1. Introduction

The word aquaculture stands for the farming of aquatic organisms like fish, molluscs, crustaceans, and aquatic plants [

1]. Aquaculture practices have a long history but aquaculture as a food production sector on a global scale is relatively young. The sector is growing even though the increase in production has been slowing down from around 2000. In spite of that, the production of farmed fish for human consumption reached 42.2% of the total production from capture fisheries and aquaculture in 2012. Aquaculture production has constantly increased its share in the total fish production, while the volume of annual capture fisheries has remained almost unchanged since the 1990s [

2]. Fish consumption has been growing and the extra demand has been met by the aquaculture sector.

The aquaculture sector spans a wide range of different production systems. Each culturing environment needs to resemble the animals’ natural environment and the culturing practices need to be conformed to the species produced; i.e., both the environment and the production system [

1]. It is estimated that more than 600 species are produced worldwide by the aquaculture sector in various types of aquaculture systems, applying methods and solutions of different levels of technical sophistication [

2]. Because of the apparent growth of the aquaculture sector, there is a great pressure on the sector as a whole to become environmentally, economically, and socially sustainable [

3,

4,

5,

6]. Sustainable development of aquaculture production is enforced by various public regulative authorities as well as private standards and certification schemes that are becoming increasingly important for aquaculture producers in order to be compatible on the market [

7]. Undoubtedly, these demands have shaped the development of aquaculture production systems and practices, and motivated many of the studies that have contributed to the sector.

Numerous studies that have been published about aquaculture have attempted to shed light on the causes of common issues in the production system. In a sector such as aquaculture production, where there is a constant development of solutions to improve the production processes towards becoming more sustainable and more efficient, there is a need for a framework or map that aggregates the functions of aquaculture production systems, where each function describes a certain purposeful activity that is carried out as a part of the production process. Such a system map would facilitate the communication of new and existing solutions and their purposes among researchers, aquaculture producers, and other stakeholders. This paper presents the first steps of a study towards creating such an overview as it is aimed towards answering the question: what are the functions of aquaculture production systems and how are they achieved?

This overview has been called for in the literature: e.g., Badiola, et al. [

8] stated that a general overview of available technical solutions and “how to integrate it all together” is missing. What has been done until now is often focused on specific technical solutions, while some studies relate functions to technical solutions. Most are ’one instance’ approaches dealing with a single site. Very few have focused on multi-functions and none draw a holistic picture of aquaculture production. The link between all functions and the means to achieve them has not been presented in a systemic way.

To be able to create such an overview of technical solutions it is essential to understand what is being done in the aquaculture production systems in terms of functions. Many studies have introduced and analysed new or existing solutions that can be applied to address each of those functions. The solutions available are of various types and extent; they range from non-technical methods to highly technical methods, from the application of biological treatments to chemical treatments, and they can involve altering a few operation activities of an existing aquaculture production system or introducing a new type of system. However, no published work has collected the available solutions that are applied in aquaculture production and classified them according to the functionalities and roles they serve, i.e., the functions and what possible main streams of solutions exist for each function. It is the purpose of this article to provide this collection and classification. Furthermore, the purpose of the paper is also to identify the main parameters or indicators that are used to evaluate each function. The results are presented graphically as a map. The approach used in this study is to start by carrying out a systematic literature review, then a generic function structure is synthesized and finally each function for solution methods is analysed. For a map—like the one presented in this paper—to be valid beyond any doubt, a comprehensive literature review has to be performed. That means that on top of a systematic literature review one has to perform a grey literature study and consult experts on eventual missing studies or in-the-pipeline work [

9]. This is included in the future work together with detailed technical solution mapping and interaction.

The structure of this article is as follows. First, the methodology will be introduced and the first two steps of the theory-building process defined by Handfield and Melnyk [

10] will be used as a framework for the process of this work. A systematic literature review will be conducted to identify the functions of aquaculture production systems. These will be used to create a system map. Finally, each function is discussed in depth and put into relation with the system map.

2. Materials and Methods

A systematic literature review requires the researcher to follow a scientific methodology throughout the whole work process. For this study, the theory-building process presented by Handfield and Melnik [

10] was considered a suitable guideline to follow. The theory building process consists of a five-step process wherein each step describes a phase in the scientific process of building a theory. The first step is observation, which is further divided into two stages where each stage describes the goals driving the research. The first stage of observation is the discovery stage, where the area of research and theory development is revealed, and the second stage of observation is the description stage where the territory of research is explored. The second step is empirical generalization, the purpose of which is to map the territory of research and to identify the key variables. The last three steps of the theory-building process are the theory creation step, hypothesis testing step, and logical deduction step [

10]. The aim of this work is to create a map describing the functions of aquaculture production systems. Therefore, the first two steps of the theory-building process were followed here but the last three were left for future studies on this topic.

