The Challenge of Producing and Marketing Colloidal Silver Water Filters in Nepal

Abstract

:1. Introduction

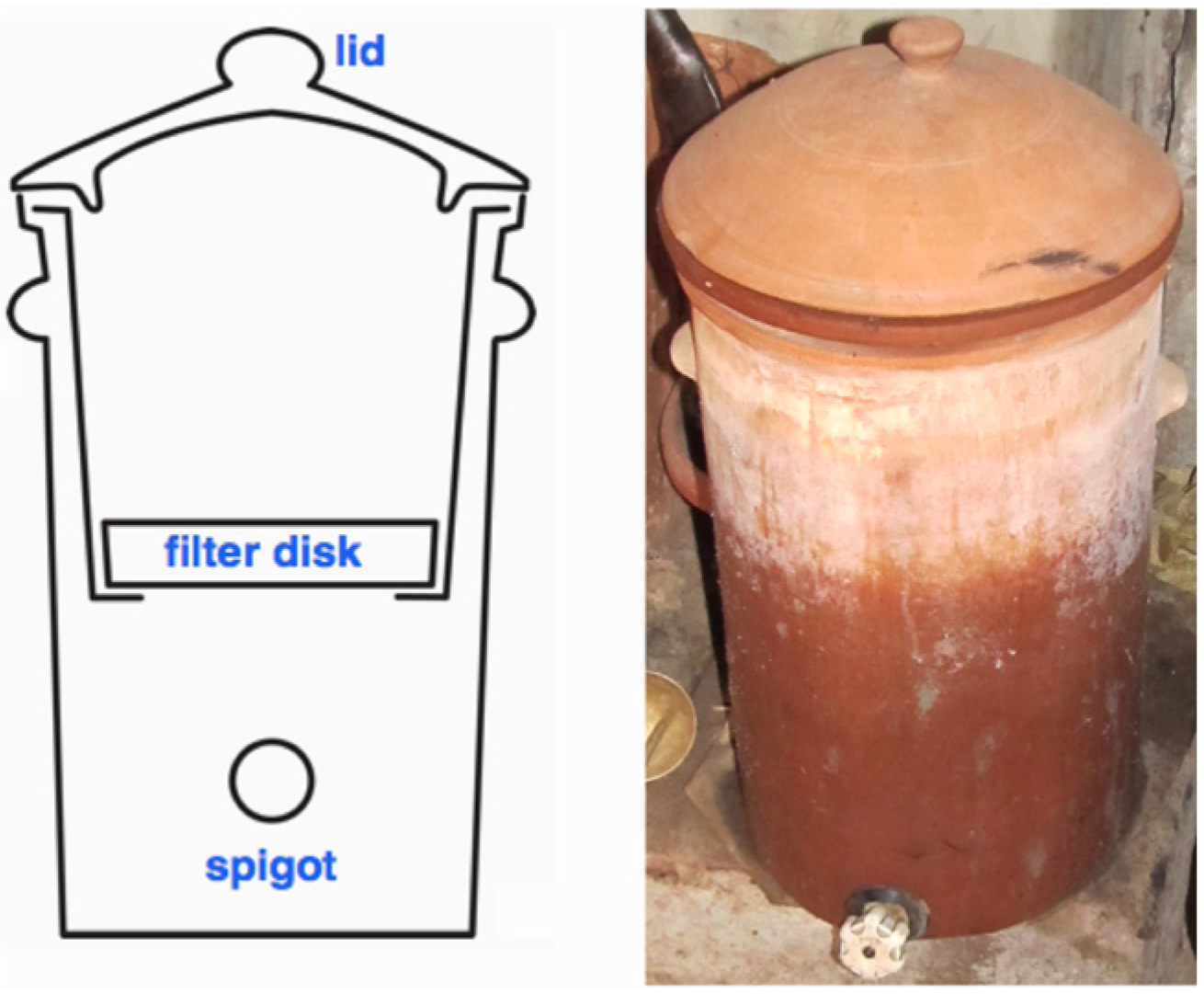

Ceramic Filters in General and in Nepal

2. Methods

2.1. Data Collection: Interviewing Potters and Organizations

2.2. Defining Conditions for Qualitative Comparative Analysis

| External Conditions | The Potter | ||||

|---|---|---|---|---|---|

| Condition | Questions | W | Condition | Questions | W |

| Production | Problems with other parts of the business | 1 | Business Management and Financial Skills | Infrastructure bought on their own | 3 |

