation in Weiyuan Area, Sichuan Basin, China. Appl. Sci. 2023, 13, 7044. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.S.; Pan, Z.J.; Niu, X.L.; Yu, Y.; Meng, S.Z. Pore structure and its fractal dimensions of transitional shale: A cross-section from east margin of the Ordos Basin, China. Fuel 2019, 241, 417–431. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, W.; Zhang, R.; Liu, S.M.; Zhou, Q.M. Characterizations of pore, mineral and petrographic properties of marine shale using multiple techniques and their implications on gas storage capability for Sichuan Longmaxi gas shale field in China. Fuel 2019, 241, 360–371. [Google Scholar] [CrossRef]

- Xi, Z.D.; Tang, S.H.; Wang, J.; Yi, J.J.; Guo, Y.Y.; Wang, K.F. Pore Structure and Fractal Characteristics of Niutitang Shale from China. Minerals 2018, 8, 163. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Yi, J.Z.; Hu, Q.H. Nano-scale pore structure and fractal dimension of organic-rich Wufeng-Longmaxi shale from Jiaoshiba area, Sichuan Basin: Investigations using FE-SEM, gas adsorption and helium pycnometry. Mar. Pet. Geol. 2016, 70, 27–45. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Fu, X.H.; Pan, J.N.; Deng, Z. Effect of N2/CO2 injection and alternate injection on volume swelling/shrinkage strain of coal. Energy 2023, 275, 127377. [Google Scholar] [CrossRef]

- Pan, J.N.; He, H.X.; Li, G.F.; Wang, X.L.; Hou, Q.L.; Liu, L.L.; Cheng, N.N. Anisotropic strain of anthracite induced by different phase CO2 injection and its effect on permeability. Energy 2023, 284, 128619. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Pan, J.N.; Hou, Q.L.; Niu, J.J.; Tian, J.J.; Wang, H.C.; Fu, X.H. Changes in the anisotropic permeability of low-rank coal under varying effective stress in Fukang mining area, China. Fuel 2018, 234, 1481–1497. [Google Scholar] [CrossRef]

- Pfeifer, P.; Wu, Y.J.; Cole, M.W.; Krim, J. Multilayer adsorption on a fractally rough surface. Phys. Rev. Lett. 1989, 62, 1997–2000. [Google Scholar] [CrossRef]

- Avnir, D.; Jaroniec, M. An isotherm equation for adsorption on fractal surfaces of heterogeneous porous materials. Langmuir 1989, 5, 1431–1433. [Google Scholar] [CrossRef]

- Neimark, A.V.; Unger, K.K. Method of discrimination of surface fractality. J. Colloid Interface Sci. 1993, 158, 412–419. [Google Scholar] [CrossRef]

- Wang, Y.J.; Fan, W.M.; Zhang, G.W.; Zhang, Y.H. Phanerozoic tectonics of the South China Block: Key observations and controversies. Gondwana Res. 2013, 23, 1273–1305. [Google Scholar] [CrossRef]

- Li, Z.; Liang, Z.K.; Jiang, Z.X.; Gao, F.L.; Zhang, Y.H.; Yu, H.Y.; Xiao, L.; Yang, Y.D. The Impacts of Matrix Compositions on Nanopore Structure and Fractal Characteristics of Lacustrine Shales from the Changling Fault Depression, Songliao Basin, China. Minerals 2019, 9, 127. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.W.; Wang, Z.Y.; Chen, J.; Pang, X.J.; Wang, S.C.; Zhou, Z.L.; He, Z.B.; Qin, Z.Q.; Fan, X.Q. A review on pore structure characterization in tight sandstones. Earth Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Zhang, B.Q.; Li, S.F. Determination of the surface fractal dimension for porous media by mercury porosimetry. Ind. Eng. Chem. Res. 1995, 34, 1383–1386. [Google Scholar] [CrossRef]

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Li, Z.Q.; Ying, D.L.; Li, H.K.; Yang, G.; Zeng, Q.; Guo, X.Y.; Chen, X. Evolution of the western Sichuan basin and its superimposed characteristic, China. Acta Pet. Sin. 2011, 27, 2362–2370. [Google Scholar]

- Liu, S.G.; Yang, Y.; Deng, B.; Zhong, Y.; Wen, L.; Sun, W.; Li, Z.W.; Jansa, L.; Li, J.X.; Song, J.M.; et al. Tectonic evolution of the Sichuan Basin, Southwest China. Earth-Sci. Rev. 2021, 213, 103470. [Google Scholar] [CrossRef]

- Zhu, H.J.; Ju, Y.W.; Qi, Y.; Huang, C.; Zhang, L. Impact of tectonism on pore type and pore structure evolution in organic-rich shale: Implications for gas storage and migration pathways in naturally deformed rocks. Fuel 2018, 228, 272–289. [Google Scholar] [CrossRef]

- Miao, Z.S.; Pei, Y.W.; Su, N.; Sheng, S.Z.; Feng, B.; Jiang, H.; Liang, H.; Hong, H.T. Spatial and temporal evolution of the Sinian and its implications on petroleum exploration in the Sichuan Basin, China. J. Pet. Sci. Eng. 2021, 210, 110036. [Google Scholar] [CrossRef]

- Feng, R.; Luo, H.R.; Chen, Z.W.; Zhang, F.S. Integrated microseismic and geomechanical analysis of hydraulic fracturing induced fault reactivation: A case study in Sichuan Basin, Southwest China. Geoemch. Geophys. Geoener. Georesour. 2023, 9, 48. [Google Scholar] [CrossRef]

