Morphology, Nucleation, and Isothermal Crystallization Kinetics of Poly(ε-caprolactone) Mixed with a Polycarbonate/MWCNTs Masterbatch

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Characterization

- (a)

- The sample was heated from 25 to 160 °C at 20 °C min−1 and maintained at that temperature for 3 min to erase thermal history.

- (b)

- It was then cooled from 160 to −20 °C at 20 °C min−1 to create the initial “standard” state and held at that temperature for 3 min.

- (c)

- It was then heated from −20 °C to a selected thermal treatment temperature or self-seeding temperature (Ts), located in the final melting temperature range of the sample, and held at that temperature for 5 min.

- (d)

- It was again cooled to −20 °C, where the effects of thermal treatment would be reflected in the crystallization behavior of the sample.

- (e)

- Finally, it was heated to 160 °C, where the effects of thermal treatment would also be reflected in the melting behavior of the sample.

3. Results and Discussion

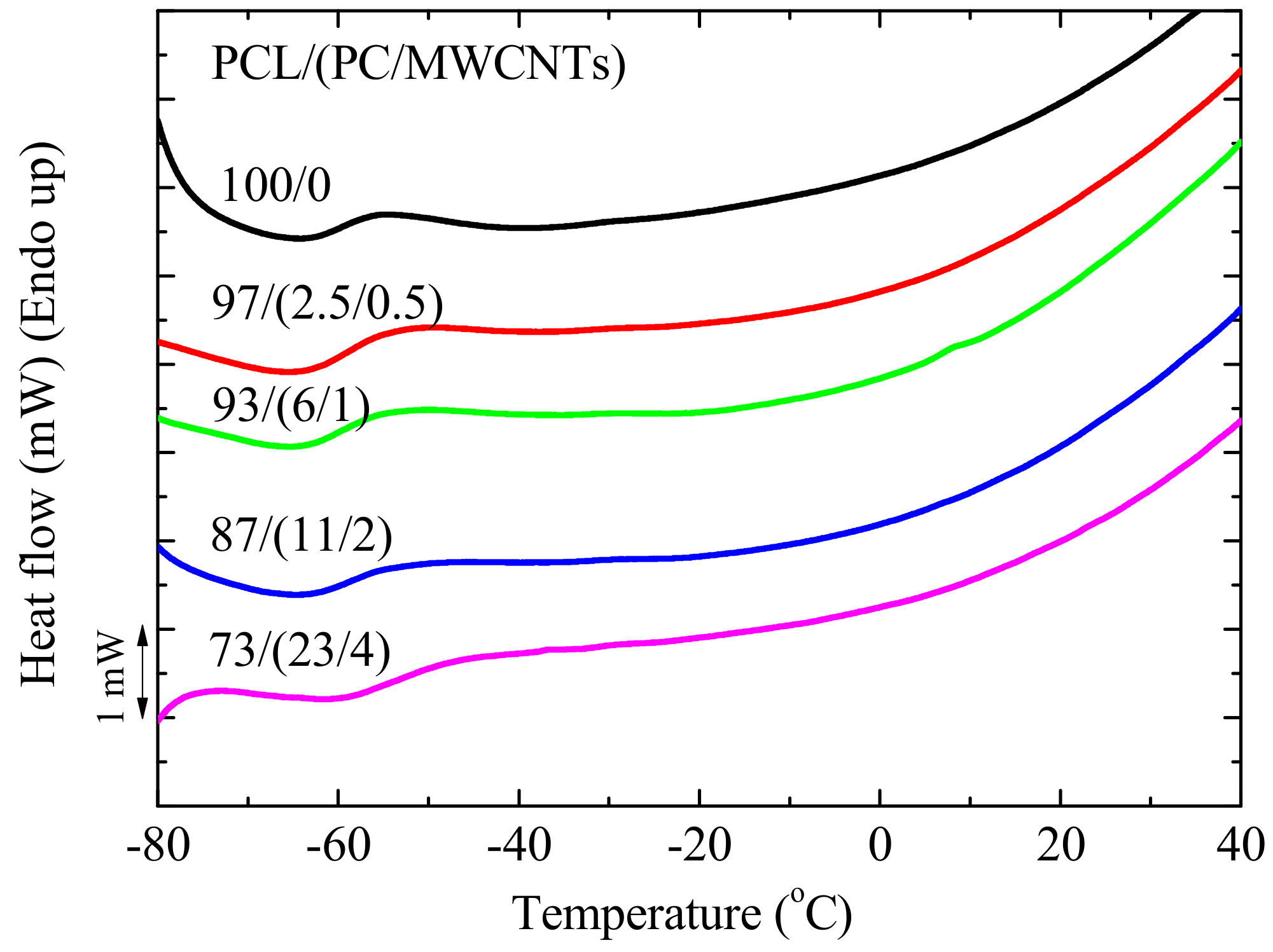

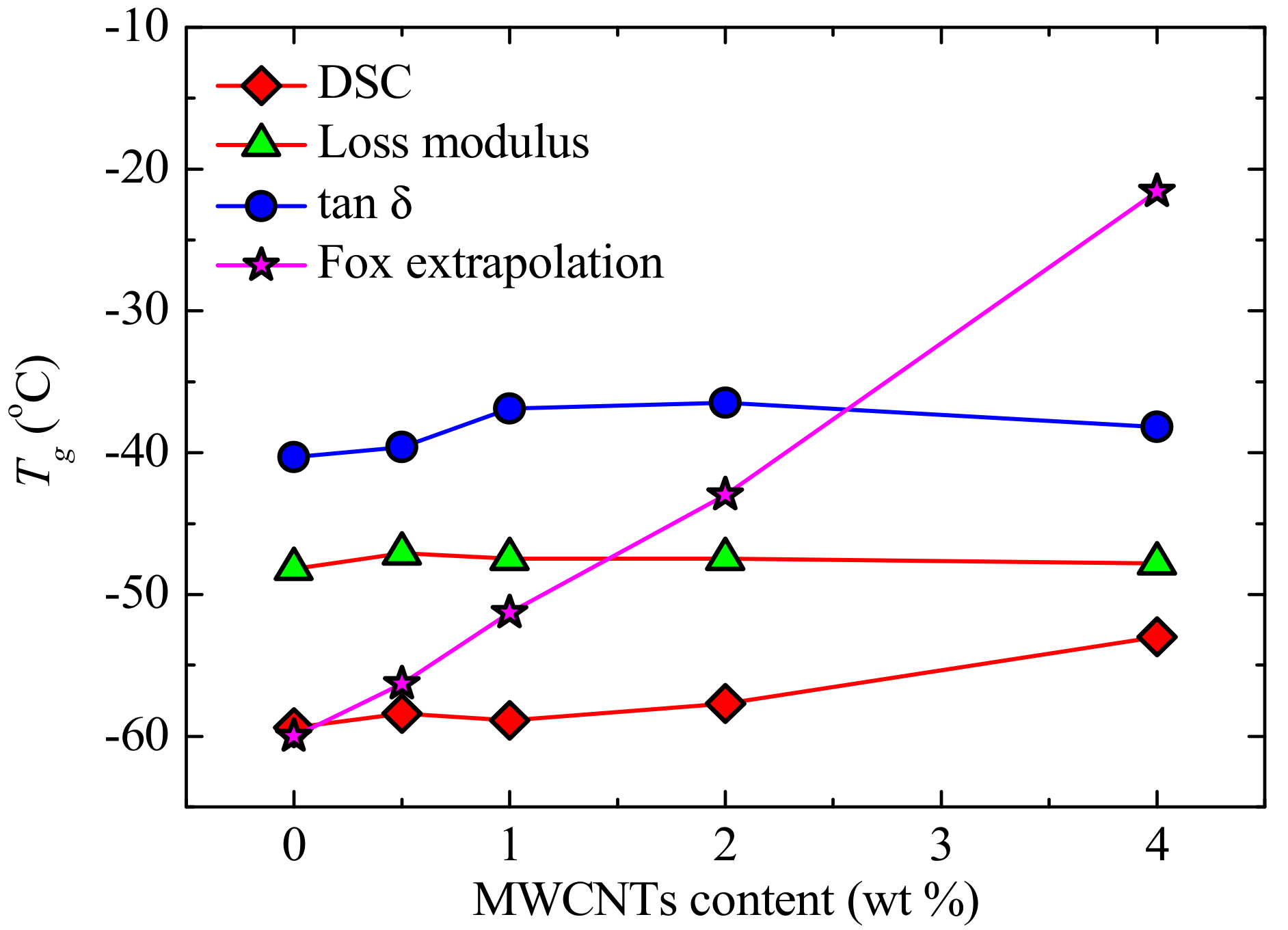

3.1. Miscibility Assessment

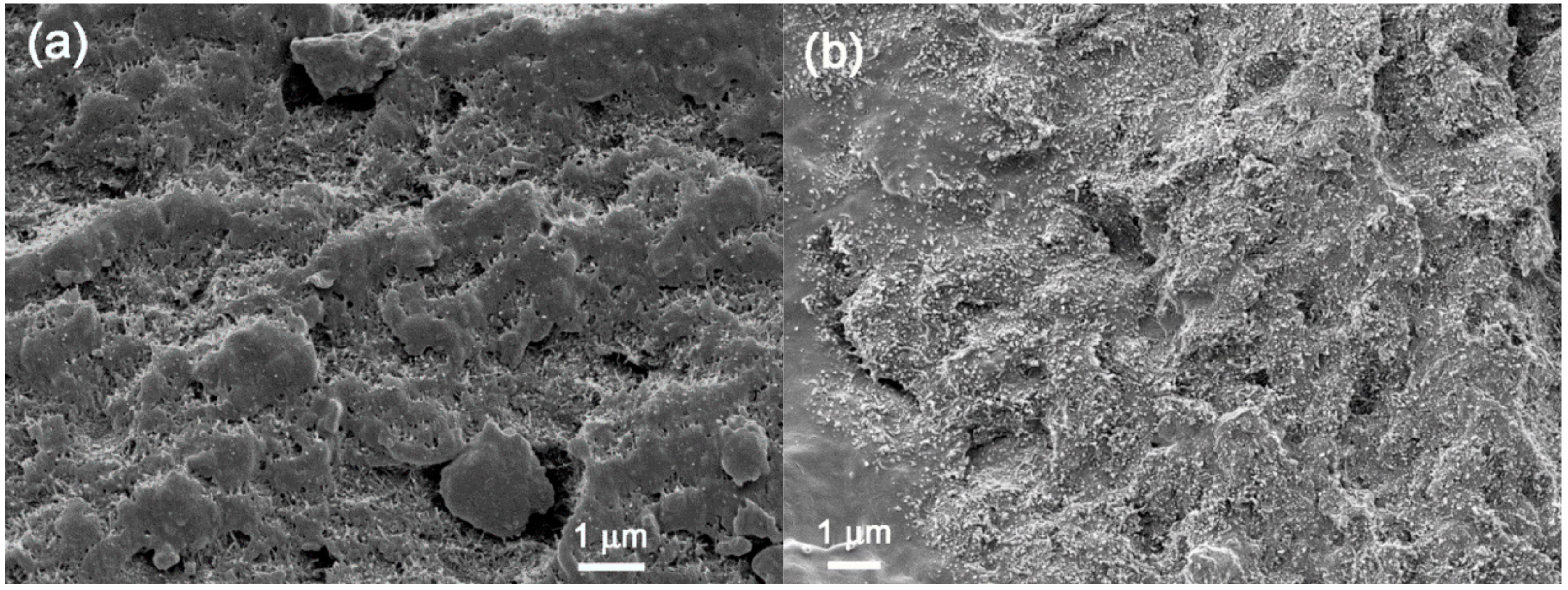

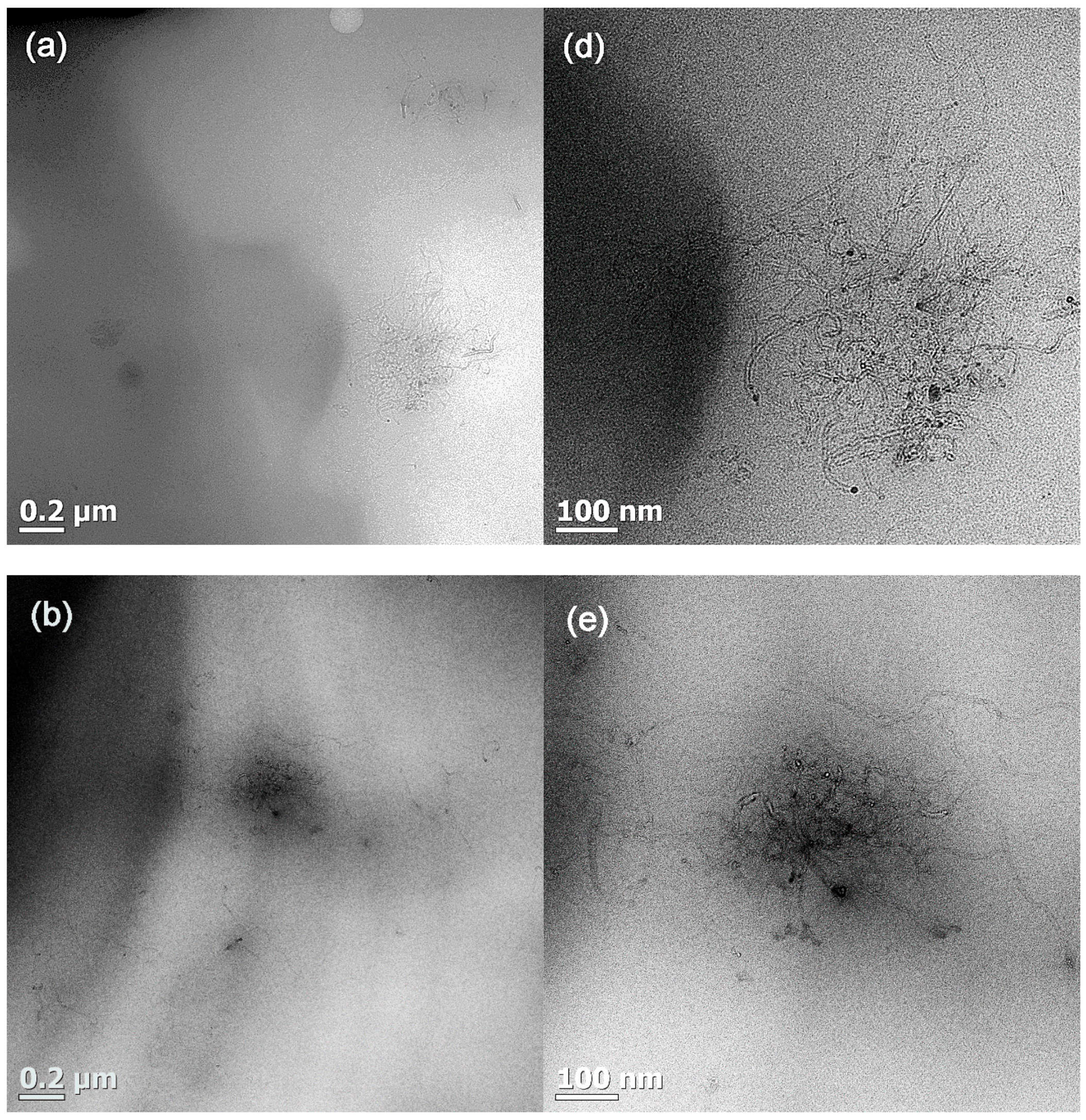

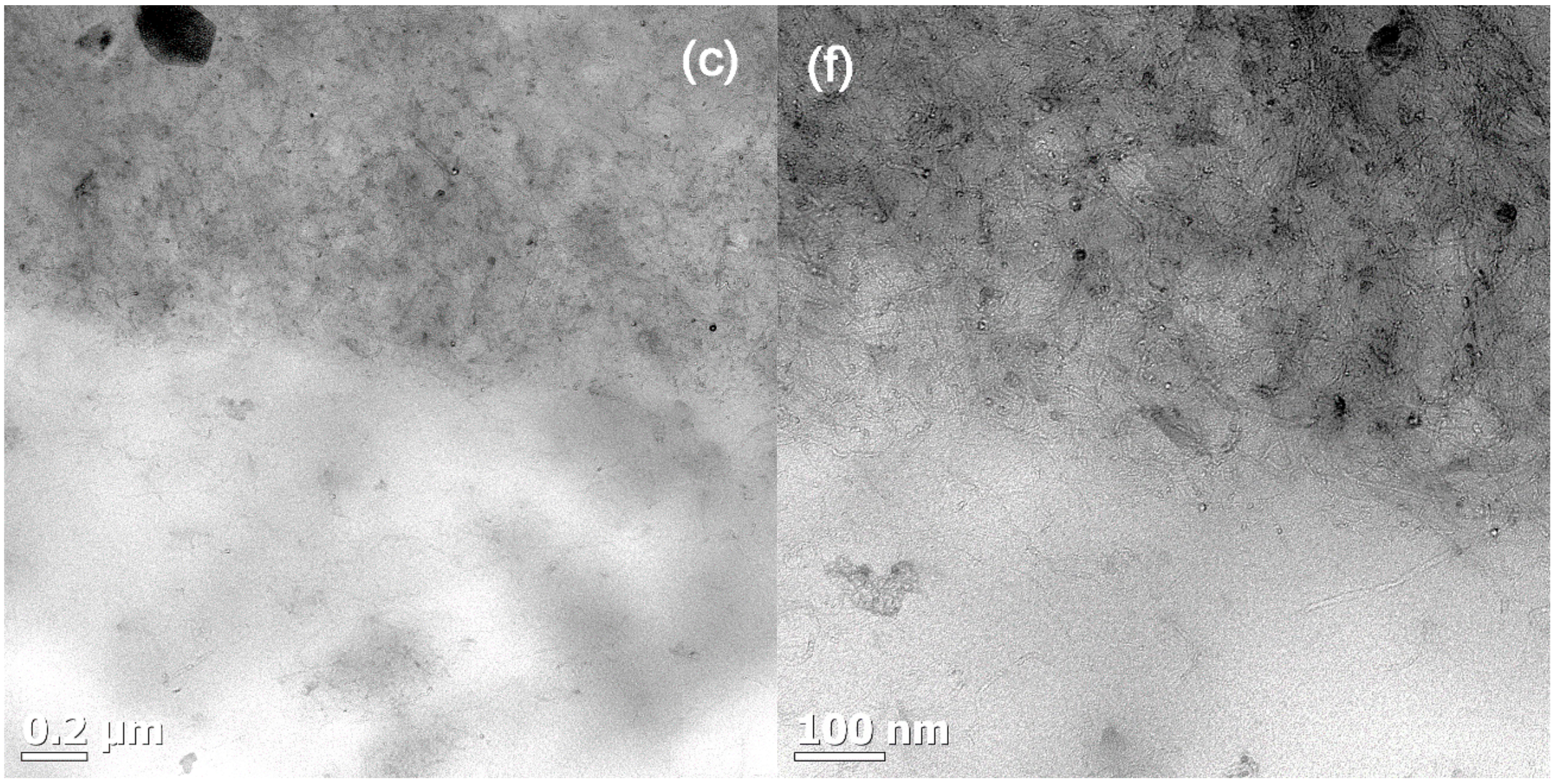

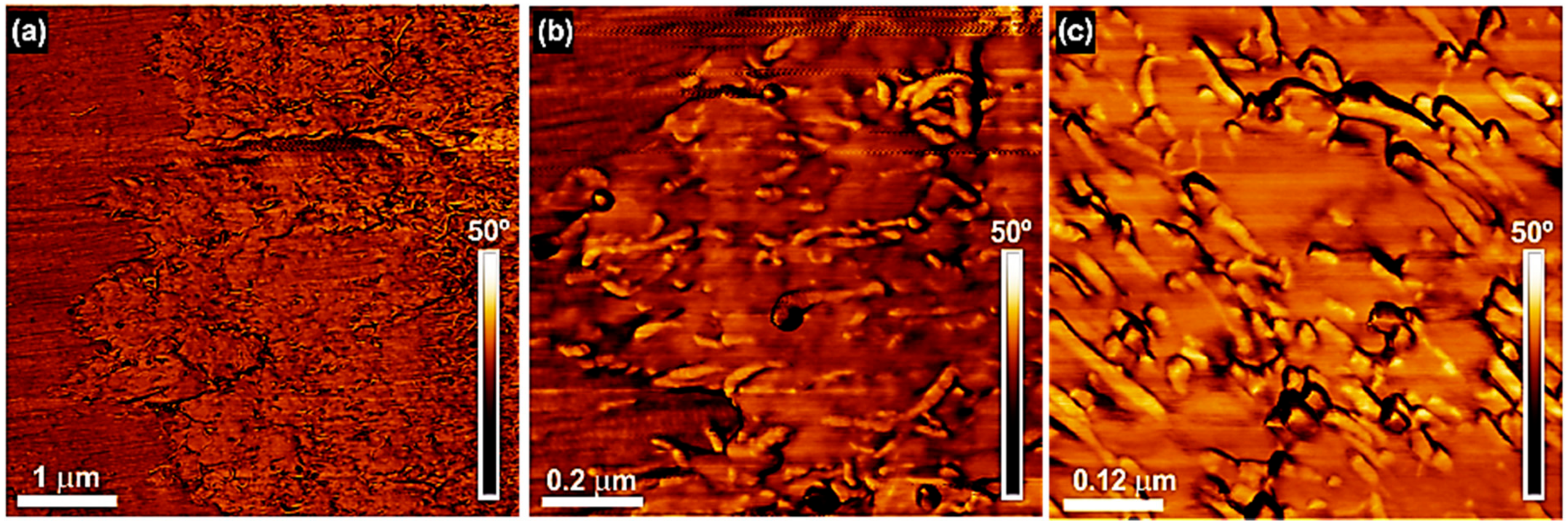