2.1. Observation: Discovery

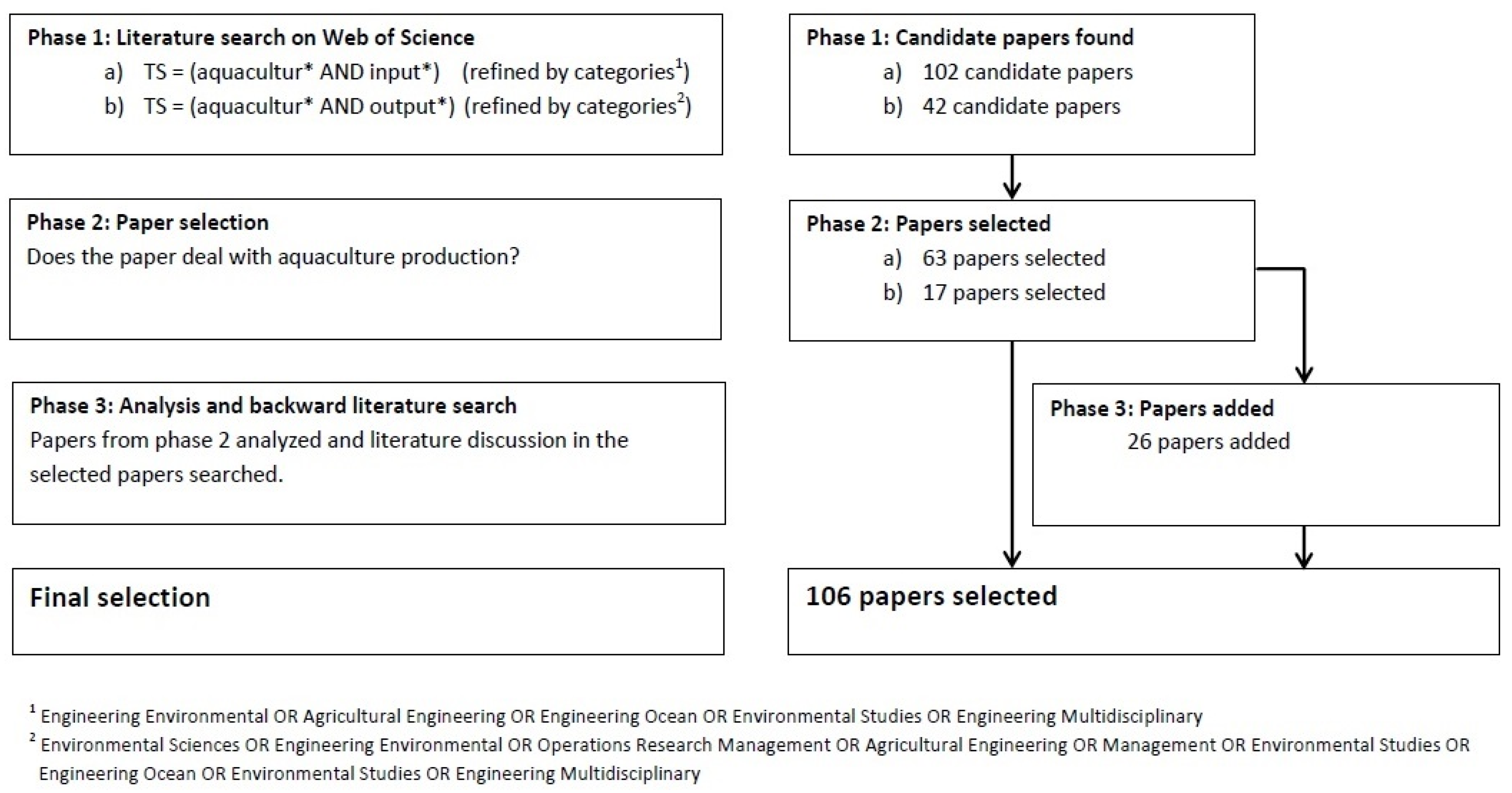

The purpose of the observation step of the theory-building process was to set the scope for the work ahead. It was decided to focus on papers that address the inputs and outputs of aquaculture production and the scope is further limited to production systems where aquatic animals are cultured for human consumption. Thomson Reuters’ Web of Science™ citation database, the largest citation database available online, was used to find sample papers for this study. The process of searching, selecting, and processing the papers can be divided into three phases (see

Figure 1). First, the results from two search queries were selected as candidate papers for the final selection. In the second phase, the coverage of each paper was roughly determined by scanning through each paper and those that were clearly outside the scope of this study were excluded.

Figure 1 provides an overview of the searching, selecting, and processing steps that took place during this part of the work.

2.2. Observation: Describe

In the third phase of the searching, selecting, and processing, the included papers were analysed and additional papers were added to the selection with a backward literature search. This resulted in a final selection of 106 papers. The analysis involved documenting the subject of each paper where the focus is set on extracting information about the production process of the system under inspection. For each paper, the inputs and the outputs of the systems, the production activities applied, technologies and equipment used in order to perform an activity, and the criteria or parameters that were used to control the production activities were listed. Additionally, the types of production systems covered in each article were documented. The result of the analysis has been summarized and categorized in

Table 1.

In this study aquaculture production systems are considered to be like any other industrial transformation system. A transformation takes an input, transforms it, and delivers an output. These three steps guided the categorization. In order to have the naming of the transformation more descriptive, they are referred to as treatments. This is in line with Timmons and Ebeling [

11]. The input group in

Table 1 consists of items that serve the most fundamental requirements of aquaculture production systems while treatments are specifically applied to increase the quality of the water of the culturing environment or to cure or prevent diseases. The group of water quality parameters consists of parameters that are measured and used as control criteria. The output group includes both animal outputs and waste outputs. Finally, the group ’types of systems’ contains names of production systems of various structures and setups. Next, the groups in

Table 1 were processed further in order to define the application of the inputs and the treatments and the processing of the outputs as production functions. The result of this work contains a list of all the papers analysed, where each paper is linked to the production function it contributed to—whether it is in the form of mentioning an input, an output, a treatment, or a quality parameter that controls the application of a treatment activity—and the types of systems covered in the paper. The list of papers is available in a

supplementary online section.

2.3. Empirical Generalization: Mapping

The last part of the process is to map the output from steps 1 and 2 in order to achieve the aim of this study; i.e., to create a clear overview of the functions of aquaculture production systems. The results will be presented and elaborated in the following sections.

2.4. Scope

This is the first article in a series of four.

Table 2 provides an overview of the whole study—showing the contents of each article and how they together create a holistic approach to aquaculture production.

2.5. Limitations

This first article is a systematic literature review. To be able to execute it, Thomson’s Web of Science™ was used as it is the largest single database on scientific articles. Using only one source of articles is of course limiting. Future work could include widening the search to other databases. Another limitation imposed is that this is a systematic literature review, which means looking at grey literature and consulting with experts is part of future work.

