SWRO-PRO System in “Mega-ton Water System” for Energy Reduction and Low Environmental Impact

Abstract

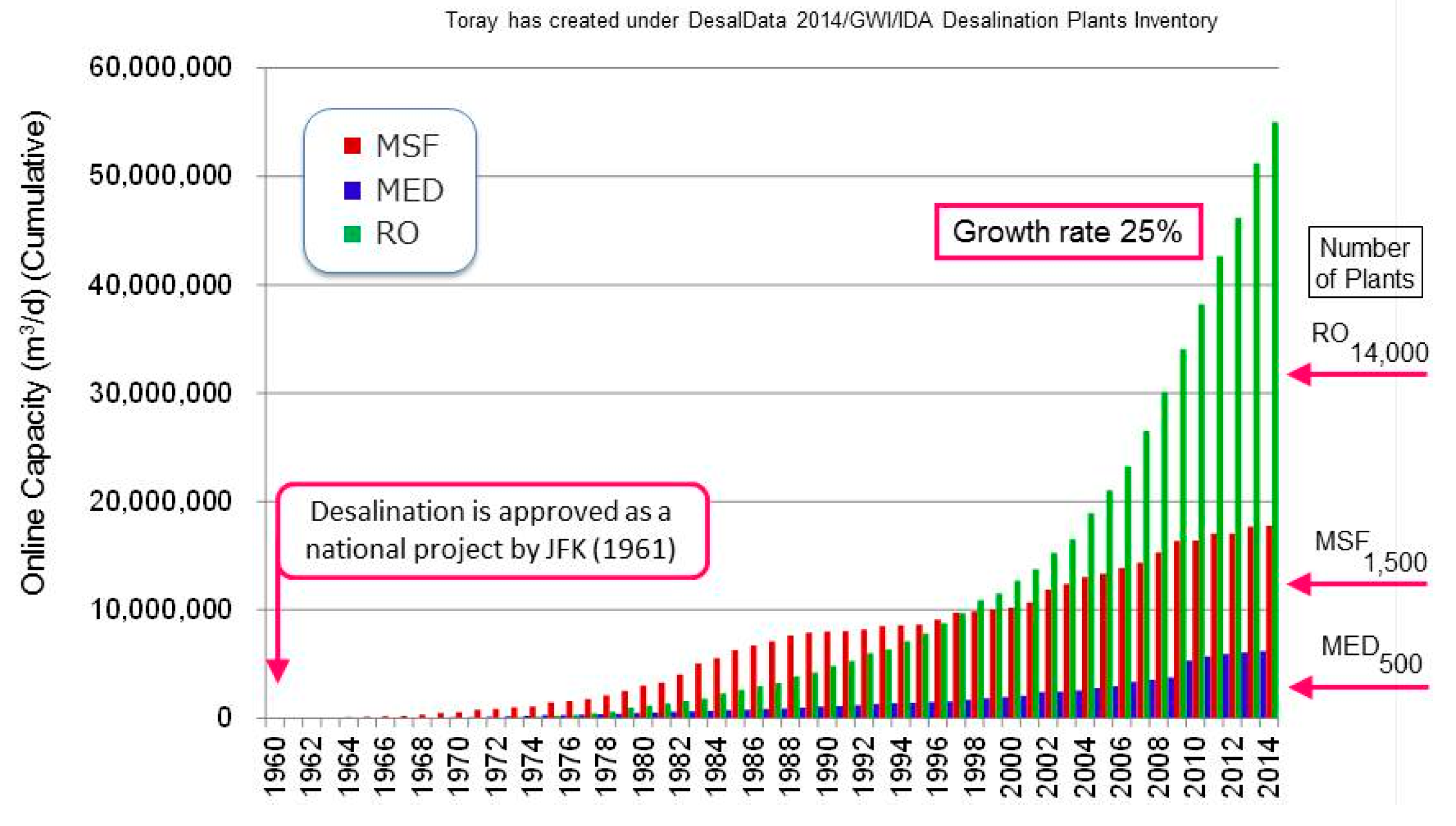

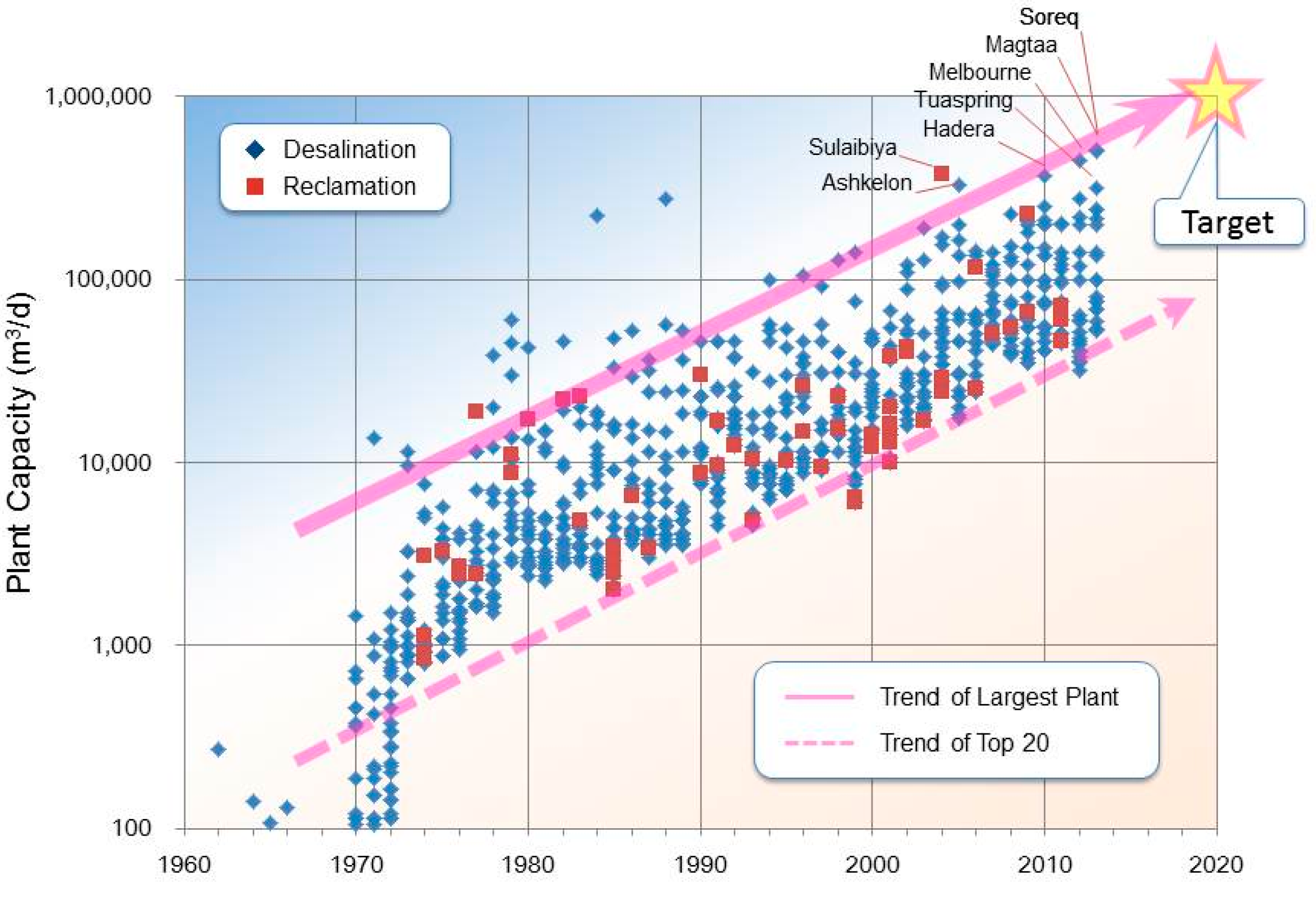

:1. Introduction

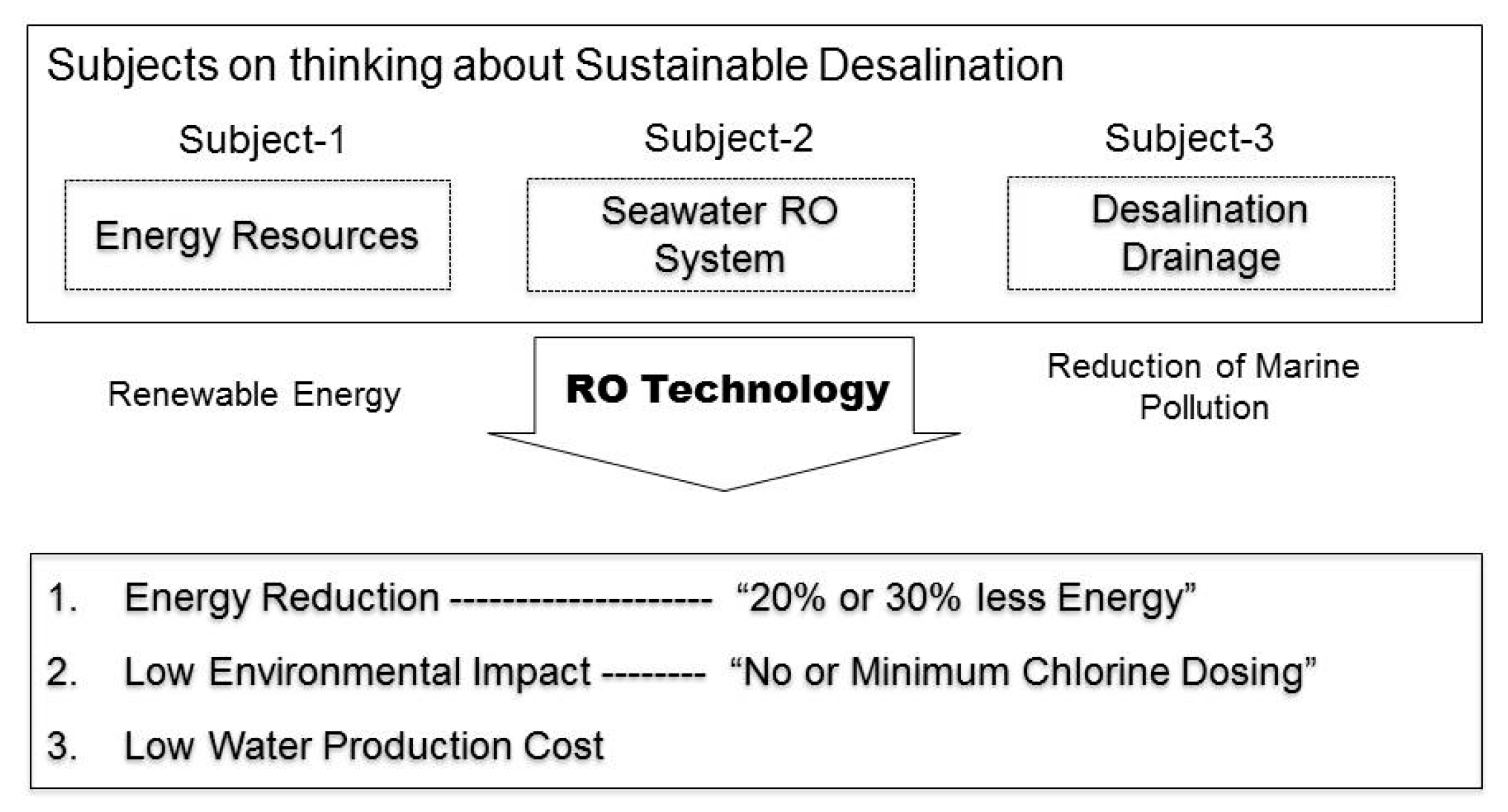

- (1)

- Energy saving (20% or 30% less energy)

- (2)

- Low environmental impact (no or minimum chlorine dosing)

- (3)

- Low water production cost

- (4)

- Reliable plant operation

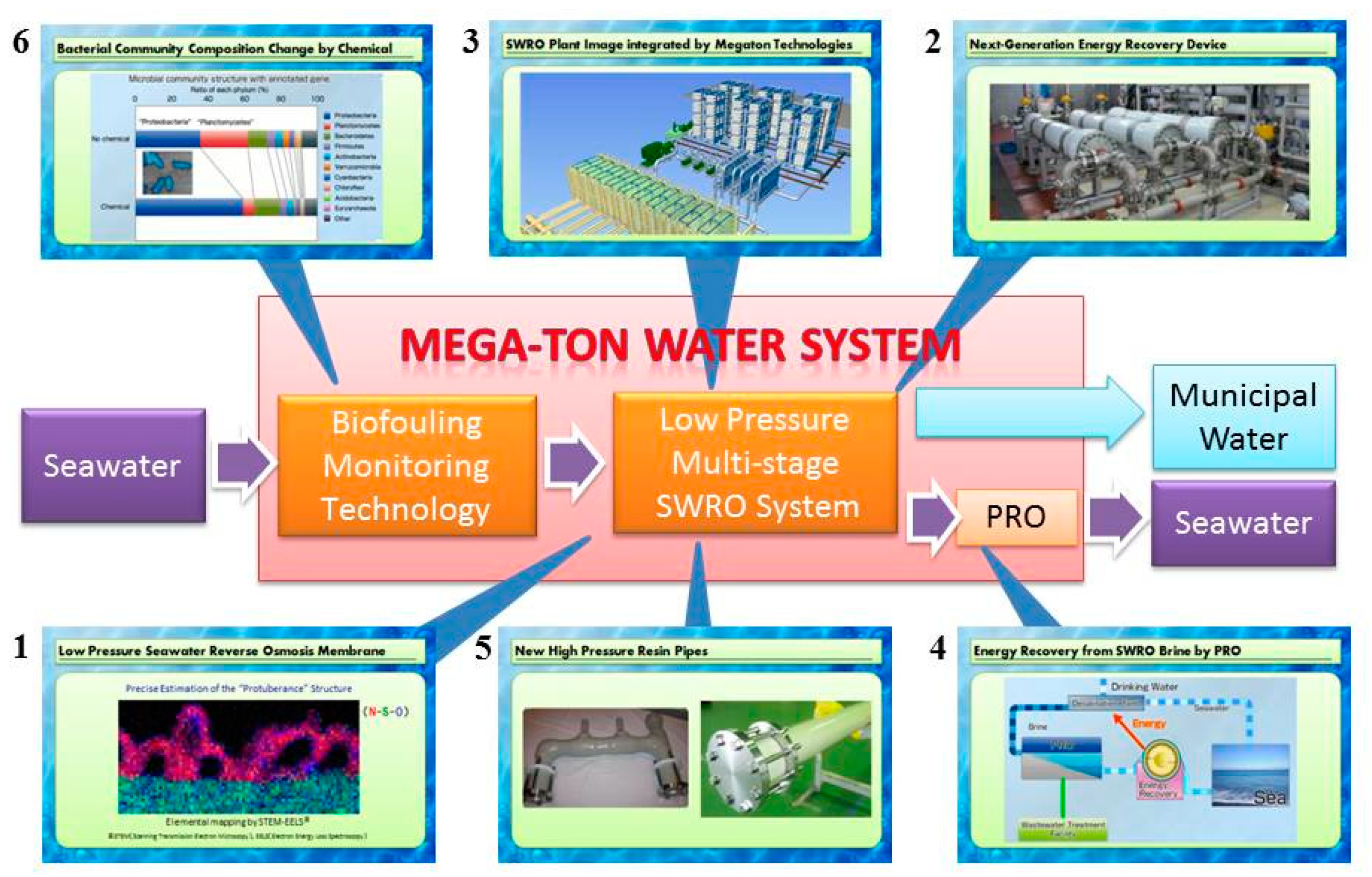

- Innovative low-pressure SWRO membrane: Mainly researched by Toray;

- Next generation energy recovery device (ERD): Mainly researched by Ebara Corporation;

- Low-pressure multistage SWRO system (LMS): Mainly researched by Hitachi;

- Pressure retarded osmosis (PRO): Mainly researched by Kyowakiden Industry;

- High durability high-pressure resin pipe: Mainly researched by Asahi Yukizai Corporation;

- Bio-fouling monitoring technology (mBFR): Mainly researched by Toray.

