Continuous-Flow Grafting of LENFLOC™ Coagulant for Water Treatment toward Circular Economy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Location of Research

2.2. Methods

2.2.1. Continuous-Flow Grafting of LENFLOC™ Using a Microwave-Assisted Copolymerisation Method

2.2.2. Experimental Design for the Optimisation of Continuous-Flow Grafting (CFG) Process

2.2.3. Characterisation Studies of Lentil Waste Extract (LWE) and Continuous-Flow Grafted LENFLOC™

2.2.4. Turbidity Test Assay Using Continuous Flow Grafted LENFLOC™

3. Results

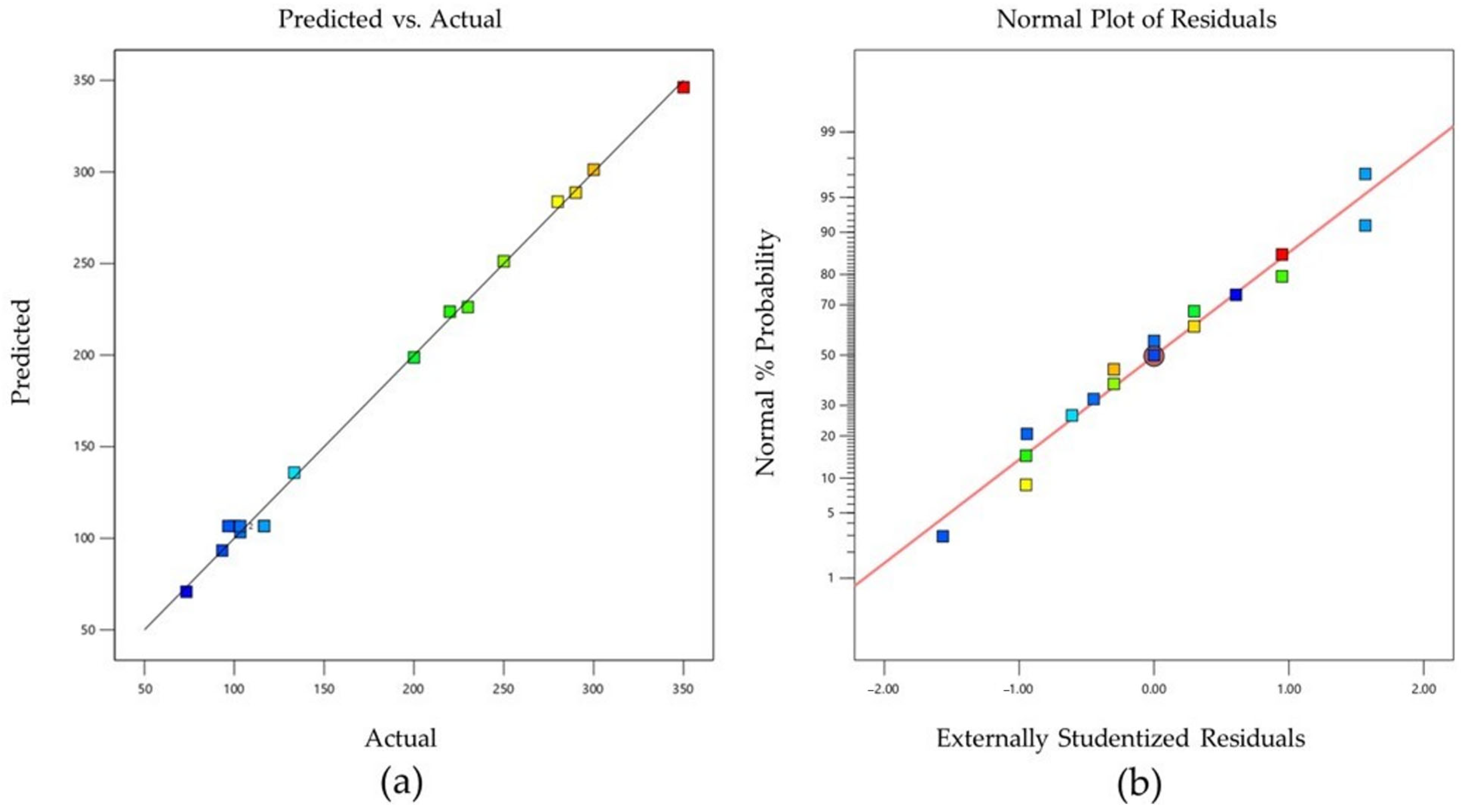

3.1. Experimental Design for Optimisation of the Continuous-Flow Grafting Process

3.2. Characterisation of Physicochemical Properties of Continuous Flow Grafted LENFLOC™

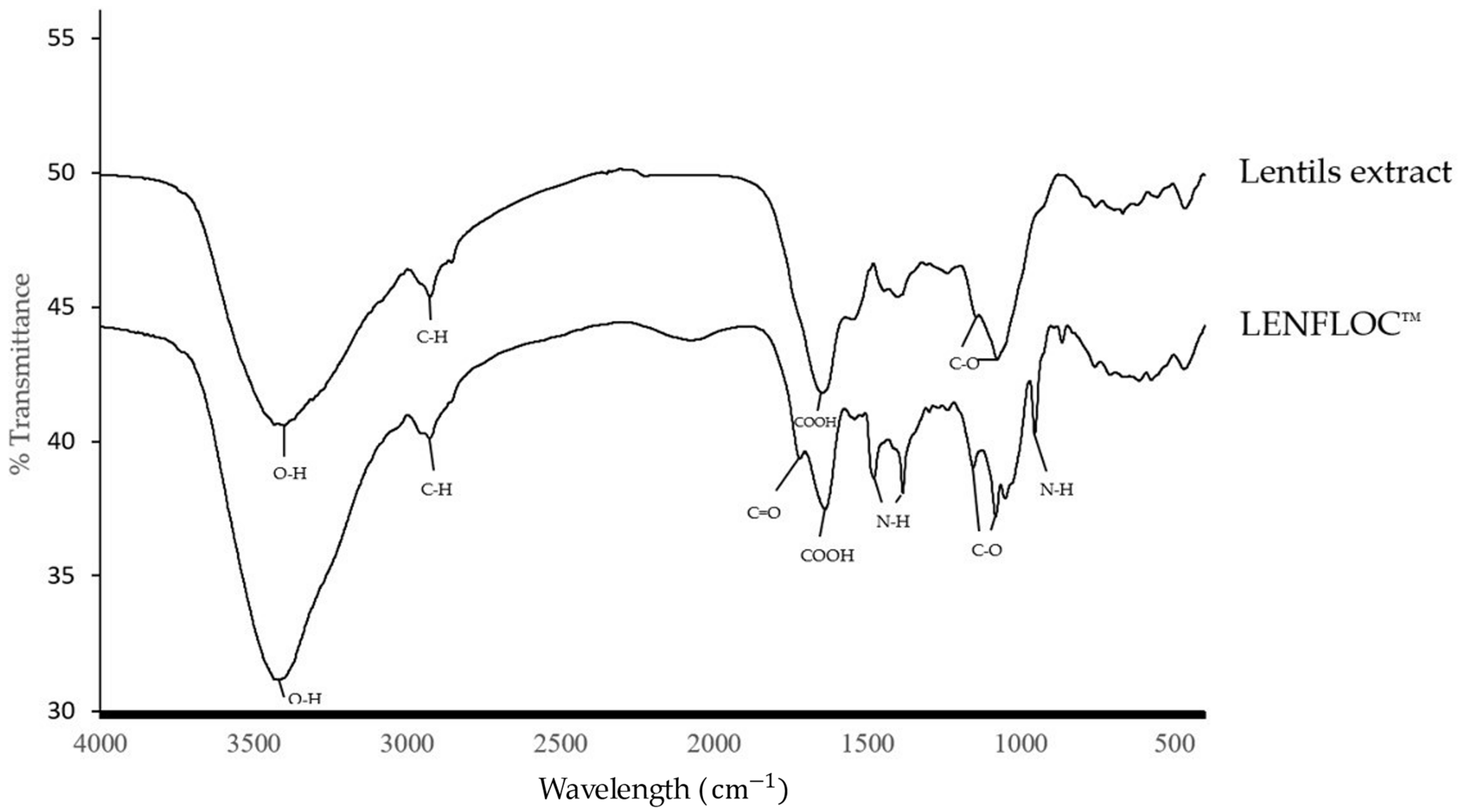

3.2.1. Fourier Transform Infrared Spectroscopy (FTIR) Analysis Was Performed to Identify Functional Groups Present in LENFLOC™, and LWE Was Used to Identify Any Change after the Grafting Process

