Performance of an Automatic Variable-Rate Fertilization System Subject to Different Initial Field Water Conditions and Fertilizer Doses in Paddy Fields

Abstract

:1. Introduction

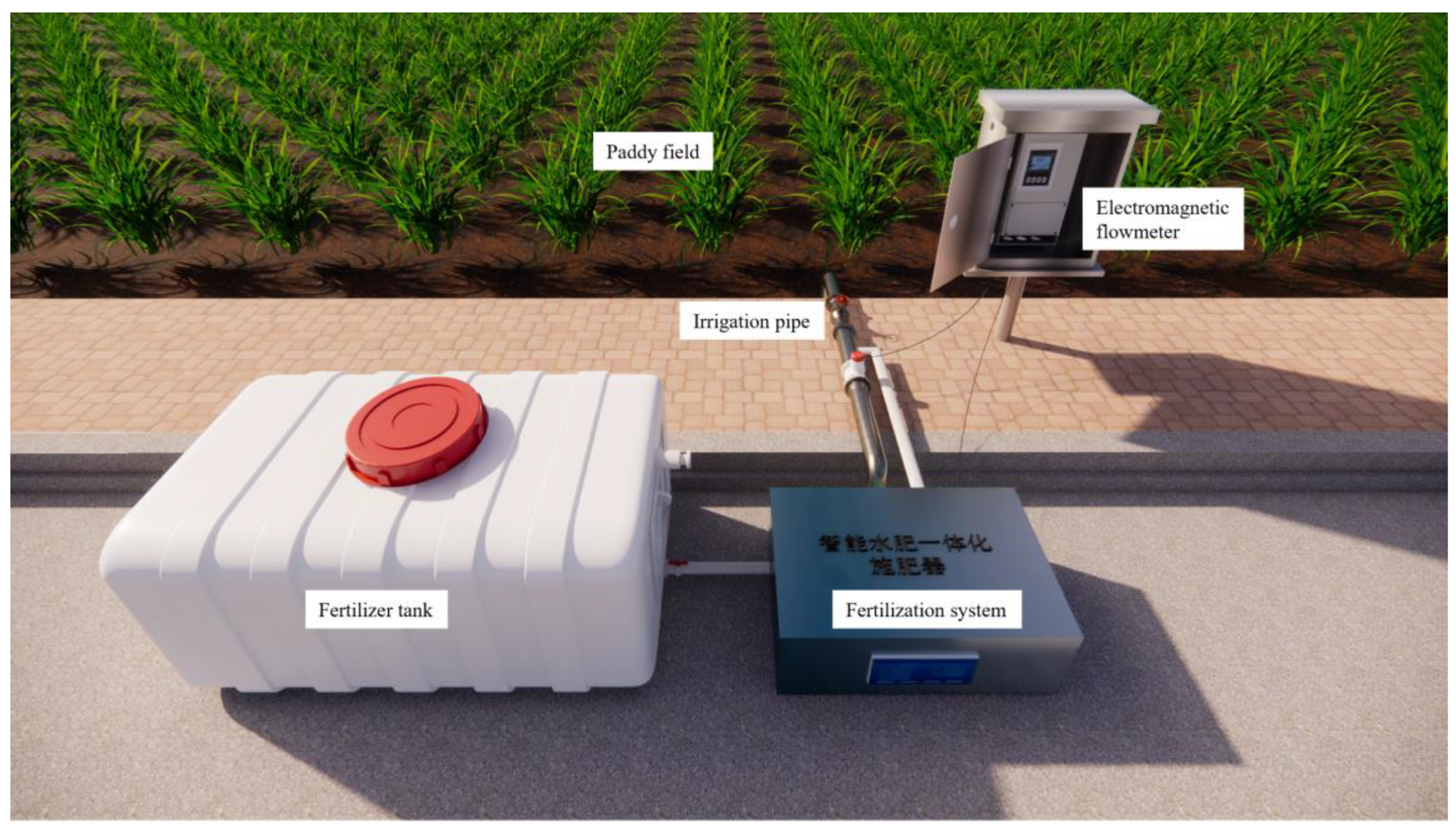

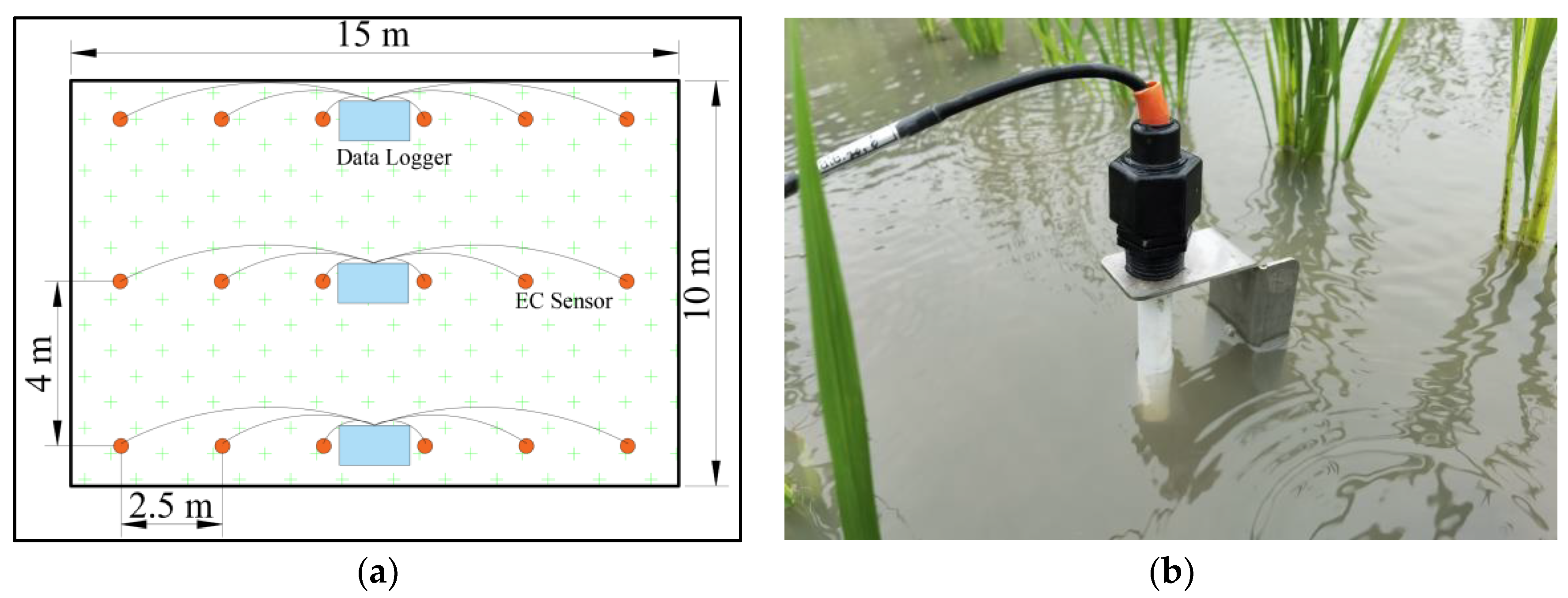

