Long-Term Durability of Basalt Fiber-Reinforced Polymer (BFRP) Sheets and the Epoxy Resin Matrix under a Wet–Dry Cyclic Condition in a Chloride-Containing Environment

Abstract

:1. Introduction

2. Experimental Program

2.1. Raw Materials

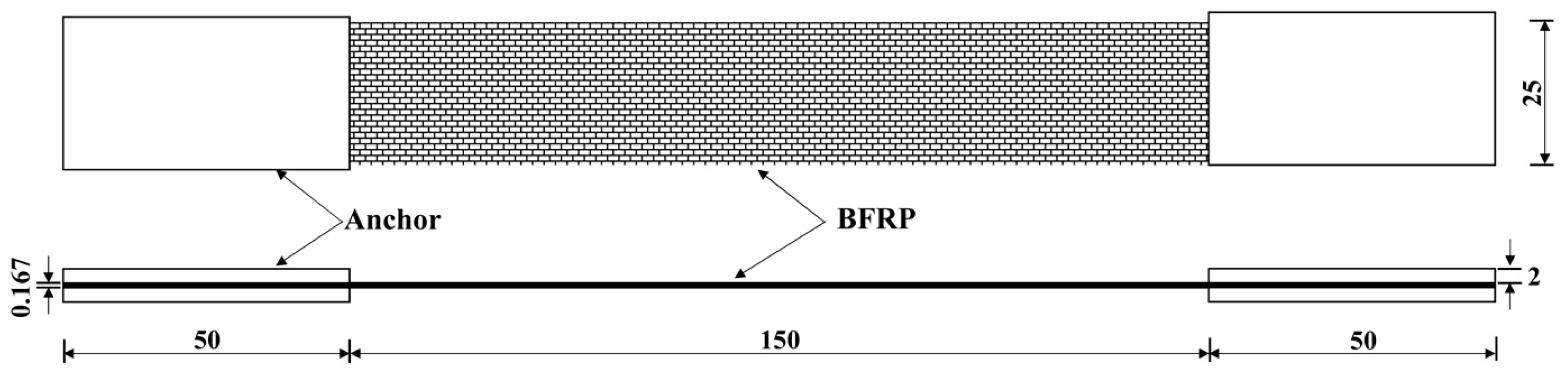

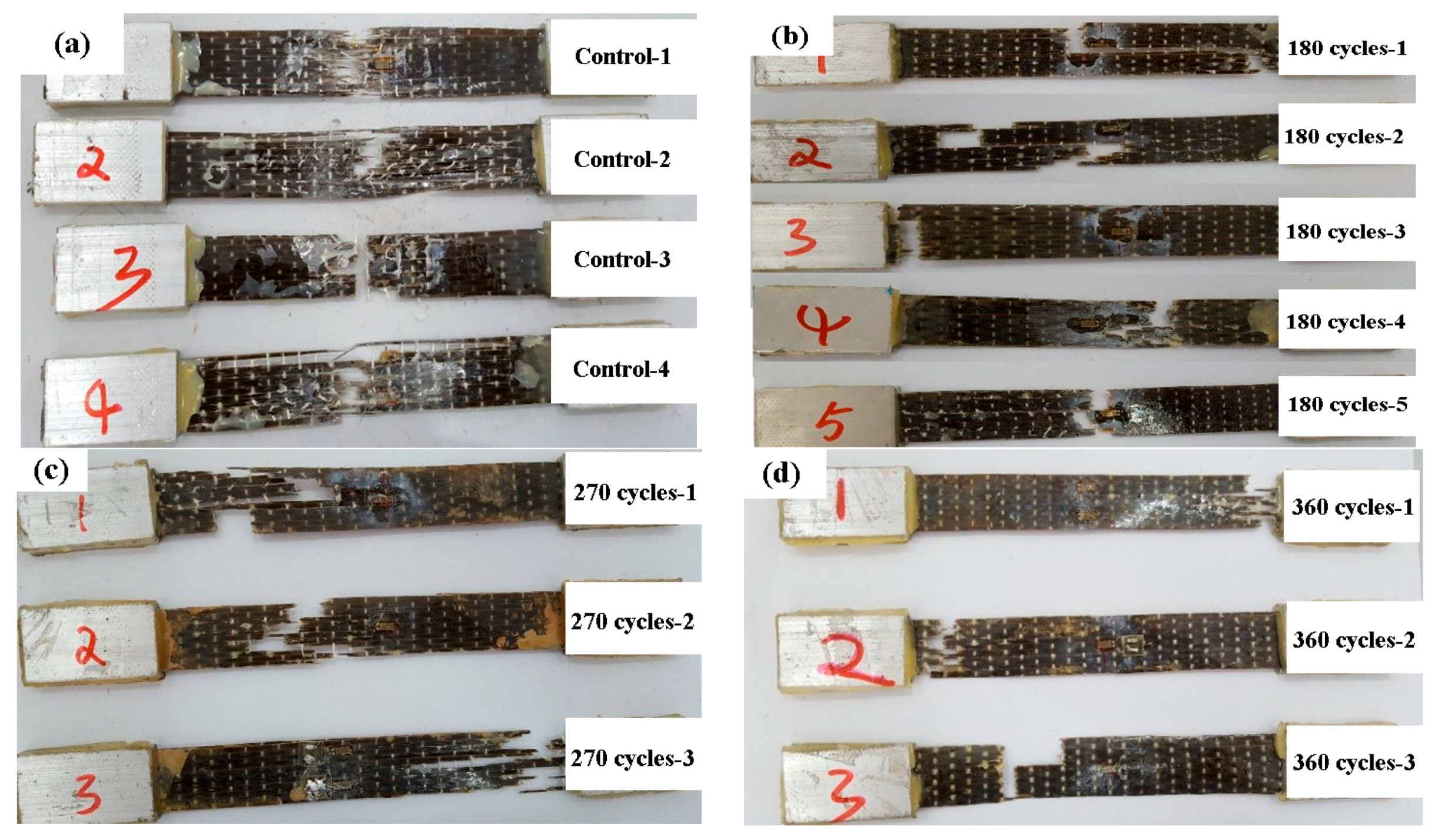

2.2. Preparation of the Specimens

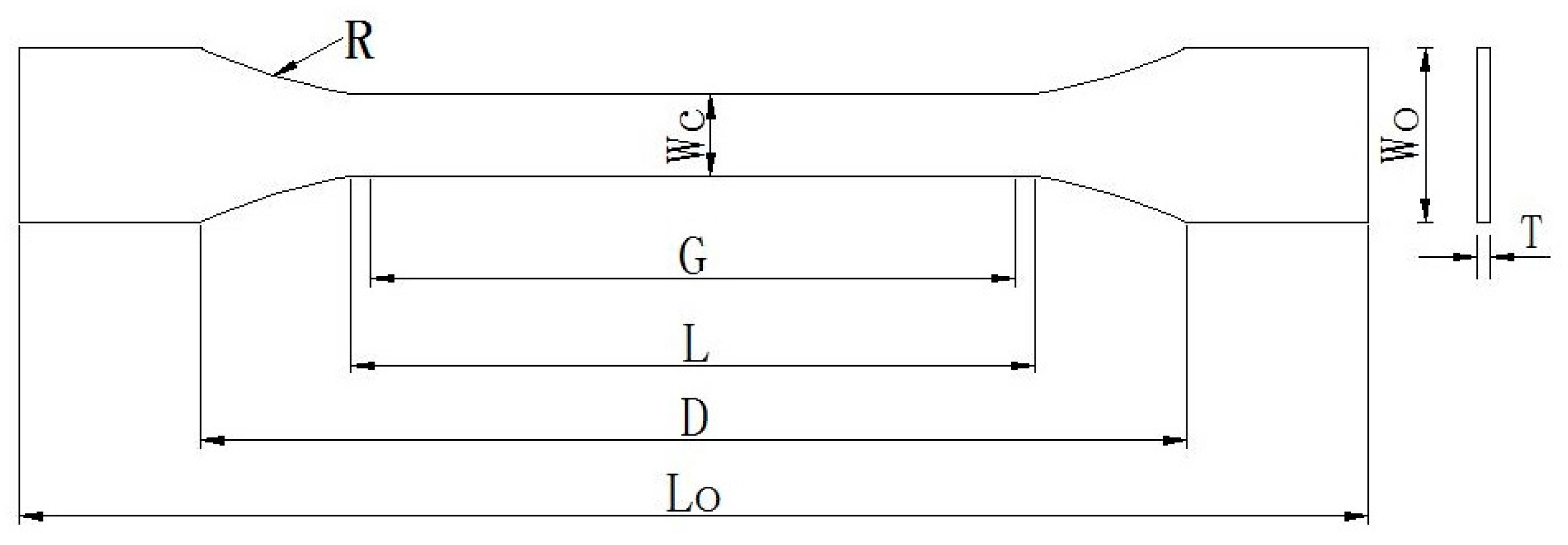

2.3. Tensile Property Tests

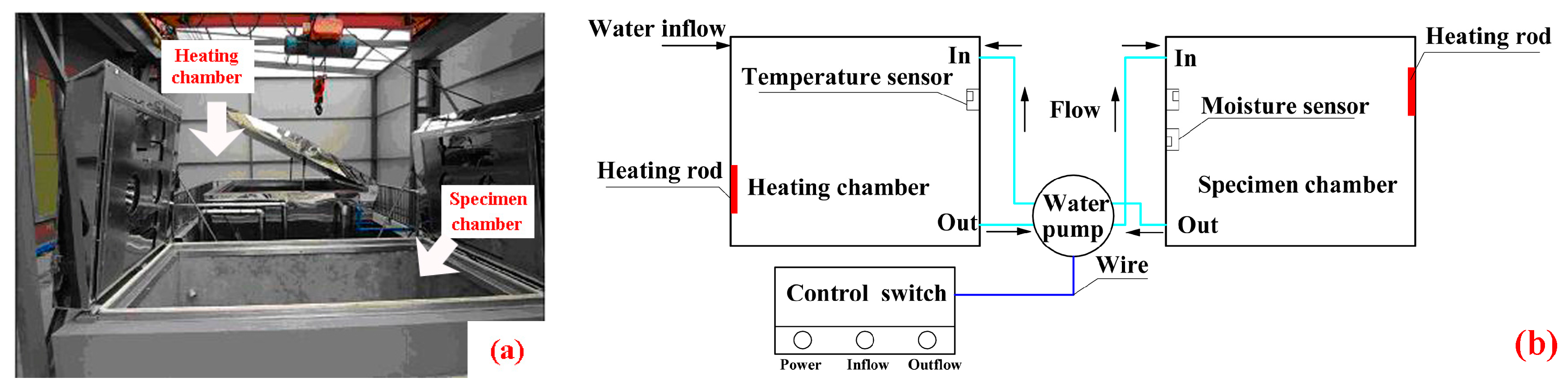

2.4. Wet–Dry Cyclic Condition

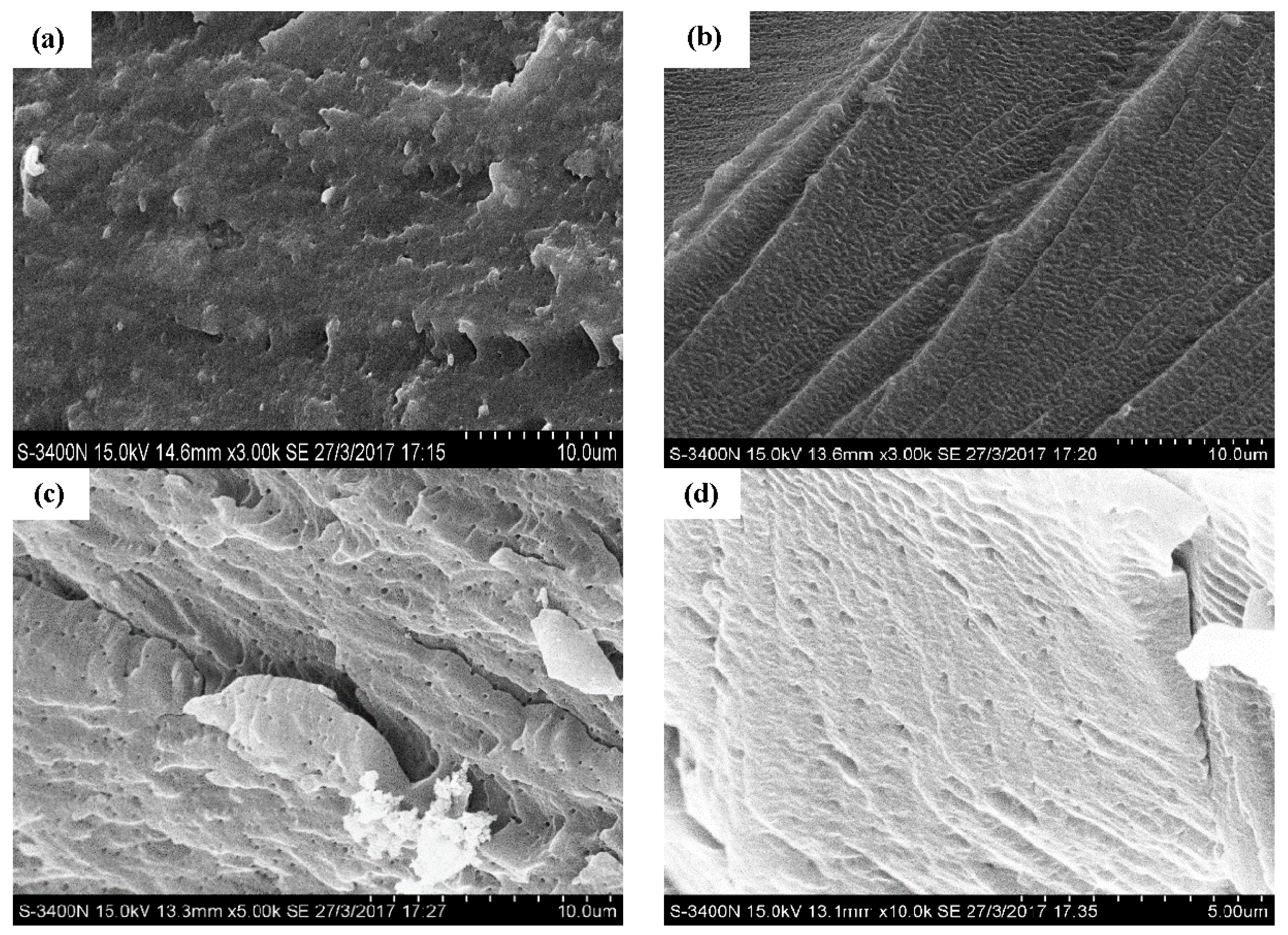

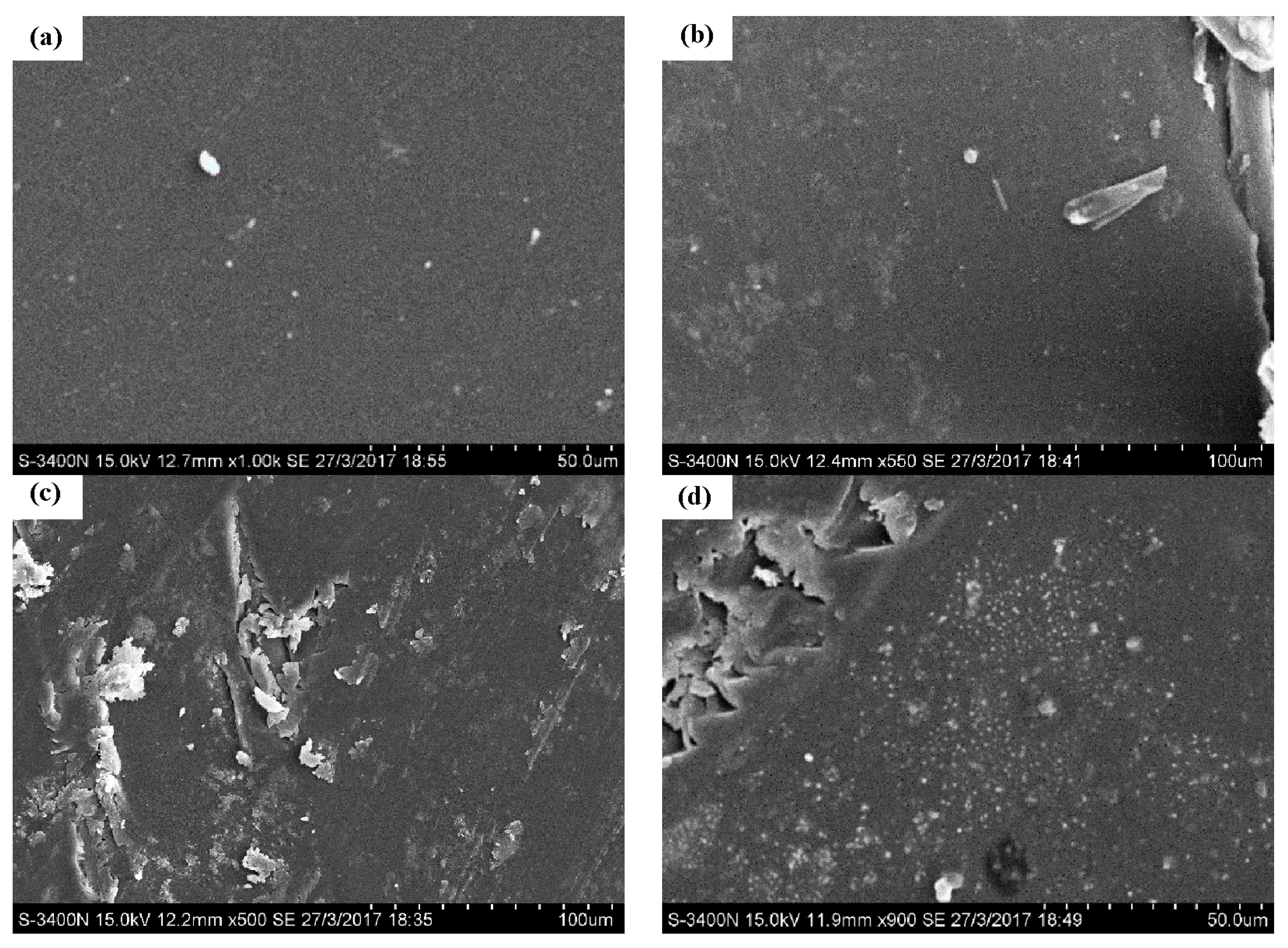