| Problems with filter availability (disk) | 1 | Own investment in equipment | 3 | ||

| Problems in production process | 3 | Employment of staff, salary | 1 | ||

| Reasons for stopping (production) | 3 | Profitability | 1 | ||

| Help for maintenance of production | 1 | Profitability challenges | 1 | ||

| Collaboration and Support | Form. relationships with other Org. | 1 | Income through other products | 1 | |

| Provider of production training | 1 | Business management training | 2 | ||

| External help with setting up | 3 | Bookkeeping | 2 | ||

| Support f. Mktg., Freq. of measures | 1 | Planning of production | 1 | ||

| Sales channels | 1 | Knowledge of costs | 2 | ||

| Funding of investment | 2 | Different prices | 1 | ||

| Funding of production | 2 | Marketing Skills and Effort | Marketing Training | 2 | |

| Availability of Customers | Differences betw. income segments | 1 | Knowledge about customers | 1 | |

| Customer segments | 1 | Sales channels | 1 | ||

| Population density | 2 | Own Marketing Measures | 2 | ||

| Selling area | 2 | Strategies for new customers | 2 | ||

| External Influences on Market (increasing Demand) | Safety of water sources | 2 | Effectiveness of own Marketing | 2 | |

| Competition of other HWTS | 1 | Entrepreneurial Spirit | Production of other products | 1 | |

| Marketing Measures | 2 | Percentage of income rel. to filters | 1 | ||

| Frequency of Marketing Measures | 2 | Infrastructure bought on their own | 2 | ||

| Awareness Raising Activities | 1 | Interest in training others | 1 | ||

| Recommendations of customers | 2 | Own Marketing, strategy for new cust. | 2 | ||

| Effectiveness of Marketing | 3 | Interest in continuation, Scale up | 3 | ||

| Interest of Customers in Filters | Problem of filter availability (demand) | 1 | Organization, tidiness of site | 1 | |

| Willingness to invest comp. to price | 1 | Opn. on Trainings, impact of design | 1 | ||

| Percentage of people treating water | 3 | Help with Setting up | 2 | ||

| Pot. customers (not yet treating) | 1 | Quality Testing | 1 | ||

| HWTS Demand | 3 | Knowledge spare parts, prod. time | 1 | ||

| Difficulty to find customers | 2 | Problem solving methods | 2 | ||

| Satisfaction of customers | 1 | Buying places, transport (special) | 1 | ||

| Complaints of customers | 1 | After Sales Services | 2 | ||

| Reasons for not buying the Filter | 1 | Help for maintenance of production | 1 | ||

| Reasons for stopping (demand) | 3 | Innov. thinking, ind. spirit (observed) | 3 | ||

2.3. Developing the Scores

2.4. Comparing the Two Approaches

2.5. QCA Procedure

| Sites | Outcome Scores | Causal Combinations | ||||||

|---|---|---|---|---|---|---|---|---|

| Cont. | Term. | R*C*~M*~P | R*~C*~M*P | ~R*~C*M*P | R*C*M*~P | R*~C*M*P | R*C*M*P | |

| I | 1 | 0 | 0.148 | 0.294 | 0.222 | 0.148 | 0.706 | 0.273 |

| II | 1 | 0 | 0.235 | 0.235 | 0.222 | 0.550 | 0.273 | 0.450 |

| III | 1 | 0 | 0.088 | 0.088 | 0.091 | 0.370 | 0.091 | 0.630 |

| IV | 0.5 | 0.5 | 0.417 | 0.182 | 0.182 | 0.556 | 0.182 | 0.421 |

| V | 0.175 | 0.825 | 0.050 | 0.083 | 0.545 | 0.050 | 0.167 | 0.167 |

| VI | 0.15 | 0.85 | 0.083 | 0.083 | 0.545 | 0.167 | 0.167 | 0.167 |

| VII | 0.15 | 0.85 | 0.556 | 0.211 | 0.211 | 0.269 | 0.211 | 0.211 |

| VIII | 0.01 | 0.99 | 0.318 | 0.519 | 0.056 | 0.269 | 0.269 | 0.269 |

| Consistency for Sufficiency | Cont. | 0.623 | 0.664 | 0.580 | 0.811 | 0.837 | 0.870 | |