2. Materials and Methods

2.1. Test Site Design

2.2. Scenario Design

2.3. Concentration Monitoring

2.4. Data Analysis

3. Results and Discussion

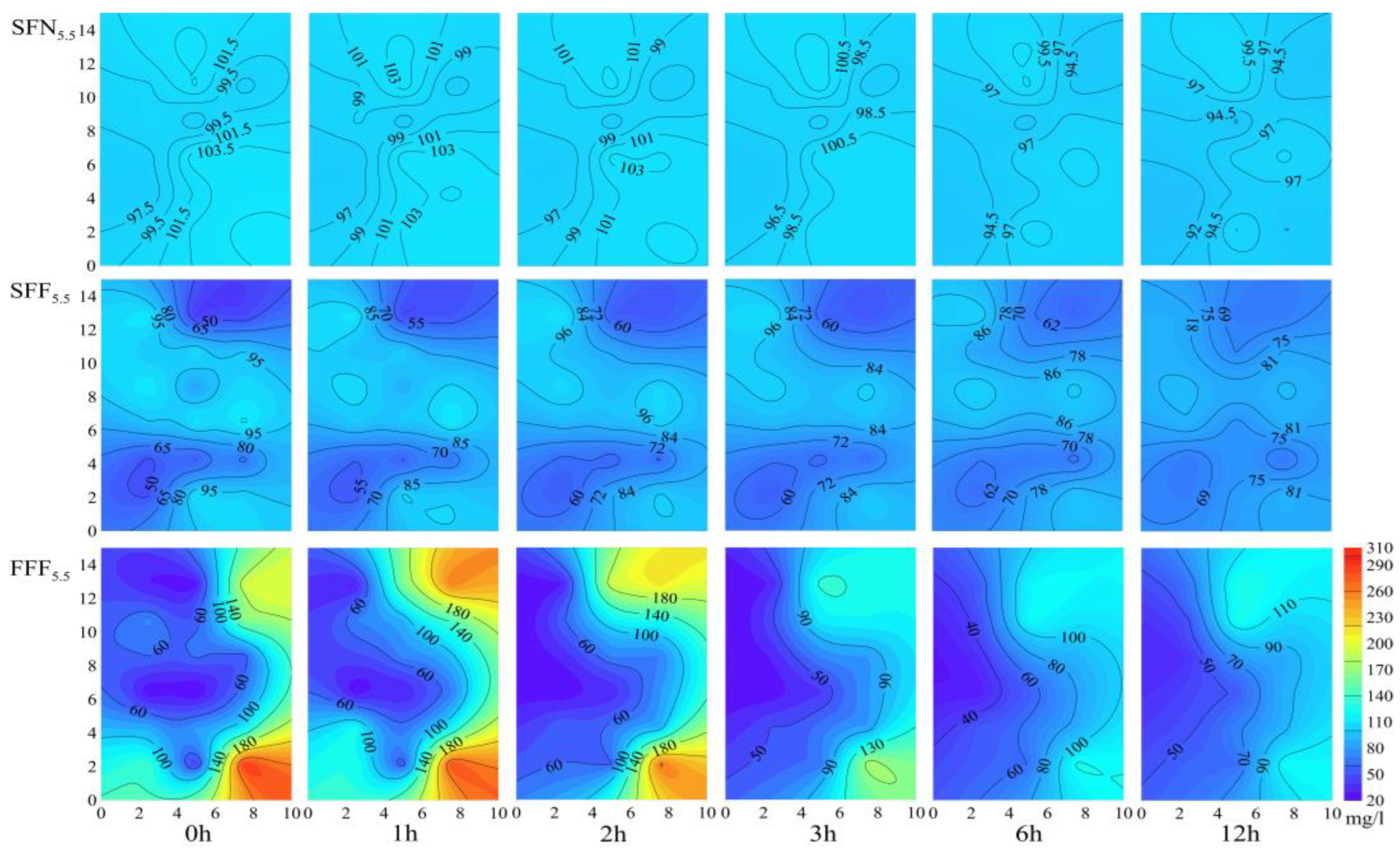

3.1. Fertilizer Concentration at the End of Fertilization