3.2. Electron Microscopy (SEM and TEM) and Atomic Force Microscopy (AFM)

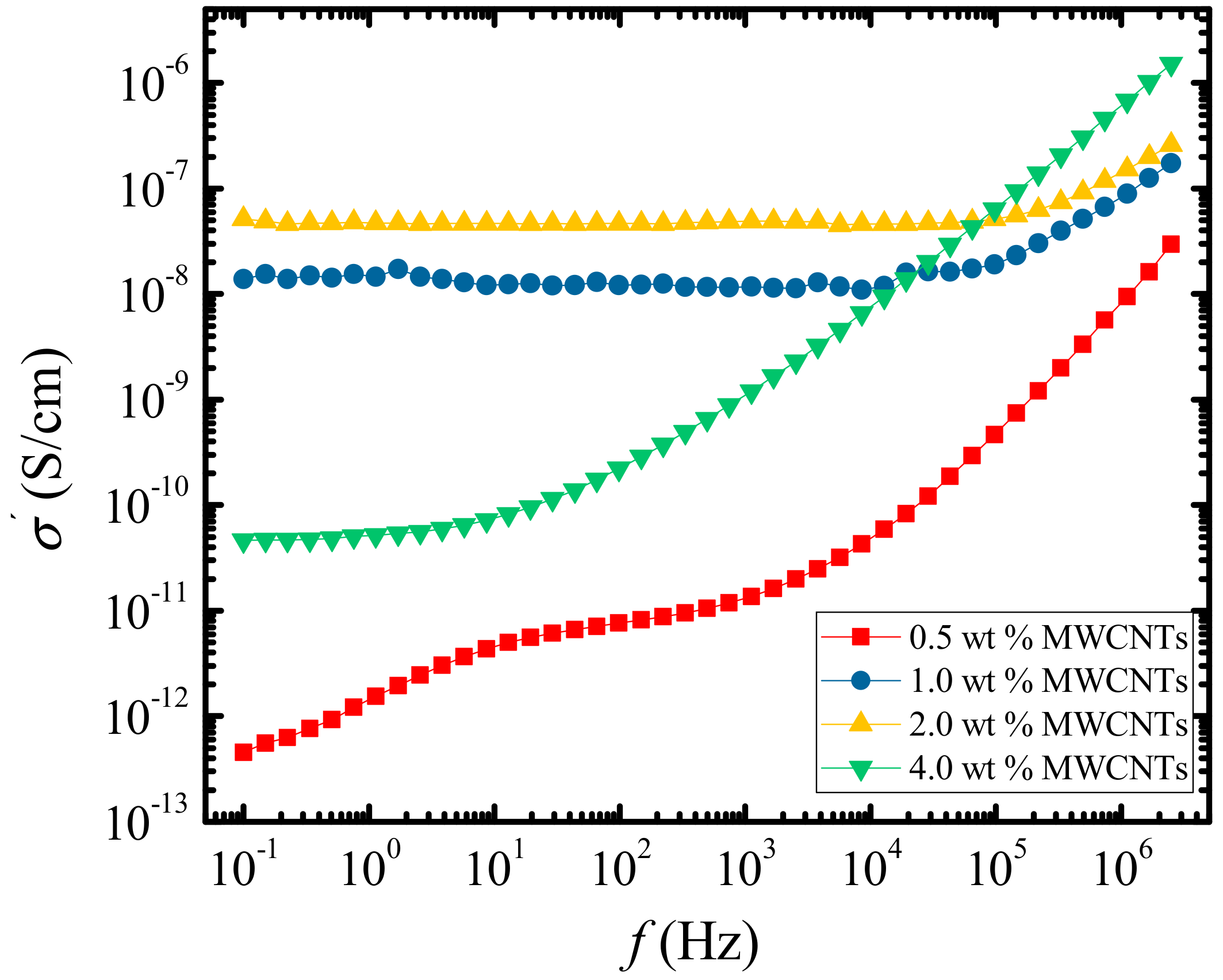

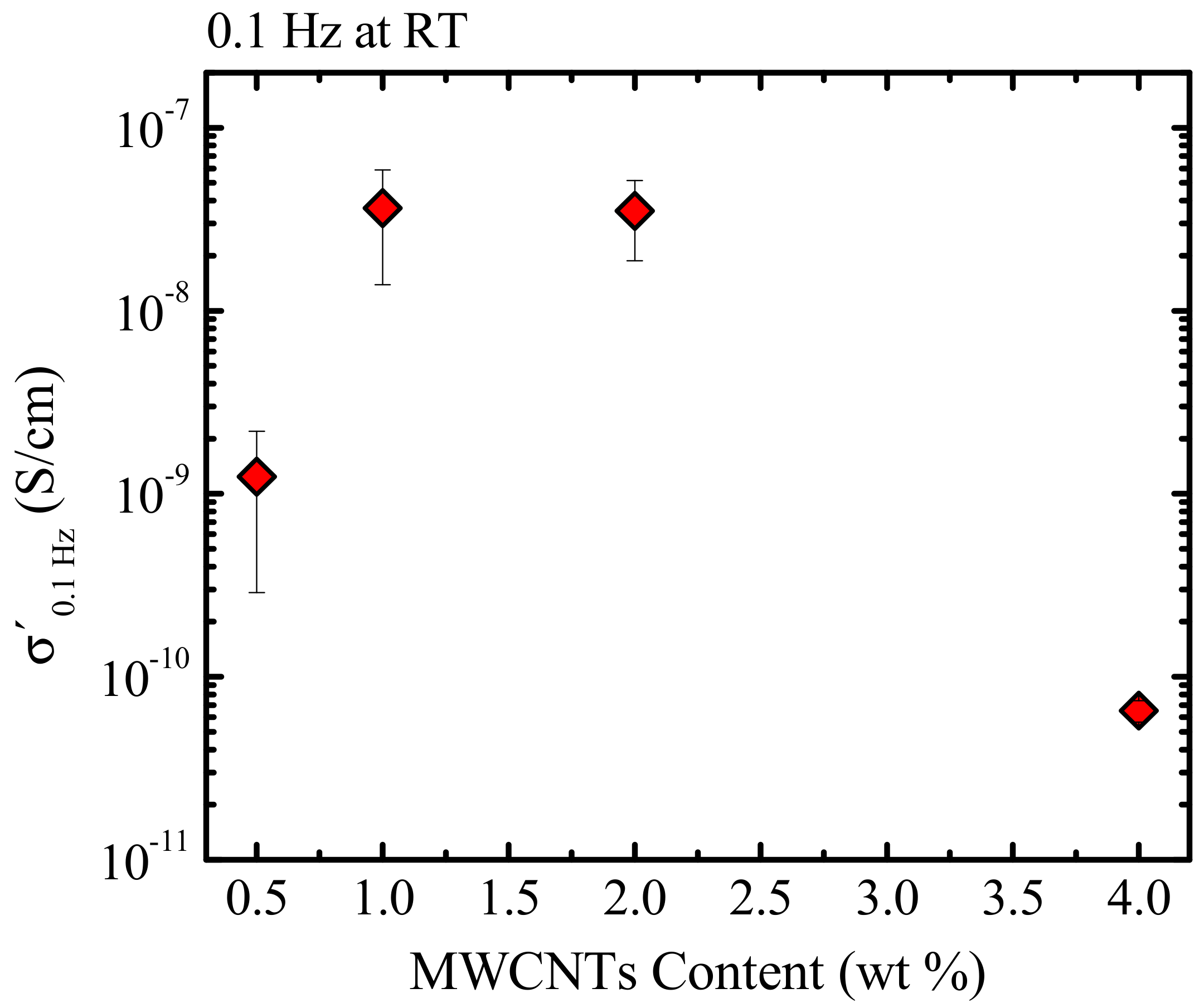

3.3. Dielectric Measurements

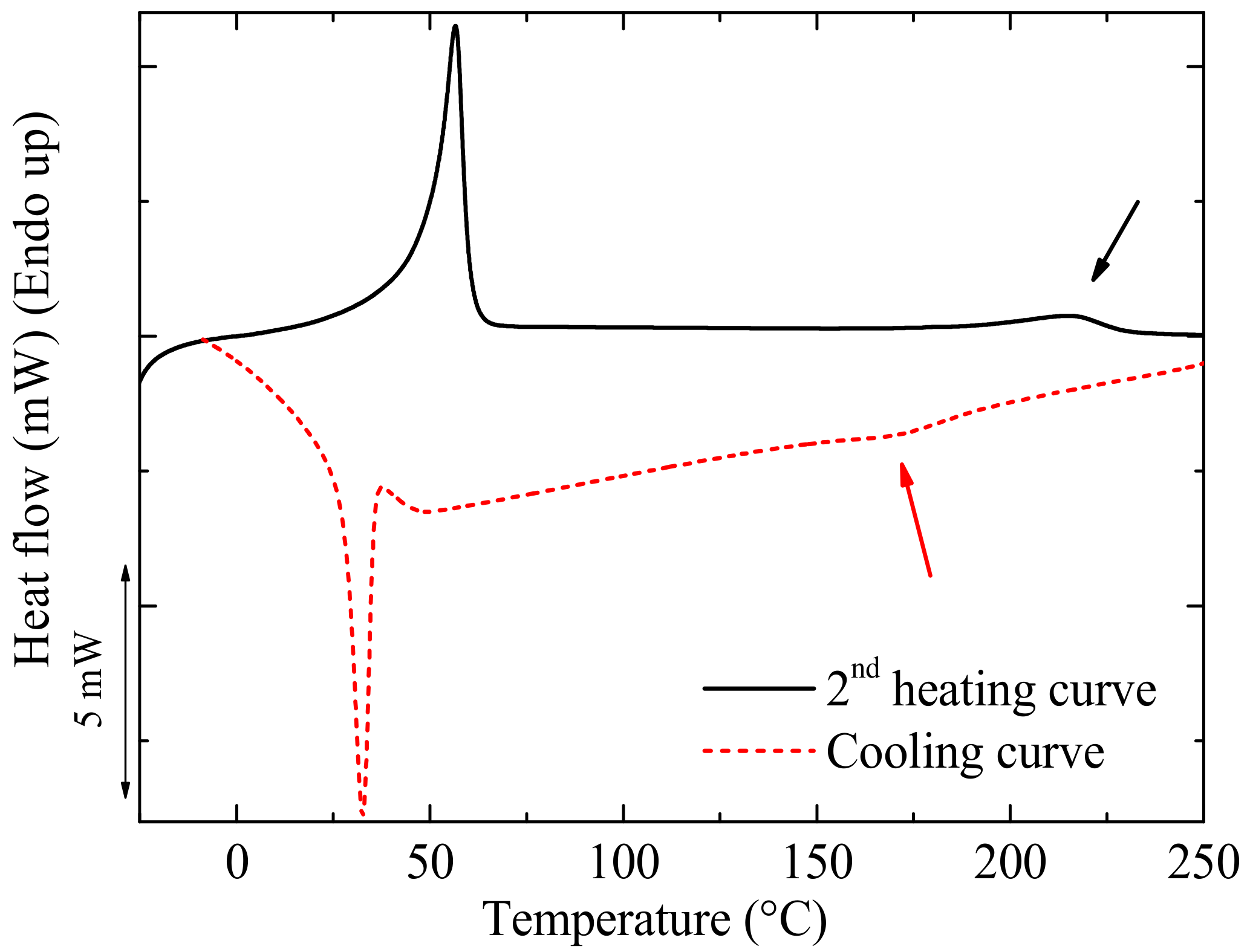

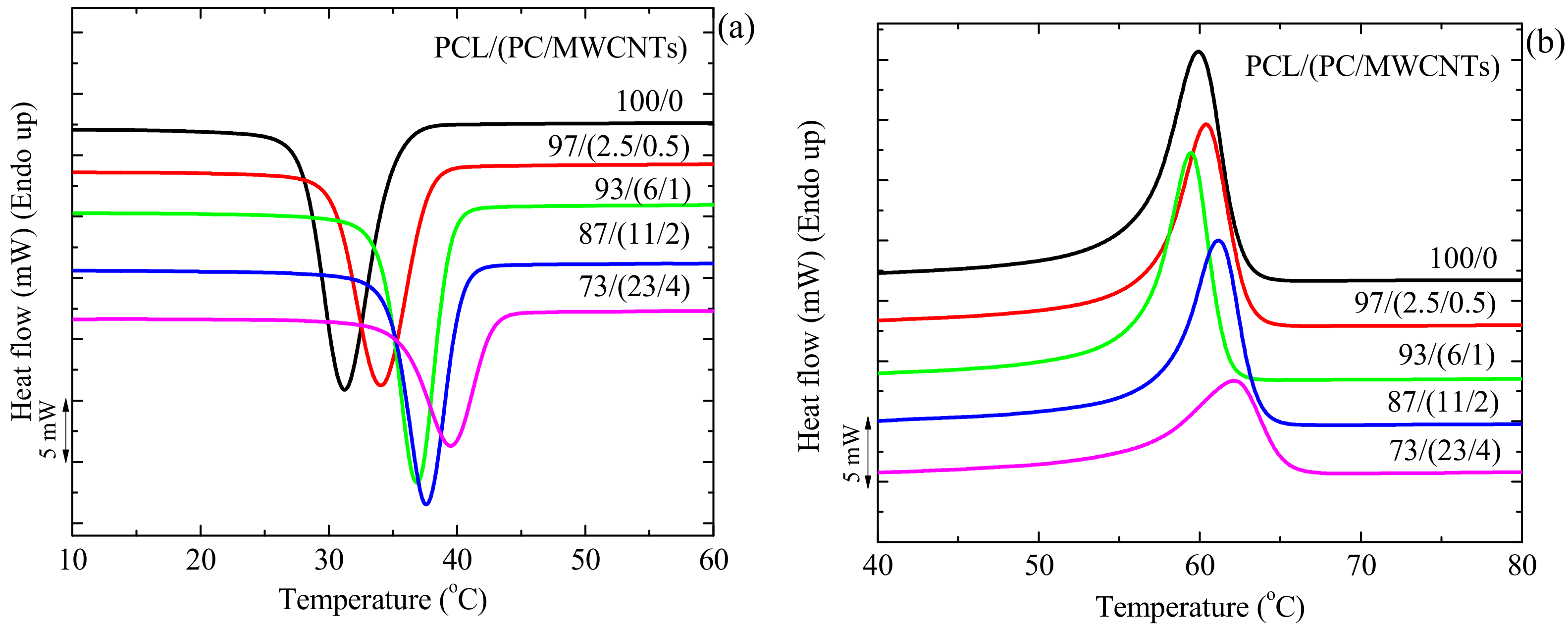

3.4. Non-Isothermal DSC

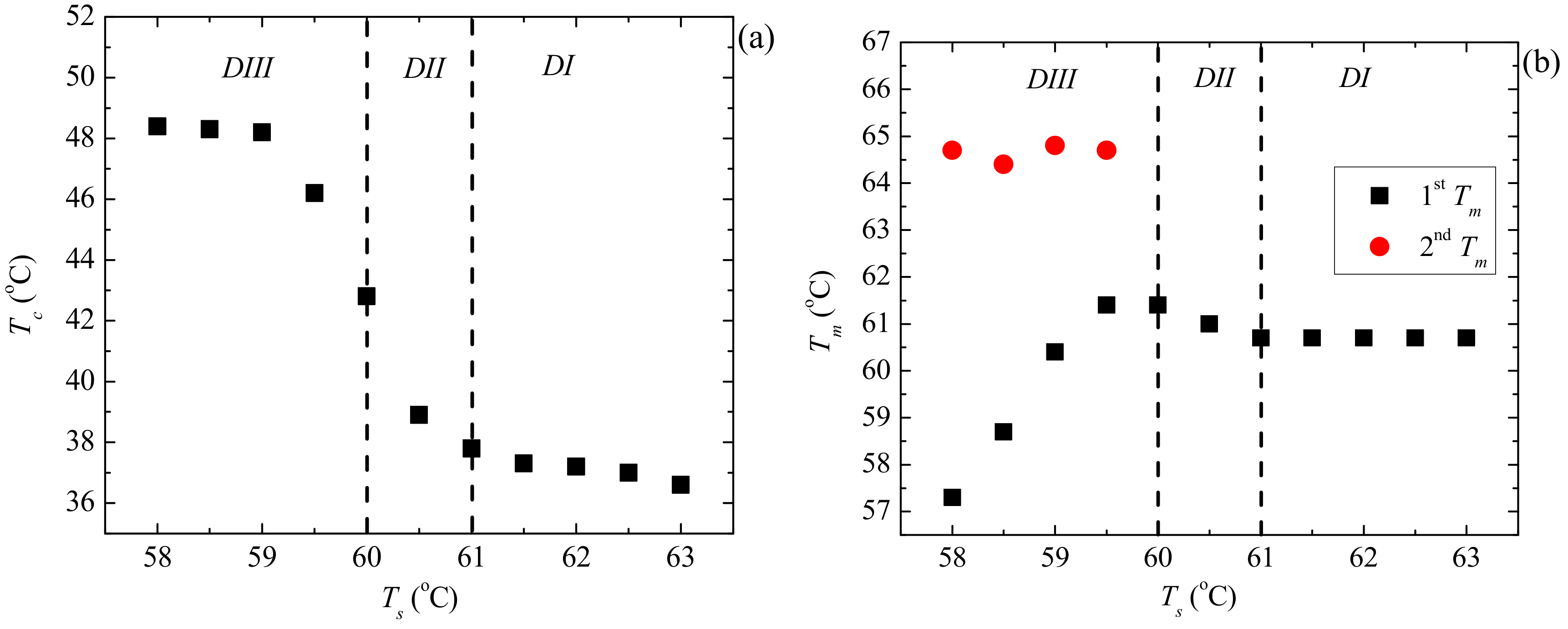

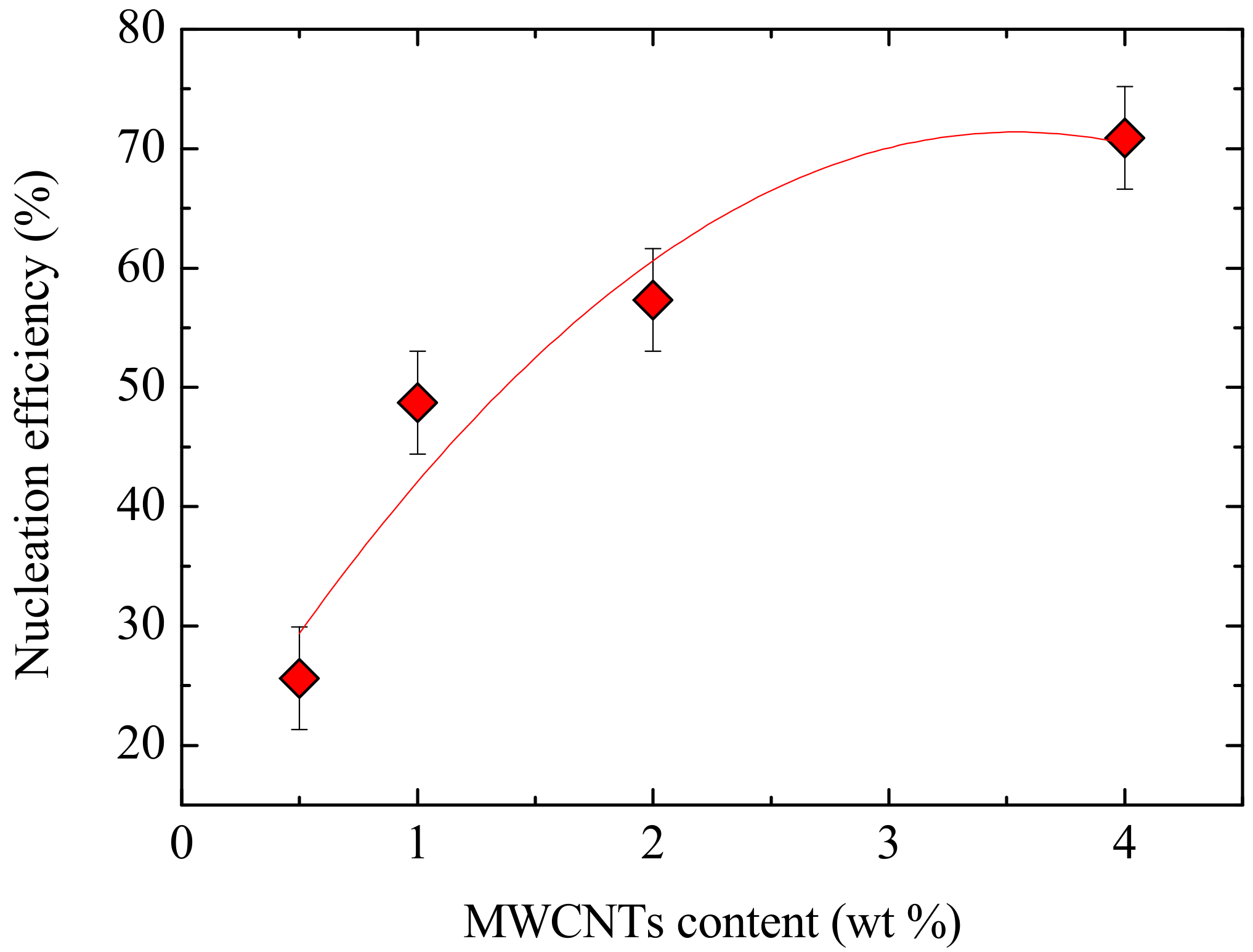

3.5. Self-Nucleation (SN)

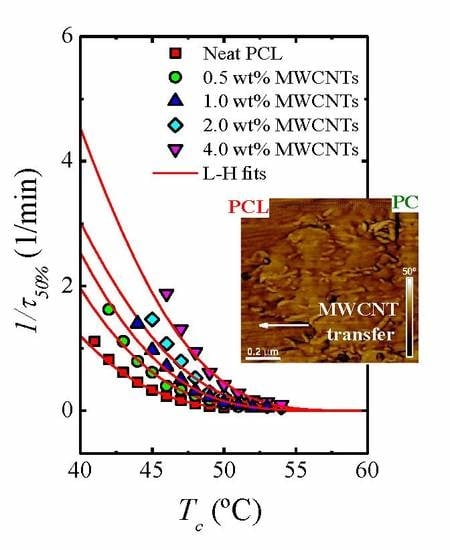

3.6. Overall Isothermal Crystallization Studied by DSC

3.6.1. Fitting DSC Isothermal Data to the Avrami Model

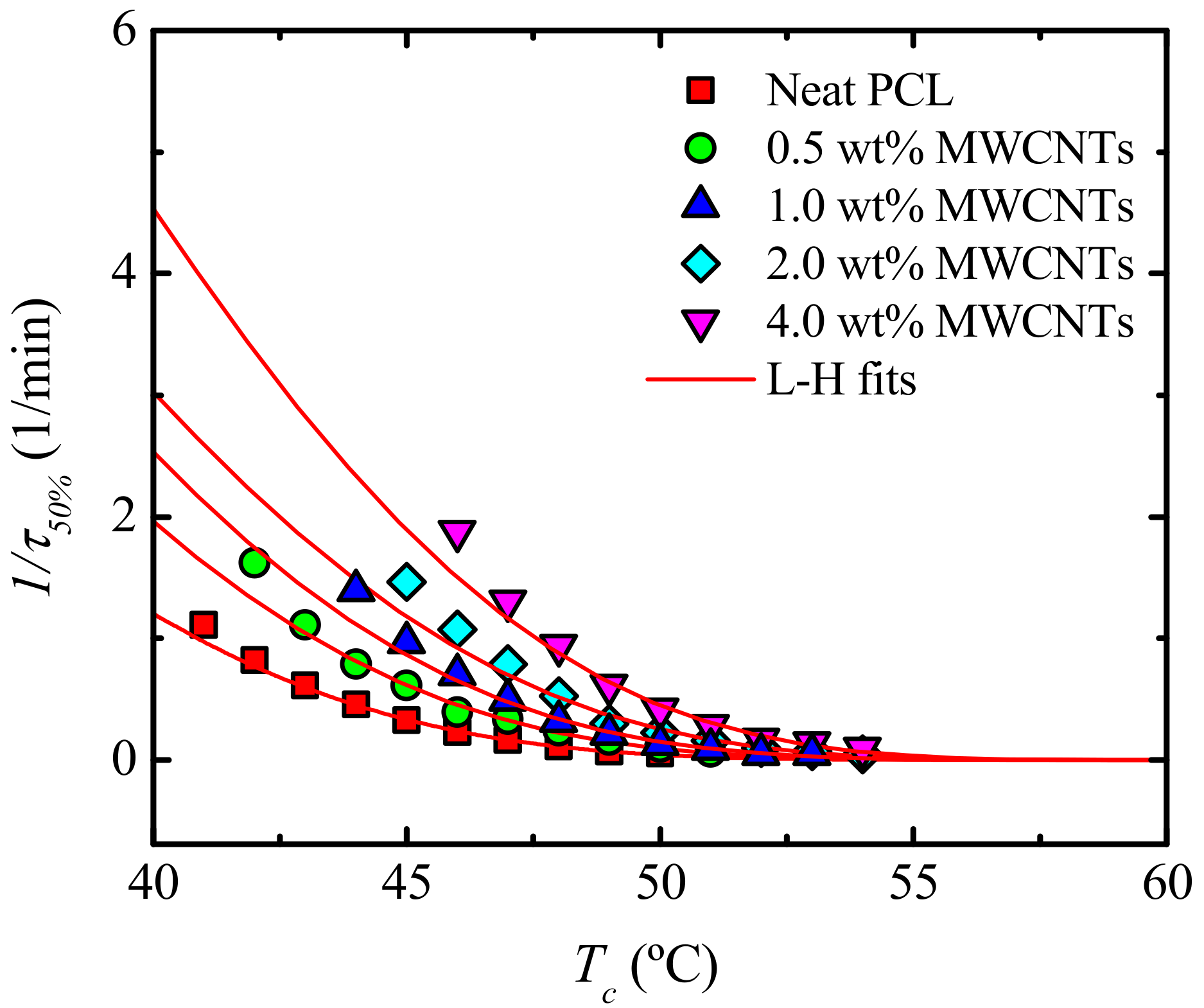

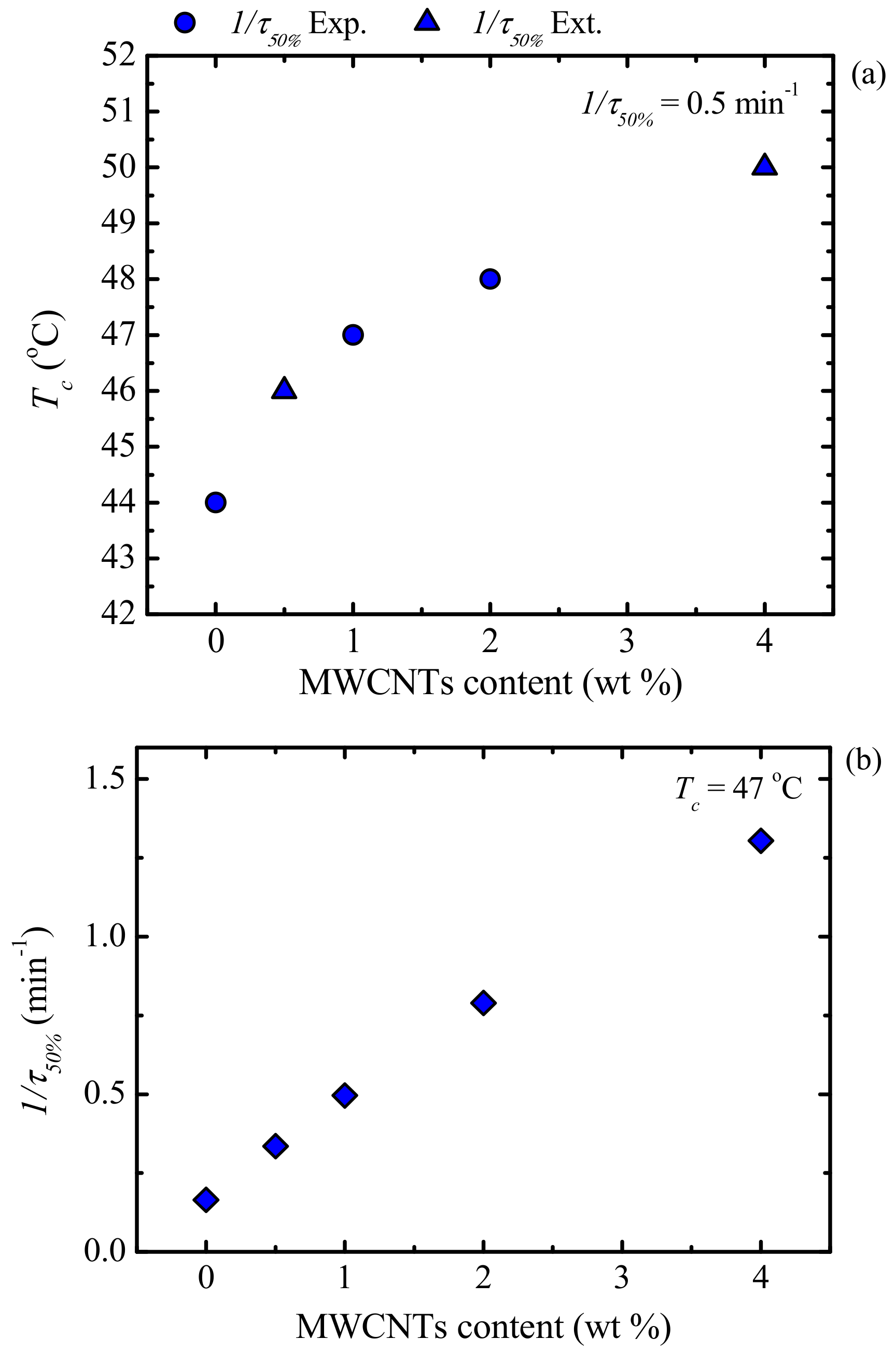

3.6.2. Overall Isothermal Crystallization Data Analyzed by the Lauritzen-Hoffman Model

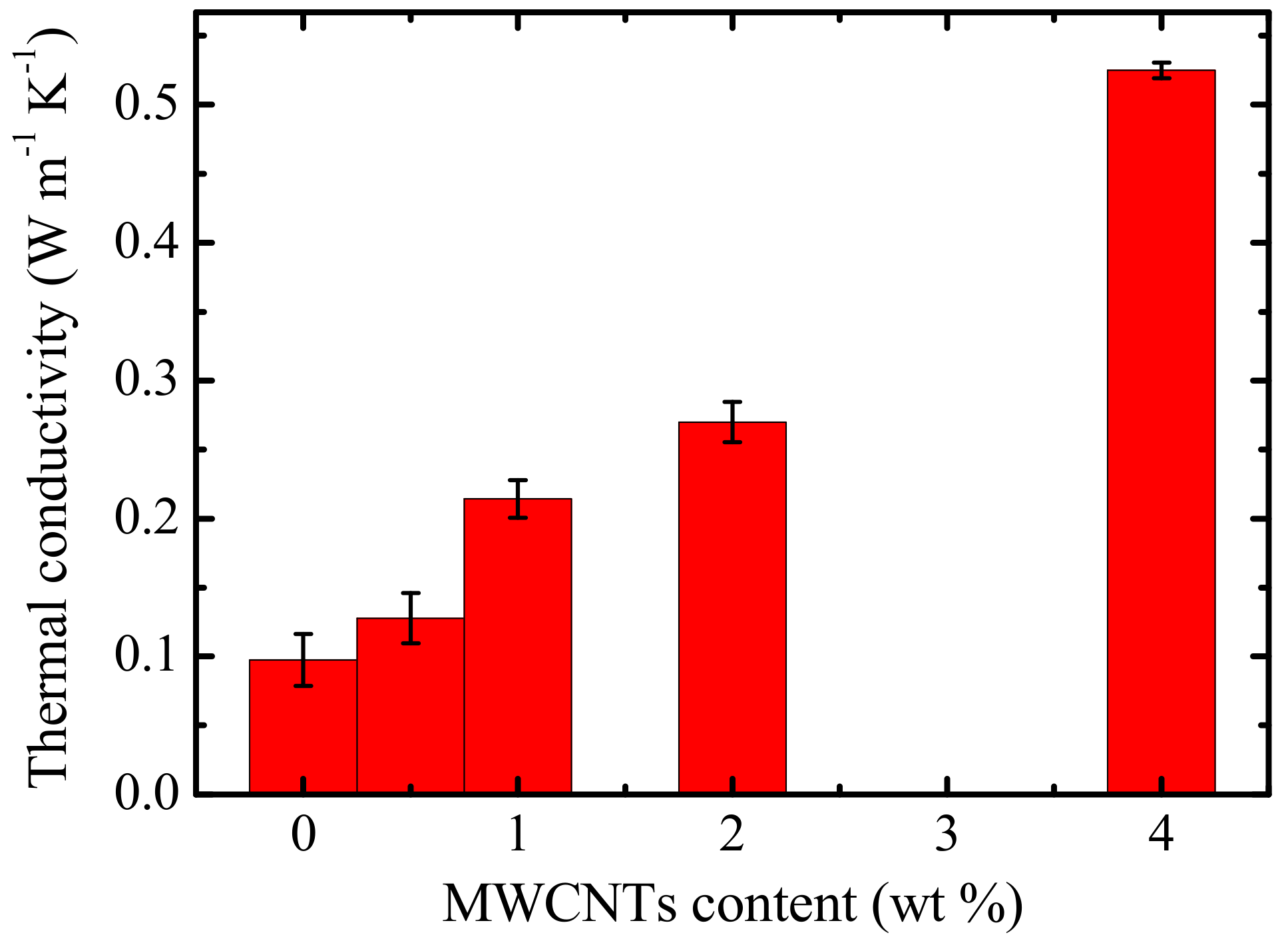

3.7. Thermal Conductivity

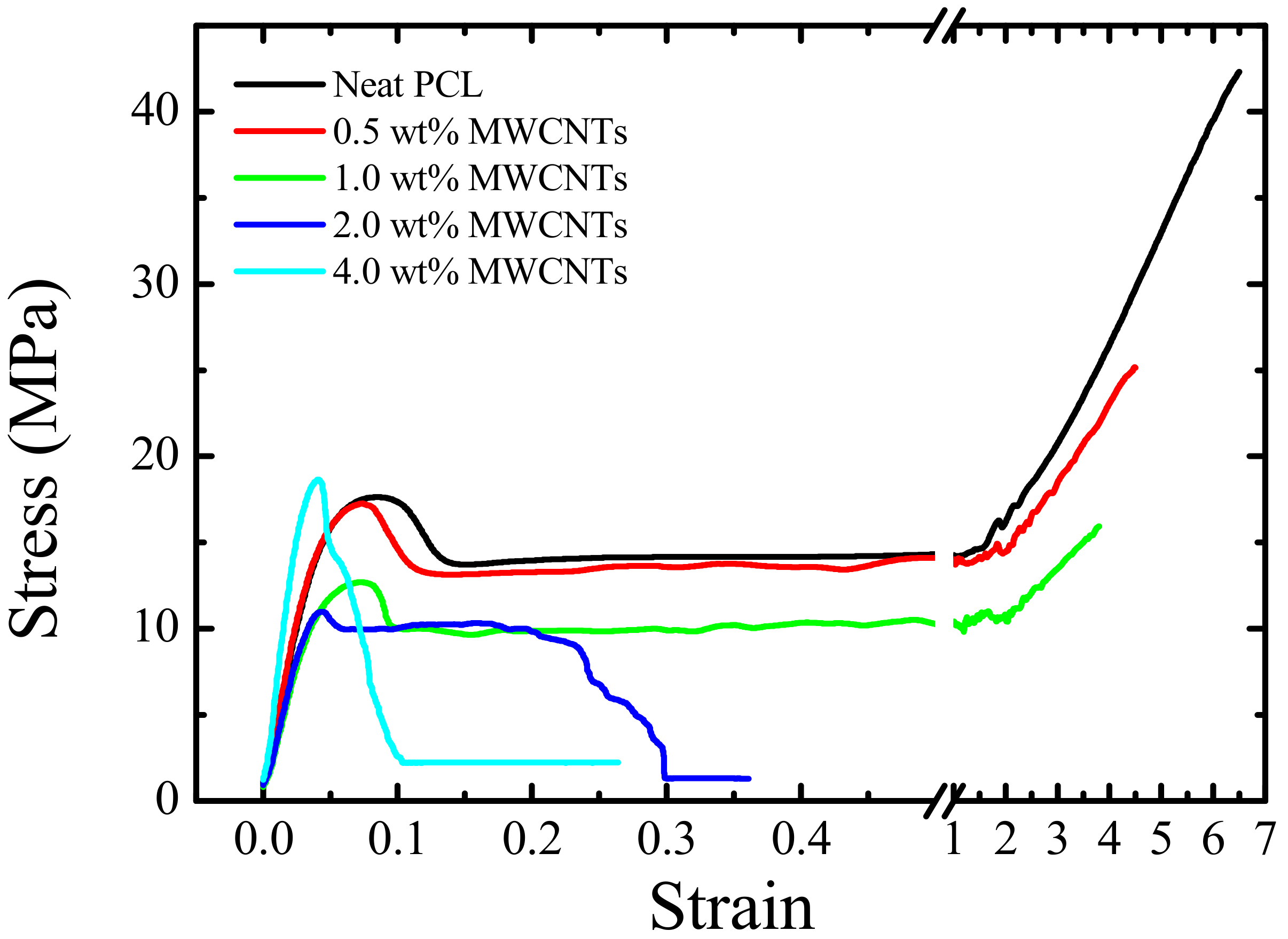

3.8. Tensile Properties

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Morent, R.; De Geyter, N.; Desmet, T.; Dubruel, P.; Leys, C. Plasma surface modification of biodegradable polymers: A Review. Plasma Process. Polym. 2011, 8, 171–190. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Babu, R.P.; Connor, K.O.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 1–16. [Google Scholar] [CrossRef]

