Multi-Objective Design of a Horizontal Flow Subsurface Wetland

Abstract

:1. Introduction

2. HFSW Behavior Model

2.1. Behavior Equations

2.2. Objective Functions

2.3. Design Variables and Constraints

2.3.1. Design Variables

2.3.2. Constraints

3. Multi-Objective HFSW Design Methodology

4. Numerical Results

4.1. Found Solutions

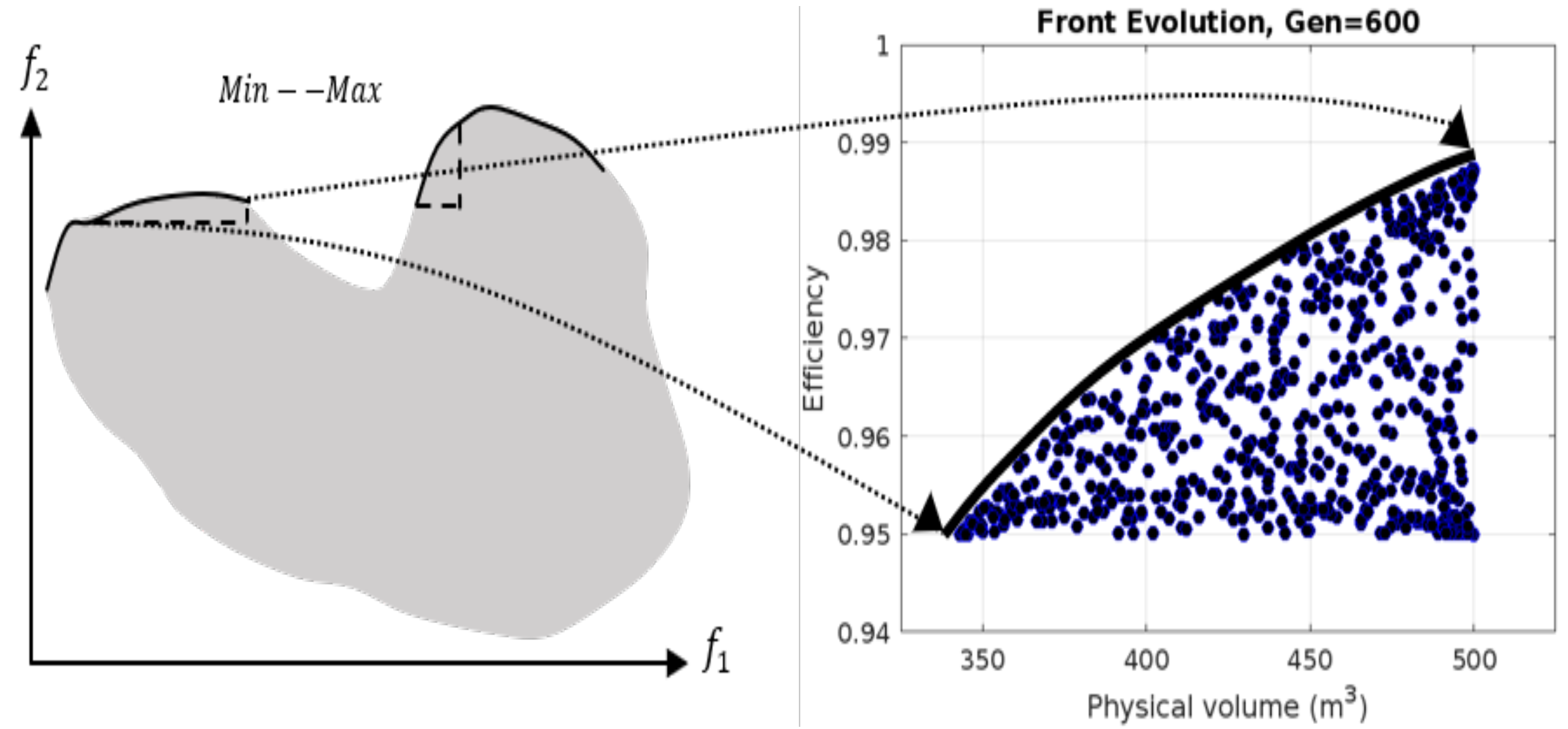

4.2. Pareto Front

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stefanakis, A.I. The Role of Constructed Wetlands as Green Infrastructure for Sustainable Urban Water Management. Sustainability 2019, 11, 6981. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Kumar, P. Constructed Wetland: A Green Technology for Wastewater Treatment. In Environmental Microbiology and Biotechnology: Volume 1: Biovalorization of Solid Wastes and Wastewater Treatment; Singh, A., Srivastava, S., Rathore, D., Pant, D., Eds.; Springer: Singapore, 2020; pp. 335–363. [Google Scholar] [CrossRef]