3.2. Fertilizer Concentration Distribution within 12 h

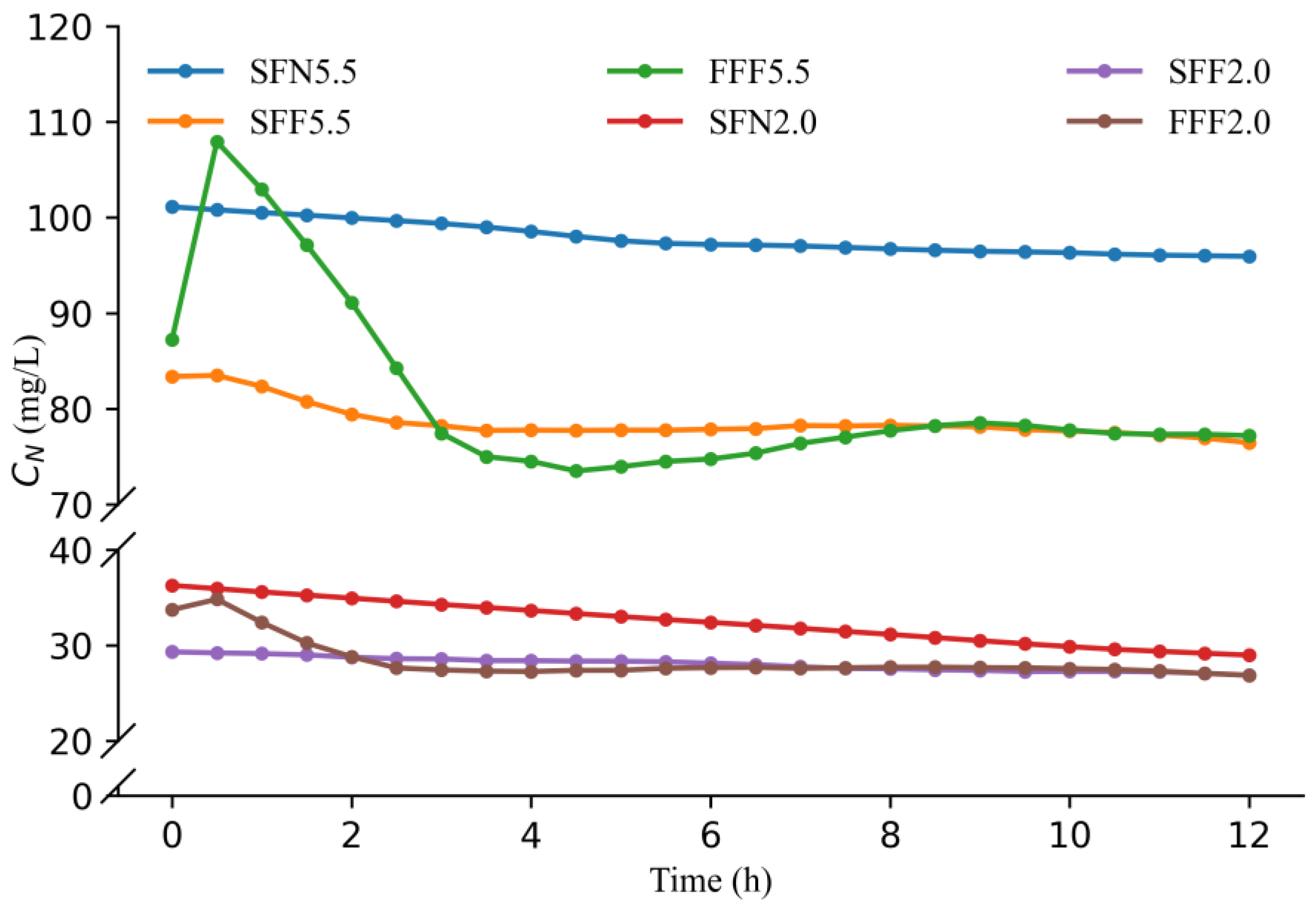

3.3. Dynamic Process of Fertilizer Concentration Changes within 12 h

3.4. Implications and Recommendations

4. Conclusions

- (1)