- George, J.J.; Bhadra, S.; Bhowmick, A.K. Influence of carbon-based nanofillers on the electrical and dielectric properties of ethylene vinyl acetate nanocomposites. Polym. Compos. 2010, 31, 218–225. [Google Scholar] [CrossRef]

- Wurm, A.; Lellinger, D.; Minakov, A.A.; Skipa, T.; Pötschke, P.; Nicula, R.; Alig, I.; Schick, C. Crystallization of poly(ε-caprolactone)/MWCNT composites: A combined SAXS/WAXS, electrical and thermal conductivity study. Polymer 2014, 55, 2220–2232. [Google Scholar] [CrossRef]

- Chin, S.J.; Vempati, S.; Dawson, P.; Knite, M.; Linarts, A.; Ozols, K.; McNally, T. Electrical conduction and rheological behaviour of composites of poly(ε-caprolactone) and MWCNTs. Polymer 2015, 58, 209–221. [Google Scholar] [CrossRef]

- Pötschke, P.; Villmow, T.; Krause, B. Melt mixed PCL/MWCNT composites prepared at different rotation speeds: Characterization of rheological, thermal, and electrical properties, molecular weight, MWCNT macrodispersion, and MWCNT length distribution. Polymer 2013, 54, 3071–3078. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Bhattacharya, M. Review: Polymer nanocomposites—A comparison between carbon nanotubes, graphene, and clay as nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef] [PubMed]

