Enhanced Injection Molding Simulation of Advanced Injection Molds

Abstract

:1. Introduction

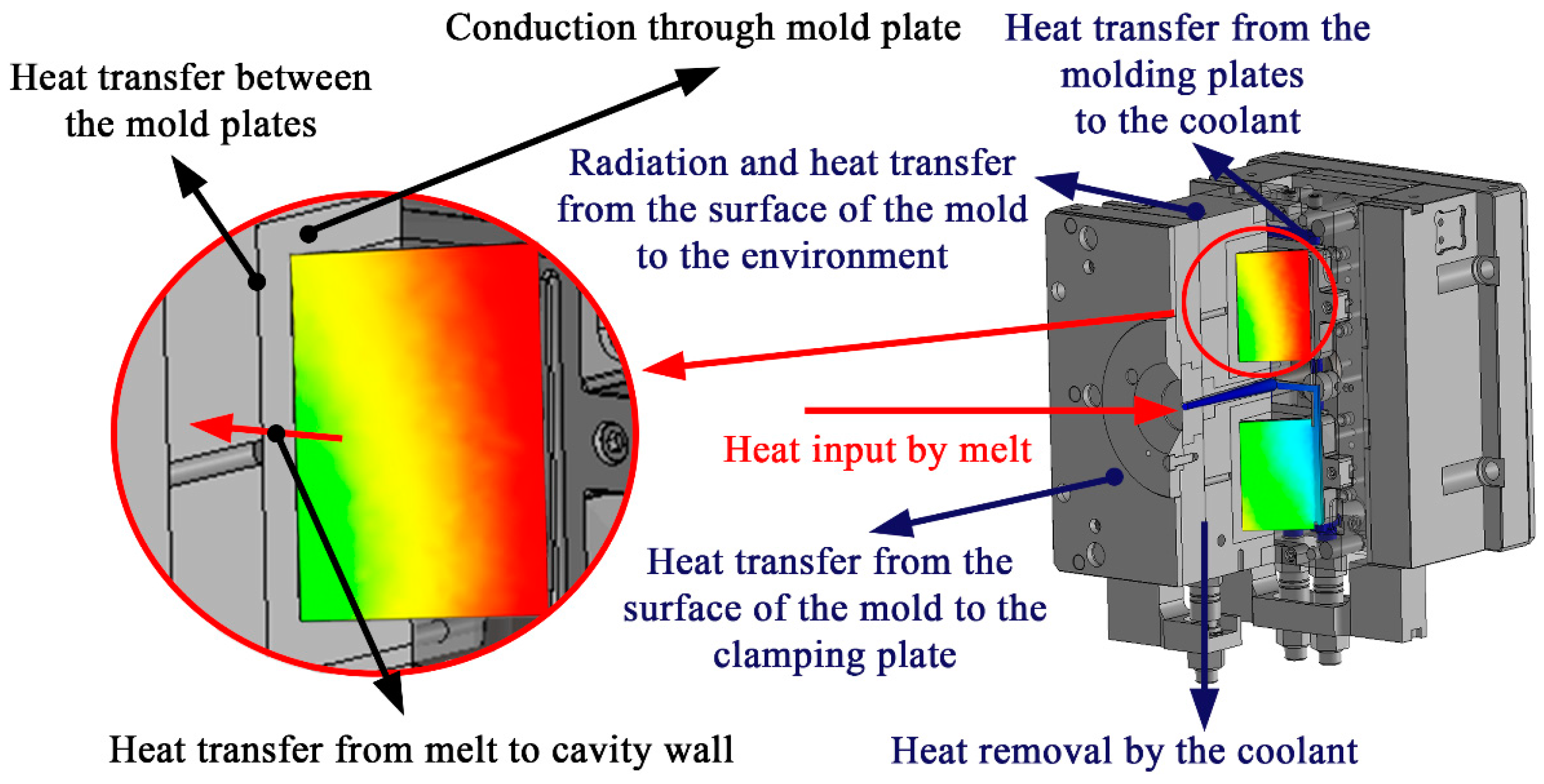

2. Heat Transfer Equations

