1. Introduction

Potable water is a scare natural resource, and its ongoing supply is one of most critical issues facing humanity today. Saltwater represents about 97.5% of the water resources on the earth and that make desalination technologies the sole reliable source for securing fresh water. Practitioners and researchers in this field are exerting great effort to enhance the performance of desalination systems because it is considered an energy intensive process [

1]. Combining a multi-effect desalination (MED) unit with thermal vapour compression (TVC) is an attractive choice for water production due to operating flexibility, fewer rotating parts, minimum corrosion risk and high effectiveness [

2]. The MED-TVC system reuses a portion of the energy extracted from the last effect through a thermo-compressor (steam ejector) to reduce the loss in the condenser and act as an energy source for the first effect [

3].

Two evaluation tools are used to assess the energy system’s performance; energy analysis based on the first law of thermodynamics and exergy analysis based on both the first and second laws of thermodynamics. The first law conserves energy but not exergy and the focus is on quality as well as quantity. Exergy analysis can identify the sources of the energy losses in the system, types and locations and suggests modifications to enhance system efficiency [

4,

5].

Hamed et al. were the first researchers to use exergy analysis to investigate the thermal performance of a four-stage MED-TVC plant located in the United Arab Emirates [

6]. The plant operated at low temperatures with a performance ratio of 6.5; exergy destruction had a maximum value at the first stage and in the thermo-compressor. A1-Najem et al. have confirmed that the maximum exergy destruction occurs in the first effect and in the thermo-compressor, due to high fuel exergy [

7]. Alasfour et al. presented a comparison study between three different configurations of ME-TVC [

8]. The results emphasised that the largest sources of irreversibilities occur in the thermo-compressor and evaporators, while the first effect constituted approximately 50% of the total exergy destruction.

Choi et al. performed an exergy analysis on a MED-TVC plant manufactured by Hyundai Heavy Industries (HHI) for different units with capacities of 4.5, 10, 16 and 20 million litres per day (1.0, 2.2, 3.5 and 4.4 MIGD—million imperial gallons per day) [

9]. The exergy destruction due to irreversibilities and exergy losses of the MED-TVC was evaluated in order to reveal potential plant efficiency improvements; results showed that 70% of the total exergy destruction occurred in the TVC and stages.

Samake et al. conducted parametric analysis of MED-TVC desalination systems based on the first and second laws of thermodynamics [

10]. Their findings confirmed the insensitivity of plant performance to concentration factor but that the ejector compression ratio played a great role in reducing the amount of required input thermal energy, and exergy destruction. These authors recommended a higher value for the compression ratio. Esfahani et al. performed an exergy analysis and optimization using a genetic algorithm based on a multi-objective function to minimize total annual cost and maximize the gain ratio (GR), the ratio of the distillate product to steam supplied to the desalination unit of the MED-TVC desalination system [

11]. The results show that maximum GR and minimum product cost was achieved by using the highest number of effects (six in total). This was later confirmed by Eshoul et al. [

12].

Recently, Alamolhoda et al. [

13] carried out a parametric analysis on the Kavian desalination unit, which consists of four stages with a total plant capacity of 192 ton per hour (about 4600 million litres per day). The Kavian desalination plant has 3.95% exergetic efficiency, which is considered low compared to other thermal applications. The major sources of irreversibilities occur in the thermo-compressor heater and evaporators.

Despite numerous studies being available in the literature for MED-TVC desalination systems, there has been no study exploring the impact of treating seawater as a real mixture and including the chemical exergy on performance. This paper will introduce a novel scheme for MED-TVC plant with preheating obtained from waste energy from the production line.