2. Research Results and Discussion

2.1. Innovative Low Pressure SWRO Membrane of the “Mega-ton Water System”

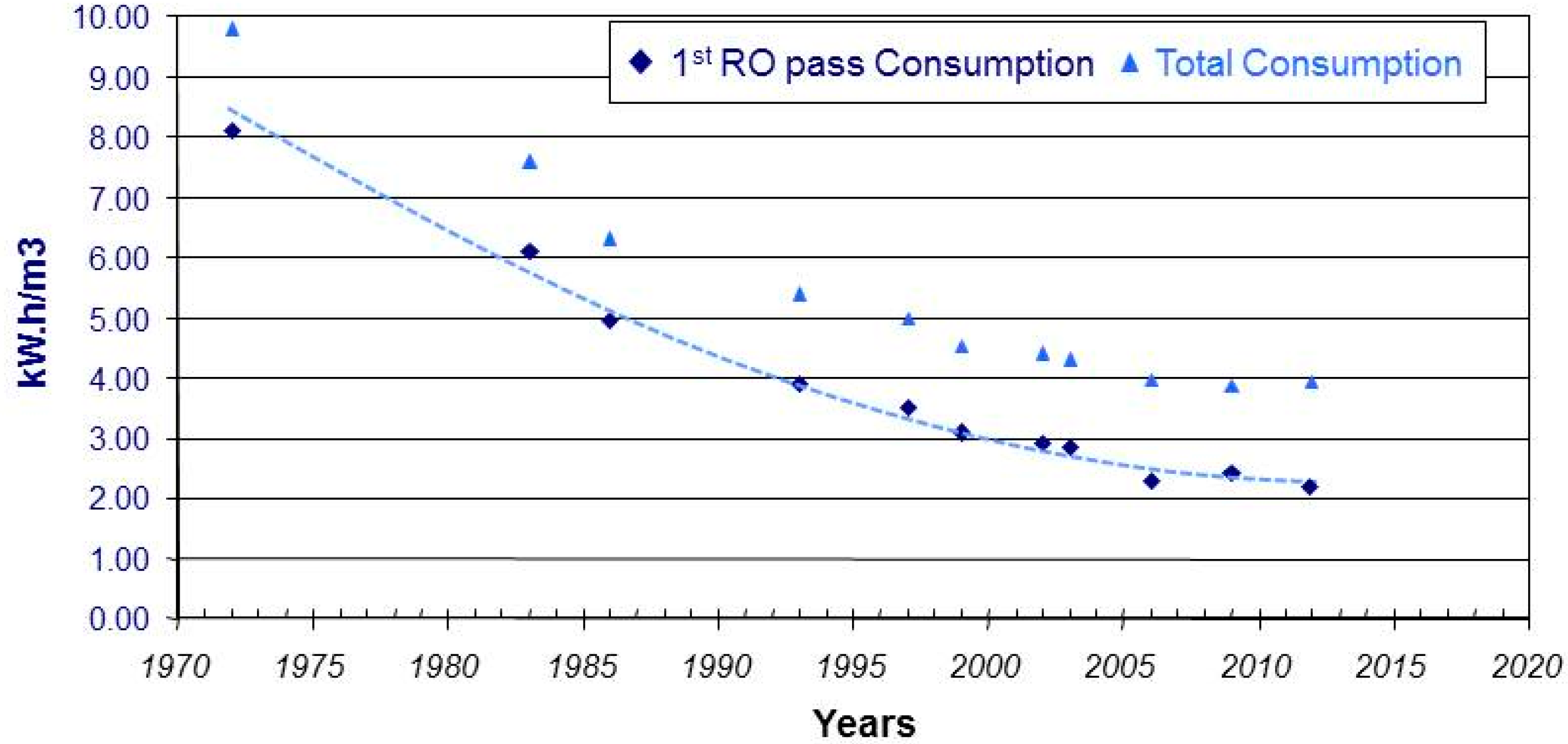

2.1.1. Requirement for Energy-Saving and Water Quality Improvement

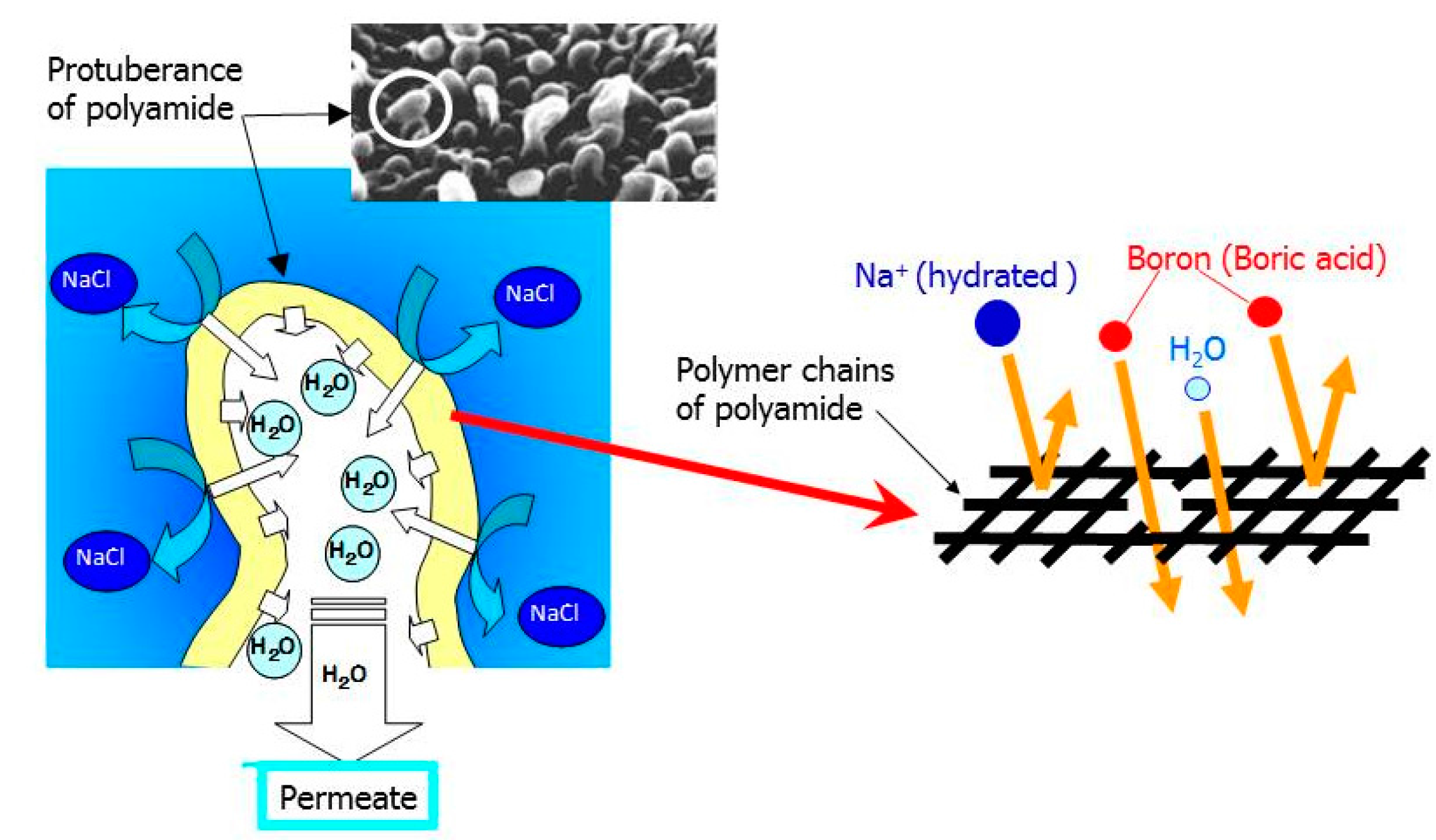