- Cheng, H.; Kim, S.; Hyun, J.H.; Choi, J.; Cho, Y.; Park, C. A multi-objective spatial optimization of wetland for Sponge City in the plain, China. Ecol. Eng. 2024, 198, 107147. [Google Scholar] [CrossRef]

- Fonseca-Castro, M. Diseño de Humedal Construido para Tratar los Lixiviados del Proyecto de Relleno Sanitario de Pococí; 2010. Available online: https://repositoriotec.tec.ac.cr/handle/2238/6158 (accessed on 17 February 2024).

- Núñez Burga, R.M.F. Tratamiento de Aguas Residuales Domésticas a Nivel Familiar, con Humedales Artificiales de flujo Subsuperficial Horizontal, Mediante la Especie Macrófita Emergente Cyperus Papyrus (Papiro). 2016. Available online: https://repositorio.upeu.edu.pe/handle/20.500.12840/555 (accessed on 17 February 2024).

- Konak, A.; Coit, D.W.; Smith, A.E. Multi-objective optimization using genetic algorithms: A tutorial. Reliab. Eng. Syst. Saf. 2006, 91, 992–1007. [Google Scholar] [CrossRef]

- Yusoff, Y.; Ngadiman, M.S.; Zain, A.M. Overview of NSGA-II for Optimizing Machining Process Parameters. Procedia Eng. 2011, 15, 3978–3983. [Google Scholar] [CrossRef]

- Ikenberry, C.; Darling, J.; Talley, C.; Williams, J.; McPeak, J.; Gilmore, S.; Steck, D.; LaFreniere, L.; Ruhge, T. A Multi-Objective Water Quality Wetland to Complement Phytoremediation of Contaminated Groundwater. In Proceedings of the World Environmental and Water Resource Congress 2006, Omaha, Nebraska, 21–25 May 2006; pp. 1–11. [Google Scholar] [CrossRef]

- Huang, J.J.; Gao, X.; Balch, G.; Wootton, B.; Jørgensen, S.E.; Anderson, B. Modelling of vertical subsurface flow constructed wetlands for treatment of domestic sewage and stormwater runoff by subwet 2.0. Ecol. Eng. 2015, 74, 8–12. [Google Scholar] [CrossRef]

- Andreo-Martínez, P.; García-Martínez, N.; Almela, L. Domestic Wastewater Depuration Using a Horizontal Subsurface Flow Constructed Wetland and Theoretical Surface Optimization: A Case Study under Dry Mediterranean Climate. Water 2016, 8, 434. [Google Scholar] [CrossRef]

- Liao, R.; Jin, Z.; Chen, M.; Li, S. An integrated approach for enhancing the overall performance of constructed wetlands in urban areas. Water Res. 2020, 187, 116443. [Google Scholar] [CrossRef]

- López-Linares, E.; Rodríguez-Álvarez, M. Evaluación de un Humedal Artificial de Flujo Subsuperficial Como Tratamiento de Agua Residual Doméstica en la Vereda Bajos de Yerbabuena en el Municipio de Chía, Cundinamarca. Master’s Thesis, Instituto Tecnológico de Costa Rica Escuela de Ingeniería en Construcción, Costa Rica, Universidad de la Salle Facultad de Ingeniería Ambiental y Sanitaria, Bogotá, Colombia, 2016. [Google Scholar]

- Dotro, G.; Langergraber, G.; Molle, P.; Nivala, J.; Puigagut, J.; Stein, O.; Von Sperling, M. Humedales para Tratamiento; Biological Wastewater Treatment Series; IWA Publishing: London UK, 2021. [Google Scholar]

- Farid, M.; Lim, H.S.; Lee, C.P.; Latip, R. Scheduling Scientific Workflow in Multi-Cloud: A Multi-Objective Minimum Weight Optimization Decision-Making Approach. Symmetry 2023, 15, 2047. [Google Scholar] [CrossRef]

- Corporación Centro de Investigación en Palma de Aceite; Gonzalez, A.; Rodríguez, N.; García, A.; Ruiz, E.; Acero, J. Humedales Artificiales Como Alternativa para el Tratamiento Terciario de Efluentes de Planta de Beneficio de Palma de Aceite. 2022. Available online: https://repositorio.fedepalma.org/handle/123456789/141561 (accessed on 17 February 2024).