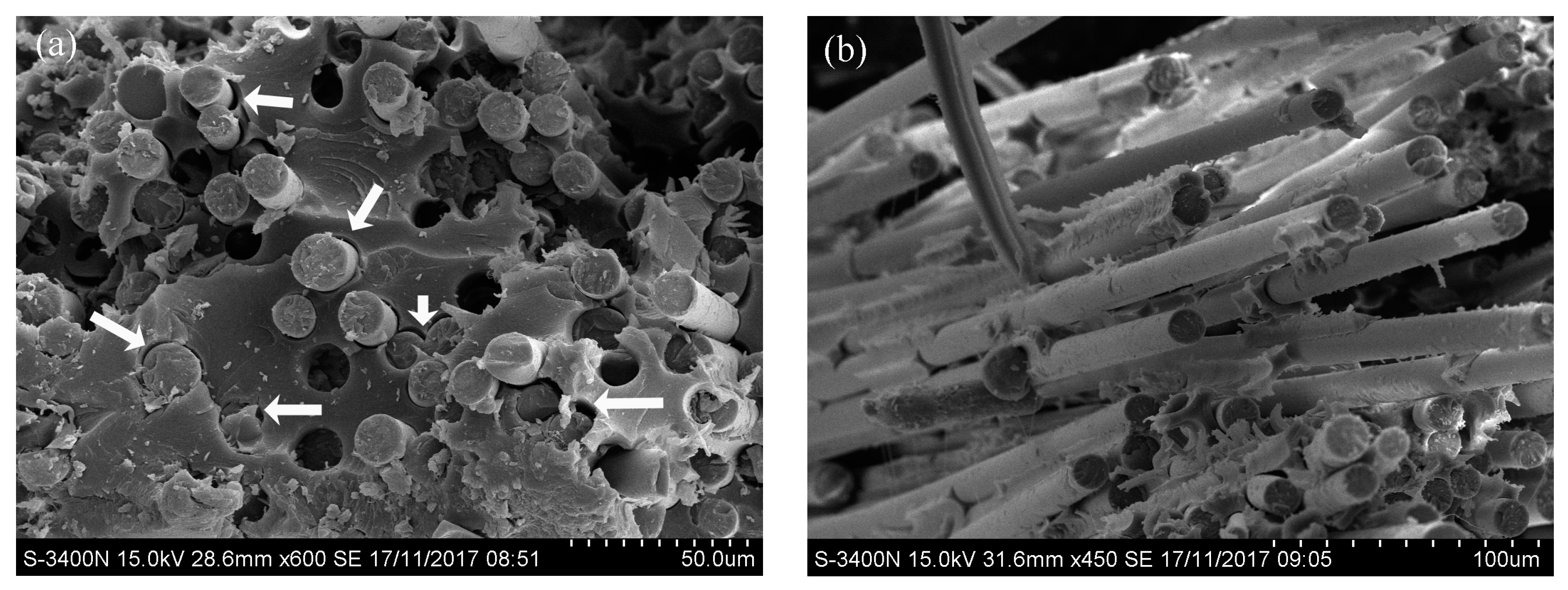

2.5. Scanning Electron Microscopy (SEM)

2.6. Void Volume Fractions Test

3. Results and Discussions

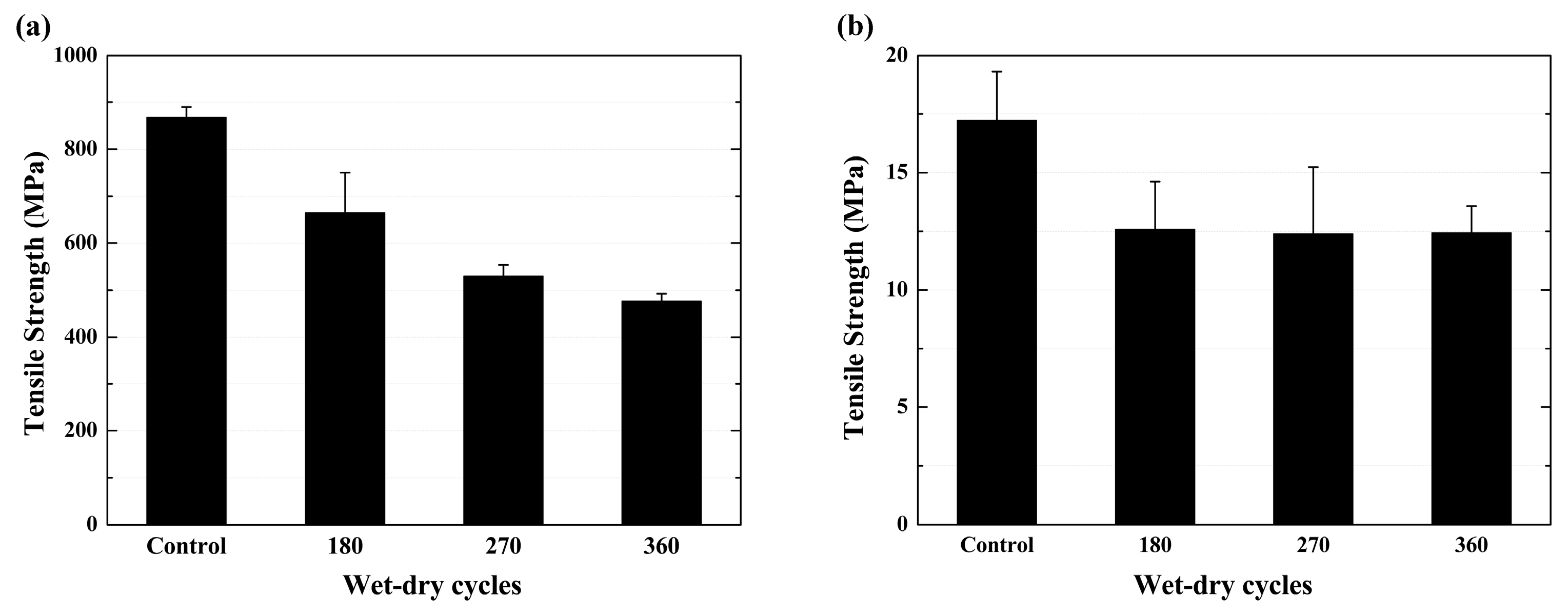

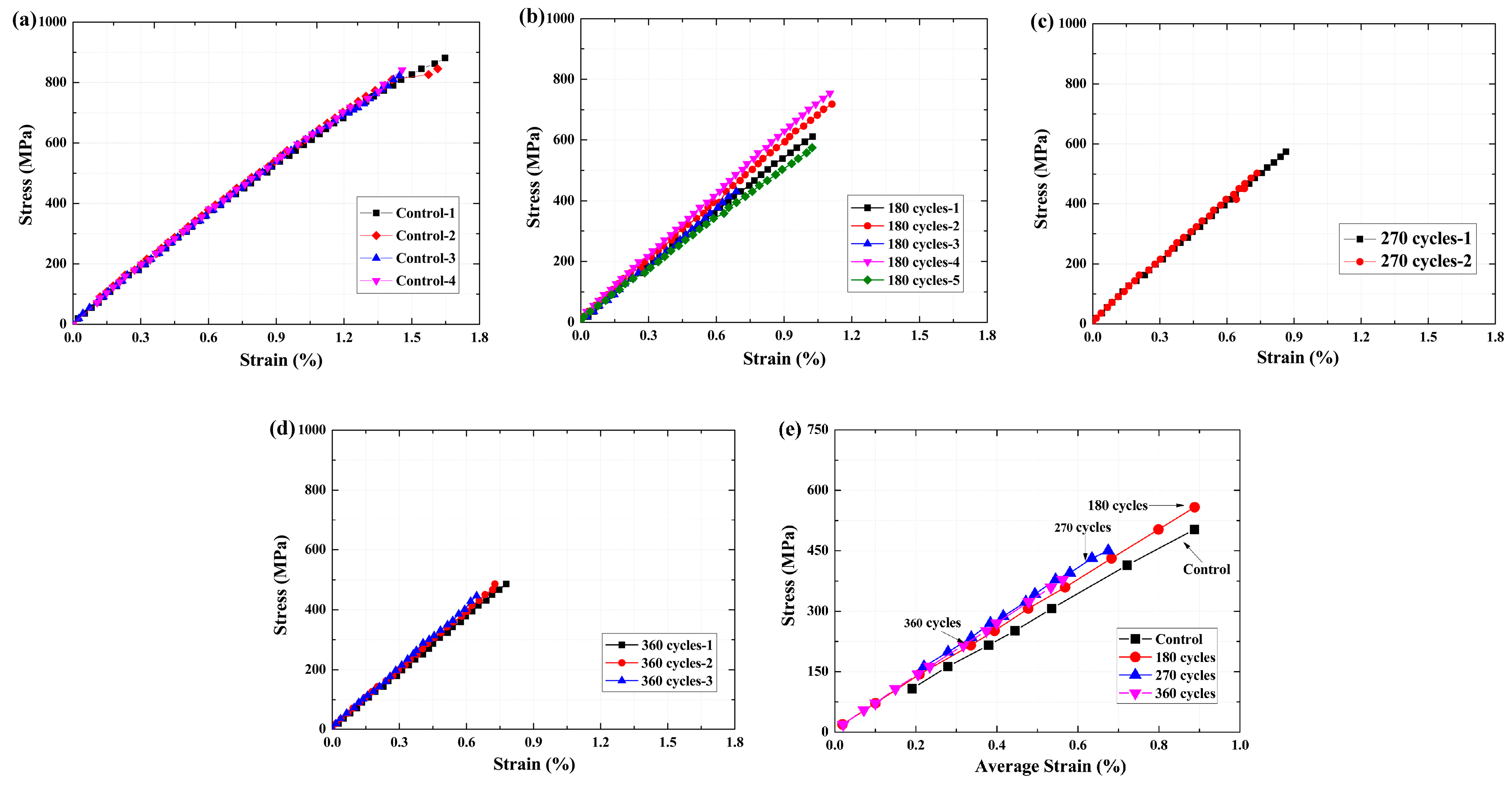

3.1. Tensile Strength

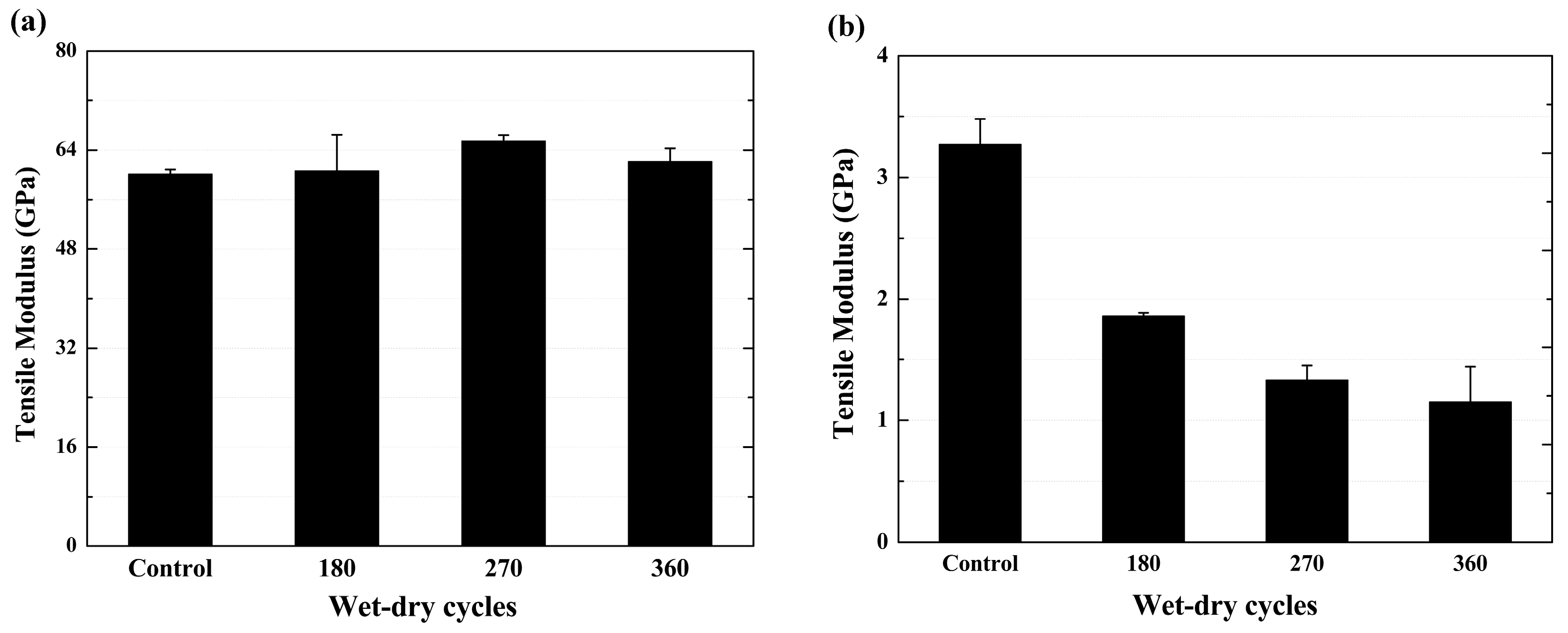

3.2. Tensile Modulus

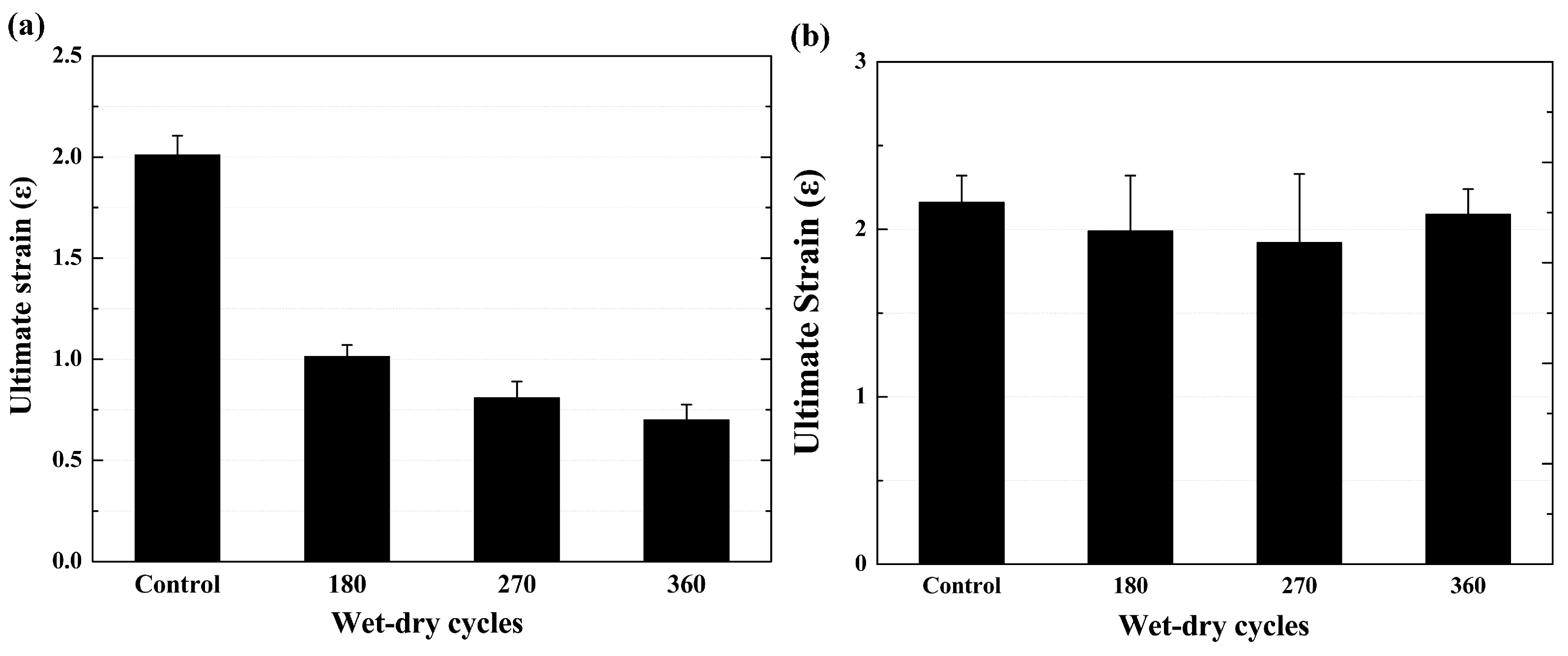

3.3. Ultimate Strain

4. Conclusions

- The wet–dry cycles with chloride-containing solution caused the hydrolysis of the epoxy resin matrix, and interfacial damage between the basalt fiber and epoxy resin matrix. Salt precipitation accelerated the