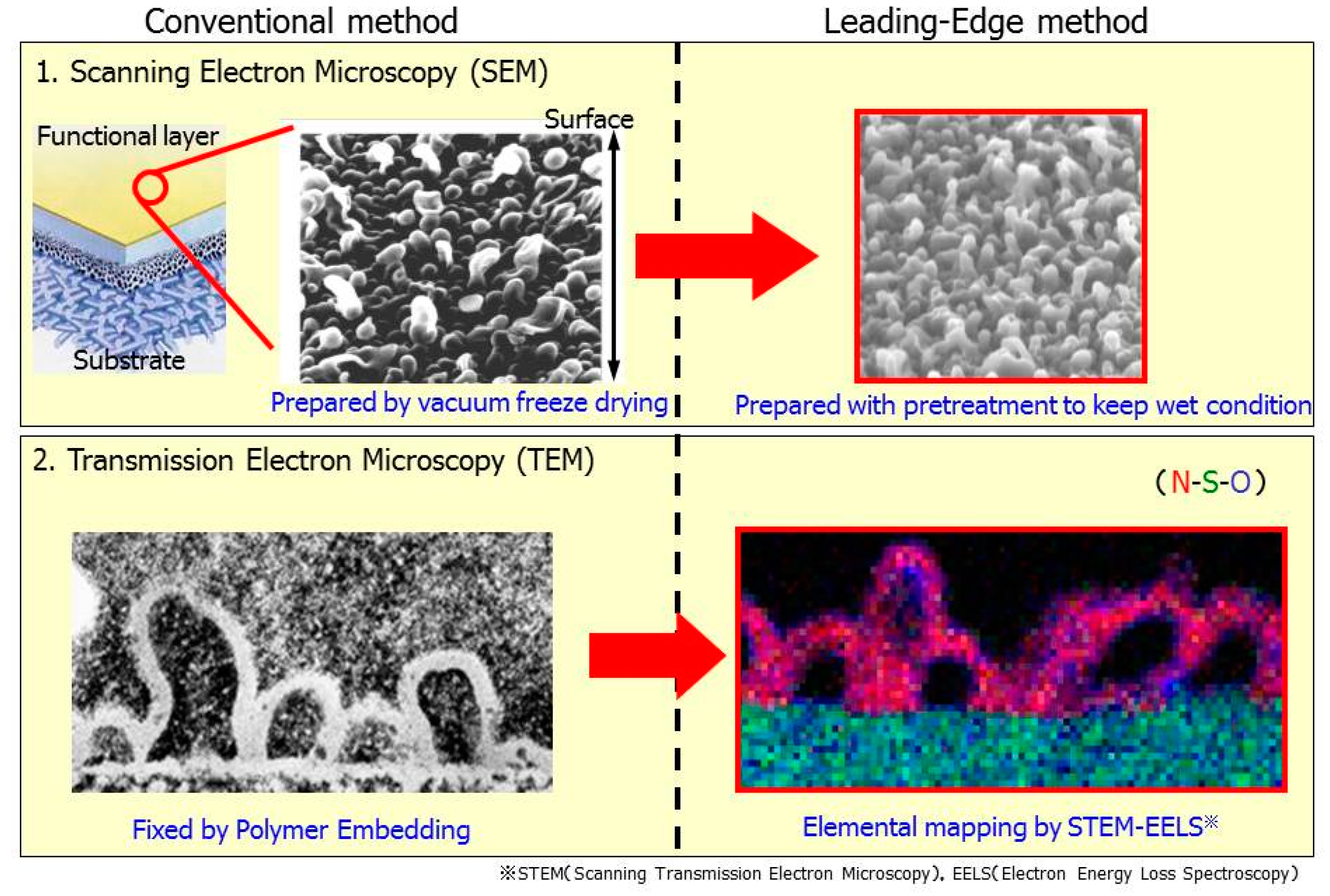

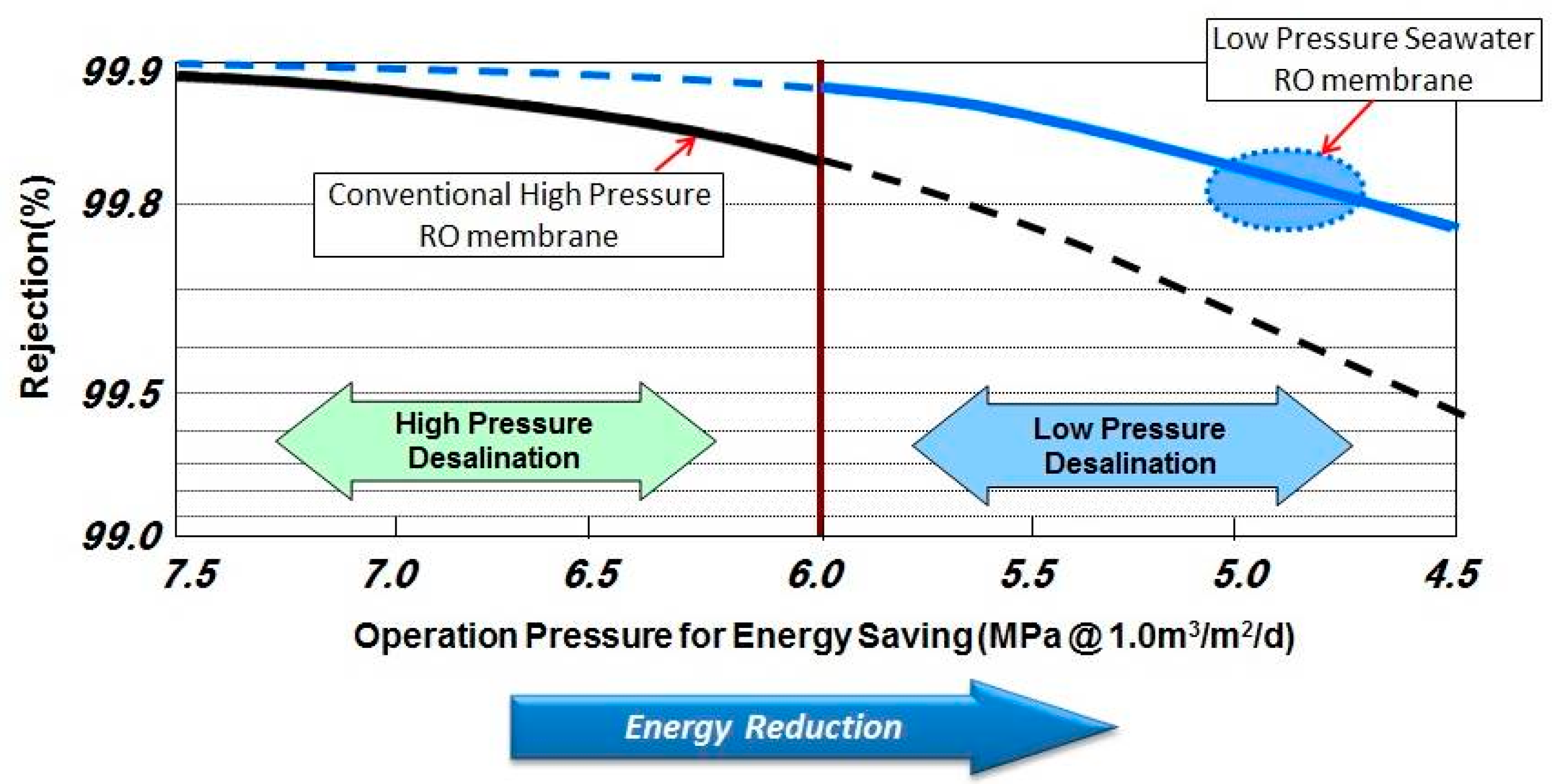

2.1.2. Innovative Low-Pressure SWRO Membrane

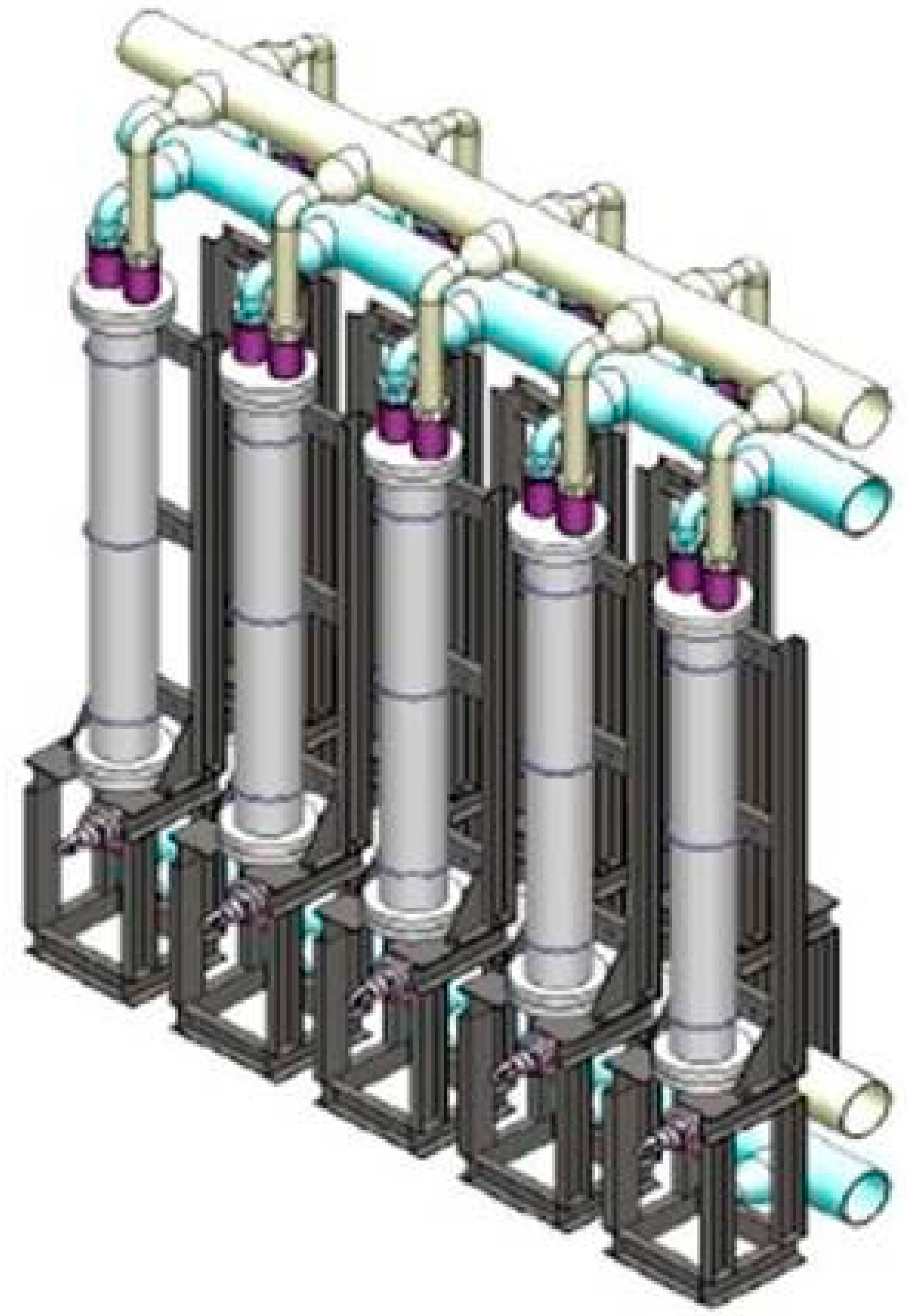

2.2. Next Generation Energy Recovery Device (New ERD)

- (1)

- It adopts a piston-less chamber so there is no wear to parts.