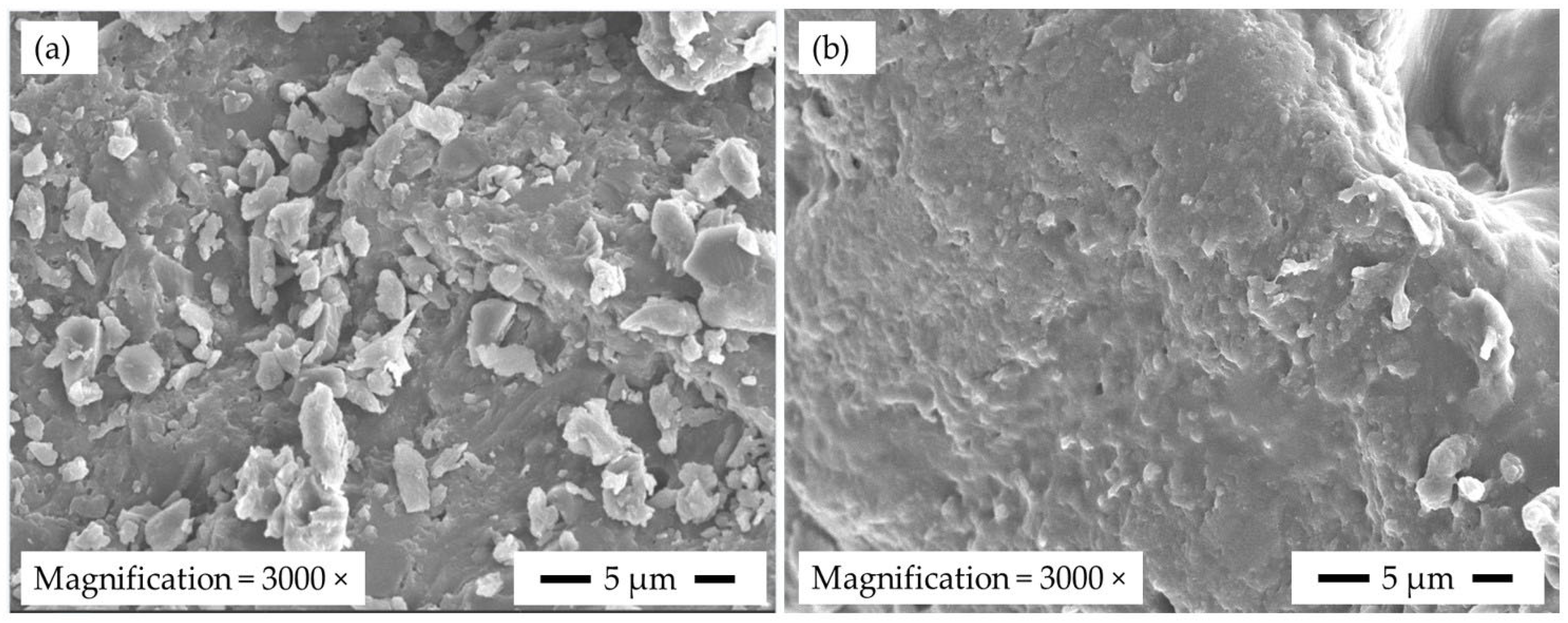

3.2.2. Scanning Electron Microscopy (SEM) Was Conducted to Observe Surface Morphology and Changes in Surface Morphology after the Grafting Process