3. The Functions of Aquaculture Production Systems

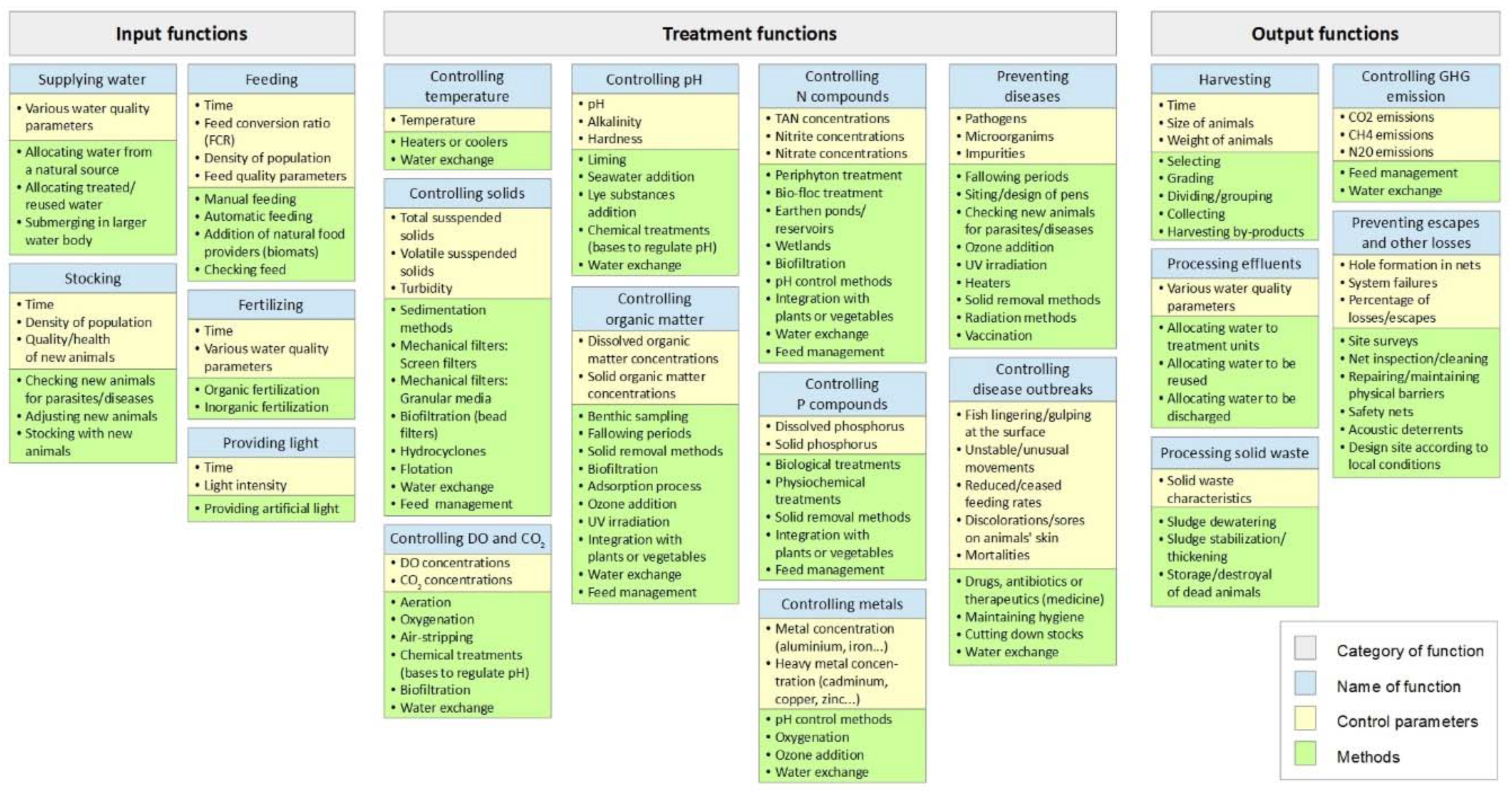

The aquaculture production system map (see

Figure 2) contains all the production functions possible in an aquaculture system. The system map divides the production functions into three groups: input functions, treatment functions, and output functions. The input functions are functions that deal with the production activities related to the inputs of the system, the treatment functions deal with activities applied in the transformation process of the production, and the output functions address the processing of the outputs of the production.

In the map, each function is represented by a box of three layers. The top layer presents the name of the function, the middle layer includes the control parameters that are used as criteria for each function, and the bottom layer contains a list of production activities, technological solutions, or methods that can be applied to carry out the function.

3.1. Input Functions

The input functions provide the aquaculture system with the most basic inputs needed for aquaculture systems to operate. The group of input functions includes supplying water, stocking, feeding, fertilizing, and providing light (see

Figure 2). It needs to be clarified that not all the input functions are always applied. Some production units are open and located within larger waterbodies, such as tidal-based or sea-based cages or net pens. For such systems the water is already there and does not need to be allocated to the production area. Further, additional feed or fertilizers do not always need to be added to the system if feed sources are produced naturally within the rearing area or if they can enter it. Production units that are not overbuilt or located inside a building receive natural light from the environment. Such types of aquaculture systems do not necessarily require any additional artificial lighting. The only input function that is always applied is stocking.

3.1.1. Supplying Water

In this study supplying water is defined to be the function of allocating water to the rearing area. The water can be supplied to the system from a natural source or it can be wastewater that has been treated before being allocated to the system. When focusing on water as an input to the system there are some factors that need to be considered. One factor is the quality of the water source as measured by various water quality parameters. In this context, the term water quality refers to physical, chemical, biological, and aesthetic properties of the water [

15]. Quality requirements are species-specific, so not all systems have the same quality standards. If the source does not fulfil the quality standards of the system of concern, the operator needs to consider whether the water source is usable at all or, if it is, the necessary treatments to reach the desired quality level [

15,

16]. In some areas, water availability is scarce and for that reason wastewater reuse and treatments for wastewater have been studied [

17].

Another important factor is the reliability of the water source. The availability of water differs between sites and sometimes it is necessary to take some precautions to ensure enough availability for a production system [

18]. Where the water supply is limited or where rainfall is seasonal, supplying water for aquaculture farms can be a challenge. At such places it can be necessary to use some water harvesting techniques to ensure that water supplies are abundant. Some studies have been conducted to find solutions to those problems. Farnworth and Petrell [

19] created a model to predict the behaviour of seepage from ponds in order to collect water to increase streamflow during temporary low precipitation periods. Tollner, Meyer, Triminio-Meyer, Verma, Pilz, and Molnar [

18] developed a model to determine supplemental water requirements for ponds under given environmental circumstances.

Many intensive systems have high water exchange rates to maintain water quality [

20,

21]. Other types of intensive systems, such as recirculating aquaculture systems, treat the effluent water from the culture unit to be able to reuse it [

22]. A recirculating system may need to use fresh make-up water up to some point to reduce off-flavours, add alkalinity, and control temperature. However, the need for fresh water is much lower for recirculating systems than for systems that use constant in-flowing water to regulate the quality of the water [

22]. Therefore, recirculating systems have received deserved attention in recent years since they require less water usage than many other systems but still provide the right conditions for intensive fish production [

6].

3.1.2. Stocking

Stocking is the function of bringing new aquatic animals, fingerlings, or seed into the culture unit. Studies have indicated that there is a relationship between stocking density, production, average harvest size, and return rate [

23]. Before new animals are introduced to an aquaculture system they might need to be gradually adjusted to the conditions of their new surroundings, such as the temperature of the system and pH, to prevent them from experiencing a shock. It is also important to check new animals for parasites and diseases to prevent disease outbreaks in the system [

24].