- Prashantha, K.; Soulestin, J.; Lacrampe, M.F.; Krawczak, P.; Dupin, G.; Claes, M. Masterbatch-based multi-walled carbon nanotube filled polypropylene nanocomposites: Assessment of rheological and mechanical properties. Compos. Sci. Technol. 2009, 69, 1756–1763. [Google Scholar] [CrossRef]

- Jajam, K.C.; Rahman, M.M.; Hosur, M.V.; Tippur, H.V. Fracture behavior of epoxy nanocomposites modified with polyol diluent and amino-functionalized multi-walled carbon nanotubes: A loading rate study. Compos. A Appl. Sci. Manuf. 2014, 59, 57–69. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hosur, M.; Zainuddin, S.; Jajam, K.C.; Tippur, H.V.; Jeelani, S. Mechanical characterization of epoxy composites modified with reactive polyol diluent and randomly-oriented amino-functionalized MWCNTs. Polym. Test. 2012, 31, 1083–1093. [Google Scholar] [CrossRef]

- Wu, T.; Chen, E.; Lin, Y.; Chiang, M.; Chang, G. Preparation and characterization of melt-processed polycarbonate/multiwalled carbon nanotube composites. Polym. Eng. Sci. 2008, 48, 1369–1375. [Google Scholar] [CrossRef]

- Robeson, L.M. Polymer Blends: A Comprehensive Review; Hanser Gardner Publication: Cincinnati, OH, USA, 2007. [Google Scholar]

- Trujillo, M.; Arnal, M.L.; Müller, A.J.; Dubois, P. Supernucleation and crystallization regime change provoked by MWCNT addition to poly(ε-caprolactone). Polymer 2012, 53, 832–841. [Google Scholar] [CrossRef]