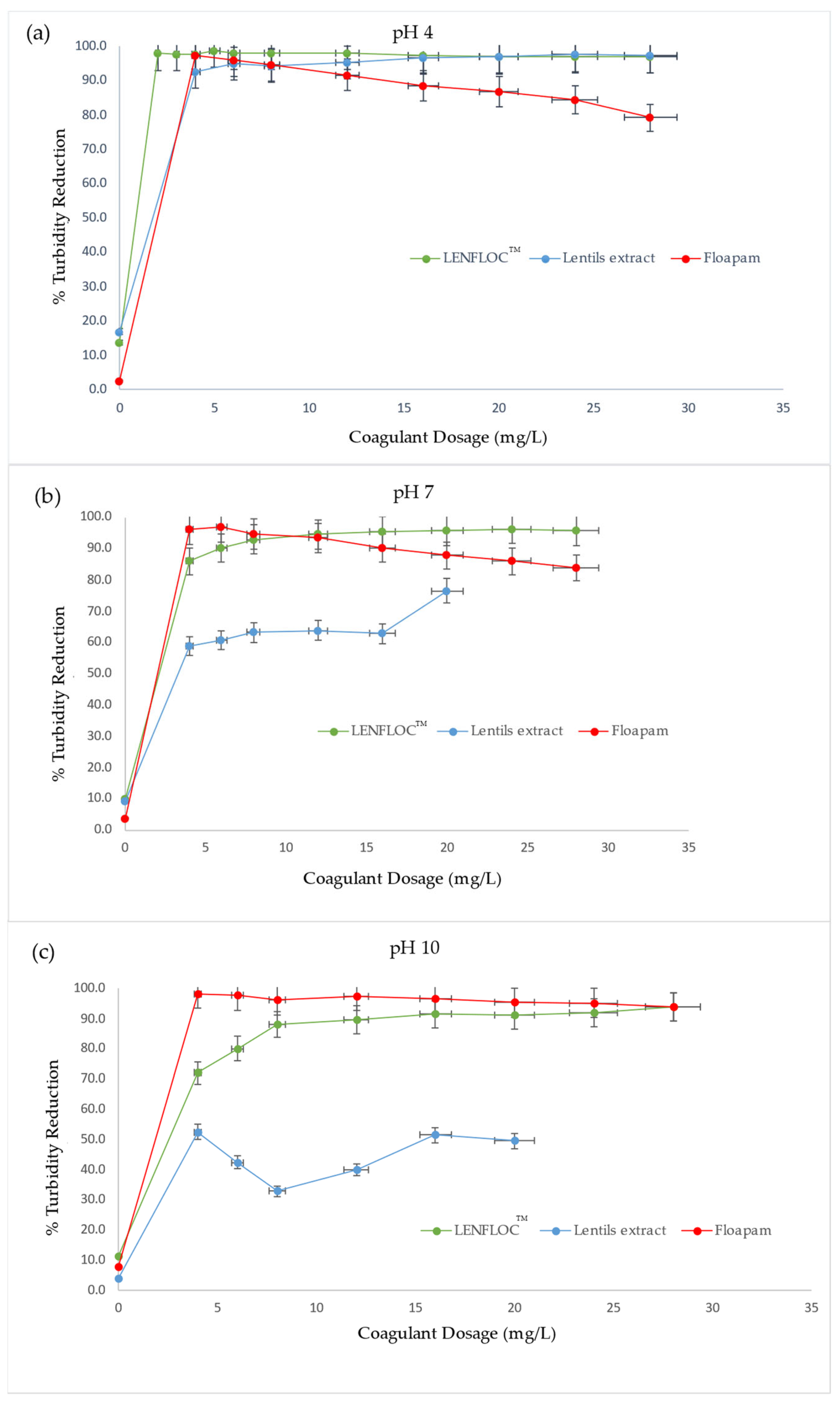

3.3. Comparison Study of Continuous-Flow-Grafted LENFLOC™, Lentil Waste Extract (LWE) and Polymer as Coagulants

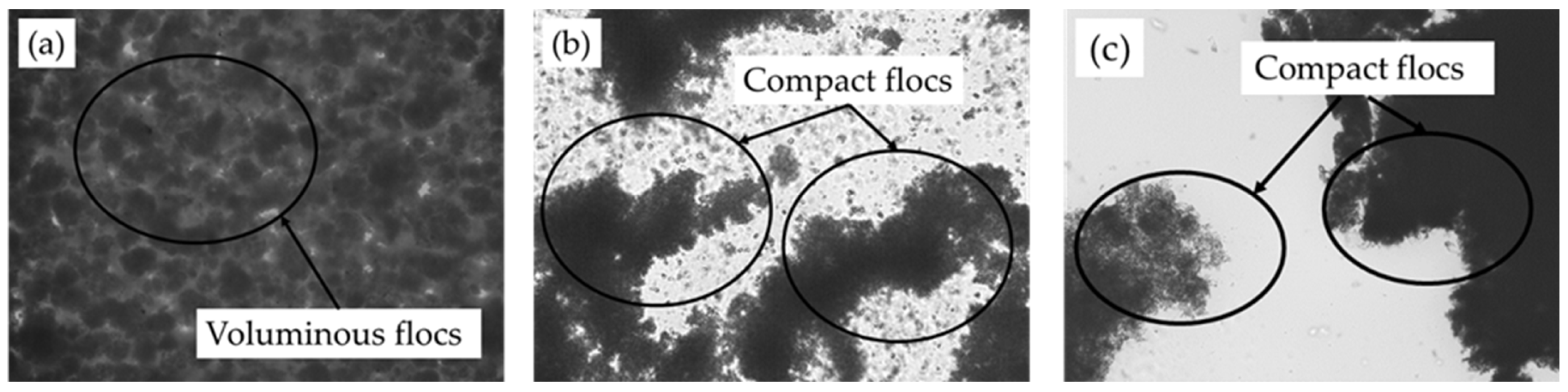

Evaluation of Flocs Produced by LWE and LENFLOC™ as Coagulants

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chauhan, C.; Parida, V.; Dhir, A. Linking circular economy and digitalisation technologies: A systematic literature review of past achievements and future promises. Technol. Forecast. Soc. Chang. 2022, 177, 121508. [Google Scholar] [CrossRef]

- Mazur-Wierzbicka, E. Towards Circular Economy—A Comparative Analysis of the Countries of the European Union. Resources 2021, 10, 49. [Google Scholar] [CrossRef]

- Mazur-Wierzbicka, E. Circular economy: Advancement of European Union countries. Environ. Sci. Eur. 2021, 33, 111. [Google Scholar] [CrossRef]

- Talens Peiro, L.; Polverini, D.; Ardente, F.; Mathieux, F. Advances towards circular economy policies in the EU: The new Ecodesign regulation of enterprise servers. Resour. Conserv. Recycl. 2020, 154, 104426. [Google Scholar] [CrossRef]