Some studies have focused on optimizing the production under different conditions in terms of stocking. Efforts have been made to optimize stocking rates [

25,

26] and stocking size [

26,

27]. A study by Yi [

28], in which the growth of tilapia is modelled, indicated that fish kept at higher stocking densities are more susceptible to water quality fluctuations, leading to reduced food consumption and slower growth rate. Other studies have indicated that for some species, such as shrimp, weight gain and production can be increased with higher stocking density [

29]. That suggests that optimal stocking management can differ between species and systems and should therefore be considered carefully in each case.

3.1.3. Feeding

The function of feeding is providing the cultured animals with nutrition in the form of feed. Feeding is one of the major costs in aquaculture and can take up a lot of time and effort, especially in systems of higher intensities. Feeding can be done manually or automatically [

30] and supplementary feeds can be classified as processed or non-processed. Processed feeds consist of animal or plant products that have been dried, fermented, ensiled, mixed, ground, or pelleted. Non-processed feed items are live, fresh, or frozen animals (invertebrates or vertebrates) or plants introduced to the system as feed [

20]. In some facilities, natural sources of feed are set up within the rearing area. An example of such a source is the application of microbial mats. They are microorganisms that can transform ammonia and organic matters, originated from waste and excretion, to nutrition for the cultured animals [

31].

Feeding and feed development is important from an environmental point of view. A large part of waste from aquaculture is originated from feeding activities [

32]. Intense systems with high stocking densities generally carry out high feeding rates in order to maximize the growth of the cultured animals [

3,

21]. For those systems it is important to focus on maximizing the efficient use of feed, water, and other resources in order to minimize feed waste and water pollution [

20]. Improving the quality of feed and optimizing feeding systems can result in less waste being produced within the farming system [

33] and reducing the feed conversion ratio (FCR) can reduce environmental impacts caused by aquaculture activities [

6]. Feed conversion efficiency has been proven to be lower when fish-based feed is used compared to other formulated feed options [

2]. Hence the transition from fish-based feed to formulated feed may be more desirable from economic, environmental, and social standpoints, providing that the production is sustainable and the feed digestibility is not decreased [

6]. It has also been suggested that the frequency and timing of feeding contributes to the FCR [

34]. Furthermore, the effects of different feed compositions and diets have been studied in order to increase feed efficiency, reduce negative environmental influences [

35], and be better able to design effective solid waste management depending on faecal waste properties resulting from different diets [

36].

Disease risk must also be considered in feed selection as feeds can be a source of disease [

37].

3.1.4. Fertilizing

The function of fertilizing is applied when organic or inorganic fertilizing substances are added to the rearing area in order to stimulate the ecosystem. Fertilization is mainly performed in order to improve the production of natural food for the cultured animals [

1]. Nitrogen and phosphorus compounds are the major nutrients that are added to aquaculture systems through fertilizing [

23]. Commonly used organic fertilizers are animal manures such as cow dung, and inorganic ones usually contain a combination of urea and triple superphosphate (TSP) [

38]. When fertilizers are added to the system it is important to monitor and control the application. Fertilizers can decrease the quality of the water and also affect the receiving water bodies around the aquaculture system [

1].

3.1.5. Providing Light

The function of providing light is applied when additional lighting is directed to the rearing area. Light is important for most aquatic species, most aquatic plants, and the ecosystem of aquaculture systems. How aquatic species need and receive light varies between species but few species can grow at very low light intensities or completely without light. The intensity of light exposed to the culture area should be considered carefully. If the light is too intense it can cause stress or, in the worst cases, death [

39]. Some species are adjusted to specific light conditions from their natural environments. The Arctic char, a northern freshwater fish species, seem to have adapted its life cycle to Arctic light conditions. Studies have indicated that farmed Arctic char that are exposed to changes in light conditions similar to those that occur in their natural environment have higher growth rates than those that are exposed to constant lighting [

40].

3.2. Treatment Functions

The treatment functions are applied in order to improve the quality of the culturing environment or to prevent or cure diseases. Various methods and technological solutions can be applied to carry out each treatment function and some of them involve adding inputs to the system. However, it is considered necessary to create the group of treatment functions to distinguish between the general application purposes of treatment functions and input functions. The input functions result in adding inputs to the system that directly contribute to the production process of the final product while treatment functions address the quality of the production environment.

Figure 2 includes all the treatment functions.

3.2.1. Controlling Temperature

The function of controlling temperature includes all methods and actions taken to change the temperature of the water for the rearing unit or to tune it towards an optimal temperature level. Temperature control is an important function for many aquaculture systems. Studies on aquatic animals and their temperature tolerances suggest that keeping the temperature within the right toleration range is a critical factor to ensure survival of the culture [

41,

42] and to ensure optimal growth. Rapid changes in temperature can induce stress and even cause mortality [

23], so it needs to be ensured that the water temperature does not change too fast. Temperature variations within the water body should also be considered when the temperature of the water inside the rearing area is measured and controlled [

43]. For indoor aquaculture systems it is possible to control the temperature directly using heaters or coolers. However, for outdoor systems it is more complex or even impossible, as in net cages, to control the water temperature because of heat losses to the environment [

44]. In order to contradict those difficulties, steps have been taken to simulate and predict temperature changes for different systems exposed to heat losses [

44,

45] and to identify thermal characteristics of systems [

46]. Water temperature can also be controlled in a more indirect way, such as with water exchange, where the temperature of the water entering the system can be manipulated [

22].

3.2.2. Controlling Solids

Removal of solids or particles is a very important function in aquaculture systems and a crucial function for systems of higher intensities where water exchange is limited. Many authors have addressed the issue of solid build-up in aquaculture systems, substance compositions of suspended solids and sediment, or various methods to monitor and control solids accumulation [

38,

47,

48,

49]. In this paper, the function of controlling solids is defined as the grouping of methods applied to remove solids, whether they are floating, settling, or mixed with water in the form of sludge, or to control their accumulation rate.

Total suspended solids (TSS) are the amount of particles that cannot pass through a fibre filter with a mesh size of 0.45 μm. The suspended solids can be both inorganic and organic. The organic ones, or volatile suspended solids (VSS), consist of faeces or bio-floc. Such organic substances decay so monitoring and controlling them is of great importance [

50].

An important factor of solid management is to try to control and minimize solid accumulation. Using quality feed, maintaining accurate feeding quantities, and keeping the feed conversion ratio low are all factors that contribute to minimizing the accumulation of solid waste originating from feed within the system [

33]. Several methods are used to remove solids and those mentioned here are based on groupings of methods originally identified by Chen and Malone [

50] but with some modifications.