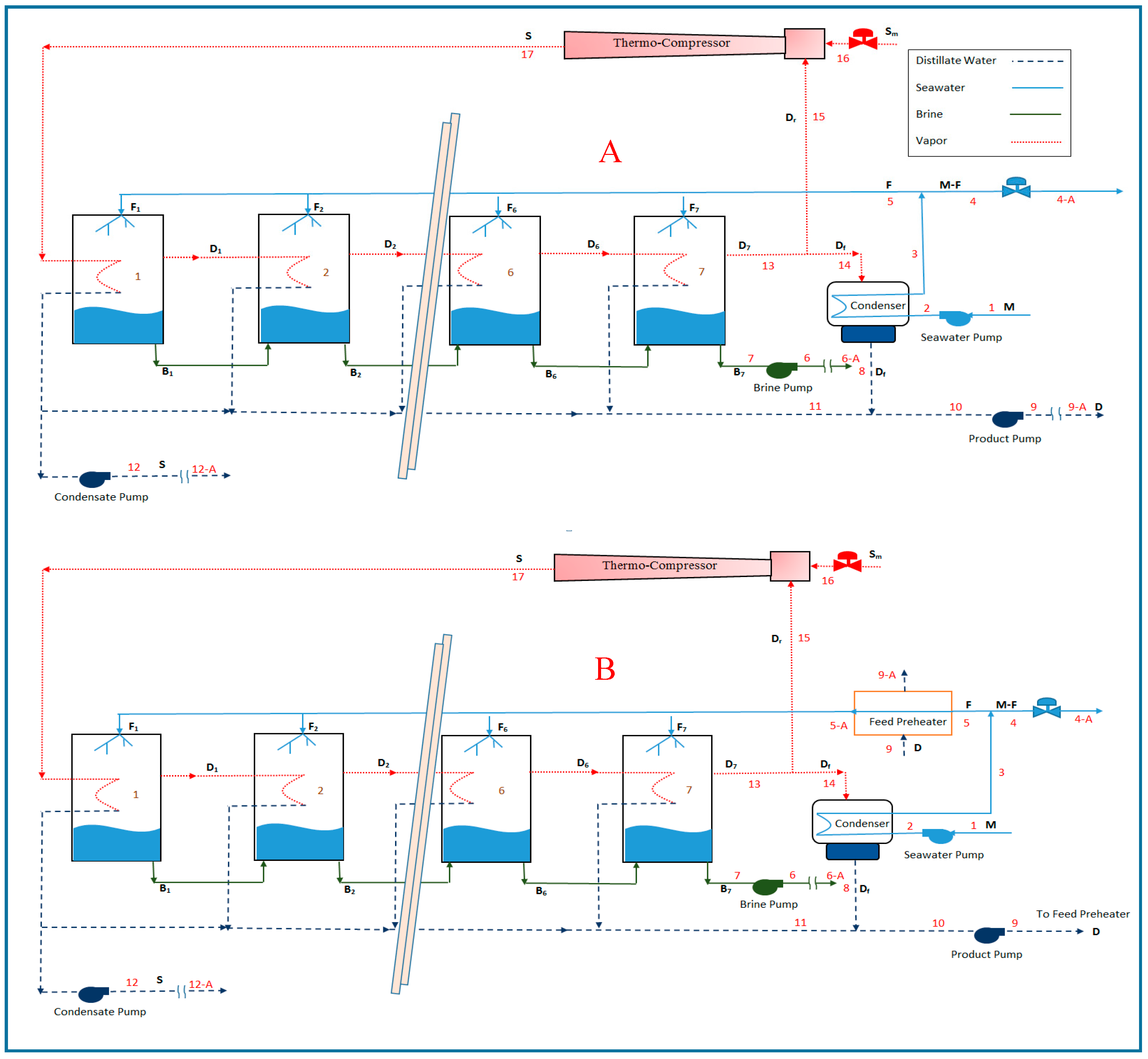

3. Process Description

Figure 1A shows a schematic diagram of a single MED-TVC unit without preheating. The cooling seawater flow (M) at stream number (1) enters the condenser to cool the distillate water and increase the seawater feed temperature. The seawater leaves the condenser at point (3) and is divided into two streams. Stream M-F goes back to the tank and stream F is directed to the effects and split into seven parts (F

1 to F

7). The extracted motive steam (S

m) goes directly to the steam ejector (Thermo-Compressor) and is mixed in the ejector or TVC with entrained steam (D

r) which was separated from the steam generated from the last effect (D

7), and the other part (D

f) entered the condenser and then combined with the steam condensate flow from the other effects. The vapour generated from the first effect is passed through demisters and enters effect number two and so on into the next effect. The brine remaining in the feed water of the first effect is passed to the second effect as raw water, B

1. Meanwhile the condensate steam from the first effect in the four blocks is split into two streams: S (in stream number 12) returns back to the CCPP while D

r passes to the product line. The vapour formed outside the tubes in the first effect is passed to the second effect and so on to the other effects (D

1 to D

7), each time to heat the feed water for the next effect. In doing so it condenses as distillate water, with all streams collected in the product line [

14,

15].

5. Results and Discussion

The thermodynamic and economic analyses were performed for one block of the MED-TVC desalination plant using different modes, with and without the feed water preheating system. Each block of the proposed system produced 6 million litres per day, and comprised seven effects. Specialised software was used for modelling and analysing the proposed systems at different operational conditions. The thermodynamic properties of seawater were treated as a real mixture using the most recently published data in the literature [

14]. The effects of entrained vapour, seawater temperature, seawater salinity, number of effects and load variation on plant performance have been probed using intake conditions as a reference state (T = 293 K, P = 1.013 bar, and w

s = 37,000 ppm).

Table 4 and

Table 5 present exergetic data for the MED-TVC desalination plant without and with preheating system respectively, and streams are denoted by the numbers shown in

Figure 1. The main equations used in the exergy analysis are summarised in

Table 6.

The exergy efficiency of MED-TVC system at design conditions is about 3.4% as illustrated in

Table 5, which was considered extremely low and might be attributed to three reasons; (i) quality of the thermal separation process, (ii) a large number of components, and (iii) high latent heat of vaporisation due to the low working pressure inside the effects. The impact of seawater temperature variation on exergy efficiency for both modes of the proposed system is shown in

Figure 2. The exergy efficiency values were between 3.2–4.7% and 3.0–4.5% over the range tested (14–30 °C) for the system with and without preheating respectively. When the MED-TVC system was integrated with a feed water preheating exchanger, the performance was enhanced slightly due to a reduction in waste exergy in the condenser and an increase in the entrained fuel exergy. Distillate water production in the preheating mode was always higher than the non-preheating mode, because of the temperature difference between the feed water and effects is lower. That means more vapour is generated in each effect as shown in