- Pérez, R.A.; López, J.V.; Hoskins, J.N.; Zhang, B.; Grayson, S.M.; Casas, M.T.; Puiggalí, J.; Müller, A.J. Nucleation and antinucleation effects of functionalized carbon nanotubes on cyclic and linear poly(ε-caprolactones). Macromolecules 2014, 47, 3553–3566. [Google Scholar] [CrossRef]

- Yeh, J.T.; Yang, M.C.; Wu, C.J.; Wu, C.S. Preparation and characterization of biodegradable polycaprolactone/multiwalled carbon nanotubes nanocomposites. J. Appl. Polym. Sci. 2009, 112, 660–668. [Google Scholar] [CrossRef]

- Vega, J.F.; Fernández-Alcázar, J.; Lόpez, J.V.; Michell, R.M.; Pérez-Camargo, R.A.; Ruelle, B.; Martίnez-Salazar, J.; Arnal, M.L.; Dubois, P.; Müller, A.J. Competition between supernucleation and plasticization in the crystallization and rheological behavior of PCL/CNT-based nanocomposites and nanohybrids. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1310–1325. [Google Scholar] [CrossRef]

- Maiti, S.; Suin, S.; Shrivastava, N.K.; Khatua, B.B. Low percolation threshold and high electrical conductivity in melt-blended polycarbonate/multiwall carbon nanotube nanocomposites in the presence of poly(ɛ-caprolactone). Polym. Eng. Sci. 2014, 54, 646–659. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, H.; Xu, C. Crystallization, mechanical properties, and controlled enzymatic degradation of biodegradable poly(ε-caprolactone)/multi-walled carbon nanotubes nanocomposites. J. Nanosci. Nanotechnol. 