Sedimentation processes involve techniques that allow solids to settle before being removed. Sedimentation is a rather inexpensive option to remove settleable solids from the main flow and is often used as the first step in particle separation. A large part of the TSS produced in intensive systems can settle, which makes sedimentation a feasible option for many systems [

33,

50]. Settling tanks or basins are used to remove suspended solids from the water, collect and discharge settled sludge, and deliver a thickened sludge of minimal volume. They are designed in such a way that turbulence is minimized [

33]. In recirculating systems, the water within the settling basin can be re-used after being separated from the sludge sediment [

51]. Some systems use flushing to remove settled solids. Then the water inflow is increased and the water level lowered so the accumulated solids can be flushed out of the culture unit. Then the solids or the sludge can be stored in a separate holding unit for further treatment. Removing dead cultured animals from the rearing area can also be considered a part of the solid removal functions and some systems have waste collectors not only intended to collect sludge or suspended solids but also to trap and collect dead animals [

47].

Swirl separators, also called tea cup settlers or hydrocyclones in the literature, are commonly used in recirculating systems to remove settleable solids [

52,

53]. A swirl separator is a cylinder tank with a conical base. Water from the rearing unit is injected tangentially at the edges of the tank, which creates a swirling flow. The rotating flow forces the heavier particles towards the bottom. The other part, mainly clear water, exits at the top of the swirl separator [

53].

Suspended and fine solids can be removed by using mechanical filters [

54]. A popular type of mechanical filter is a screen filter [

33]. The size of the solids removed depends on the mesh size of the screen filter media. Another type of mechanical filter uses granular media filters to remove solids. Water is passed through a bed of granular material that separates suspended solids from the water [

50]. A bead filter, or an expandable granular biofilter, is a type of biofilter that combines sludge removal and nitrification [

33,

54]. There are also methods intended to remove fine solids that do not settle easily, such as foam fractionation or flotation [

33].

When solid particles have been removed from the rearing unit they might need to be processed further before being discharged or used for other purposes. The function of processing solids will be explained in

Section 3.3.3.

3.2.3. Controlling DO and CO2

Maintaining the right level of various dissolved gasses concentrations is one of the most important water quality functions in aquaculture systems [

55,

56]. The function of controlling DO and CO

2 includes all methods used to ensure that dissolved oxygen (DO) levels are kept close to an optimal value while carbon dioxide levels are limited.

Dissolved oxygen needs to be kept over a certain value in the water of the rearing system to ensure viable conditions, especially in systems where water exchange is limited. The optimal concentration value of oxygen varies among species and too high concentrations are not recommended [

55]. However, as the intensity and stocking density of the system increases the demand for oxygen also increases. Two common methods to increase dissolved oxygen concentrations in the water are aeration and oxygenation. Aeration is a method where bubbling air is pumped into the water or when water droplets are forced into contact with air. Oxygenation is where pure oxygen gas is injected into the water [

57].

When oxygen is consumed by the cultured species or other organisms, it will increase the carbon dioxide concentration in the rearing area resulting from fish metabolism [

23]. Carbon dioxide in too high levels can be toxic for the cultured animals. In intensive systems, where pure oxygen is injected to the system, there is a risk of excess carbon dioxide concentration build-up within the rearing area resulting from low water exchange and because pure oxygen systems do not facilitate sufficient carbon dioxide removal [

57]. Carbon dioxide accumulation can also affect other characteristics of the water. For some alkalinity values respiratory carbon dioxide can lower the pH and create a suboptimal life condition for the cultured animals [

55,

58].

Aeration limits the accumulation of carbon dioxide as carbon dioxide is stripped out during the process to some extent [

58]. There are also other methods that can be used to remove excess carbon dioxide from the water. Air-stripping columns can be used to remove dissolved carbon dioxide from the water. In some recirculating systems chemicals are used to remove carbon dioxide. Two types of chemicals can be used to control carbon dioxide as well as to regulate the pH: strong bases that do not contain carbon, such as sodium hydroxide; and those that contain carbon, such as sodium bicarbonate [

57]. Biofilters such as trickling filters, mainly used in recirculating systems to remove ammonia from the water, also serve the purpose of removing carbon dioxide from the water [

59].

3.2.4. Controlling pH

The pH scale measures the acidity and alkalinity in water or other aqueous solutions. The alkalinity is a measure of the water’s capacity to keep the pH constant by neutralizing acids. For low alkalinity values the pH of the water is more likely to fluctuate. Hardness measures the sum of all metal ions in the water [

30]. This function includes all methods used to adjust the levels of the above mentioned parameters.

Generally, aquatic animals can tolerate a pH range from 6 to 9.5 [

24]. Extreme pH values or a rapid change in pH can induce stress or even cause mortality [

60]. Dangerous pH conditions are not likely to occur since a suitable water source should be chosen for each system [

24]. Therefore, the pH value might not need to be managed so much in systems with high water exchange rates. However, other substances in water, such as carbon dioxide and ammonia, that need to be kept under acceptable limits are dependent on the pH and their concentrations and transformations can be affected by the pH [

61].

As mentioned earlier, there are chemical treatments such as addition of sodium bicarbonate or sodium hydroxide that serve the double purpose of regulating the pH as well as removing carbon dioxide from the water [

57]. Liming is another common method applied that involves adding liming substances to the water to increase the pH. Among other methods used to increase the pH of water is the addition of sea water to increase the pH or lye substances for pH regulation [

30]. If the alkalinity is too low, dolomite can be applied to raise the alkalinity level. If the alkalinity level is too high, organic acids can be added to reduce the level [

3].

3.2.5. Controlling N Compounds

Impurities in water can be classified as nutrients and organic matter. A high level of nutrients in aquaculture effluents can pollute receiving waters and cause problems within the rearing unit [

5]. This function includes methods used to transform or remove organic or inorganic nitrogen compounds from the water or controlling accumulation of those substances.

Nitrogen is a nutrient that mainly enters aquaculture systems in the form of feed or fertilizers. It is one of the key nutrients needed for plants in fertilized ponds to grow but it can also transform into ammonia and nitrite, which can be toxic for the animals cultured within an aquaculture system [

23]. Total ammonia nitrogen (TAN) concentrations are frequently measured in aquaculture systems in order to monitor water quality. Total ammonia nitrogen is the sum of un-ionized ammonia (NH

3) and ionized ammonia (NH

4+) and there is a balance between the concentrations of those two forms of ammonia in water that depends on the pH of the water [

5]. In wastewater these substances are considered to be one of the major contributors to environmental pollution [

62,

63].