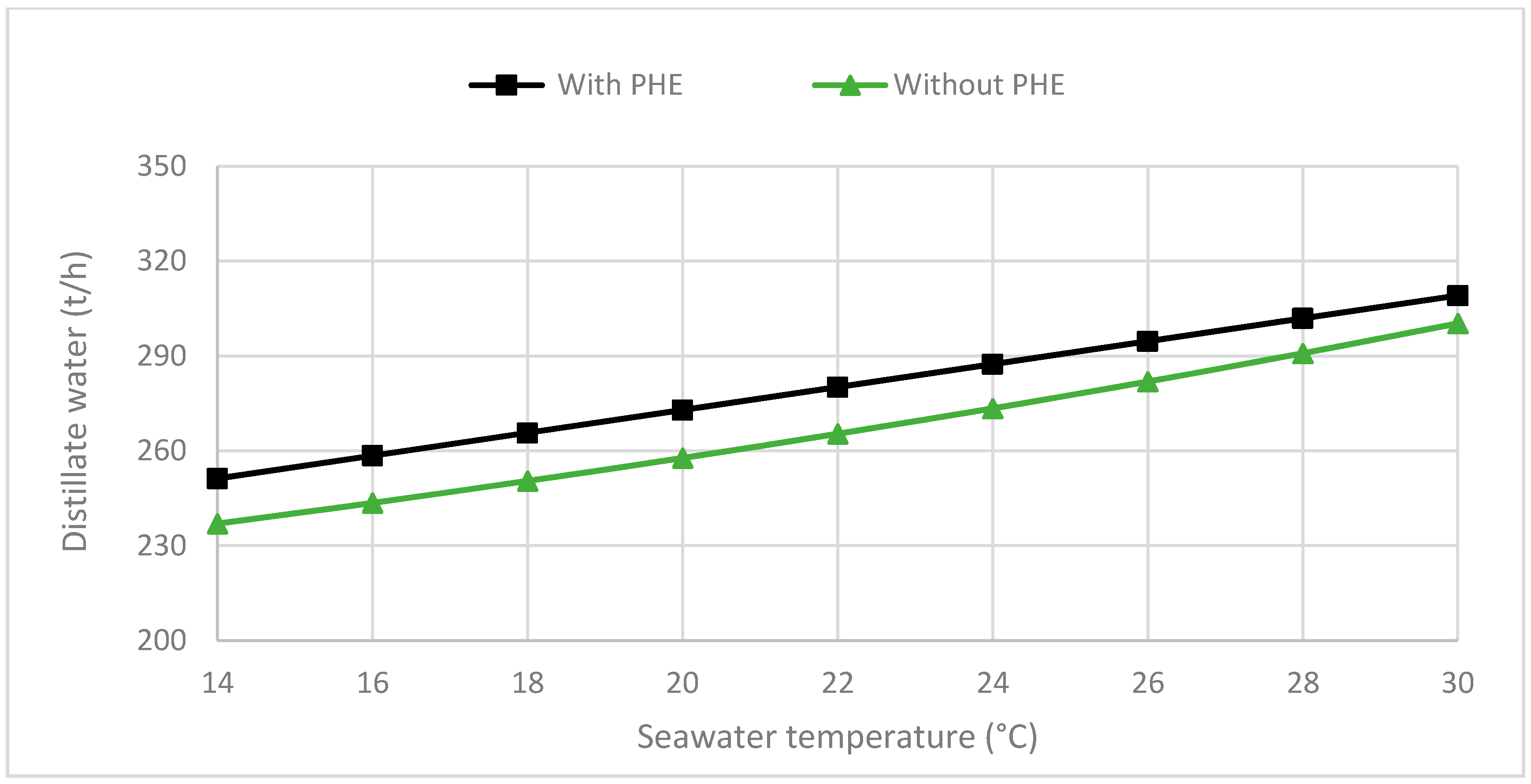

Figure 3. The impact of the preheating system will reduce as the seawater temperature increases because the temperature difference between the seawater and distillate water reduces.