- Foundation, E.M. What Is Circular Economy? Ellen MacArthur Foundation. 2021. Available online: https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed on 20 March 2023).

- Morseletto, P.; Mooren, C.E.; Munaretto, S. Circular Economy of Water: Definition, Strategies and Challenges. Circ. Econ. Sustain. 2022, 2, 1463–1477. [Google Scholar] [CrossRef]

- Ghimire, U.; Sarpong, G.; Gude, V.G. Transitioning Wastewater Treatment Plants toward Circular Economy and Energy Sustainability. ACS Omega 2021, 6, 11794–11803. [Google Scholar] [CrossRef]

- Mannina, G.; Badalucco, L.; Barbara, L.; Cosenza, A.; Di Trapani, D.; Gallo, G.; Laudicina, V.; Marino, G.; Muscarella, S.; Presti, D.; et al. Enhancing a Transition to a Circular Economy in the Water Sector: The EU Project WIDER UPTAKE. Water 2021, 13, 946. [Google Scholar] [CrossRef]

- Qtaishat, Y.; Hofman, J.; Adeyeye, K. Circular Water Economy in the EU: Findings from Demonstrator Projects. Clean Technol. 2022, 4, 865–892. [Google Scholar] [CrossRef]

- Bourguignon, D. Nature-Based Solutions Concept, Opportunities, and Challenges; EPRS|European Parliamentary Research Service, European Parliament: Brussels, Belgium, 2017. Available online: http://www.europarl.europa.eu/thinktank/ (accessed on 23 January 2023).