3. Experimental and Simulation

3.1. Simulation

3.2. Mold Materials

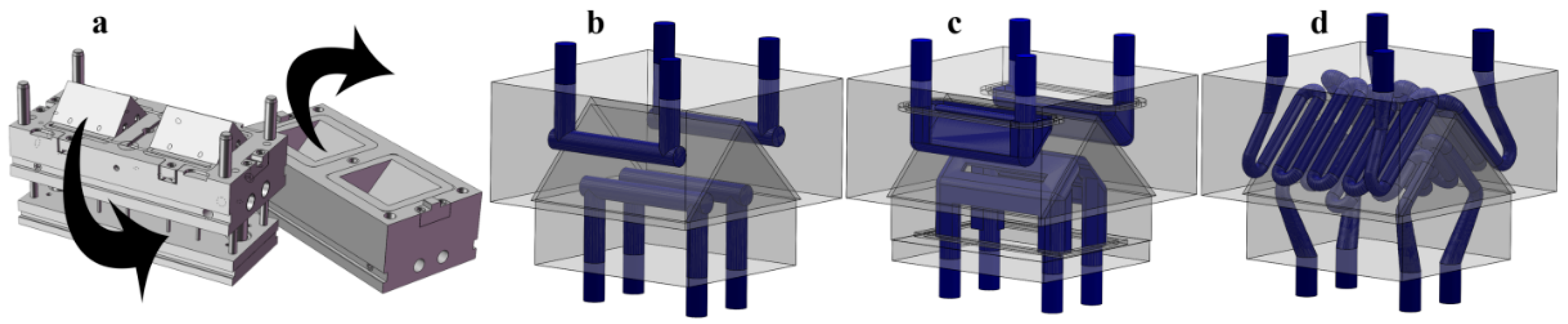

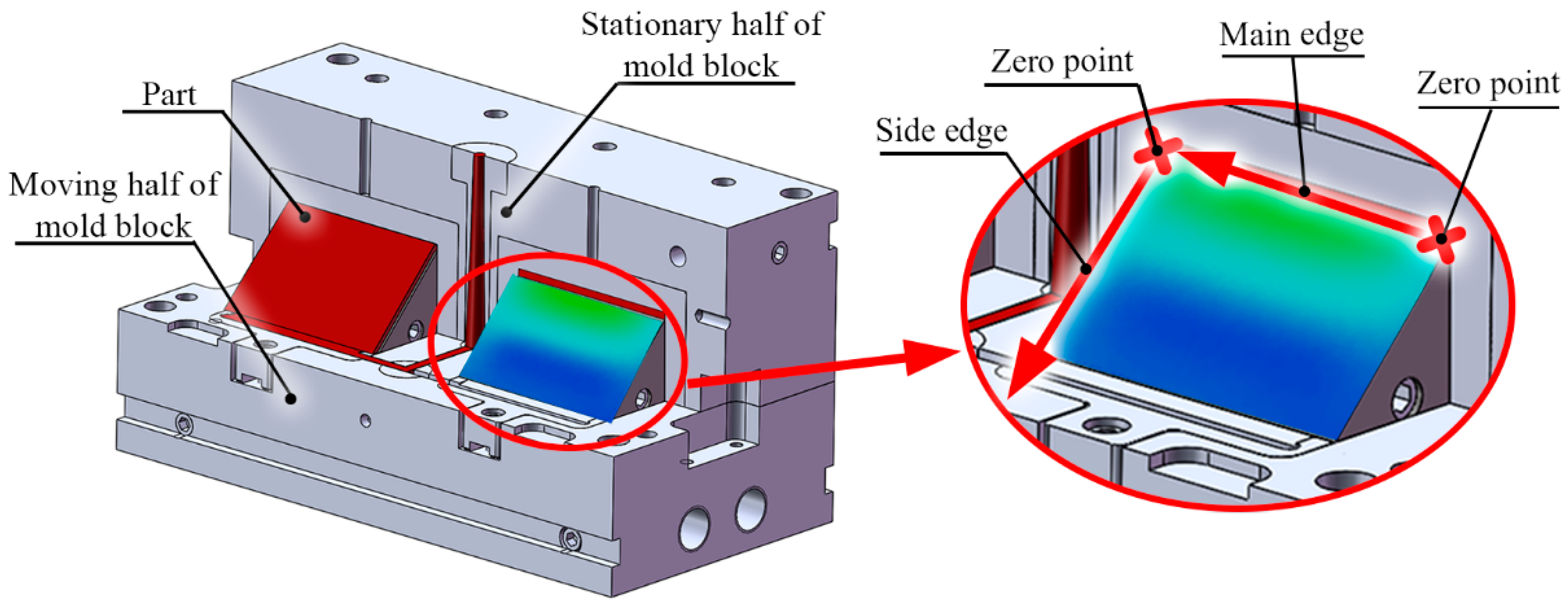