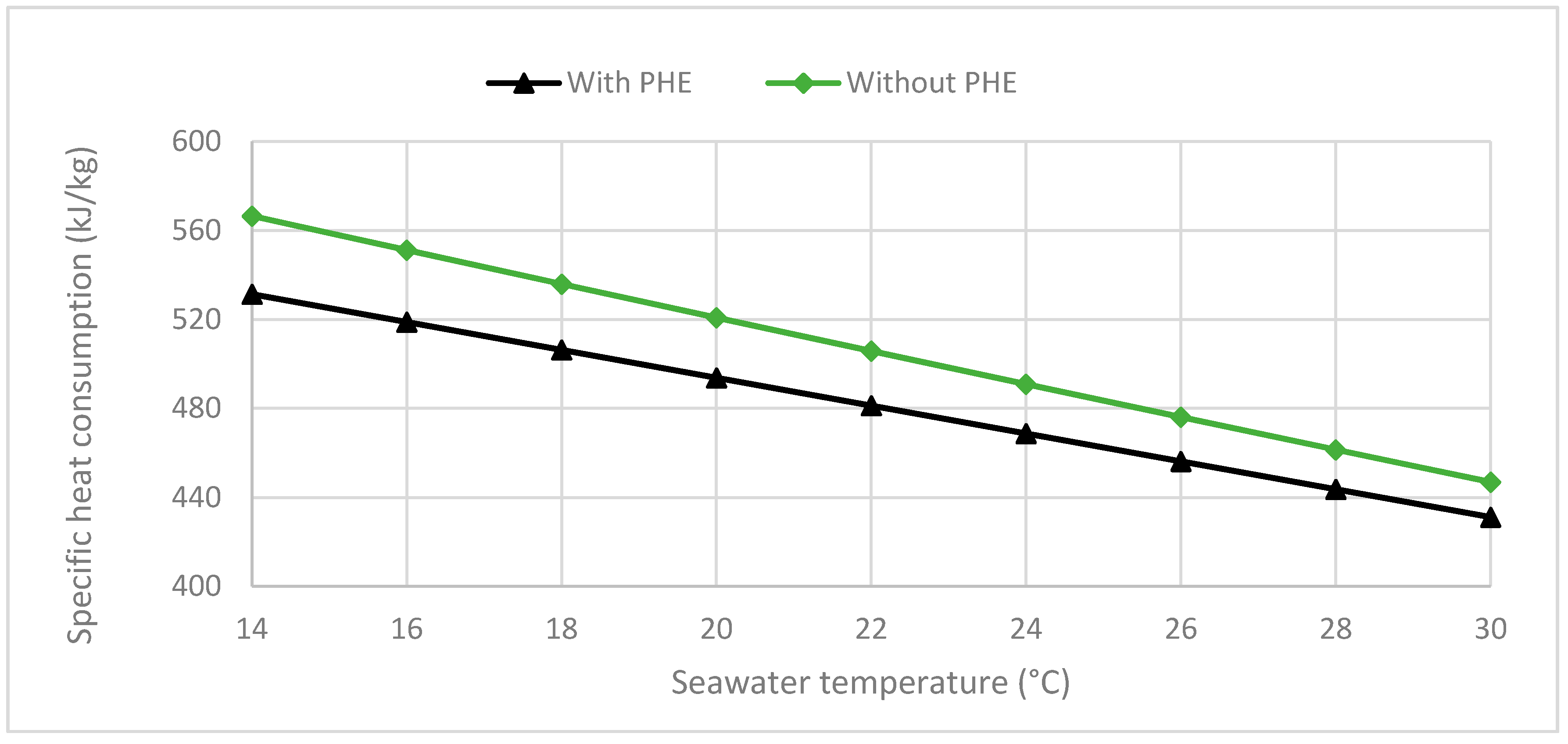

This means that the effectiveness of the preheater will be less in the summer, relative to the winter season. The relation between specific heat consumption and the seawater temperature is shown in

Figure 4. The specific heat consumption is the amount of energy consumed to produce 1 kg of distillate water. The rate of increase in distillate water production is higher than the rate of increase of energy consumption, and that means there is a significant reduction in specific heat consumption and improvement in the MED-TVC gain ratio.

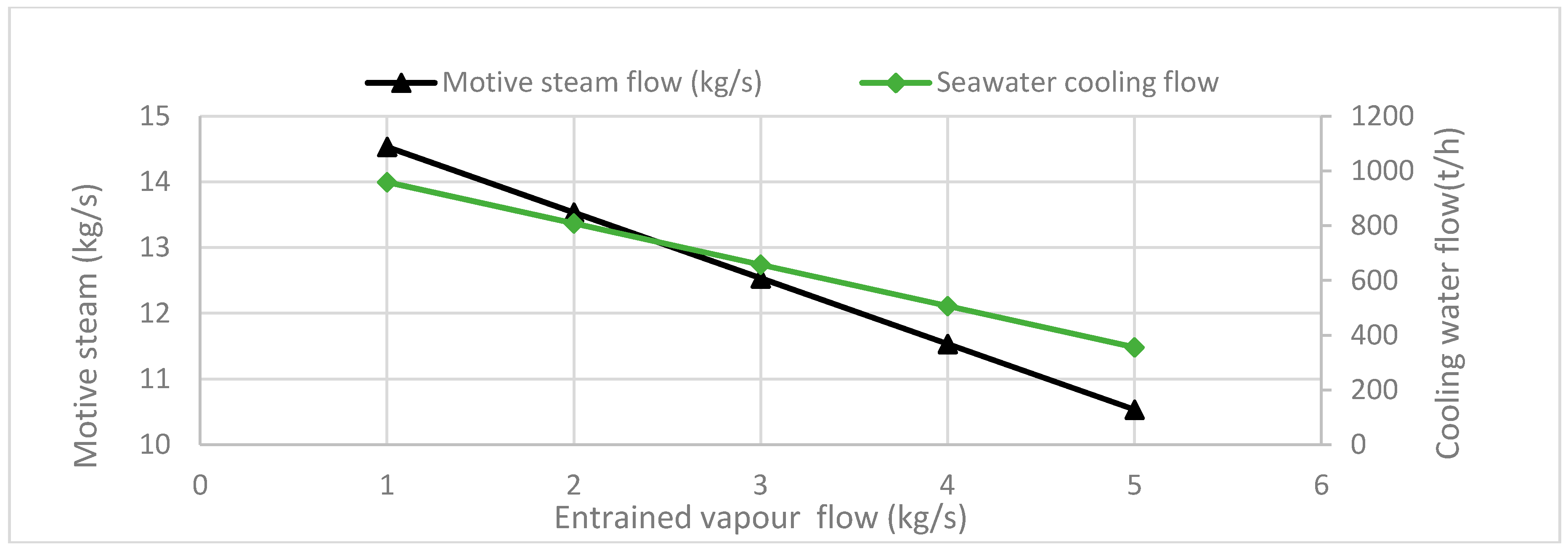

In MED-TVC thermal desalination technology, the entrainment ratio (ratio of motive steam mass flow rate to the mass of entrained vapour) is considered an important factor in determining energy input and plant size. A thermo-compressor compresses the entrained vapour which is mixed with motive steam then directed to the first effect in the MED-TVC unit. The entrained vapour represents only a small portion of the vapour generated in the last effect, while the remaining vapour moves forward to the condenser to continue the process.