2011, 11, 7884–7893. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.H.; Shin, U.S.; Jin, G.Z.; Kim, H.W. Highly homogeneous carbon nanotube polycaprolactone composites with various and controllable concentrations of ionically-modified MWCNTs. Bull. Korean Chem. Soc. 2011, 32, 157–161. [Google Scholar] [CrossRef]

- Pan, L.; Pei, X.; He, R.; Wan, Q.; Wang, J. Multiwall carbon nanotubes/polycaprolactone composites for bone tissue engineering application. Colloids Surf. B 2012, 93, 226–234. [Google Scholar] [CrossRef] [PubMed]

- Kasaliwal, G.R.; Göldel, A.; Pötschke, P.; Heinrich, G. Influences of polymer matrix melt viscosity and molecular weight on MWCNT agglomerate dispersion. Polymer 2011, 52, 1027–1036. [Google Scholar] [CrossRef]

- Fillon, B.; Wittmann, J.C.; Lotz, B.; Thierry, A. Self-nucleation and recrystallization of isotactic polypropylene (α phase) investigated by differential scanning calorimetry. J. Polym. Sci. Part B Polym. Phys. 1993, 31, 1383–1393. [Google Scholar] [CrossRef]

- Lorenzo, A.T.; Arnal, M.A.; Sánchez, J.J.; Müller, A.J. Effect of annealing time on the self-nucleation behaviour of semicrystalline polymers. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 1738–1750. [Google Scholar] [CrossRef]