Accumulation of nitrogen can be minimized through feed management but for systems of higher intensity it might be necessary to apply some methods to remove or transform nitrogen compounds from the water. Crab, Avnimelech, Defoirdt, Bossier, and Verstraete [

5] grouped nitrogen removal methods into two categories: removal methods inside the culture unit and removal methods outside the culture unit. They mentioned two methods within the rearing area, pheriphyton treatment and bio-flocs technology. Both methods remove nitrogen compounds or convert them into less toxic forms. A positive side effect of applying these treatments is that the transformation can result in an additional food source for the animals being grown in the system and therefore might decrease the need for direct feeding [

64]. Biomats, discussed in

Section 3.1.3, can also be grouped with other biological methods to transform ammonia and organic matter to food [

31]. In integrated systems such as aquaponics, the plants growing in the system can recover a part of the nitrogen supplied to the system [

65,

66].

Crab, Avnimelech, Defoirdt, Bossier, and Verstraete [

5] identified earthen treatment ponds or reservoirs as nitrogen removal methods that are applied outside the culture unit. Constructed wetlands have been used to replace the loss of natural ones for the purpose of removing ammonia and nitrate compounds from the outlet water [

67]. Wetlands also serve other treatment purposes, such as to remove solids, phosphorus, trace elements, and microorganisms [

68].

Using biofilters to treat effluents outside the culture unit is another prominent technique to control total ammonia nitrogen concentrations. Many types of biofilters exist but here the focus is on two categories of biofilter technologies that have been identified in the literature: fixed film filters and suspended growth filters [

69,

70]. Fixed film filters have been more favoured than suspended growth systems because of more stability in their performance [

70]. The main biological process that biofilters perform is nitrification, which is converting ionized ammonia to nitrite and nitrate [

30,

54]. Denitrification biofilters seem to have received less attention in the literature but their role is to remove excess nitrate from the system and prevent it from exceeding the tolerance limits of the cultured animals [

6,

51].

Optimal design and techniques to estimate the requirements of biofilters for recirculation systems have been studied in the literature [

71], and models to predict ammonia concentrations have also received substantial attention [

72].

3.2.6. Controlling Organic Matter

In the previous section it is explained that organic matter compounds can be classified as impurities that exist in the water of aquaculture systems. The function controlling organic matter includes all methods used to remove or keep organic matter concentrations under acceptable limits.

Organic matter enters culture systems with feed, fertilizers, or other agents added to the system [

3]. Feed management is therefore an important factor of minimizing organic matter accumulation. Organic substances are also created within the system in the form of metabolic waste [

48]. When organic matter accumulates in the system it can decrease DO levels and over-stimulate phytoplankton growth [

62], and when organic matter mineralizes it can attribute to the emergence of toxic compounds inside the rearing unit [

64]. Organic matter in solid form can be removed from the system using some of the previously mentioned solid removal methods. Fine particulate organics can be removed using foam fractionation with ozone gas [

33]. Ozone treatment, which is commonly used to disinfect the water, has been proven to reduce total organic carbon (TOC) up to a point, but it needs to be used carefully since the residual ozone can be toxic for both fish and humans. UV irradiation has been used to counteract potentially toxic effects as it destroys ozone residuals in the water [

68]. Biofilters, which are commonly used in recirculating systems mainly to control total ammonia nitrogen concentrations, can also reduce concentrations of dissolved organics [

69]. However, particulate organic matter can cause problems in their performance if the loading rates are too high [

59].

Sufficient water exchange can counteract the build-up of soluble organic matter and for recirculating systems it has been recommended to perform a complete water exchange after each production cycle [

24]. Organic chemicals and total organic carbon can also be removed through an adsorption process [

68]. Studies on integrated multi-trophic aquaculture (IMTA) and aquaponics have indicated that the integration of plants, algae, seaweed, and/or other species creating a balanced ecosystem can recover a large part of the organic matter concentrations in the water [

66,

73]. In marine aquaculture monitoring the benthic condition and fallowing between each production cycle is necessary to maintain a healthy environment and prevent diseases [

74].

3.2.7. Controlling P Compounds

Phosphorus compounds are nutrients that enter culture units mainly in the form of feed or fertilizers. In natural waters phosphorus concentrations are relatively low but they tend to accumulate in aquaculture systems of higher intensity [

23]. As environmental disturbances deriving from aquaculture systems have been a concerning matter in many studies throughout the years [

75,

76,

77,

78], too high concentrations of phosphorus in effluent water have raised concerns due to its role in the eutrophication process [

79]. This function addresses methods used to remove phosphorus compounds from the water of the rearing area or the effluent water or controlling the accumulation.

Phosphorus compounds exist in both solid phase (SP) and dissolved phase (DP). Solid removal methods should decrease the phosphorus discharged but studies have indicated that a large part of the total phosphorus in the discharged water from flow-through systems is in dissolved form. Technologies to remove phosphorus can be grouped into two categories: biological and physiochemical. Biological methods are performed through sludge treatments whereby phosphorus is removed. Physiochemical methods are more common. They involve adding chemicals that transform phosphorus to solid form so it will settle [

78] and can then be removed with other settleable solids. Integrated systems such as IMTA and aquaponics seem to be beneficial for the fact that the co-farmed animals/plants can reduce the phosphorus concentrations of the rearing area water and therefore from the effluent water [

66].

3.2.8. Controlling Metals

The function of controlling metals includes activities performed to reduce the possibility of metal compounds in the water becoming toxic to the cultured animals, the environment, or the consumer. High metal concentrations in the water inside the rearing area can be a serious problem as they can result in heavy metal intoxication to consumers [

80]. Therefore, it is essential to ensure that the level of metals in the water stays within an acceptable level. Heavy metals such as cadmium, copper, and zinc have been identified as substances that should be observed closely in recirculation systems. In those systems there is even more risk of heavy metal concentrations building up because of limited make-up water usage. The toxicity of heavy metals is, however, dependent on other factors such as alkalinity and hardness and can be reduced when those levels are high [

55]. Other metals of concern are aluminium and iron compounds.