| Term. | 0.751 | 0.636 | 0.742 | 0.528 | 0.482 | 0.477 | ||

3. Results and Discussion

3.1. The Potters’ Stories

3.2. Results of the Two Scoring Approaches

| Conditions | Scoring Method | Sites | |||||||

|---|---|---|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | VII | VIII | ||

| Production (R) | Subjective | 4 | 4 | 5 | 3 | 2 | 2 | 3 | 5 |

| Methodical | 4 | 4 | 5 | 3 | 1 | 1 | 3 | 5 | |

| Collaboration and Support (C) | Subjective | 2 | 4 | 5 | 5 | 3 | 3 | 4 | 1 |

| Methodical | 2 | 4 | 5 | 5 | 3 | 3 | 4 | 2 | |

| Availability of Customers | Subjective | 4 | 2 | 5 | 3 | 5 | 5 | 1 | 2 |

| Methodical | 4 | 3 | 4 | 3 | 5 | 5 | 1 | 2 | |

| External Influences on Market (increasing demand) | Subjective | 4 | 4 | 3 | 2 | 5 | 5 | 1 | 1 |

| Methodical | 4 | 4 | 3 | 3 | 5 | 5 | 2 | 2 | |

| Interest in Filter | Subjective | 4 | 4 | 5 | 2 | 5 | 5 | 1 | 2 |

| Methodical | 4 | 4 | 5 | 3 | 4 | 4 | 1 | 1 | |

| Business Management and Financial Skills | Subjective | 5 | 2 | 3 | 3 | 5 | 3 | 1 | 3 |

| Methodical | 4 | 2 | 3 | 3 | 4 | 3 | 2 | 3 | |

| Marketing Skills and Effort | Subjective | 3 | 3 | 2 | 2 | 5 | 4 | 1 | 2 |

| Methodical | 2 | 3 | 1 | 2 | 5 | 4 | 1 | 2 | |

| Entrepreneurial Spirit | Subjective | 5 | 2 | 3 | 2 | 4 | 3 | 1 | 2 |

| Methodical | 5 | 2 | 4 | 2 | 3 | 3 | 1 | 3 | |

| Total Scores and Ranking (Score: Rank) | Subjective 1 | 31: 2 | 25: 5 | 31: 2 | 22: 6 | 34: 1 | 30: 4 | 13: 8 | 18: 7 |

| Methodical 2 | 29: 3 | 26: 5 | 30: 1 | 24: 6 | 30: 1 | 28: 4 | 15: 8 | 20: 7 | |

| Total number of Filters sold | - | 15,000 | 4000 | 3750 | 500 | 175 | 150 | 150 | 10 |

3.3. Results of the QCA

| Conditions | Sites | |||||||

|---|---|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | VII | VIII | |

| Production (R) | 0.778 | 0.778 | 0.889 | 0.556 | 0.167 | 0.167 | 0.556 | 0.944 |

| Collaboration and Support (C) | 0.273 | 0.727 | 0.909 | 0.818 | 0.455 | 0.455 | 0.727 | 0.318 |

| Market (M) joined by logical OR | 0.706 | 0.765 | 0.912 | 0.583 | 0.917 | 0.917 | 0.269 | 0.269 |

| Availability of Customers | 0.667 | 0.417 | 0.750 | 0.583 | 0.917 | 0.917 | 0.167 | 0.250 |

| Ext. Influences Market | 0.615 | 0.615 | 0.462 | 0.462 | 0.846 | 0.808 | 0.269 | 0.269 |

| Interest in Filter | 0.706 | 0.765 | 0.912 | 0.412 | 0.706 | 0.706 | 0.118 | 0.147 |

| Potter (P) joined by logical OR | 0.852 | 0.450 | 0.630 | 0.421 | 0.950 | 0.650 | 0.211 | 0.519 |

| Business Mgmt and Financial Skills | 0.816 | 0.237 | 0.421 | 0.421 | 0.737 | 0.421 | 0.211 | 0.500 |

| Marketing and Effort | 0.400 | 0.450 | 0.200 | 0.250 | 0.950 | 0.650 | 0.150 | 0.400 |

| Entrepreneurial Spirit | 0.852 | 0.389 | 0.630 | 0.370 | 0.593 | 0.556 | 0.185 | 0.519 |