- SFN achieved the highest uniformity with CU approaching the maximum value (100%), compared with SFF; its CU increased by 35.98% (5.5 kg/plot) and 33.58% (2.0 kg/plot). Probably because the freshly irrigated water did not fully mix with the original water in the paddy fields, they had clear boundaries between them. Compared with FF, the CU of SFN increased by 137.68% and 93.72%.

- (2)

- Within 12 h after fertilization, the uniformity of the FFF and SFF treatments were significantly improved with the dissolution of solid fertilizer and the diffusion of ions driven by osmotic potential, but they were still unable to transcend SFN, which maintained a high uniformity all along.

- (3)

- The fertilization dose did not affect the uniformity of SF significantly because fertilizer can be considered as an indicator of water flow movement and mixing during fertigation, and it does not affect anything.

- (4)

- An automatic fertigation system combined with a water-saving irrigation mode and efficient fertilization management is suggested for paddy fields.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, A.B.; Wang, W.Q.; Jiang, G.L.; Sun, H.J.; Jiang, M.; Man, J.G.; Cui, K.H.; Huang, J.L.; Peng, S.B.; Nie, L.X. Source-sink regulation and its effects on the regeneration ability of ratoon rice. Field Crops Res. 2019, 236, 155–164. [Google Scholar] [CrossRef]

- Hu, L.L.; Ren, W.Z.; Tang, J.J.; Li, N.N.; Zhang, J.; Chen, X. The productivity of traditional rice-fish co-culture can be increased without increasing nitrogen loss to the environment. Agric. Ecosyst. Environ. 2013, 177, 28–34. [Google Scholar] [CrossRef]

- Shahi, U.P.; Singh, V.K.; Kumar, A.; Upadhyay, P.K.; Rai, P.K. Site-specific nutrient management: Impact on productivity, nutrient uptake and economics of rice-wheat system. Indian J. Agric. Sci. 2022, 92, 195–198. [Google Scholar] [CrossRef]

- Chen, Y.T.; Peng, J.; Wang, J.; Fu, P.H.; Hou, Y.; Zhang, C.D.; Fahad, S.; Peng, S.B.; Cui, K.H.; Nie, L.X.; et al. Crop management based on multi-split topdressing enhances grain yield and nitrogen use efficiency in irrigated rice in China. Field Crops Res. 2015, 184, 50–57. [Google Scholar] [CrossRef]

- Xu, J.; Liu, B.; Wang, H.; Liu, W.; Li, Y.; Dai, Y.; Lu, T. Ammonia volatilization and nitrogen leaching following top-dressing of urea from water-saving irrigated rice field: Impact of two-split surge irrigation. Paddy Water Environ. 2019, 17, 45–51. [Google Scholar] [CrossRef]

- Zhu, J.; Peng, H.; Ji, X.H.; Li, C.J.; Li, S.N. Effects of reduced inorganic fertilization and rice straw recovery on soil enzyme activities and bacterial community in double-rice paddy soils. Eur. J. Soil Biol. 2019, 94, 103116. [Google Scholar] [CrossRef]

- Rahman, K.M.A.; Zhang, D.F. Effects of Fertilizer Broadcasting on the Excessive Use of Inorganic Fertilizers and Environmental Sustainability. Sustainability 2018, 10, 759. [Google Scholar] [CrossRef] [Green Version]

- Hu, R.F.; Cao, J.M.; Huang, J.K.; Peng, S.B.; Huang, J.L.; Zhong, X.H.; Zou, Y.B.; Yang, J.C.; Buresh, R.J. Farmer participatory testing of standard and modified site-specific nitrogen management for irrigated rice in China. Agric. Syst. 2007, 94, 331–340. [Google Scholar] [CrossRef]

- Erisman, J.W.; Galloway, J.N.; Seitzinger, S.; Bleeker, A.; Dise, N.B.; Petrescu, A.M.R.; Leach, A.M.; de Vries, W. Consequences of human modification of the global nitrogen cycle. Philos. Trans. R. Soc. B-Biol. Sci. 2013, 368, 20130116. [Google Scholar] [CrossRef] [Green Version]

- Zhao, W.N.; Liang, H.L.; Fu, Y.; Liu, Y.B.; Yang, C.; Zhang, T.; Wang, T.Y.; Rong, L.Y.; Zhang, S.; Wu, Z.X.; et al. Effects of different fertilization modes on rice yield and quality under a rice-crab culture system. PLoS ONE 2020, 15, e0230600. [Google Scholar] [CrossRef]

- Wei, H.Y.; Chen, Z.F.; Xing, Z.P.; Zhou, L.; Liu, Q.Y.; Zhang, Z.Z.; Jiang, Y.; Hu, Y.J.; Zhu, J.Y.; Cui, P.Y.; et al. Effects of slow or controlled release fertilizer types and fertilization modes on yield and quality of rice. J. Integr. Agric. 2018, 17, 2222–2234. [Google Scholar] [CrossRef]

- MOA. Guidelines for Scientific Rice Fertilization in 2022. Available online: http://www.moa.gov.cn/xw/zxfb/202203/t20220329_6394524.htm (accessed on 9 March 2023).