- Carvalho, P.N.; Finger, D.C.; Masi, F.; Cipolletta, G.; Oral, H.V.; Tóth, A.; Regelsberger, M.; Exposito, A. Nature-based solutions addressing the water-energy-food nexus: Review of theoretical concepts and urban case studies. J. Clean. Prod. 2022, 338, 130652. [Google Scholar] [CrossRef]

- Castellar, J.A.C.; Torrens, A.; Buttiglieri, G.; Monclús, H.; Arias, C.A.; Carvalho, P.N.; Galvao, A.; Comas, J. Nature-based solutions coupled with advanced technologies: An opportunity for decentralized water reuse in cities. J. Clean. Prod. 2022, 340, 130660. [Google Scholar] [CrossRef]

- Faivre, N.; Fritz, M.; Freitas, T.; de Boissezon, B.; Vandewoestijne, S. Nature-Based Solutions in the EU: Innovating with nature to address social, economic and environmental challenges. Environ. Res. 2017, 159, 509–518. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, C.S.S.; Potočki, K.; Kapović-Solomun, M.; Kalantari, Z. Nature-Based Solutions for Flood Mitigation and Resilience in Urban Areas. In Nature-Based Solutions for Flood Mitigation: Environmental and Socio-Economic Aspects; Ferreira, C.S.S., Kalantari, Z., Hartmann, T., Pereira, P., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 59–78. [Google Scholar] [CrossRef]

- Tijjani Usman, I.M.; Lee, F.-W.; Ho, Y.-C.; Khaw, H.-P.; Chong, Q.-W.; Kee, Y.-M.; Lim, J.-W.; Show, P.-L. Evaluation of Annona diversifolia Seed Extract as A Natural Coagulant for Water Treatment. Sustainability 2023, 15, 6324. [Google Scholar] [CrossRef]

- Bratby, J. Coagulation and flocculation in water and wastewater treatment. In Coagulation and Flocculation in Water and Wastewater Treatment; IWA Publishing: London, UK, 2016. [Google Scholar] [CrossRef]

- Chua, S.-C.; Show, P.L.; Chong, F.K.; Ho, Y.-C. Lentil waste as a novel natural coagulant for agricultural wastewater treatment. Water Sci. Technol. 2020, 82, 1833–1847. [Google Scholar] [CrossRef] [PubMed]

- Chua, S.C.; Chong, F.K.; Ul Mustafa, M.R.; Mohamed Kutty, S.R.; Sujarwo, W.; Abdul Malek, M.; Show, P.L.; Ho, Y.C. Microwave radiation-induced grafting of 2-methacryloyloxyethyl trimethyl ammonium chloride onto LWE (LE-g-DMC) as an emerging high-performance plant-based grafted coagulant. Sci. Rep. 2020, 10, 3959. [Google Scholar] [CrossRef] [Green Version]

- Shahbazi, F.; Valizade, S.; Dowlatshah, A. Mechanical damage to green and red lentil seeds. Food Sci. Nutr. 2017, 5, 943–947. [Google Scholar] [CrossRef]

- Zhang, X.-W.; Lan, M.-Y.; Wang, F.; Wang, C.-C.; Wang, P.; Ge, C.; Liu, W. Immobilized N-C/Co derived from ZIF-67 as PS-AOP catalyst for effective tetracycline matrix elimination: From batch to continuous process. J. Chem. Eng. 2022, 450, 138082. [Google Scholar] [CrossRef]

- Wiles, C.; Watts, P. Continuous process technology: A tool for sustainable production. Green Chem. 2014, 16, 55–62. [Google Scholar] [CrossRef]

- Glasnov, T.N.; Kappe, C.O. Microwave-Assisted Synthesis under Continuous-Flow Conditions. Macromol. Rapid Commun. 2007, 28, 395–410. [Google Scholar] [CrossRef]

- Baumann, M.; Moody, T.S.; Smyth, M.; Wharry, S. A Perspective on Continuous Flow Chemistry in the Pharmaceutical Industry. Org. Process Res. Dev. 2020, 24, 1802–1813. [Google Scholar] [CrossRef]

- Bennett, J.A.; Campbell, Z.S.; Abolhasani, M. Role of continuous flow processes in green manufacturing of pharmaceuticals and specialty chemicals. Curr. Opin. Chem. Eng. 2019, 26, 9–19. [Google Scholar] [CrossRef]