3.4. Concerns and Recommendations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- World Health Organization (WHO). Investigating in Water and Sanitation: Increasing Access, Reducing Inequalities. Un-water Global Analysis and Assessment of Sanitation and Drinking Water; Glaas Report; WHO: Geneva, Switzerland, 2014. [Google Scholar]

- Brown, J.; Clasen, T. High adherence is necessary to realize health gains from water quality interventions. PLoS ONE 2012, 7. [Google Scholar] [CrossRef] [PubMed]

- U.S. Agency International Development (USAID). Bringing the Consumer to the Table: Perceptions and Practice of Household Water Treatment Methods in Nepal; Hygiene Improvement Project (HIP); Academy for Educational Development: Washington, DC, USA, 2006.

- Clasen, T. Scaling up Household Water Treatment among Low-income Populations; World Health Organization: Geneva, Switzerland, 2009. [Google Scholar]

- Rice, P.M. Pottery Analysis; University of Chicago Press: Chicago, IL, USA, 1987. [Google Scholar]

- Cooper, E. Ten Thousand Years of Pottery; University of Pennsylvania Press: Philadelphia, PA, USA, 2000. [Google Scholar]

- Hayes, J.W. Late Roman Pottery; British School at Rome: Rome, Italy, 1970; Volume 38. [Google Scholar]

- Lantagne, D.; Klarman, M.; Mayer, A.; Preston, K.; Napotnik, J.; Jellison, K. Effect of production variables on microbiological removal in locally-produced ceramic filters for household water treatment. Int. J. Environ. Health Res. 2010, 20, 171–187. [Google Scholar] [CrossRef] [PubMed]

- Oyanedel-Craver, V.A.; Smith, J.A. Sustainable colloidal-silver-impregnated ceramic filter for point-of-use water treatment. Environ. Sci. Technol. 2008, 42, 927–933. [Google Scholar] [CrossRef] [PubMed]

- Ron Rivera. Available online: http://www.thelancet.com/pdfs/journals/lancet/PIIS0140-6736%2808%2961859-0.pdf (accessed on 6 July 2015).

- Brown, J.; Sobsey, M.D. Microbiological effectiveness of locally produced ceramic filters for drinking water treatment in cambodia. J. Water Health 2010, 8, 1–10. [Google Scholar] [CrossRef] [PubMed]

- VillageForward. Available online: http: //www.villageforward.com (accessed on 26 November 2014).

- Anderson, J.; Billou, N. Serving the world’s poor: Innovation at the base of the economic pyramid. J. Bus. Strategy 2007, 28, 14–21. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Standards of Good Practice in Qualitative Comparative Analysis (QCA) and Fuzzy-Sets. Available online: http://www.compasss.org/wpseries/WagemannSchneider2007.pdf (acessed on 6 July 2015).

- Rihoux, B. Qualitative comparative analysis (QCA) and related systematic comparative methods: Recent advances and remaining challenges for social science research. Int. Soc. 2006, 21, 679–706. [Google Scholar] [CrossRef]

- Rihoux, B. Bridging the gap between the qualitative and quantitative worlds? A retrospective and prospective view on qualitative comparative analysis. Field Methods 2003, 15, 351–365. [Google Scholar]

- Scouvart, M.; Adams, R.; Caldas, M.; Dale, V.; Mertens, B.; Nedelec, V.; Pacheco, P.; Rihoux, B.; Lambin, E.F. Causes of deforestation in the brazilian amazon: A qualitative comparative analysis. J. Land Use Sci. 2007, 2, 257–282. [Google Scholar] [CrossRef]

- Fischer, M. Institutions and coalitions in policy processes: A cross-sectoral comparison. J. Public Policy 2014, 35, 1–24. [Google Scholar] [CrossRef]

- Kitchener, M.; Beynon, M.; Harrington, C. Qualitative comparative analysis and public services research: Lessons from an early application. Public Manag. Rev. 2002, 4, 485–504. [Google Scholar] [CrossRef]