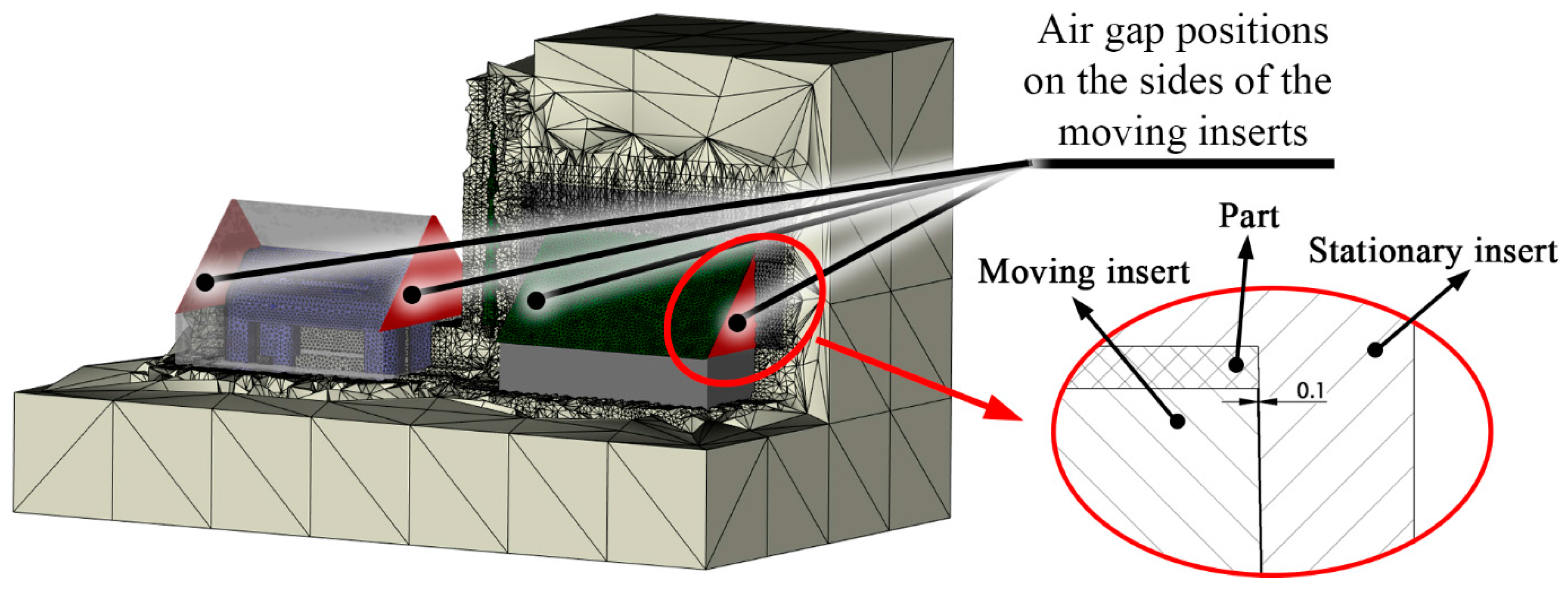

3.3. Mold Design

3.4. Temperature Measurent

4. Results and Discussion

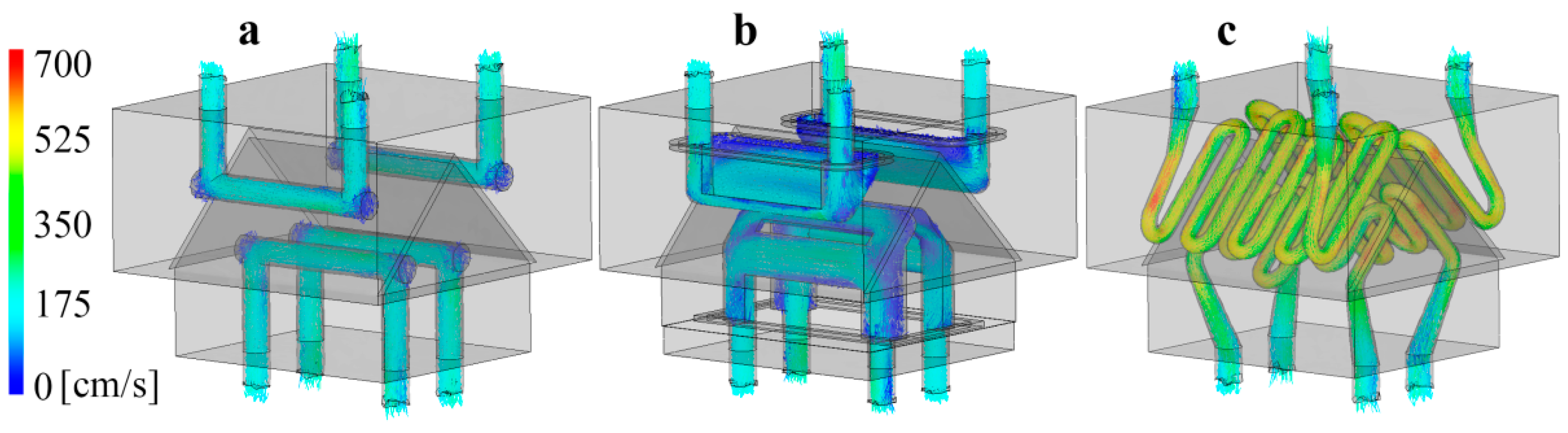