- CONAGUA. Manual de Agua Potable, Alcantarillado y Saneamiento Diseño de Plantas de Tratamiento de Aguas Residuales Municipales: Zonas Rurales, Periurbanas y Desarrollos Ecoturísticos. Available online: https://agua.org.mx/biblioteca/manual-de-agua-potable-alcantarillado-y-saneamiento/ (accessed on 17 February 2024).

- Val del Río, Á.; Campos Gómez, J.; Mosquera Corral, A. Technologies for the Treatment and Recovery of Nutrients from Industrial Wastewater; Advances in Environmental Engineering and Green Technologies (2326-9162); IGI Global: Hershey, PA, USA, 2016. [Google Scholar]

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; Wiley Interscience Series in Systems and Optimization; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- MathWorks®. Matlab Online. 2024. Available online: https://la.mathworks.com/products/matlab-online.html (accessed on 17 February 2024).

| Design Variable | Literature | This Work | Units |

|---|---|---|---|

| t | 4–15 1, 2–7 2,3 | 1–60 | d |

| W | 1–61 2 | 20–100 | m |

| L | 1–15 2 | 20–100 | m |

| 0.46–0.76 1, 0.5–0.6 2 | 0.7–10 | m | |

| 0.061–0.3 1, 0.4–0.5 2 | 0.1–0.8 | m | |

| s | 0.5–1 1 | 0–1 | % |

| Objectives | Design Variables | Constraints | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | G | t | W | L | s | (7) | (8) | (9) | ||||

| 200 | 200 | 0.986 | 497.249 | 16.371 | 57.690 | 85.842 | 0.121 | 1.983 | 0.205 | 0.036 | 2.751 | 87.228 |

| 0.960 | 445.689 | 12.249 | 58.355 | 91.402 | 0.125 | 1.993 | 0.241 | 0.010 | 54.311 | 83.664 | ||

| 0.952 | 365.519 | 11.551 | 57.281 | 89.345 | 0.125 | 1.972 | 0.209 | 0.002 | 134.481 | 82.499 | ||

| 0.954 | 415.011 | 11.715 | 58.005 | 84.922 | 0.128 | 1.939 | 0.208 | 0.004 | 84.989 | 89.092 | ||

| 400 | 400 | 0.964 | 420.480 | 12.671 | 75.585 | 91.314 | 0.102 | 1.999 | 0.258 | 0.013 | 79.520 | 135.442 |

| 0.983 | 484.063 | 15.568 | 70.908 | 86.127 | 0.101 | 1.998 | 0.249 | 0.033 | 15.937 | 126.599 | ||

| 0.952 | 399.941 | 11.602 | 71.475 | 87.568 | 0.103 | 1.925 | 0.266 | 0.002 | 100.059 | 126.857 | ||

| 0.958 | 401.298 | 12.125 | 73.624 | 89.531 | 0.101 | 2.000 | 0.265 | 0.008 | 98.702 | 131.339 | ||

| 600 | 600 | 0.970 | 448.090 | 13.357 | 30.290 | 78.446 | 0.100 | 2.000 | 0.574 | 0.020 | 51.911 | 12.423 |

| 0.957 | 489.734 | 12.036 | 35.909 | 77.218 | 0.100 | 1.998 | 0.582 | 0.007 | 10.266 | 30.508 | ||

| 0.968 | 401.445 | 13.122 | 27.446 | 74.869 | 0.100 | 2.000 | 0.556 | 0.018 | 98.555 | 7.468 | ||

| 0.970 | 422.962 | 13.384 | 26.367 | 74.646 | 0.101 | 2.000 | 0.589 | 0.020 | 77.038 | 4.455 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendez-Valencia, J.; Sánchez-López, C.; Reyes-Pérez, E. Multi-Objective Design of a Horizontal Flow Subsurface Wetland. Water 2024, 16, 1253. https://doi.org/10.3390/w16091253

Mendez-Valencia J, Sánchez-López C, Reyes-Pérez E. Multi-Objective Design of a Horizontal Flow Subsurface Wetland. Water. 2024; 16(9):1253. https://doi.org/10.3390/w16091253

Chicago/Turabian StyleMendez-Valencia, Jhonatan, Carlos Sánchez-López, and Eneida Reyes-Pérez. 2024. "Multi-Objective Design of a Horizontal Flow Subsurface Wetland" Water 16, no. 9: 1253. https://doi.org/10.3390/w16091253