- Vanderborght, Y.; Yamasaki, S. Des cas logiques contradictoires? Un piège de l’aqqc déjoué à travers l’étude de la faisabilité politique de l’allocation universelle. Rev. Int. Polit. Comp. 2004, 11, 51–66. [Google Scholar] [CrossRef]

- Brueggemann, J.; Boswell, T. Realizing solidarity: Sources of interracial unionism during the great depression. Work Occup. 1998, 25, 436–482. [Google Scholar] [CrossRef]

- Hellström, E. Conflict Cultures: Qualitative Comparative Analysis of Environmental Conflicts in Forestry; The Finnish Society of Forest Science/The Finnish Forest Research Institute: Helsinki, Finland, 2001. [Google Scholar]

- Ragin, C.C. The Comparative Method: Moving beyond Qualitative and Quantitative Strategies; University California Press: Berkeley, CA, USA, 1987. [Google Scholar]

- Ragin, C.C. Set relations in social research: Evaluating their consistency and coverage. Polit. Anal. 2006, 14, 291–310. [Google Scholar] [CrossRef]

- Srinivasan, V.; Lambin, E.F.; Gorelick, S.M.; Thompson, B.H.; Rozelle, S. The nature and causes of the global water crisis: Syndromes from a meta-analysis of coupled human-water studies. Water Resour. Res. 2012, 48. [Google Scholar] [CrossRef]

- Schneider, C.Q.; Wagemann, C. Standards of good practice in qualitative comparative analysis (QCA) and fuzzy-sets. Comp. Sociol. 2010, 9, 397–418. [Google Scholar] [CrossRef]

- Ragin, C.C. Qualitative comparative analysis using fuzzy sets (FSQCA). In Configurational Comparative Analysis; Rihoux, B., Ragin, C.C., Eds.; Sage Publications: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Mosler, H.J. A systematic approach to behavior change interventions for the water and sanitation sector in developing countries: A conceptual model, a review, and a guideline. Int. J. Environ. Health Res. 2012, 22, 431–449. [Google Scholar] [CrossRef] [PubMed]

- Mosler, H.J.; Kraemer, S. Which psychological factors change when habitual water treatment practices alter? J. Public Health (Germany) 2012, 20, 71–79. [Google Scholar] [CrossRef]

- Evans, W.D.; Pattanayak, S.K.; Young, S.; Buszin, J.; Rai, S.; Bihm, J.W. Social marketing of water and sanitation products: A systematic review of peer-reviewed literature. Soc. Sci. Med. 2014, 110, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Crittenden, J.C. Mwh’s Water Treatment: Principles and Design; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Kallman, E.N.; Oyanedel-Craver, V.A.; Smith, J.A. Ceramic filters impregnated with silver nanoparticles for point-of-use water treatment in rural guatemala. J. Environ. Eng. 2011, 137, 407–415. [Google Scholar] [CrossRef]

- Access to Safe Water for the Base of the Pyramid. Available online: http://hystra.com/safe-water (accessed on 2 July 2015).

- PATH. Perspectives. Commercial Approaches to Delivering Household Water Treatment and Safe Storage Products and Solutions to Low-income Households; Program for Appropriate Technology in Health: Seattle, WA, USA, 2012. [Google Scholar]

- Gero, A.; Carrard, N.; Murta, J.; Willetts, J. Private and social enterprise roles in water, sanitation and hygiene for the poor: A systematic review. J. Water Sanit. Hyg. for Dev. 2014, 4, 331–345. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogler, A.; Meierhofer, R. The Challenge of Producing and Marketing Colloidal Silver Water Filters in Nepal. Water 2015, 7, 3599-3612. https://doi.org/10.3390/w7073599

Bogler A, Meierhofer R. The Challenge of Producing and Marketing Colloidal Silver Water Filters in Nepal. Water. 2015; 7(7):3599-3612. https://doi.org/10.3390/w7073599

Chicago/Turabian StyleBogler, Anne, and Regula Meierhofer. 2015. "The Challenge of Producing and Marketing Colloidal Silver Water Filters in Nepal" Water 7, no. 7: 3599-3612. https://doi.org/10.3390/w7073599