4.1. Flow Analysis of Cooling Circuits

4.2. Examination of the Cross-Sectional Temperature of Mold Inserts

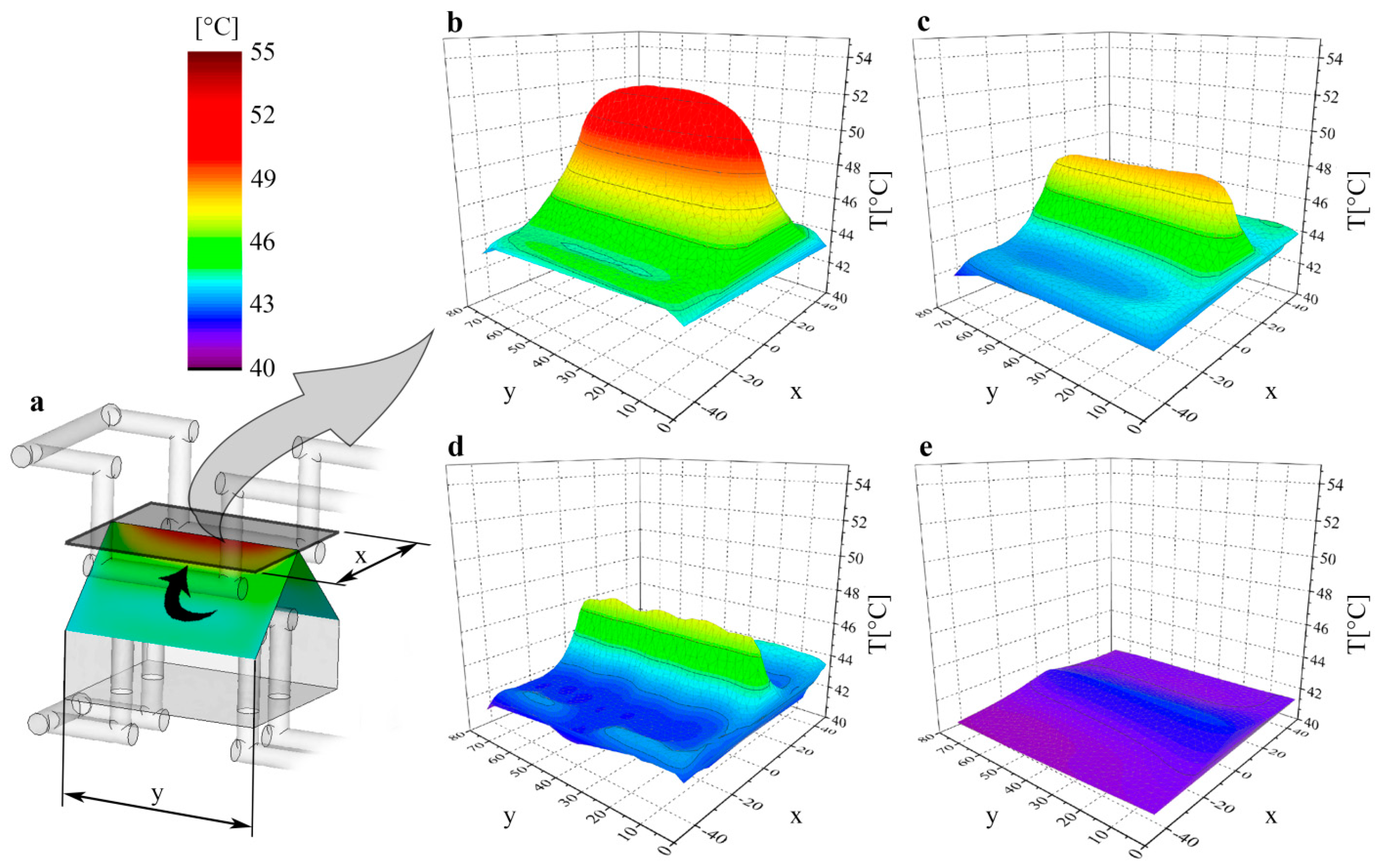

4.3. Evaluation of Surface Temperature