- (2)

- It prevents over-flush, which reduces the waste of pretreatment water, as well as minimizes the mixture of pretreatment water and concentrated water.

- (3)

- Adoption of the one-chamber, one-control valve form enables high-precision control, which does not generate internal leakages and is resistant to contamination.

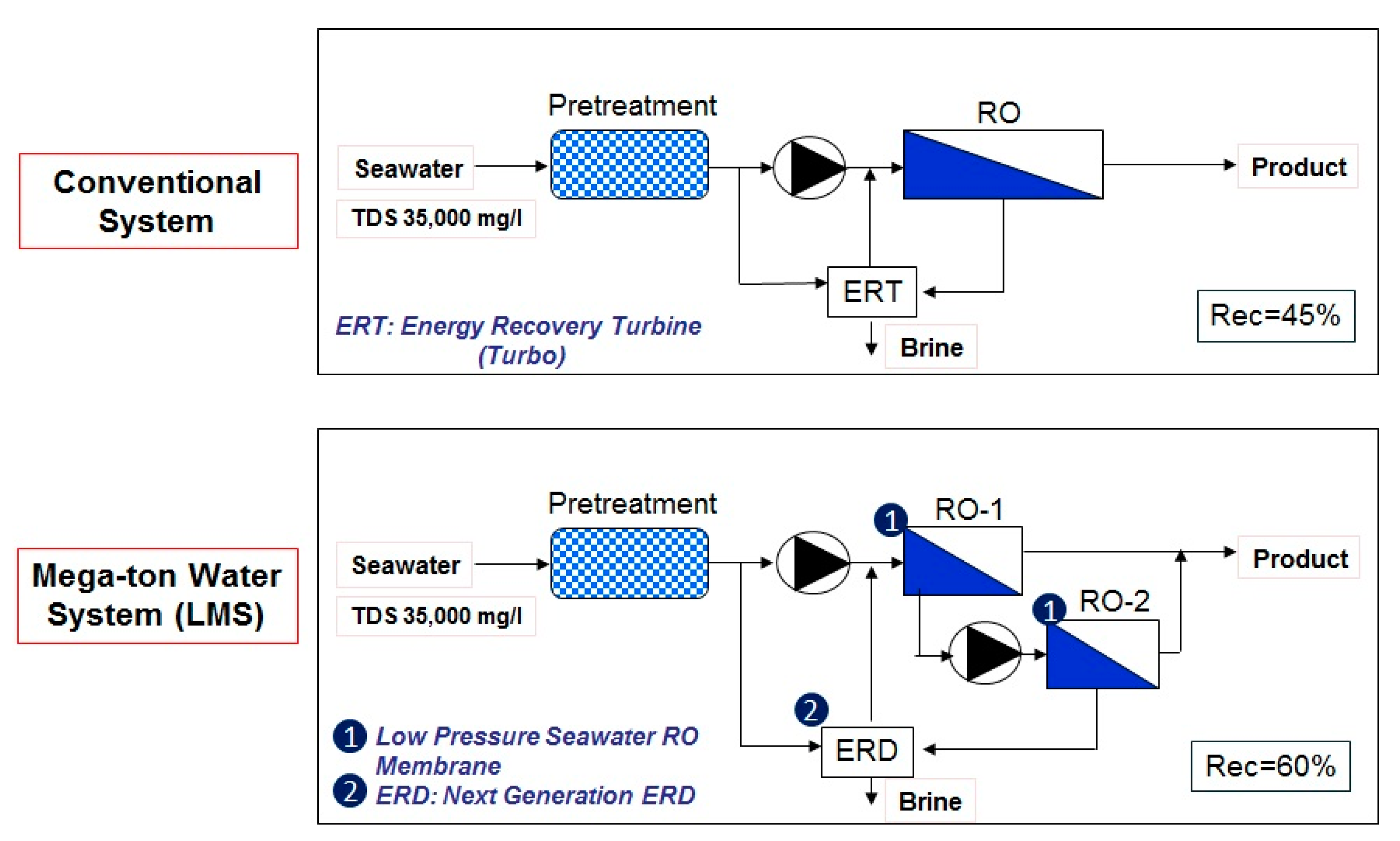

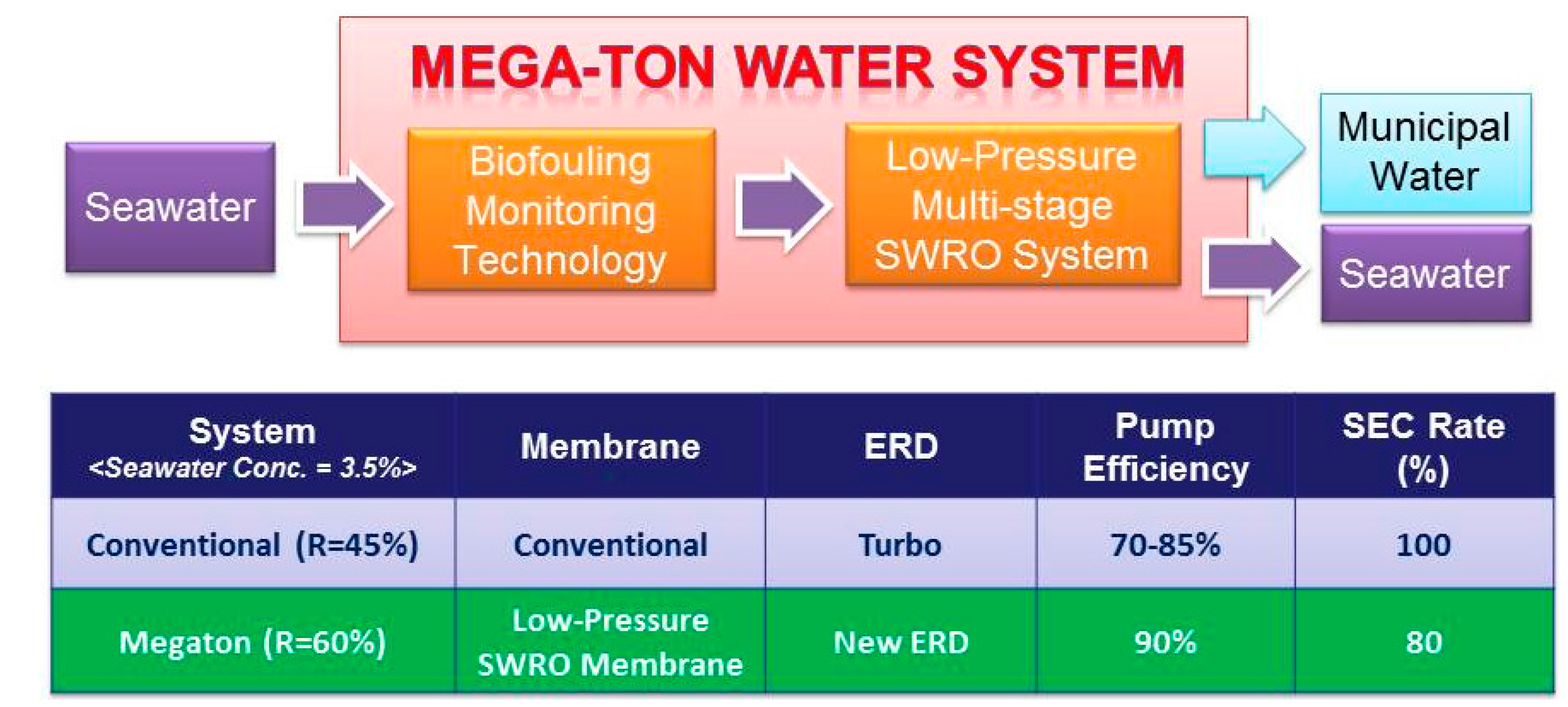

2.3. Low-Pressure Multi-Stage SWRO System (LMS) of the “Mega-ton Water System”

2.3.1. Brine Conversion Two-Stage SWRO System

- Plant installation space can be reduced to 2/3.

- Plant capacity is easily expanded to 1.5 times by only adding BCS second stage into the conventional plant.

- Disposed concentrated brine water is reduced to 2/3.