fiber–matrix interfacial debonding during the wet–dry cycles, resulting in serious degradation of the tensile strength of the BFRP sheet. The longer the exposure time, the more serious the degradation found.

- Chloride ions accelerated the penetration and degradation of the epoxy resin matrix, resulting in the degradation of the tensile strength of the resin matrix. With the increase in the number of cycles, more water ingressed led to more plasticization, which was responsible for the reduction in the tensile modulus.

- The deformation was governed by the basalt fiber for the BFRP sheet. The decreased stress-transfer at the interface between the basalt fiber and resin matrix led to degradation of the tensile strength of the BFRP sheet, but the tensile modulus remained approximately constant as the cycling time increased.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, Y.; Xian, G.; Silva, M.A.G. Effects of water immersion on the bond behavior between CFRP plates and concrete substrate. Constr. Build. Mater. 2015, 101, 326–337. [Google Scholar] [CrossRef]

- Li, S.; Hu, J.; Ren, H. The combined effects of environmental conditioning and sustained load on mechanical properties of wet lay-up fiber reinforced polymer. Polymers 2017, 9, 244. [Google Scholar] [CrossRef]

- Nishizaki, I.; Sakuraba, H.; Tomiyama, T. Durability of pultruded gfrp through ten-year outdoor exposure test. Polymers 2015, 7, 2494–2503. [Google Scholar] [CrossRef]

- Chen, Y.; Davalos, J.F.; Ray, I.; Kim, H.Y. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures. Compos. Struct. 2007, 78, 101–111. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Xu, Y. Experimental study on the bond durability between steel-FRP composite bars (SFCBS) and sea sand concrete in ocean environment. Constr. Build. Mater. 2016, 115, 277–284. [Google Scholar] [CrossRef]