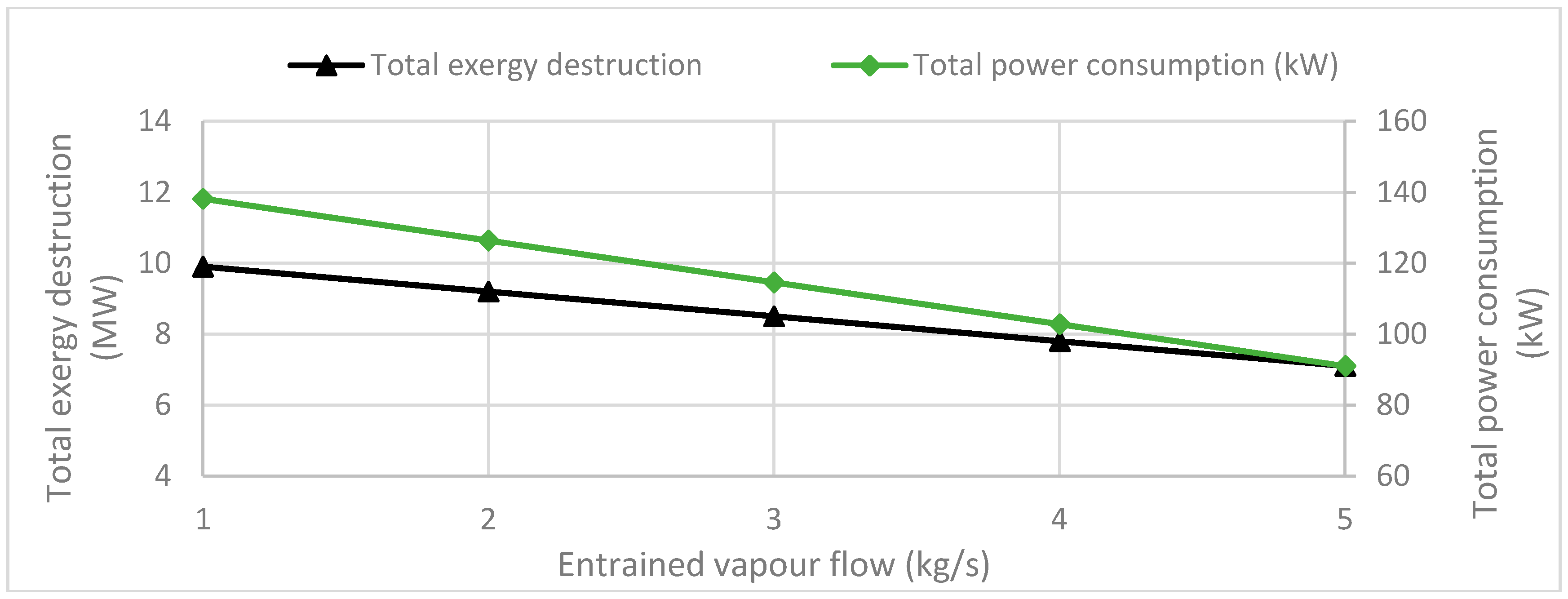

Figure 5 shows the effect of entrained vapour on motive steam, and cooling water flow. Both motive steam and cooling water flow decrease as entrained vapour flow increases, which means more fuel exergy is saved in the system, and exergy loss in the condenser is reduced. The rate of reduction of the cooling water flow is steeper than motive steam because of the reduction in the condenser load. The relation between the entrained vapour and total exergy destruction and total power consumption is shown in

Figure 6. The reduction in total exergy destruction might be attributed to the reduction in fuel exergy while in the total power consumption falls with reduction of product line mass flow.