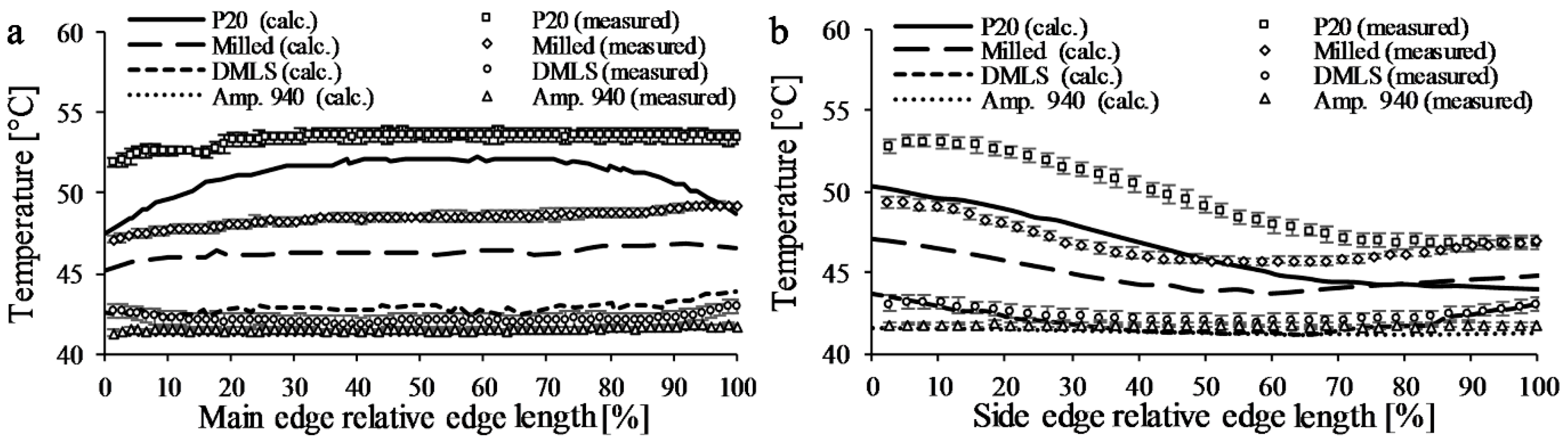

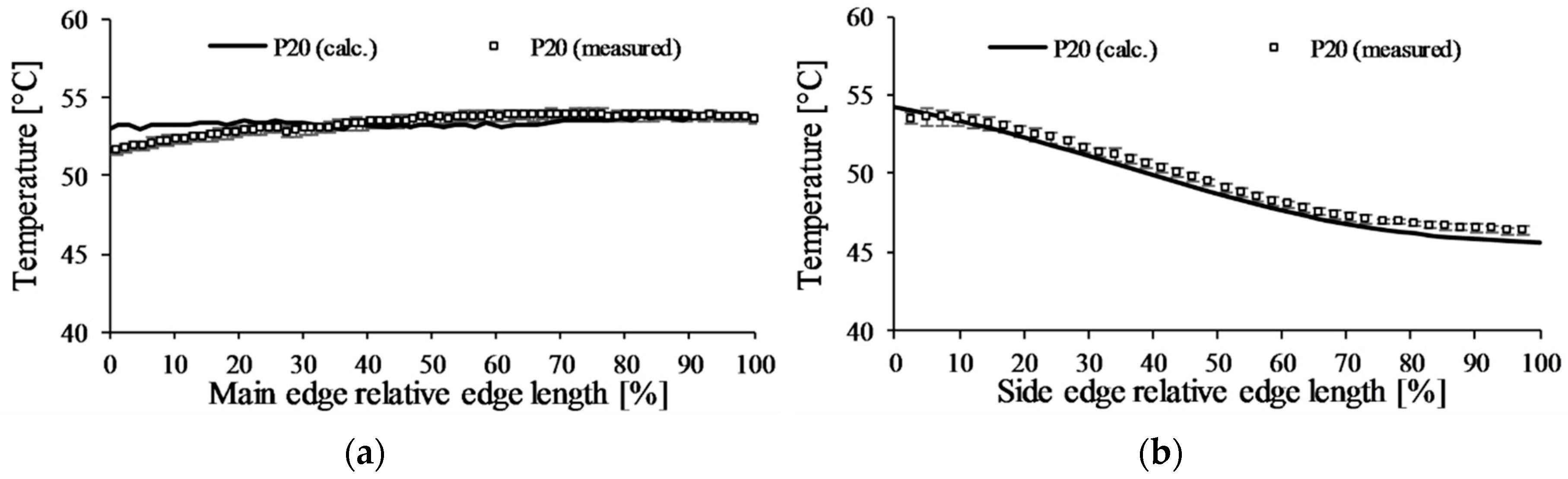

4.4. Measurement of Surface Temperature

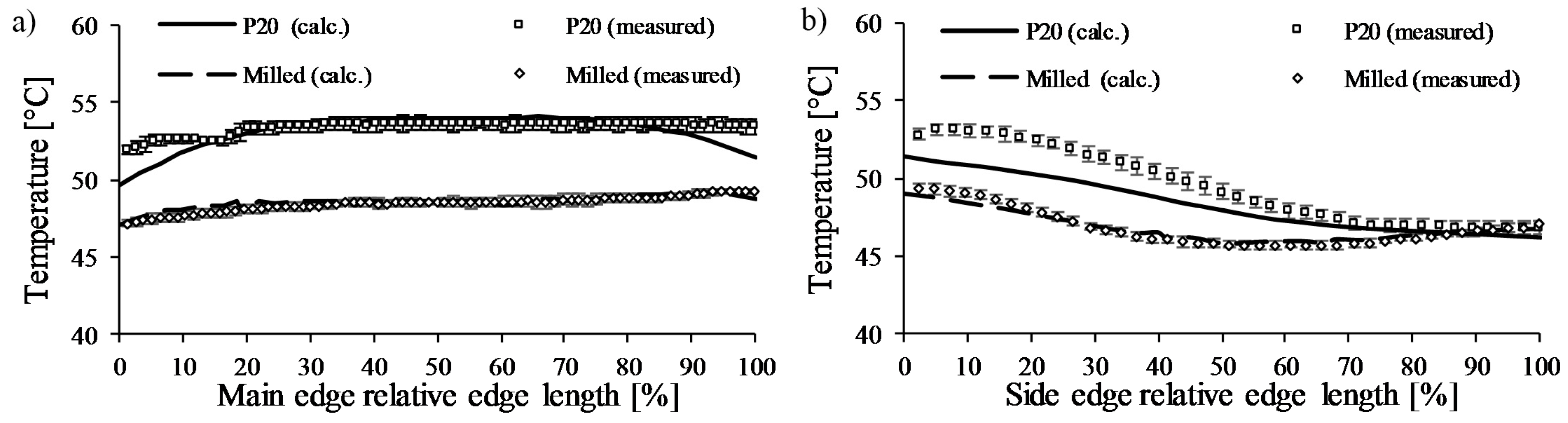

4.5. Investigating the Temperature Differences

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| ρ | density, kg·m−3 | v | velocity, ms−1 |