- Gu, B.; Zhang, X.; Lam, S.K.; Yu, Y.; van Grinsven, H.J.M.; Zhang, S.; Wang, X.; Bodirsky, B.L.; Wang, S.; Duan, J.; et al. Cost-effective mitigation of nitrogen pollution from global croplands. Nature 2023, 613, 77–84. [Google Scholar] [CrossRef]

- Zhang, W.F.; Cao, G.X.; Li, X.L.; Zhang, H.Y.; Wang, C.; Liu, Q.Q.; Chen, X.P.; Cui, Z.L.; Shen, J.B.; Jiang, R.F.; et al. Closing yield gaps in China by empowering smallholder farmers. Nature 2016, 537, 671–674. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.L.; He, F.; Cui, K.H.; Buresh, R.J.; Xu, B.; Gong, W.H.; Peng, S.B. Determination of optimal nitrogen rate for rice varieties using a chlorophyll meter. Field Crops Res. 2008, 105, 70–80. [Google Scholar] [CrossRef]

- Ghosh, M.; Swain, D.K.; Jha, M.K.; Tewari, V.K.; Bohra, A. Optimizing chlorophyll meter (SPAD) reading to allow efficient nitrogen use in rice and wheat under rice-wheat cropping system in eastern India. Plant Prod. Sci. 2020, 23, 270–285. [Google Scholar] [CrossRef] [Green Version]

- Islam, Z.; Bagchi, B.; Hossain, M. Adoption of leaf color chart for nitrogen use efficiency in rice: Impact assessment of a farmer-participatory experiment in West Bengal, India. Field Crops Res. 2007, 103, 70–75. [Google Scholar] [CrossRef]

- Pampolino, M.F.; Manguiat, I.J.; Ramanathan, S.; Gines, H.C.; Tan, P.S.; Chi, T.T.N.; Rajendran, R.; Buresh, R.J. Environmental impact and economic benefits of site-specific nutrient management (SSNM) in irrigated rice systems. Agric. Syst. 2007, 93, 1–24. [Google Scholar] [CrossRef]

- Liu, L.J.; Chen, T.T.; Wang, Z.Q.; Zhang, H.; Yang, J.C.; Zhang, J.H. Combination of site-specific nitrogen management and alternate wetting and drying irrigation increases grain yield and nitrogen and water use efficiency in super rice. Field Crops Res. 2013, 154, 226–235. [Google Scholar] [CrossRef]

- Rodriguez, D.G.P. An Assessment of the Site-Specific Nutrient Management (SSNM) Strategy for Irrigated Rice in Asia. Agric. -Basel 2020, 10, 559. [Google Scholar] [CrossRef]

- Sutton, M.A.; Bleeker, A.; Howard, C.M.; Erisman, J.W.; Zhang, F.S. Our Nutrient World. The Challenge to Produce More Food & Energy with Less Pollution; Centre for Ecology and Hydrology (CEH): Bailrigg, UK, 2013. [Google Scholar]

- Wu, Y.Y.; Xi, X.C.; Tang, X.; Luo, D.M.; Gu, B.J.; Lam, S.K.; Vitousek, P.M.; Chen, D.L. Policy distortions, farm size, and the overuse of agricultural chemicals in China. Proc. Natl. Acad. Sci. USA 2018, 115, 7010–7015. [Google Scholar] [CrossRef] [Green Version]

- MinTech. Factors that Affect Uniform Fertilizer Application, Even Distribution Can Directly Impact Crop Yield. Available online: https://mintech.com/factors-that-affect-uniform-fertilizer-application/ (accessed on 6 June 2023).

- Li, S.; Wei, Q.; Xu, J.; Wang, H.; Zhou, J. Improving Nitrogen Use Efficiency and Growth of Paddy Rice Using Controlled Fertigation. J. Irrig. Drain. 2021, 40, 79–86, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Dong, X.Q.; Song, J.N.; Zhang, J.K.; Kang, X.J.; Wang, J.C. Working performance and experiment on granular fertilizer spreader with cone disk. Trans. Chin. Soc. Agric. Eng. 2013, 29, 33–40, (In Chinese with English abstract). [Google Scholar]

- Scheufler, B. Mineral Fertilizing, Yearbook Agricultural Engineering; Max-Eyth-Stiftung: Hessen, Germany, 2010. [Google Scholar]