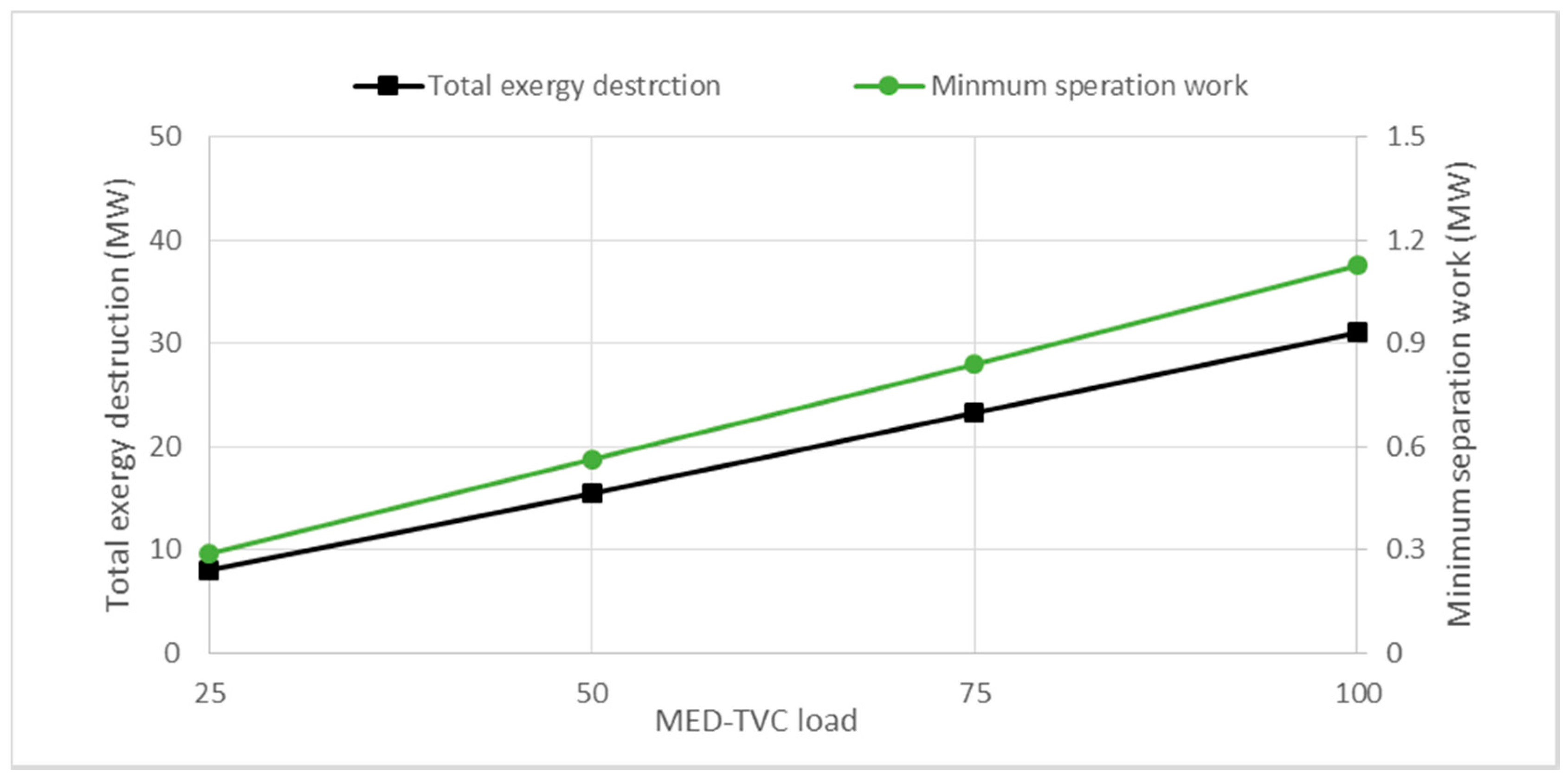

Figure 7 shows the effect of change in plant capacity from 25% to 100% load. 25% total plant capacity is achieved by operating one block, 50% two blocks, 75% three blocks and 100% all four blocks. Thermal desalination technologies are highly energy intensive processes due to the energy required for separation. More load capacity means a higher level of minimum separation work as well as total exergy destruction. The latter results are compatible with thermal design criteria by reducing the sources of irreversibilities through fewer components being utilised in the system. The low exergy efficiency mainly results from high fuel exergy input relative to minimum separation work. Thermal desalination technologies have low efficiency compared to other thermal processes, but their use is vital in regions where there is a lack of fresh water. However, setting the plant capacity at low load is acceptable from an operational perspective.