- Dallinger, D.; Kappe, C.O. Why flow means green—Evaluating the merits of continuous processing in the context of sustainability. Curr. Opin. Green Sustain. Chem. 2017, 7, 6–12. [Google Scholar] [CrossRef]

- Montgomery, D.C. Response Surface Methods and Designs. In Design and Analysis of Experiments; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; pp. 489–558. [Google Scholar]

- APHA; AWWA; WEF. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1999. [Google Scholar]

- Aronhime, S.; Calcagno, C.; Jajamovich, G.H.; Dyvorne, H.A.; Robson, P.; Dieterich, D.; Fiel, M.I.; Martel-Laferriere, V.; Chatterji, M.; Rusinek, H.; et al. DCE-MRI of the liver: Effect of linear and nonlinear conversions on hepatic perfusion quantification and reproducibility. J. Magn. Reson. Imaging 2014, 40, 90–98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cilluffo, G.; Zicari, A.M.; Ferrante, G.; Malizia, V.; Fasola, S.; Duse, M.; De Castro, G.; De Vittori, V.; Schiavi, L.; Brindisi, G.; et al. Assessing repeatability and reproducibility of Anterior Active Rhinomanometry (AAR) in children. BMC Med. Res. Methodol. 2020, 20, 86. [Google Scholar] [CrossRef] [Green Version]

- Campbell, M.J.; Walters, S.J.; Machin, D. Medical Statistics: A Textbook for the Health Sciences, 4th ed.; Wiley: Hoboken, NJ, USA, 2007; Available online: http://www.dawsonera.com/depp/reader/protected/external/AbstractView/S9780470976630 (accessed on 3 May 2023).

- Carney, A.S.; Bateman, N.D.; Jones, N.S. Reliable and reproducible anterior active rhinomanometry for the assessment of unilateral nasal resistance. Clin. Otolaryngol. Allied Sci. 2000, 25, 499–503. [Google Scholar] [CrossRef]

- Thulesius, H.L.; Cervin, A.; Jessen, M. Can we always trust rhinomanometry? Rhinology 2011, 49, 46–52. [Google Scholar] [CrossRef]

- Aziz, H.A.; Rahim, N.A.; Ramli, S.F.; Alazaiza, M.Y.D.; Omar, F.M.; Hung, Y.-T. Potential Use of Dimocarpus longan Seeds as a Flocculant in Landfill Leachate Treatment. Water 2018, 10, 1672. [Google Scholar] [CrossRef] [Green Version]

- Chua, S.-C.; Malek, M.A.; Chong, F.-K.; Sujarwo, W.; Ho, Y.-C. Red Lentil (Lens culinaris) Extract as a Novel Natural Coagulant for Turbidity Reduction: An Evaluation, Characterization, and Performance Optimization Study. Water 2019, 11, 1686. [Google Scholar] [CrossRef] [Green Version]

- Bello, O.S.; Adegoke, K.A.; Akinyunni, O.O. Preparation and characterization of a novel adsorbent from Moringa oleifera leaf. Appl. Water Sci. 2017, 7, 1295–1305. [Google Scholar] [CrossRef] [Green Version]

- Choong Lek, B.L.; Peter, A.P.; Qi Chong, K.H.; Ragu, P.; Sethu, V.; Selvarajoo, A.; Arumugasamy, S.K. Treatment of palm oil mill effluent (POME) using chickpea (Cicer arietinum) as a natural coagulant and flocculant: Evaluation, process optimization and characterization of chickpea powder. J. Environ. Chem. Eng. 2018, 6, 6243–6255. [Google Scholar] [CrossRef]

- Xu, Y.; Gan, K.; Liang, S.; Liu, H.; Wang, Q. Investigation and Optimization of Chitosan Performance in Flocculating Kaolin Suspensions Using a Real-Time Suspending Solid Concentration Measuring Method. Water 2021, 13, 513. [Google Scholar] [CrossRef]

- Xiong, B.; Loss, R.D.; Shields, D.; Pawlik, T.; Hochreiter, R.; Zydney, A.L.; Kumar, M. Polyacrylamide degradation and its implications in environmental systems. NPJ Clean Water 2018, 1, 17. [Google Scholar] [CrossRef]