- Song, C.C.; Zang, Y.; Zhou, Z.Y.; Luo, X.W.; Zhao, L.L.; Ming, R.; Zi, L.; Zang, Y. Test and Comprehensive Evaluation for the Performance of UAV-Based Fertilizer Spreaders. IEEE Access 2020, 8, 202153–202163. [Google Scholar] [CrossRef]

- Abd Kharim, M.N.; Wayayok, A.; Shariff, A.R.M.; Abdullah, A.F.; Husin, E.M. Droplet deposition density of organic liquid fertilizer at low altitude UAV aerial spraying in rice cultivation. Comput. Electron. Agric. 2019, 167, 105045. [Google Scholar] [CrossRef]

- Song, C.; Zhou, Z.; Zang, Y.; Zhao, L.; Yang, W.; Luo, X.; Jiang, R.; Ming, R.; Zang, Y.; Zi, L.; et al. Variable-rate control system for UAV-based granular fertilizer spreader. Comput. Electron. Agric. 2021, 180, 105832. [Google Scholar] [CrossRef]

- Xu, T.S.; Su, N.; Wang, R.J.; Song, L.T. A Novel Variable Rate Fertilization System Based on the Android Platform. In Proceedings of the 3rd IEEE International Conference on Progress in Informatcs and Computing (IEEE PIC), Nanjing, China, 18–20 December 2015; pp. 395–398. [Google Scholar]

- Vakilian, K.A.; Massah, J. A farmer-assistant robot for nitrogen fertilizing management of greenhouse crops. Comput. Electron. Agric. 2017, 139, 153–163. [Google Scholar] [CrossRef]

- Shi, Y.; Hu, Z.; Wang, X.; Odhiambo, M.O.; Ding, W. Motion analysis and system response of fertilizer feed apparatus for paddy Variable-Rate fertilizer spreader. Comput. Electron. Agric. 2018, 153, 239–247. [Google Scholar] [CrossRef]

- Sharmiladevi, R.; Ravikumar, V. Simulation of nitrogen fertigation schedule for drip irrigated paddy. Agric. Water Manag. 2021, 252, 106841. [Google Scholar] [CrossRef]

- Li, Y.W.; Xu, J.Z.; Liu, X.Y.; Liu, B.Y.; Liu, W.X.; Jiao, X.Y.; Zhou, J.Y. Win-win for monosodium glutamate industry and paddy agriculture: Replacing chemical nitrogen with liquid organic fertilizer from wastewater mitigates reactive nitrogen losses while sustaining yields. J. Clean. Prod. 2022, 347, 131287. [Google Scholar] [CrossRef]

- Wang, H.; Gu, Z.; Xu, J.; Li, S.; Qi, Z.; Li, Y.; Zhou, J. Automatic variable rate fertilisation system for improved fertilisation uniformity in paddy fields. Biosyst. Eng. 2022, 219, 56–67. [Google Scholar] [CrossRef]

- Qi, L.; Niu, H.D.; Zhou, P.; Jia, R.J.; Gao, M. Effects of Biochar on the Net Greenhouse Gas Emissions under Continuous Flooding and Water-Saving Irrigation Conditions in Paddy Soils. Sustainability 2018, 10, 1403. [Google Scholar] [CrossRef] [Green Version]

- MOA. Paddy Controlled Irrigation Area Reached 30 million Mu in Heilongjiang Province. Available online: http://www.moa.gov.cn/xw/zxfb/202203/t20220329_6394524.htm (accessed on 9 March 2023).

- Redhyka, G.G.; Setiawan, D.; Soetraprawata, D. Embedded Sensor Fusion and Moving-average Filter for Inertial Measurement Unit (IMU) on the Microcontroller-based Stabilized Platform. In Proceedings of the International Conference on Automation, Cognitive Science, Optics, Micro Electro-Mechanical System, and Information Technology (ICACOMIT), Lipi Balai Pengembangan Instrumentasi, Bandung, Indonesia, 29–30 October 2015; pp. 72–77. [Google Scholar]

- Xiong, J.B.; Wang, Q.R.; Wan, J.F.; Ye, B.Y.; Xu, W.C.; Liu, J.Q. Detection of Outliers in Sensor Data Based on Adaptive Moving Average Fitting. Sens. Lett. 2013, 11, 877–882. [Google Scholar] [CrossRef]

- Bourg, I.C.; Richter, F.M.; Christensen, J.N.; Sposito, G. Isotopic mass dependence of metal cation diffusion coefficients in liquid water. Geochim. Et Cosmochim. Acta 2010, 74, 2249–2256. [Google Scholar] [CrossRef] [Green Version]

- Wanner, P.; Hunkeler, D. Isotope fractionation due to aqueous phase diffusion—What do diffusion models and experiments tell?—A review. Chemosphere 2019, 219, 1032–1043. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Peng, S.; Yang, S.; Wang, W. Ammonia volatilization losses from a rice paddy with different irrigation and nitrogen managements. Agric. Water Manag. 2012, 104, 184–192. [Google Scholar] [CrossRef]