- Müller, A.J.; Arnal, M.L. Thermal fractionation of polymers. Prog. Polym. Sci. 2005, 30, 559–603. [Google Scholar] [CrossRef]

- Michell, R.M.; Mugica, A.; Zubitur, M.; Müller, A.J. Self-nucleation of crystalline phases within homopolymers, polymer blends, copolymers, and nanocomposites. Adv. Polym. Sci. 2017, 276, 215–256. [Google Scholar] [CrossRef]

- Lorenzo, A.T.; Arnal, M.L.; Albuerne, J.; Müller, A.J. DSC isothermal polymer crystallization kinetics measurements and the use of the Avrami equation to fit the data: Guidelines to avoid common problems. Polym. Test. 2007, 26, 222–231. [Google Scholar] [CrossRef]

- Hoffman, J.D.; Weeks, J.J. Melting process and the equilibrium melting temperature of polychlorotrifluoroethylene. J. Res. Natl. Bur. Stand. Sect. A 1962, 66, 13–28. [Google Scholar] [CrossRef]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Zhang, Y.; Han, J.H. Crystallization of high-amylose starch by the addition of plasticizers at low and intermediate concentrations. J. Food Sci. 2010, 75, N8–N16. [Google Scholar] [CrossRef] [PubMed]

- Müller, A.J.; Paredes, E. Melting behavior, mechanical properties and fracture of crystallized polycarbonates. Lat. Am. J. Metall. Mater. 1985, 5, 130–141. [Google Scholar]