| t | time, s | p | pressure, Pa |

| η | dynamic viscosity Pas | g | gravitational acceleration, m·s−2 |

| cp | specific heat, Jkg−1·K−1 | T | temperature K |

| ∆T | temperature difference, K | λ | thermal conductivity, Wm−1·K−1 |

| β | polymer expansivity, K−1 | σ0 | Stefan-Boltzmann constant, Wm−2·K−4 |

| ε | emissivity, - | A | cross section, m2 |

| δ | thickness, m | α | heat transfer coefficient, Wm−2·K−1 |

References

- Michaeli, W.; Schönfeld, M. Komplexe Formteile kühlen. Kunststoffe 2006, 8, 37–41. [Google Scholar]

- Petzoldt, F.; Pohl, H.; Simchi, A.; Alcantara, B. DMLS gets an expert once-over. Met. Powder Rep. 2006, 61, 10–13. [Google Scholar] [CrossRef]

- Khaing, M.W.; Fuh, J.Y.H.; Lu, L. Direct metal laser sintering for rapid tooling: Processing and characterisation of EOS parts. J. Mater. Process. Technol. 2001, 113, 269–272. [Google Scholar] [CrossRef]

- Simchi, A. Direct laser sintering of metal powders: Mechanism, kinetics and microstructural features. Mater. Sci. Eng. 2006, 428, 148–158. [Google Scholar] [CrossRef]

- Rossi, S.; Deflorian, F.; Venturini, F. Improvement of surface finishing and corrosion resistance of prototypes produced by direct metal laser sintering. J. Mater. Process. Technol. 2004, 148, 301–309. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Bandyopadhyay, K.; Saha, P. Development of an in-situ multi-component reinforced Al-based metal matrix composite by direct metal laser sintering technique Optimization of process parameters. Mater. Charact. 2014, 93, 68–78. [Google Scholar] [CrossRef]

- Tang, Y.; Loh, H.T.; Wong, Y.S.; Fuh, J.Y.H.; Lu, L.; Wang, X. Direct laser sintering of a copper-based alloy for creating three-dimensional metal parts. J. Mater. Process. Technol. 2003, 140, 368–372. [Google Scholar] [CrossRef]

- Yana, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Z.; Zhou, H.; Li, D. A rapid BEM-based method for cooling simulation of injection molding. Eng. Anal. Bound. Elem. 2015, 52, 110–119. [Google Scholar] [CrossRef]

- Liu, Y.; Gehde, M. Evaluation of heat transfer coefficient between polymer and cavity wall for improving cooling and crystallinity results in injection molding simulation. Appl. Therm. Eng. 2015, 80, 238–246. [Google Scholar] [CrossRef]

- Ilyas, I.; Taylor, C.; Dalgarno, K.; Gosden, J. Design and manufacture of injection mould tool inserts produced using indirect SLS and machining processes. Rapid Prototyp. J. 2010, 16, 429–440. [Google Scholar] [CrossRef]

- Meckley, J.; Edwards, R. A study on the design and effectiveness of conformal cooling channels in rapid tooling inserts. Technol. Interface J. 2009, 10, 1–28. [Google Scholar]

- Coremans, A.; Kauf, M.; Hoffmann, P. Laser assisted rapid tooling of molds and dies. In Proceedings of the 5th European Conference on Rapid Prototyping and Manufacturing, Helsinki, Finland, 4–5 June 1996; pp. 195–210.