- Peng, S.-Z.; Yang, S.-H.; Xu, J.-Z.; Luo, Y.-F.; Hou, H.-J. Nitrogen and phosphorus leaching losses from paddy fields with different water and nitrogen managements. Paddy Water Environ. 2011, 9, 333–342. [Google Scholar] [CrossRef]

- Qiu, H.N.; Yang, S.H.; Jiang, Z.W.; Xu, Y.; Jiao, X.Y. Effect of Irrigation and Fertilizer Management on Rice Yield and Nitrogen Loss: A Meta-Analysis. Plants 2022, 11, 1690. [Google Scholar] [CrossRef]

| Abbreviation | Fertilization Method | Initial Field Status | Fertilizer Dosage |

|---|---|---|---|

| FFF5.5 | FF | Flooded, ≈6.0 cm | 5.5 kg/plot |

| SFF5.5 | SF | Flooded, ≈2.0 cm | 5.5 kg/plot |

| FFF2.0 | FF | Flooded, ≈6.0 cm | 2.0 kg/plot |

| SFF2.0 | SF | Flooded, ≈2.0 cm | 2.0 kg/plot |

| SFN2.0 | SF | Non-Flooded | 2.0 kg/plot |

| SFN5.5 | SF | Non-Flooded | 5.5 kg/plot |

| Indicator | Equation | Variable |

|---|---|---|

| Christiansen Uniformity Coefficient (CU, %) | where is the i-th observation of the N concentration (mg/L); is the mean N concentration (mg/L); M is the number of observation points, M = 18; is the mean value of the smaller quarter of M observations (mg/L); and are the maximum and minimum N concentrations from M observations (mg/L), respectively. | |