- Balsamo, V.; Calzadilla, N.; Mora, G.; Müller, A.J. Thermal characterization of polycarbonate/polycaprolactone blends. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 771–785. [Google Scholar] [CrossRef]

- Hu, H.; Dorset, D.L. Crystal structure of poly(iɛ-caprolactone). Macromolecules 1990, 23, 4604–4607. [Google Scholar] [CrossRef]

- Pötschke, P.; Bhattacharyya, A.R.; Janke, A.; Goering, H. Melt mixing of polycarbonate/multi-wall carbon nanotube composites. Compos. Interface 2003, 10, 389–404. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Y.; Prada-Silvy, R.; Tan, Y.; Azad, S.; Krause, B.; Pötschke, P.; Grady, B.P. Aspect ratio effects of multi-walled carbon nanotubes on electrical, mechanical, and thermal properties of polycarbonate/MWCNT composites. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 73–83. [Google Scholar] [CrossRef]

- Castillo, F.Y.; Socher, R.; Krause, B.; Headrick, R.; Grady, B.P.; Prada-Silvy, R.; Pötschke, P. Electrical, mechanical, and glass transition behavior of polycarbonate-based nanocomposites with different multi-walled carbon nanotubes. Polymer 2011, 52, 3835–3845. [Google Scholar] [CrossRef]

- Cruz, C.A.; Paul, D.R.; Barlow, J.W. Polyester-polycarbonate blends. IV. Poly(ε-caprolactone). J. Appl. Polym. Sci. 1979, 23, 589–600. [Google Scholar] [CrossRef]

- Chun, Y.S.; Park, J.; Sun, J.B.; Kim, W.N. Blends of polycarbonate and poly(ε-caprolactone) and the determination of the polymer-polymer interaction parameter of the two polymers. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 2072–2076. [Google Scholar] [CrossRef]

- Ketelaars, A.A.J.; Papantoniou, Y.; Nakayama, K. Analysis of the density and the enthalpy of poly(ε-caprolactone)-polycarbonate blends: Amorphous phase compatibility and the effect of secondary crystallization. J. Appl. Polym. Sci. 1997, 66, 921–927. [Google Scholar] [CrossRef]

- Jonza, J.M.; Porter, R.S. Bisphenol A polycarbonate/poly(ε-caprolactone) blends: Melting point depression and reactivity. Macromolecules 1986, 19, 1946–1951. [Google Scholar] [CrossRef]

- Herrera, D.; Zamora, J.C.; Bello, A.; Grimau, M.; Laredo, E.; Müller, A.J.; Lodge, T.P. Miscibility and crystallization in polycarbonate/poly(ε-caprolactone) blends: Application of the self-concentration model. Macromolecules 2005, 38, 5109–5117. [Google Scholar] [CrossRef]

- Cheung, Y.W.; Stein, R.S.; Chu, B.; Wu, G. Evolution of crystalline structures of poly(ε-caprolactone)/polycarbonate blends. 1. Isothermal crystallization kinetics as probed by synchrotron small-angle X-ray scattering. Macromolecules 1994, 27, 3589–3595. [Google Scholar] [CrossRef]

- Young, R.J.; Lovell, P.A. Introduction to Polymers; CRC Press: New York, NY, USA, 2011. [Google Scholar]

- Favis, B.D.; Therrien, D. Factors influencing structure formation and phase size in an immiscible polymer blend of polycarbonate and polypropylene prepared by twin-screw extrusion. Polymer 1991, 32, 1474–1481. [Google Scholar] [CrossRef]

- Shih, K.S.; Beatty, C.L. Blends of polycarbonate and poly(hexamethylene sebacate): II. Effect of molecular weight on compatibility. Polym. Eng. Sci. 1987, 27, 1530–1541. [Google Scholar] [CrossRef]

- Oyarzabal, A.; Cristiano-Tassi, A.; Laredo, E.; Newman, D.; Bello, A.; Etxeberría, A.; Eguiazabal, J.I.; Zubitur, M.; Mugica, A.; Müller, A.J. Dielectric, mechanical and transport properties of bisphenol A polycarbonate/graphene nanocomposites prepared by melt blending. J. Appl. Polym. Sci. 2017, 134, 44654–44667. [Google Scholar] [CrossRef]

- Greenhoe, B.M.; Hassan, M.K.; Wiggins, J.S.; Mauritz, K.A. Universal power law behavior of the AC conductivity versus frequency of agglomerate morphologies in conductive carbon nanotube reinforced epoxy networks. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1918–1923. [Google Scholar] [CrossRef]

- Belaabed, B.; Lamouri, S.; Naar, N.; Bourson, P.; Hamady, S.O.S. Polyaniline-doped benzene sulfonic acid/epoxy resin composites: Structural, morphological, thermal and dielectric behaviors. Polym. J. 2010, 42, 546–554. [Google Scholar] [CrossRef]

- Arup, C. Polyaniline/silver nanocomposites. Dielectric properties and ethanol vapor sensitivity. Sens. Actuators B 2009, 138, 318–325. [Google Scholar] [CrossRef]

- Saeed, K.; Park, S.Y. Preparation and properties of multiwalled carbon nanotube/polycaprolactone nanocomposites. J. Appl. Polym. Sci. 2007, 104, 1957–1963. [Google Scholar] [CrossRef]

- Pötschke, P.; Abdel-Goad, M.; Alig, I.; Dudkin, S.; Lellinger, D. Rheological and dielectrical characterization of melt mixed polycarbonate-multiwalled carbon nanotube composites. Polymer 2004, 45, 8863–8870. [Google Scholar] [CrossRef]

- Fillon, B.; Lotz, B.; Thierry, A.; Wittmann, J.C. Self-nucleation and enhanced nucleation of polymers. Definition of a convenient calorimetric “efficiency scale” and evaluation of nucleating additives in isotactic polypropylene (α phase). J. Polym. Sci. Part B Polym. Phys. 1993, 31, 1395–1405. [Google Scholar] [CrossRef]

- Avrami, M. Granulation, phase change, and microstructure kinetics of phase change III. J. Chem. Phys. 1941, 9, 177–184. [Google Scholar] [CrossRef]

- Reiter, G.; Strobl, G.R. Progress in Understanding Polymer Crystallization; Lecture Notes Physics 714; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar] [CrossRef]

- Lorenzo, A.T.; Müller, A.J. Estimation of the nucleation and crystal growth contributions to the overall crystallization energy. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 1478–1487. [Google Scholar] [CrossRef]

- Poveda, R.L.; Gupta, N. Carbon Nanofiber Reinforced Polymer Composites; SpringerBriefs in Materials; Springer: Brooklyn, NY, USA, 2016. [Google Scholar]

- Meng, H.; Gui, G.X.; Fang, P.F.; Yang, R. Effects of acid- and diamine-modified MWNTs on the mechanical properties and crystallization behavior of polyamide 6. Polymer 2008, 49, 610–620. [Google Scholar] [CrossRef]

| PCL (%) | PC (%) | MWCNTs (%) |

|---|---|---|

| 100 | 0 | 0 |

| 97 | 2.55 | 0.45 |

| 93 | 5.95 | 1.05 |

| 87 | 11.05 | 1.95 |

| 73 | 22.95 | 4.05 |

| Sample | d-Spacing (nm)/(plane) | d * (nm) |

|---|---|---|

| Neat PCL | 0.378 (110) | 19.8 |

| 0.343 (200) | ||

| 0.400 (111) | ||

| 93/(6/1) w/w PCL/(PC/MWCNTs) | 0.378 (110) | 19.9 |

| 0.344 (200) | ||

| 0.400(111) | ||

| 73/(23/4) w/w PCL/(PC/MWCNTs) | 0.464 * | 17.2 ** |

| 0.378 (110) | ||

| 0.344 (200) | ||

| 0.400 (111) |

| w/w PCL/(PC/MWCNTs) | /MPa | /% | E/MPa | /MPa |

|---|---|---|---|---|

| 100/0 | 34.3 ± 12.9 | 578 ± 151 | 388 ± 29 | 16.2 ± 1.9 |

| 97/(2.5/0.5) | 15.9 ± 7.1 | 285 ± 152 | 354 ± 77 | 13.7 ± 3.3 |

| 93/(6/1) | 10.3 ± 5.0 | 154 ± 198 | 352 ± 28 | 13.6 ± 1.0 |

| 87/(11/2) | 6.9 ± 1.9 | 22.8 ± 2.0 | 336 ± 33 | 11.3 ± 4.1 |

| 73/(23/4) | 15.6 ± 0.9 | 4.3 ± 0.7 | 592 ± 62 | 17.1 ± 1.4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gumede, T.P.; Luyt, A.S.; Hassan, M.K.; Pérez-Camargo, R.A.; Tercjak, A.; Müller, A.J. Morphology, Nucleation, and Isothermal Crystallization Kinetics of Poly(ε-caprolactone) Mixed with a Polycarbonate/MWCNTs Masterbatch. Polymers 2017, 9, 709. https://doi.org/10.3390/polym9120709

Gumede TP, Luyt AS, Hassan MK, Pérez-Camargo RA, Tercjak A, Müller AJ. Morphology, Nucleation, and Isothermal Crystallization Kinetics of Poly(ε-caprolactone) Mixed with a Polycarbonate/MWCNTs Masterbatch. Polymers. 2017; 9(12):709. https://doi.org/10.3390/polym9120709

Chicago/Turabian StyleGumede, Thandi P., Adriaan S. Luyt, Mohammad K. Hassan, Ricardo A. Pérez-Camargo, Agnieszka Tercjak, and Alejandro J. Müller. 2017. "Morphology, Nucleation, and Isothermal Crystallization Kinetics of Poly(ε-caprolactone) Mixed with a Polycarbonate/MWCNTs Masterbatch" Polymers 9, no. 12: 709. https://doi.org/10.3390/polym9120709