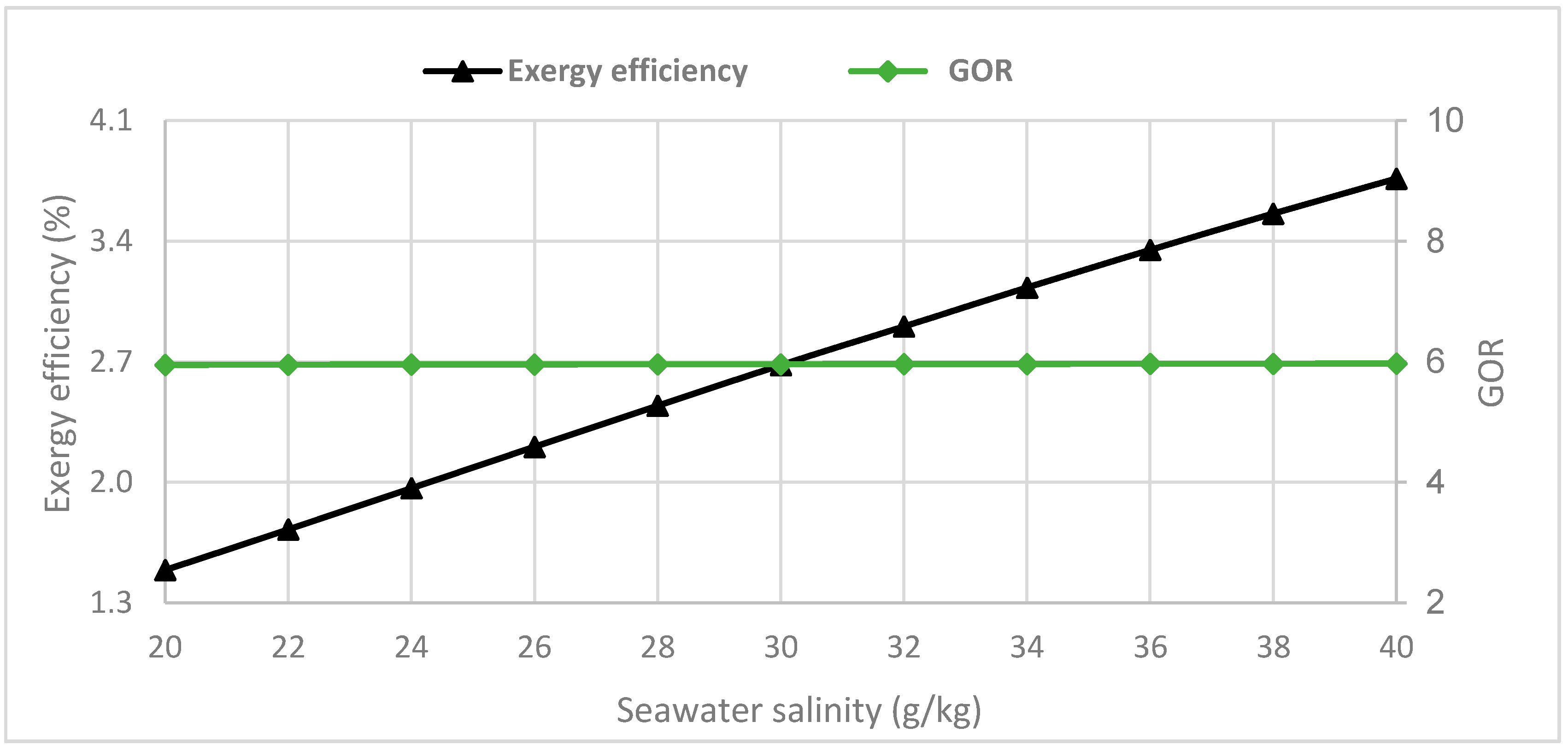

The impact of seawater salinity variation on the exergy efficiency and gain ratio is illustrated in

Figure 8. The gain ratio values are almost constant at a value of 6 over the tested salinity range, this is because it does not take into account the availability or the work utilised by the pumping system. Conversely, the exergy efficiency includes both these factors which have an immediate effect on MED-TVC thermal desalination performance. The relation between the seawater salinity and exergy efficiency of the MED-TVC system is linearly proportional. The main reason for that is the proportional increase in work required for minimum separation is greater than the proportional increase in fuel exergy. Consequently, exergy efficiency increases.

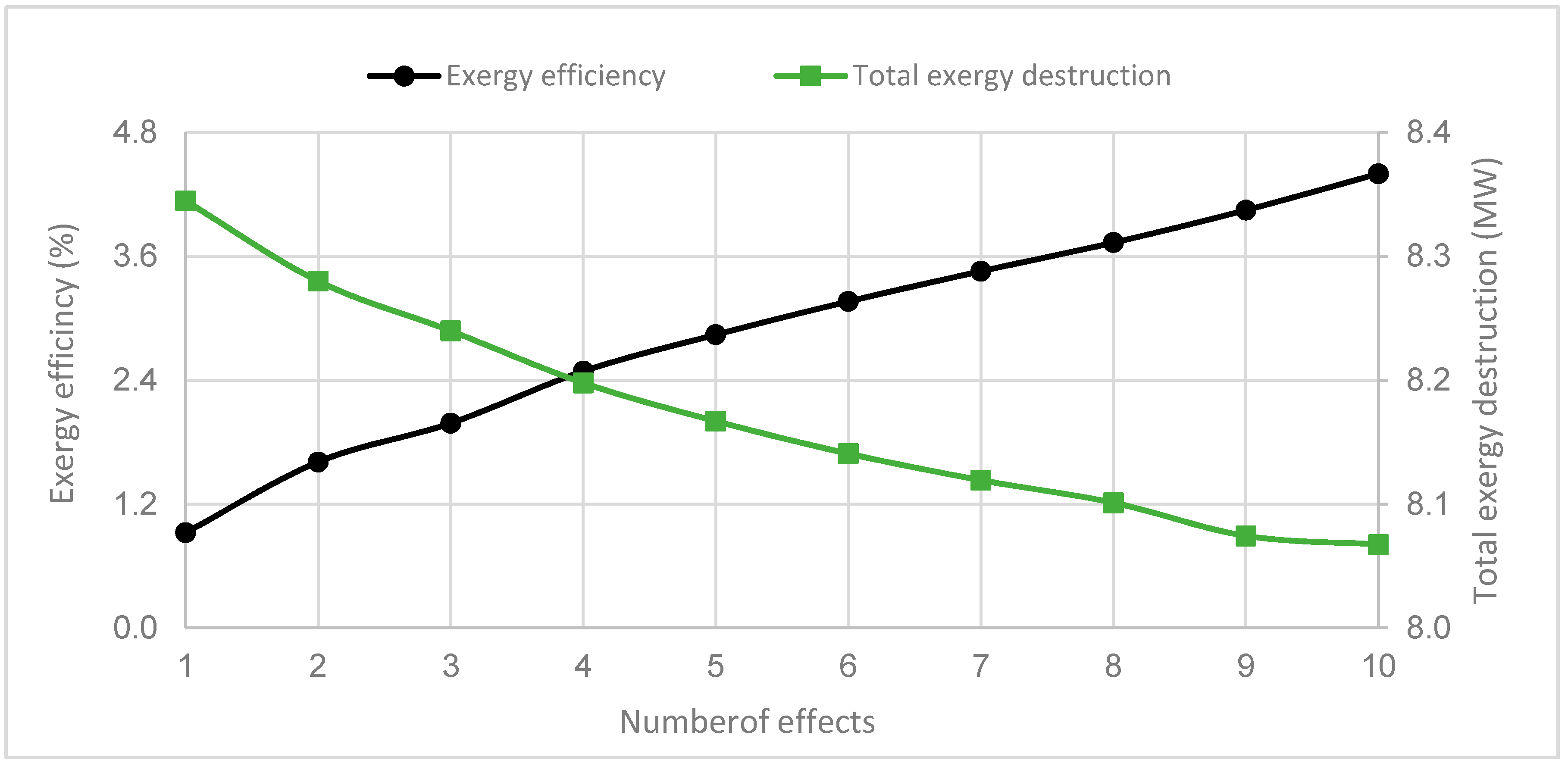

The relation between the number of effects in the MED-TVC unit with the exergy efficiency and total exergy destruction is shown in

Figure 9. Increasing the number of effects improves overall plant efficiency due to greater utilisation of energy input to the desalination unit. However, more effects lead to increased minimum work of separation because more distillate water is produced.