| Uniformity of Distribution (DU) | ||

| Coefficient of Variation (Cv) | ||

| Range (R, mg/L) |

| Treatment | Time (h) | CU (%) | DU | CV | R (mg/L) |

|---|---|---|---|---|---|

| SFN5.5 | 0 | 97.12 | 0.96 | 0.03 | 10.21 |

| 1 | 97.15 | 0.96 | 0.03 | 9.23 | |

| 2 | 97.36 | 0.96 | 0.03 | 8.88 | |

| 3 | 97.26 | 0.96 | 0.03 | 9.46 | |

| 6 | 96.98 | 0.96 | 0.03 | 10.16 | |

| 12 | 96.77 | 0.96 | 0.04 | 12.21 | |

| SFF5.5 | 0 | 71.42 | 0.55 | 0.32 | 73.75 |

| 1 | 75.34 | 0.61 | 0.28 | 66.56 | |

| 2 | 77.88 | 0.67 | 0.25 | 57.55 | |

| 3 | 79.86 | 0.69 | 0.23 | 55.31 | |

| 6 | 83.48 | 0.76 | 0.19 | 43.83 | |

| 12 | 88.89 | 0.84 | 0.13 | 26.65 | |

| FFF5.5 | 0 | 40.86 | 0.30 | 0.81 | 273.36 |

| 1 | 46.50 | 0.34 | 0.71 | 260.25 | |

| 2 | 44.60 | 0.39 | 0.75 | 242.58 | |

| 3 | 58.25 | 0.45 | 0.54 | 154.63 | |

| 6 | 65.70 | 0.57 | 0.40 | 95.08 | |

| 12 | 68.04 | 0.59 | 0.38 | 88.46 | |

| SFN2.0 | 0 | 95.34 | 0.92 | 0.05 | 5.57 |

| 1 | 95.42 | 0.92 | 0.05 | 5.45 | |

| 2 | 95.47 | 0.92 | 0.05 | 5.81 | |

| 3 | 95.52 | 0.93 | 0.05 | 5.74 | |

| 6 | 95.66 | 0.93 | 0.05 | 5.49 | |

| 12 | 95.36 | 0.93 | 0.06 | 5.50 | |

| SFF2.0 | 0 | 71.37 | 0.50 | 0.34 | 29.26 |

| 1 | 71.73 | 0.51 | 0.34 | 28.99 | |

| 2 | 71.92 | 0.51 | 0.34 | 28.01 | |

| 3 | 72.94 | 0.53 | 0.33 | 27.17 | |

| 6 | 78.13 | 0.62 | 0.26 | 21.77 | |

| 12 | 85.48 | 0.79 | 0.17 | 14.21 | |

| FFF2.0 | 0 | 49.21 | 0.27 | 0.57 | 54.82 |

| 1 | 52.46 | 0.35 | 0.53 | 49.46 | |

| 2 | 61.34 | 0.45 | 0.44 | 42.64 | |

| 3 | 68.35 | 0.53 | 0.37 | 33.83 | |

| 6 | 78.66 | 0.68 | 0.26 | 24.50 | |

| 12 | 82.26 | 0.72 | 0.22 | 21.81 |

| CU (%) | SFN5.5 | SFF5.5 | FFF5.5 | SFN2.0 | SFF2.0 | FFF2.0 | |

|---|---|---|---|---|---|---|---|

| 97.12 | 71.42 | 40.86 | 95.34 | 71.37 | 49.21 | ||

| SFN5.5 | 97.12 | 0.00 | −26.46 | −57.93 | −1.83 | −26.51 | −49.33 |

| SFF5.5 | 71.42 | 35.98 | 0.00 | −42.79 | 33.49 | −0.07 | −31.09 |

| FFF5.5 | 40.86 | 137.68 | 74.79 | 0.00 | 133.32 | 74.67 | 20.44 |

| SFN2.0 | 95.34 | 1.87 | −25.09 | −57.14 | 0.00 | −25.14 | −48.38 |

| SFF2.0 | 71.37 | 36.08 | 0.07 | −42.75 | 33.58 | 0.00 | −31.04 |

| FFF2.0 | 49.21 | 97.34 | 45.12 | −16.97 | 93.72 | 45.02 | 0.00 |

| DU | SFN5.5 | SFF5.5 | FFF5.5 | SFN2.0 | SFF2.0 | FFF2.0 | |

|---|---|---|---|---|---|---|---|

| 0.96 | 0.55 | 0.30 | 0.92 | 0.50 | 0.27 | ||

| SFN5.5 | 0.96 | 0.00 | −42.95 | −68.29 | −3.53 | −47.74 | −71.65 |

| SFF5.5 | 0.55 | 75.30 | 0.00 | −44.41 | 69.10 | −8.39 | −50.30 |

| FFF5.5 | 0.30 | 215.32 | 79.88 | 0.00 | 204.18 | 64.78 | −10.60 |

| SFN2.0 | 0.92 | 3.66 | −40.86 | −67.12 | 0.00 | −45.83 | −70.61 |

| SFF2.0 | 0.50 | 91.35 | 9.16 | −39.31 | 84.59 | 0.00 | −45.75 |

| FFF2.0 | 0.27 | 252.71 | 101.21 | 11.86 | 240.25 | 84.32 | 0.00 |

| Cv | SFN5.5 | SFF5.5 | FFF5.5 | SFN2.0 | SFF2.0 | FFF2.0 | |

|---|---|---|---|---|---|---|---|

| 0.03 | 0.32 | 0.81 | 0.05 | 0.34 | 0.57 | ||

| SFN5.5 | 0.03 | 0.00 | −848.81 | −2288.76 | −58.68 | −901.25 | −1574.32 |

| SFF5.5 | 0.32 | 89.46 | 0.00 | −151.76 | 83.28 | -5.53 | −76.47 |

| FFF5.5 | 0.81 | 95.81 | 60.28 | 0.00 | 93.36 | 58.09 | 29.91 |

| SFN2.0 | 0.05 | 36.98 | −497.93 | −1405.36 | 0.00 | −530.97 | −955.13 |

| SFF2.0 | 0.34 | 90.01 | 5.24 | −138.58 | 84.15 | 0.00 | −67.22 |

| FFF2.0 | 0.57 | 94.03 | 43.33 | −42.67 | 90.52 | 40.20 | 0.00 |

| R (mg/L) | SFN5.5 | SFF5.5 | FFF5.5 | SFN2.0 | SFF2.0 | FFF2.0 | |

|---|---|---|---|---|---|---|---|

| 10.21 | 73.75 | 273.36 | 5.57 | 29.26 | 54.82 | ||

| SFN5.5 | 10.21 | 0.00 | −63.54 | −263.15 | - | - | - |

| SFF5.5 | 73.75 | 63.54 | 0.00 | −199.61 | - | - | - |

| FFF5.5 | 273.36 | 263.15 | 199.61 | 0.00 | - | - | - |

| SFN2.0 | 5.57 | - | - | - | 0.00 | −23.69 | −49.26 |

| SFF2.0 | 29.26 | - | - | - | 23.69 | 0.00 | −25.57 |

| FFF2.0 | 54.82 | - | - | - | 49.26 | 25.57 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Xu, J.; Chen, B.; Li, Y.; Li, S.; Liang, H.; Jiang, Q.; He, Y.; Xi, W. Performance of an Automatic Variable-Rate Fertilization System Subject to Different Initial Field Water Conditions and Fertilizer Doses in Paddy Fields. Agronomy 2023, 13, 1629. https://doi.org/10.3390/agronomy13061629

Wang H, Xu J, Chen B, Li Y, Li S, Liang H, Jiang Q, He Y, Xi W. Performance of an Automatic Variable-Rate Fertilization System Subject to Different Initial Field Water Conditions and Fertilizer Doses in Paddy Fields. Agronomy. 2023; 13(6):1629. https://doi.org/10.3390/agronomy13061629

Chicago/Turabian StyleWang, Haiyu, Junzeng Xu, Bing Chen, Yawei Li, Shuai Li, Hao Liang, Qianjing Jiang, Yong He, and Wenjia Xi. 2023. "Performance of an Automatic Variable-Rate Fertilization System Subject to Different Initial Field Water Conditions and Fertilizer Doses in Paddy Fields" Agronomy 13, no. 6: 1629. https://doi.org/10.3390/agronomy13061629