- Liang, X.; Liu, S.G.; Wang, S.B.; Deng, B.; Zhou, S.Y.; Ma, W.X. Analysis of the Oldest Carbonate Gas Reservoir in China New Geological Significance of the Dengying Gas Reservoir in the Weiyuan Structure, Sichuan Basin. J. Earth Sci. 2019, 30, 348–366. [Google Scholar] [CrossRef]

- Jiang, F.J.; Chen, D.; Chen, J.; Li, Q.W.; Liu, Y.; Shao, X.H.; Hu, T.; Dai, J.X. Fractal analysis of shale pore structure of continental gas shale reservoir in the Ordos Basin, NW China. Energy Fuels 2016, 30, 4676–4689. [Google Scholar] [CrossRef]

- Song, Z.Z.; Liu, G.D.; Yang, W.W.; Zou, H.Y. Multi-fractal distribution analysis for pore structure characterization of tight sandstone—A case study of the Upper Paleozoic tight formations in the Longdong District, Ordos Basin. Mar. Pet. Geol. 2018, 92, 842–854. [Google Scholar] [CrossRef]

- Gang, T.; Kelkar, M.G. A More General Capillary Pressure Curve and Its Estimation from Production Data. In Proceedings of the Rocky Mountain Oil & Gas Technology Symposium, Denver, CO, USA, 16–18 April 2007; pp. 2–3. [Google Scholar]

- Eichheimer, P.; Thielmann, M.; Popov, A.; Golabek, G.J.; Fujita, W.; Kottwitz, M.O.; Kaus, B.J.P. Pore-scale permeability prediction for Newtonian and non-Newtonian fluids. Solid Earth 2019, 10, 1717–1731. [Google Scholar] [CrossRef]

- Miao, H.; Guo, J.Y.; Wang, Y.B.; Jiang, Z.X.; Zhang, C.J.; Li, C.M. Mineralogical and elemental geochemical characteristics of Taodonggou Group mudstone in the Taibei Sag, Turpan–Hami Basin: Implication for its formation mechanism. Solid Earth 2023, 14, 1031–1052. [Google Scholar] [CrossRef]

- Glaser, K.S.; Miller, C.K.; Johnson, G.M.; Kleinberg, R.L.; Pennington, W.D. Seeking the sweet Spot: Reservoir and completion quality in organic shales. Oilfield Rev. 2014, 25, 16–29. [Google Scholar]

- Li, X.Y.; Chen, S.B.; Wang, Y.W.; Zhang, Y.K.; Wang, Y.K.; Wu, J.J.; Zhang, J.J.; Khan, J. Influence of Pore Structure Particularity and Pore Water on the Occurrence of Deep Shale Gas: Wufeng–Longmaxi Formation, Luzhou Block, Sichuan Basin. Nat. Resour. Res. 2022, 31, 1403–1423. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, D.; Zhang, L.; Xing, Y.; Zhang, Y.; Wang, W.; Liu, Y.; Mao, H. Research on Microscopic Pore Structure Characteristics and Influencing Factors of Shale Reservoirs: A Case Study of the Second Member of the Permian Lucaogou Formation in Malang Sag, Santanghu Basin. Energies 2023, 16, 2453. [Google Scholar] [CrossRef]

- Trabucho-Alexandre, J.; Hay, W.W.; de Boer, P.L. Phanerozoic environments of black shale deposition and the Wilson Cycle. Solid Earth 2012, 3, 29–42. [Google Scholar] [CrossRef]

- Wang, G.Z.; Jiang, Z.X.; Tang, X.L.; He, S.J.; Wang, Y.C.; Chang, J.Q. Critical conditions and capacities of shale gas diffusion and seepage types in the Longmaxi Formation in Jiaoshiba area, Sichuan Basin. Acta Geol. Sin. 2023, 91, 210–220, (In Chinese with an English abstract). [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Wu, Q.; Xu, L.; Yang, Y.; Liu, J.; Yin, Y.; Jiang, Z.; Tang, X.; Miao, H. Pore Structure and Migration Ability of Deep Shale Reservoirs in the Southern Sichuan Basin. Minerals 2024, 14, 100. https://doi.org/10.3390/min14010100

Wu J, Wu Q, Xu L, Yang Y, Liu J, Yin Y, Jiang Z, Tang X, Miao H. Pore Structure and Migration Ability of Deep Shale Reservoirs in the Southern Sichuan Basin. Minerals. 2024; 14(1):100. https://doi.org/10.3390/min14010100

Chicago/Turabian StyleWu, Jianfa, Qiuzi Wu, Liang Xu, Yuran Yang, Jia Liu, Yingzi Yin, Zhenxue Jiang, Xianglu Tang, and Huan Miao. 2024. "Pore Structure and Migration Ability of Deep Shale Reservoirs in the Southern Sichuan Basin" Minerals 14, no. 1: 100. https://doi.org/10.3390/min14010100

APA StyleWu, J., Wu, Q., Xu, L., Yang, Y., Liu, J., Yin, Y., Jiang, Z., Tang, X., & Miao, H. (2024). Pore Structure and Migration Ability of Deep Shale Reservoirs in the Southern Sichuan Basin. Minerals, 14(1), 100. https://doi.org/10.3390/min14010100