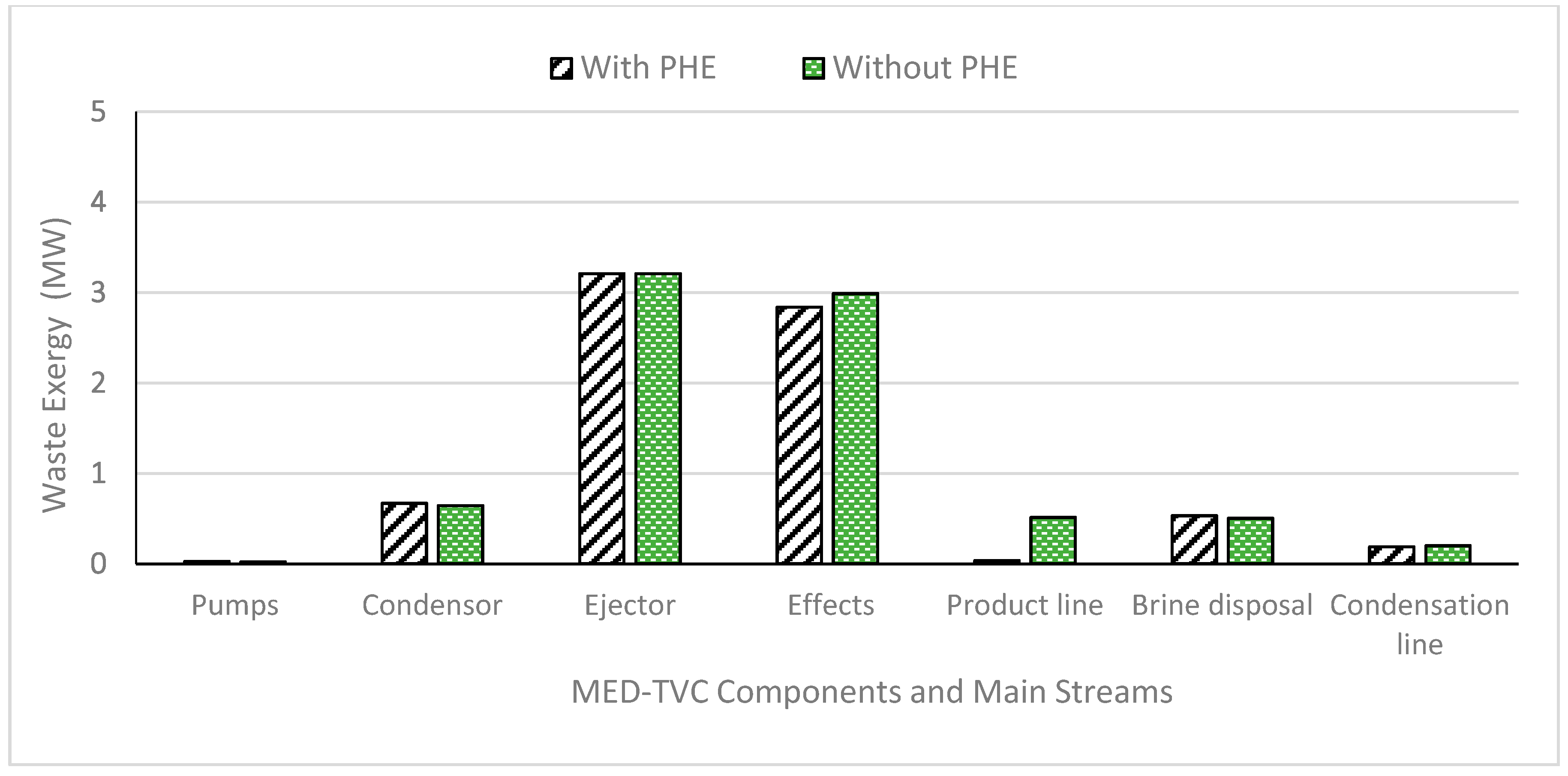

The waste exergy rates for all the main components of the MED-TVC under design conditions, for both proposed modes, are shown in

Figure 10. The major waste exergy occurs in the ejector (thermo-compressor) due to the mixing process, its configuration produces high fuel exergy, as confirmed by [

22]. The second greatest waste takes place in the effects due to temperature differences and the separation process. The amount of waste exergy in non-preheating mode is higher across all effects, but slightly lower when in preheating mode, due to increasing quality of fuel exergy. The condenser represents the third major source of irreversibilities in the system, because of the energy lost to the coolant during the condensation process. The fourth source of irreversibilities is the product stream in non-preheating mode due to its relatively high temperature. In preheating mode, the brine line represents the fourth source of irreversibilities due to high salinity and temperature.

Figure 11 shows the PBP and NPV for both modes of the proposed MED-TVC desalination plant. As can be seen the MED-TVC system without preheating has the longer PBP, about 4.5 years compared with the system with preheating. This period could be reduced to 2.9 years by adding the preheater to raise feed water temperature. This result agrees with thermodynamic analysis which showed that the exergy efficiency improved with the addition of a preheater. The NPV is equal to 71 M

$ and 104 M

$, without and with preheating system respectively. The addition of preheating system enhances the economic performance and increases the NPV at the end of project life by 33 M

$. Furthermore, the payback period is reduced in spite of an increase in capital investment cost. That may be attributed to an increase in the plant capacity due to reducing the thermal load per effect. However, the profit factors show MED-TVC desalination plant with preheating demonstrates better economic efficiency.