2.3.2. Low-Pressure Multi-Stage SWRO System (LMS)

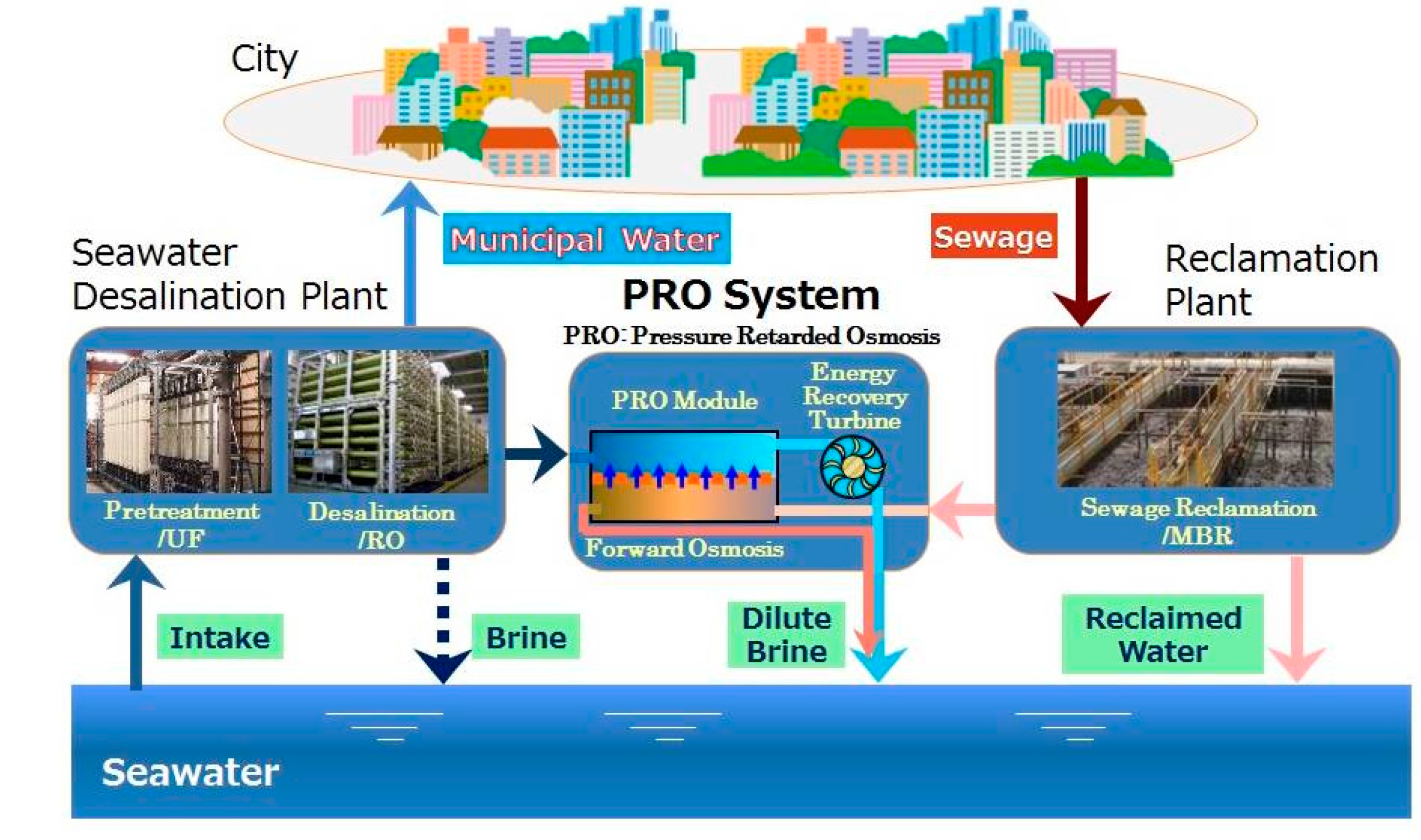

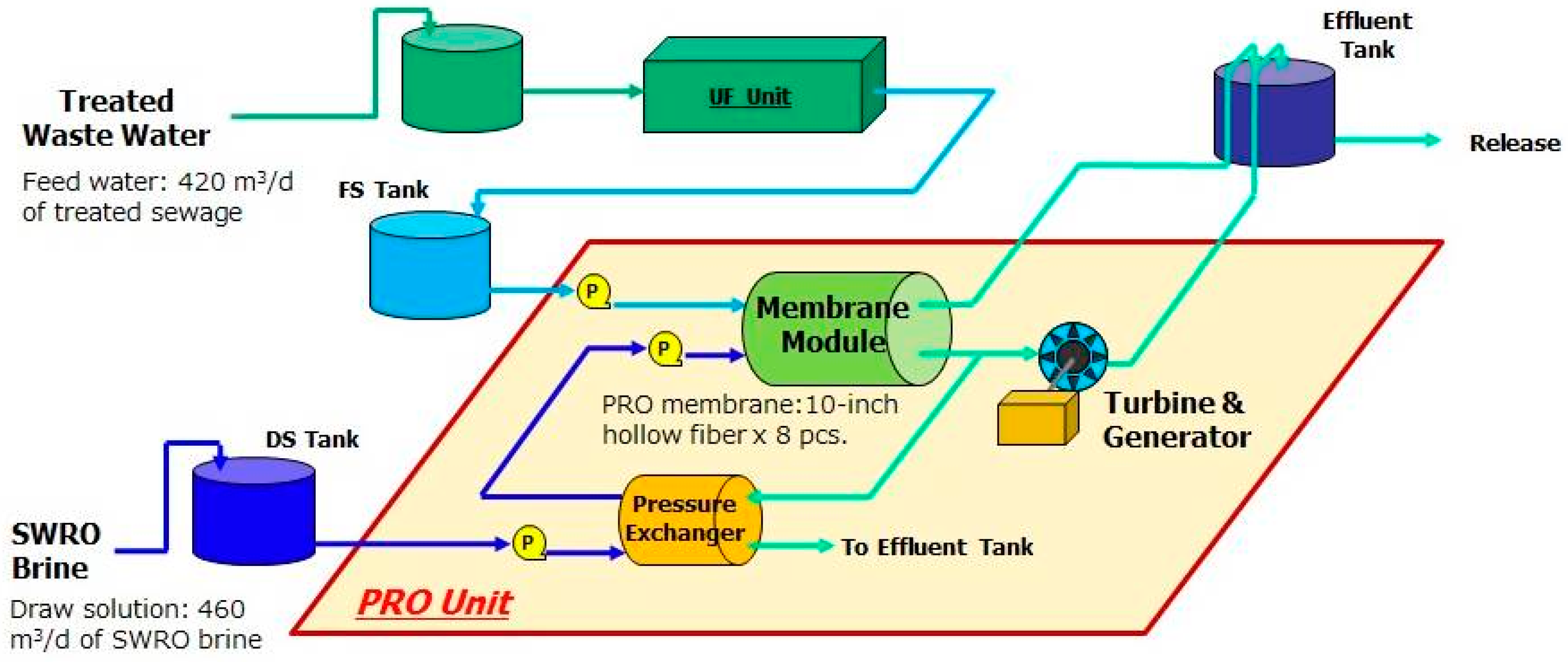

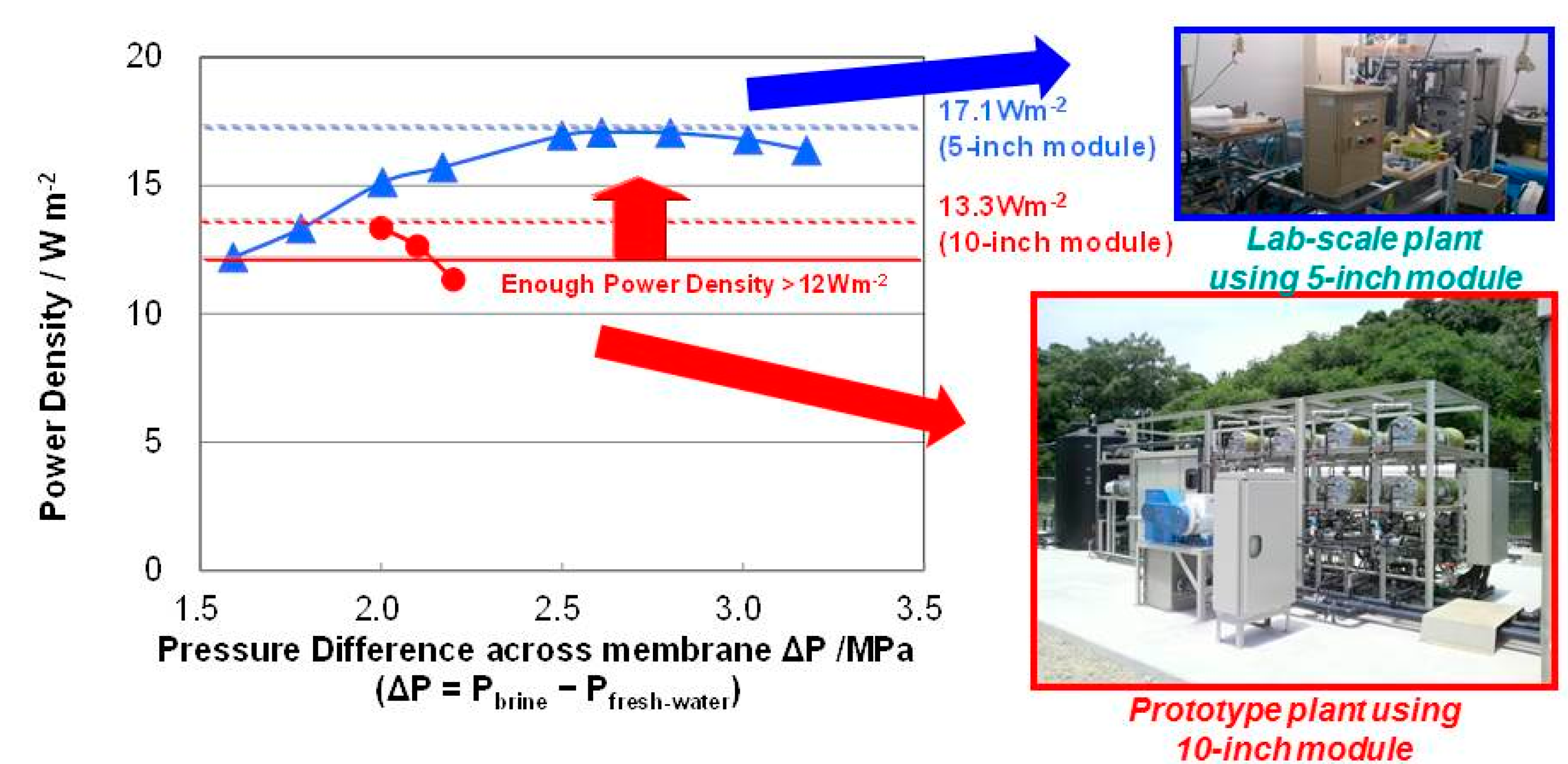

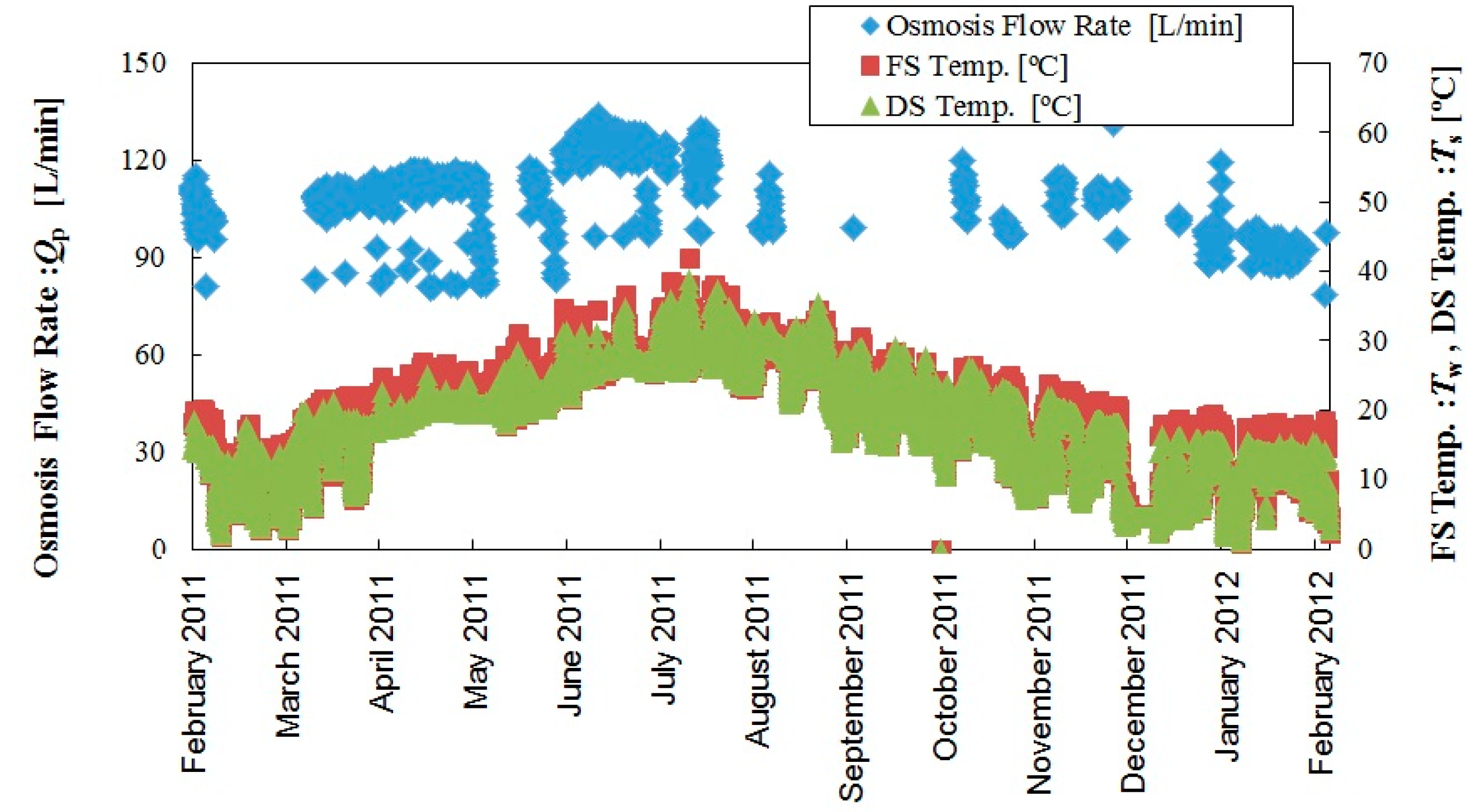

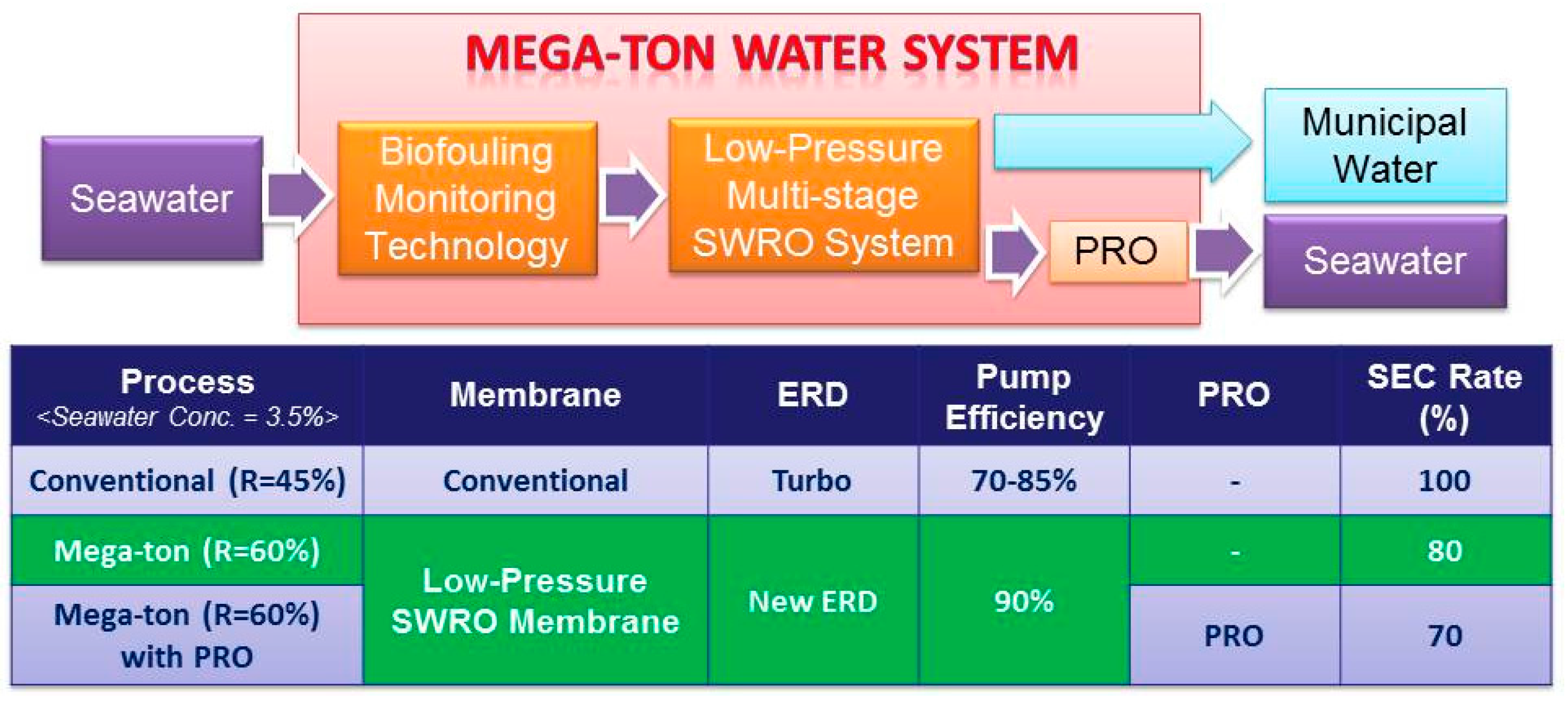

2.4. SWRO-PRO System of “Mega-ton Water System”

3. Conclusions

- (1)

- There are three key challenges to developing sustainable desalination technologies that will be required in the 21st century: (1) energy saving; (2) low environmental impact; and (3) low water production cost. Solutions to these challenges are being developed through funding from the Japanese government “FIRST Program” in the “Mega-ton Water System” project.