Metals can enter the water in various ways. At some sites there are metal substances in the inlet water that need to be monitored and controlled if the metal concentration reaches too high levels. Problems with too high aluminium concentration in the water have been related to low pH levels. Therefore, some techniques to bring down aluminium levels of water are the same as for controlling (increasing) pH levels; such as liming, adding sea water, or lye addition. Adding oxygen or ozone has been applied to reduce high levels of iron compounds in the water [

16]. The bioculture in the water also plays an important part in regulating the metal concentration levels. Studies have indicated that the application of microbial mats can facilitate the removal of heavy metals from the water due to their ability of sequestering metals from the environment [

31]. Finally, the equipment and the environment of the rearing area can also affect the characteristics of the water. If metal equipment is used or if the tank/rearing unit is made of metallic material then it needs to be observed if corrosion occurs [

42].

3.2.9. Preventing Diseases

It has been suggested that outbreaks of infectious fish diseases can limit the growth of the global aquaculture industry [

81]. Therefore, the function of preventing diseases is introduced, which covers methods that are applied to prevent diseases from manifesting within aquaculture systems.

Some precautions can be taken to reduce the probability of pathogens, or any impurities that can cause diseases, entering the culture unit. One of them is checking fish or fingerlings for parasites and diseases before they are released into the system. This is important since it can be hard to control a disease outbreak once it has been introduced to the system and contagious diseases can spread quickly inside a tightly stocked rearing area. Sterilizing all the equipment used for the system will also reduce the likelihood of disease outbreaks [

24]. There is always the probability of underlying diseases being present within the stock that can emerge if the cultured animals are exposed to some kind of stress releaser, such as suboptimal environmental conditions [

30]. Thus maintaining optimal water quality reduces the likelihood of disease outbreaks.

As defined by Lekang [

30], disinfection methods are performed to reduce concentrations of microorganisms that can cause outbreaks of infectious diseases for the cultured animals. Disinfection can be carried out during several stages of the production. The inlet water is often disinfected to ensure acceptable concentration of microorganisms. In recirculating systems, disinfecting effluent water before reuse may be necessary for the same reasons. Lekang grouped disinfection methods into four categories. Chemical methods involve using various chemical agents such as ozone for disinfection. Physical methods consist of physical agents such as heating or UV irradiation. In the third group there are mechanical methods including the solid removal techniques that have already been mentioned here. The last group contains radiation methods such as electromagnet, acoustic, or particle radiation [

30].

For some systems and some types of cultured animals, vaccinations are used to prevent diseases. However, not all species tolerate vaccination. For example, shellfish in general have primitive immune systems so vaccinations have not proven to be effective and possibly never will [

23]. In marine farming, fallowing periods between production cycles are used to prevent diseases [

77]. Feed can transfer diseases and has to be monitored [

37]. In marine aquaculture, the design, like single point mooring and siting of pens, can be used to reduce disease likelihoods [

82].

3.2.10. Controlling Disease Outbreaks

If a disease breaks out inside the culture area then actions need to be taken to prevent spreading. This section addresses methods used to manage disease outbreaks in aquaculture systems.

There are numerous known fish diseases, infectious and non-infectious. They can enter the system from the incoming water, from new fish entering the culture unit, or from equipment used within the area. Infectious diseases spread faster in systems of higher intensity and density of stocks [

23]. Sick fish can show symptoms like lingering at the surface, gulping at the surface, unstable or unusual movements, or reducing or cutting off feeding rates. Other indicators are discolorations or sores on the skin or mortalities. Drugs, antibiotics, or therapeutics are sometimes used to treat diseases but not all species tolerate those treatments. Using chemical treatments can also impact other functions of the culture unit, such as biofilters in recirculating systems [

24]. In shellfish cultures, medicine is generally not used outside of hatcheries. To encourage recovery from disease outbreaks in shellfish cultures, it can be effective to increase the water flow rate, maintain good hygiene, or cut down the stock [

23].

Sea lice have caused disease problems in salmon cultures. Sea lice pathogens can be controlled by using medicine but because of the possible harmful effects of chemical treatments on the environment, medicine use must be kept under allowed limits. However, farmed fish are tolerant to sea lice up to a point but their numbers should be monitored [

77].

3.3. Output Functions

Each aquaculture production system should deliver a final product and some systems also produce secondary products. Many aquaculture systems also produce a large amount of waste, effluent and solid. The group of output functions includes functions that address all types of the outputs of aquaculture systems.

Figure 2 displays the group of output functions.

3.3.1. Harvesting

The function of harvesting includes selecting, grading, dividing or grouping, and finally collecting the cultured animals. It also includes harvesting byproducts if they are cultured in the system as well. Harvesting is considered to be the final step of the production in this review.

All functions and methods aim at maximizing the profit from the production by maximizing the output and ensuring that it meets set quality standards. Production planning is very important to reach that goal [

27]. As the intensity of the farming increases, the need to interfere with the behaviour and location of the cultured species increases. Necessary interfering actions can be dividing, grouping, size grading, and weighting the fish. These actions can be considered as a part of preparing harvesting. In some cases, size grading takes place during harvesting. If it turns out that the animals are not ready to be harvested, they can be redirected to a proper place within the rearing unit [

30].

Harvesting methods can induce stress and even increase mortality rates. Studies have indicated that harvesting techniques that minimize handling the animals can reduce stress and mortality [

83]. The timing of harvesting is also critical. In an attempt to maximize the profit of the production, models have been made to optimize harvesting schedules for aquaculture systems [

27,

84].

Harvesting techniques vary among cultured species but also among systems. In aquaponics, the plants or vegetables that are cultured along with the animals need to be harvested as well as the animals [

65,

85].

3.3.2. Processing Effluents

The function of processing effluent water describes different processing options for the output water. In some aquaculture systems, effluent water is discharged directly without any treatment. However, if the water is too contaminated, discharging it directly might have negative effects on the receiving environment [

86]. In recirculation systems where the effluent water is reused, water quality criteria should be assessed and developed for the production system of concern [

55]. Furthermore, aquaculture facilities need to consider quality standards set by them, consumers, and international and local regulations regarding effluent water discharge or reuse [

17,

77]. How the effluent water is processed is therefore dependent on rules and quality standards, the characteristics of the water, and if it should be reused or not.

Methods applied to treat effluent water have already been mentioned in earlier sections. Solid concentrations in waste effluents is one of the urgent environmental issues related to aquaculture systems [

76]. Solid removal methods are therefore important for systems where solid concentrations are too high. Methods to remove nutrients, such as nitrogen compounds and phosphorus, and organic matter are also important to maintain the water quality of the reused water within recirculating systems [

5,

63,

87] as well as to minimize environmental effects [

62]. Unfortunately, wastewater treatments are often expensive and it has been pointed out that not all systems can afford expensive equipment for treating wastewater and need to employ low-cost treatment options [

88].