- Al Momani, F.A.; Örmeci, B. Measurement of polyacrylamide polymers in water and wastewater using an in-line UV–vis spectrophotometer. J. Environ. Chem. Eng. 2014, 2, 765–772. [Google Scholar] [CrossRef]

- Tran, T.V.; Nguyen, D.T.C.; Nguyen, T.T.T.; Nguyen, D.H.; Alhassan, M.; Jalil, A.A.; Nabgan, W.; Lee, T. A critical review on pineapple (Ananas comosus) wastes for water treatment, challenges, and future prospects towards circular economy. Sci. Total Environ. 2023, 856 Pt 1, 158817. [Google Scholar] [CrossRef] [PubMed]

| Significant Factors | Units | Coded Symbols | Range and Level | ||

|---|---|---|---|---|---|

| Low | Centre Point | High | |||

| DMC dosage | g | X1 | 0.5 | 2.75 | 5 |

| Microwave power | W | X2 | 400 | 500 | 600 |

| Dilution ratio | X3 | 0.5 | 0.75 | 1 | |

| Source | Sum of Squares | Mean Square | F-Value | p-Value | Significancy |

|---|---|---|---|---|---|

| Model | 1.286 × 105 | 14,284.31 | 232.19 | <0.0001 | Significant |

| DMC dosage (X1) | 1512.50 | 1512.50 | 24.59 | 0.0016 | |

| Microwave power (X2) | 2812.50 | 2812.50 | 45.72 | 0.0003 | |

| Dilution (X3) | 1250.00 | 1250.00 | 20.32 | 0.0028 | |

| X1X2 | 25.00 | 25.00 | 0.4064 | 0.5441 | |

| X1X3 | 0.0000 | 0.0000 | 0.0000 | 1.0000 | |

| X2X3 | 400.00 | 400.00 | 6.50 | 0.0381 | |

| X12 | 7755.96 | 7755.96 | 126.07 | <0.0001 | |

| X22 | 5789.48 | 5789.48 | 94.11 | <0.0001 | |

| X32 | 1.095 × 105 | 1.095 × 105 | 1779.59 | <0.0001 | |

| Lack of Fit | 75.00 | 25.00 | 0.2812 | 0.8373 | Non-significant |

| DMC Dosage (gm) | Microwave Power (W) | Dilution | Predicted Value (%) | Experimental Value (%) | Coefficient of Variation |

|---|---|---|---|---|---|

| 0.500 | 500.000 | 0.500 | 223.750 | 210 | 4.55 |

| 2.750 | 400.000 | 0.500 | 288.750 | 320 | 3.17 |

| 2.750 | 600.000 | 1.000 | 301.250 | 330 | 5.13 |

| Weight (%) | ||

|---|---|---|

| Elements | Lentil Waste Extract (LWE) | LENFLOC™ |

| Ca | 0.04 | 0.02 |

| C | 45.94 | 51.48 |

| O | 33.05 | 25.79 |

| N | 16.62 | 14.18 |

| Cl | 0.31 | 7.88 |

| K | 3.01 | 0.18 |

| P | 1.02 | 0.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Usman, I.M.T.; Ho, Y.-C.; Lam, M.-K.; Show, P.-L.; Sujarwo, W. Continuous-Flow Grafting of LENFLOC™ Coagulant for Water Treatment toward Circular Economy. Water 2023, 15, 2484. https://doi.org/10.3390/w15132484

Usman IMT, Ho Y-C, Lam M-K, Show P-L, Sujarwo W. Continuous-Flow Grafting of LENFLOC™ Coagulant for Water Treatment toward Circular Economy. Water. 2023; 15(13):2484. https://doi.org/10.3390/w15132484

Chicago/Turabian StyleUsman, Ibrahim Muntaqa Tijjani, Yeek-Chia Ho, Man-Kee Lam, Pau-Loke Show, and Wawan Sujarwo. 2023. "Continuous-Flow Grafting of LENFLOC™ Coagulant for Water Treatment toward Circular Economy" Water 15, no. 13: 2484. https://doi.org/10.3390/w15132484