- Rännar, L.-E.; Glad, A.; Gustafson, C.-G. Efficient cooling with tool inserts manufactured by electron beam melting. Rapid Prototyp. J. 2007, 13, 128–135. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, K.-M.; Wang, C.C.L.; Zhang, Y. Automatic design of conformal cooling circuits for rapid tooling. Comput. Aided Des. 2011, 43, 1001–1010. [Google Scholar] [CrossRef]

- Kmetty, A.; Tabi, T.; Kovacs, J.G.; Barany, T. Development and characterisation of injection moulded, all-polypropylene composites. Express Polym. Lett. 2013, 7, 134–145. [Google Scholar] [CrossRef]

- Imre, B.; Renner, K.; Pukanszky, B. Interactions, structure and properties in poly(lactic acid)/thermoplastic polymer blends. Express Polym. Lett. 2014, 8, 2–14. [Google Scholar] [CrossRef]

- Hassan, H.; Regnier, N.; le Bot, C.; Defaye, G. 3D study of cooling system effect on the heat transfer during polymer injection molding. Int. J. Therm. Sci. 2010, 49, 161–169. [Google Scholar] [CrossRef]

- Liu, Y.; Gehde, M. Effects of surface roughness and processing parameters on heat transfer coefficient between polymer and cavity wall during injection molding. Int. J. Adv. Manuf. Technol. 2016, 84, 1325–1333. [Google Scholar] [CrossRef]

| Injection molding temperature (°C) | 240 |

| Ejection temperature (°C) | 120 |

| Ambient temperature (°C) | 25 |

| Mold surface temperature (°C) | 40 |

| Cooling time (s) | 15 |

| Initial mold temperature (°C) | 40 |

| Mold block conductance (W/m2·°C) | 30,000 |

| Number of heat flux time steps (-) | 16 |

| Transient mold temperature convergence tolerance (°C) | 0.1 |

| Maximum number of transient mold temperature cycles (-) | 100 |

| Main characteristics | 1.2311 | Ampcoloy 940 | MS1 |

|---|---|---|---|

| Density (kg/m3) | 7800 | 8710 | 8100 |

| Tensile strength (MPa) | 1020 | 544 | 1950 |

| Yield point (MPa) | 900 | 475 | 1900 |

| Young’s modulus (GPa) | 250 | 131 | 180 |

| Thermal conductivity coefficient (W/mK) | 29 | 208 | 20 |

| Specific heat capacity (J/kgK) | 460 | 380 | 450 |

| Cooling channel geometry | Conventional | Milled | Conformal | Conventional |

|---|---|---|---|---|

| Mold insert material | 1.2311 | 1.2311 | MS1 | Ampcoloy 940 |

| Max. surface temperature (°C) | 52.6 | 48.6 | 47.2 | 42.5 |

| Average surface temperature (°C) | 46.4 | 44.3 | 43.2 | 41.5 |

| Temperature difference on the surface (°C) | 9.9 | 6.6 | 5.8 | 1.8 |

| Density (kg/m3) | 1.079 |

| Specific heat (J/kgK) | 1008 |

| Thermal conductivity (W/m·°C) | 0.02822 |

| Kinematic viscosity (m2/s) | 17.44 × 10−6 |

| Coefficient of thermal expansion (1/°C) | 0.003104 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zink, B.; Szabó, F.; Hatos, I.; Suplicz, A.; Kovács, N.K.; Hargitai, H.; Tábi, T.; Kovács, J.G. Enhanced Injection Molding Simulation of Advanced Injection Molds. Polymers 2017, 9, 77. https://doi.org/10.3390/polym9020077

Zink B, Szabó F, Hatos I, Suplicz A, Kovács NK, Hargitai H, Tábi T, Kovács JG. Enhanced Injection Molding Simulation of Advanced Injection Molds. Polymers. 2017; 9(2):77. https://doi.org/10.3390/polym9020077

Chicago/Turabian StyleZink, Béla, Ferenc Szabó, István Hatos, András Suplicz, Norbert Krisztián Kovács, Hajnalka Hargitai, Tamás Tábi, and József Gábor Kovács. 2017. "Enhanced Injection Molding Simulation of Advanced Injection Molds" Polymers 9, no. 2: 77. https://doi.org/10.3390/polym9020077

APA StyleZink, B., Szabó, F., Hatos, I., Suplicz, A., Kovács, N. K., Hargitai, H., Tábi, T., & Kovács, J. G. (2017). Enhanced Injection Molding Simulation of Advanced Injection Molds. Polymers, 9(2), 77. https://doi.org/10.3390/polym9020077