Some studies have focused on tools to forecast the efficiency of treatment methods applied. An example is a neural network model introduced by Chen et al. [

89] to predict reuse potentials of treated wastewater. Bunting [

17] created a bioeconomic model to compare traditional and rational designs for lagoon-based treatments for wastewater to be reused.

3.3.3. Processing Solid Waste

Various solid removal methods have already been introduced in earlier sections. Some methods, such as filtration or settling methods, leave the operators with solid waste that needs to be processed before being further used or disposed of. This function addresses methods related to the processing of solid waste after it has been separated from the water.

In some cases, solid waste is collected in containers where it can be treated. As an example, particle concentrators are devices located by the outlet from a rearing area that assist the settling and concentration of solids. Sludge from aquaculture systems can be disposed of but it might also have beneficial uses after being removed from the system [

33]. Sludge has proven to be a good fertilizer for crops. Before being used as such, it is commonly thickened or dewatered [

54]. Methods like liming stabilize and thicken the sludge as well as kill pathogenic diseases and prevent the sludge from decomposing [

33]. Biological methods can also be applied to remove phosphorus compounds from the sludge [

78].

3.3.4. Preventing Escapes and Other Losses

In aquaculture systems, where the culture unit is not a completely enclosed area, there is always a risk of animal losses due to the exposure to the outside environment. The function of preventing escapes and other losses covers methods applied to reduce the risk of such losses.

When animals escape from an aquaculture system it is an economic loss for the farm [

90] but it can also have considerable effects on the wild population and the ecosystem outside the culture area. Genetic interactions between escapees and wild fish can occur and diseases can be transferred from the escaped fish to the wild ones [

77]. Every aquaculture farm needs to be designed and structured in such a way that the risk of escaping is minimized but preventative actions must also be implemented in routine operations of farms where escape risk is present. Most fish escapes take place because of mooring system failures or the formation of holes in net cages. Fish biting, fouling, wear and tear, and abrasion can all lead to formation of holes in the nets. Frequent site surveys, net inspection, net cleaning, and repairing system components when necessary are operational activities that reduce the risk of escape incidents [

91]. Other preventative measures include applying safety nets around the culture area. They serve the purpose of preventing fish from escaping during activities such as net changing [

90] and also keep away wild fish that might be tempted to bite the nets that fence off the rearing area [

91].

Local conditions such as extreme weather (storms) and/or natural hazards (floods, earthquakes) have to be taken into account during system design. Predators such as birds and marine mammals may be kept away by using acoustic devices [

92]. However, it should be taken into account that some types of acoustic devices are believed to cause pain to marine mammals while other types are believed to be harmless [

93].

3.3.5. Controlling GHG Emission

It has been pointed out in the literature that not many studies have focused on the formation and effects of greenhouse gasses (GHG) from aquaculture systems [

35], but in recent years more articles have dealt with the issue. The function of controlling greenhouse gas emission includes efforts made to limit formation of greenhouse gasses from aquaculture systems.

The major types of greenhouse gasses from aquaculture systems are carbon dioxide, methane (CH

4), and nitrous oxide (N

2O) [

6,

94]. These gasses stem from decomposition of organic materials, from metabolic excretion from the cultured animals, or during nitrification or denitrification processes [

94]. Studies have indicated that on average only 25% of the feed nitrogen and feed carbon is transformed into fish biomass and the rest is delivered through the environment in other forms [

23,

35]. New types of systems such as partitioned aquaculture systems (PAS) try to improve feeding efficiency and aim to eliminate feed wastage. Those systems are claimed to be more sustainable and environmentally friendly and should discharge less waste in solid or effluent form as well as reduce atmospheric emissions [

23]. High levels of greenhouse gas emissions have been traced to activities of aquaculture systems of higher intensity, such as to high feeding rates and low water turnover rates [

94].

4. Discussion

In this study the first steps towards a theory of aquaculture production systems were taken. These steps were carried out with a systematic literature review that has its drawbacks and as a result the review is not comprehensive. The articles used in the study came from only one database (the Thomson Reuter—ISI) and the choice of search criteria might have been biased. Other sources may add new viewpoints. This was done to start the work. Future work should include other databases. Furthermore, experts were not consulted for validation or on what was missing. This is only partly true; throughout the work several experts were consulted on the matter but it should be done in a formalized manner. In future work, following this paper, a formal expert panel review will be conducted. It is also the intention to validate the map and its subsequent components (in Parts 2 to 4) with the industry. The authorswould like to construct an aquaculture engineering design methodology.

No taxonomies exist on all functions that are possibly relevant in aquaculture production. A search on Web of Science™ for ’aquaculture’ and ’taxonomy’ results in 157 hits but all are either on biology (like seaweed or bacteria) or not related at all. There are some part taxonomies on technical solutions and they will be dealt with in Parts 2 and 3 [

12,

13]. The most complete work on aquaculture production system seems to be major books in the field like

Recirculating Aquaculture by Timmons and Ebeling [

11],

Aquaculture Engineering by Lekang [

30], and

Aquaculture Production Systems by Tidwell [

23]. While these books deal with most of the functions included in themap that was introduced in this paper, they present their findings as either instance approaches [

23] (different forms of aquaculture systems like pens or ponds or RAS etc.), technical solution approaches [

30] (how to build), or a blend of the two [

11]. General function overview is only implicitly discussed and means–end approaches are not the focus. The authors of this paper are confident that the map, and subsequent taxonomy of means [

12,

13] and interactions [

14], is novel and useful.

The resulting map from this study identifies the main functionalities of aquaculture systems and introduces various methods and technologies applied to carry out the production functions. The authors hope that future studies carry on with this work by following the last three steps of the theory-building process in order to understand the interaction between the functions presented in the map. The system map needs to be an ongoing project. It must be continuously maintained and updated to keep up with changes and trends in aquaculture systems when methods and technologies evolve or new ones emerge. Finally, it needs to be emphasized that the system map aggregates production functions of different types of aquaculture production systems. It is highly probable that there is a large variety in the application of functions among systems and what means are used to perform the needed functions. Some systems might require all the functions to be performed, while others might need just a few of them. An interesting subject for future studies would be to analyse the application of the functions in production systems of different types.

As mentioned earlier, this is the first of four papers in the generation of a taxonomy of means and ends in aquaculture production. Parts 2 and 3 will lay out the technical solutions for the treatment functions in a visual taxonomy [

12,

13]. The fourth part will look at the interaction between technical solutions and treatments—how a single technical solution achieves or influences more than one treatment function, both in a positive and negative way.