- (2)

- Innovative low-pressure SWRO membranes were obtained by controlled preparation technology based on a precise estimation of the protuberance of the membranes.

- (3)

- As new membrane process technology, low-pressure multi-stage system (LMS), makes it possible to operate high recovery and low-pressure operation up to 60%, which contributes to reducing the size of the plant and reducing the cost of low water production.

- (4)

- Applying the various technologies in the “Mega-ton Water System” project to large-scale desalination plants would enable a 20% saving of energy consumption compared with commercialized systems.

- (5)

- The SWRO-PRO system of the “Mega-ton Water System” allows 30% energy saving compared with conventional systems. The SWRO-PRO system in the “Mega-ton Water System” can be commercialized with the development of a high performance (13.3 W/m2) hollow fiber PRO membrane and system operation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Desalination Association and Global Water Intelligence. DesalData 2014 Plant Inventory Report; Global Water Intelligence: Oxford, UK, 2014. [Google Scholar]

- Kurihara, M.; Hanakawa, M. “Mega-ton Water System”: Japanese national research and development project on seawater desalination and wastewater reclamation. Desalination 2013, 308, 131–137. [Google Scholar] [CrossRef]

- Lattemann, S.; Höpner, T. Environmental impact and impact assessment of seawater desalination. Desalination 2008, 220, 1–15. [Google Scholar] [CrossRef]

- McCann, B.; Asano, T. Water21 Magazine; International Water Association: London, UK, 2011. [Google Scholar]

- Kurihara, M.; Sasaki, T.; Nakatsuji, K.; Kimura, M.; Henmi, M. Low pressure SWRO membrane for desalination in the “Mega-ton Water System”. Desalination 2015, 368, 135–139. [Google Scholar] [CrossRef]

- Kurihara, M. Membrane research for water treatment facing the age of global mega competition & collaboration, Oral Presentation in IUPAC World Polymer Congress Polymer and Polymer-based Membranes for Energy and Environmental Applications II. In Proceedings of the 2012 World Polymer Congress (WPC) of the International Union of Pure and Applied Chemistry (IUPAC), Blacksburg, VA, USA, 24–29 June 2012. [Google Scholar]

- Kurihara, M.; Sasaki, T. The most advanced membrane analysis and the save-energy type: Low Pressure Seawater Reverse Osmosis Membrane developed by “Mega-ton Water System” Project. In Comprehensive Membrane Science and Engineering, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2017; Volume 4, pp. 131–149. [Google Scholar]

- Sanz, M.A. Energy as Motor of Seawater Reverse Osmosis Desalination Development. In Proceedings of the Mega-ton Water System International Symposium, Tokyo, Japan, 21–22 November 2013. [Google Scholar]

- Kurihara, M.; Sasaki, T. The Pursuits of Ultimate Membrane Technology including Low Pressure Seawater Reverse Osmosis Membrane developed by “Mega-ton Water System” Project. J. Membr. Sci. Res. 2017, 3, 157–173. [Google Scholar]

- Stover, R.L.; Andrews, B. Isobaric Energy Recovery Devices—Past, Present and Future, IDAWC/PER11-103. In Proceedings of the IDA World Congress, Perth, Australia, 4–9 September 2011. [Google Scholar]

- Takahashi, T.; Shinoda, M.; Takita, S.; Goto, A. A Next-Generation Isobaric Energy Recovery Device with Piston-less and No-Leakage Concepts for SWRO Desalination, IDAWC/TIAN13-008. In Proceedings of the International Desalination Association World Congress, Tianjin, China, 20–25 October 2013. [Google Scholar]

- Kurihara, M.; Yamamura, H.; Nakanishi, T. High recovery/high pressure membranes for brine conversion SWRO process development and its performance data. Desalination 1999, 125, 9–15. [Google Scholar] [CrossRef]

- Wei, Q.; McGovern, R.; Lienhard, J.H.V. Saving energy with an optimized two-stage reverse osmosis system. Environ. Sci. Water Res. Technol. 2017, 3, 659–670. [Google Scholar] [CrossRef]

- Wei, Q.; McGovern, R.; Lienhard, J. Two-stage reverse osmosis: Optimal element configuration and energy savings. In Proceedings of the IDA World Congress 2017, World Trade Center, Sao Paulo, Brazil, 19 October 2017. [Google Scholar]

- Kishizawa, N.; Tsuzuki, K.; Hayatsu, M. Low pressure multi-stage RO system developed in “Mega-ton Water System” for large-scaled SWRO plant. Desalination 2015, 368, 81–88. [Google Scholar] [CrossRef]

- Loeb, S. Method and Apparatus for Generation Power Utilizing Pressure-Retarded Osmosis. U.S. Patent 3906250, 16 September 1975. [Google Scholar]

- Loeb, S. Method and Apparatus Generating Power Utilizing Pressure-Retarded Osmosis. U.S. Patent 4193267, 18 May 1980. [Google Scholar]

- Loeb, S. Production of energy from concentrated brines by pressure-retarded osmosis. J. Membr. Sci. 1976, 1, 49–63. [Google Scholar] [CrossRef]

- Loeb, S.; van Hessen, F.; Shahaf, D. Production of energy from concentrated brines by pressure-retarded osmosis: II. Experimental results and projected energy costs. J. Membr. Sci. 1976, 1, 249–269. [Google Scholar] [CrossRef]

- Sarp, S. Pressure Retarded Osmosis (PRO): Current Statue and prospects. In Proceedings of the 2nd International Conference on Desalination Using Membrane Technology, Singapore, 26–29 July 2015. [Google Scholar]

- Skilhagen, S.E.; Dugstad, J.E.; Aaberg, R.J. Osmotic power—Power production based on the osmotic pressure difference between waters with varying salt gradients. Desalination 2008, 220, 476–482. [Google Scholar] [CrossRef]

- Kurihara, M.; Sakai, H.; Tanioka, A.; Tomioka, H. Role of pressure-retarded osmosis (PRO) in the mega-ton water project. Desalin. Water Treat. 2016, 57, 26518–26528. [Google Scholar] [CrossRef]

- Tanioka, A.; Higa, M.; Sakai, H. Energy Recovery by Pressure Retarded Osmosis System. J. Membr. 2015, 40, 67–72. [Google Scholar] [CrossRef]

- Saito, K. Power generation with salinity gradient by pressure retarded osmosis using concentrated brine from SWRO system and treated sewage as pure water. Desalin. Water Treat. 2012, 41, 114–121. [Google Scholar] [CrossRef]

- Hong, S.; Kim, J.; Cha, G.; Kim, J. Low-energy seawater reverse osmosis (SWRO) desalination plant optimized for the Middle East. In Proceedings of the IDA World Congress 2017, World Trade Center, Sao Paulo, Brazil, 18 October 2017. [Google Scholar]

| No. | Mission | Energy Saving | Low Environmental Impact | Low Water Production Cost | Plant Operation Reliability | |

|---|---|---|---|---|---|---|

| Theme | ||||||

| 1 | Innovative Low-Pressure SWRO Membrane | X | X | X | ||

| 2 | Next Generation Energy Recovery Device (ERD) | X | X | X | X | |

| 3 | Low-pressure Multi-stage SWRO System (LMS) | X | X | |||

| 4 | Pressure Retarded Osmosis (PRO) | X | X | X | ||

| 5 | High Durability High-Pressure Resin Pipe | X | X | |||

| 6 | Bio-fouling Monitoring Technology (mBFR) | X | X | X | ||

| Key Items | Ideal ERD | New ERD | Conventional ERD with Over-Flush | Conventional ERD without Over-Flush |

|---|---|---|---|---|

| Energy Recovery Effectiveness | 100% | 98.3% | 96.4% | 96.4% |

| Mixing | 0.0% | 1.3% | 2.5% | 6.0% |

| Over-Flush | 0.0% | 0.0% | 5.0% | 0.0% |

| Normalized S.E.C. for RO core process | 1.000 | 1.025 | 1.059 | 1.069 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurihara, M.; Takeuchi, H. SWRO-PRO System in “Mega-ton Water System” for Energy Reduction and Low Environmental Impact. Water 2018, 10, 48. https://doi.org/10.3390/w10010048

Kurihara M, Takeuchi H. SWRO-PRO System in “Mega-ton Water System” for Energy Reduction and Low Environmental Impact. Water. 2018; 10(1):48. https://doi.org/10.3390/w10010048

Chicago/Turabian StyleKurihara, Masaru, and Hiromu Takeuchi. 2018. "SWRO-PRO System in “Mega-ton Water System” for Energy Reduction and Low Environmental Impact" Water 10, no. 1: 48. https://doi.org/10.3390/w10010048