- Mishra, A.K.; Chakraborty, S. Inverse detection of constituent level elastic parameters of FRP composite panels with elastic boundaries using finite element model updating. Ocean Eng. 2016, 111, 358–368. [Google Scholar] [CrossRef]

- Ceroni, F.; Cosenza, E.; Gaetano, M.; Pecce, M. Durability issues of FRP rebars in reinforced concrete members. Cem. Concr. Compos. 2006, 28, 857–868. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Li, H. Effects of exposure to elevated temperatures and subsequent immersion in water or alkaline solution on the mechanical properties of pultruded BFRP plates. Compos. Part B 2015, 77, 421–430. [Google Scholar] [CrossRef]

- Wang, Z.K.; Zhao, X.L.; Xian, G.J.; Wu, G.; Raman, R.K.S.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Xian, G.; Karbhari, V.M. Segmental relaxation of water-aged ambient cured epoxy. Polym. Degrad. Stab. 2007, 92, 1650–1659. [Google Scholar] [CrossRef]

- Al-Sabagh, A.; Taha, E.; Kandil, U.; Awadallah, A.; Nasr, G.-A.M.; Reda Taha, M. Monitoring moisture damage propagation in GFRP composites using carbon nanoparticles. Polymers 2017, 9, 94. [Google Scholar] [CrossRef]

- Aboelseoud, M.A.; Myers, J.J. Durability of hybrid composite beam bridges subjected to various environmental conditioning. J. Compos. Constr. 2016, 20. [Google Scholar] [CrossRef]

- Wang, X.; Wu, G.; Wu, Z.; Dong, Z.; Xie, Q. Evaluation of prestressed basalt fiber and hybrid fiber reinforced polymer tendons under marine environment. Mater. Des. 2014, 64, 721–728. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Durability of bonded FRP-to-steel joints: Effects of moisture, de-icing salt solution, temperature and FRP type. Compos. Part B 2017, 119, 153–167. [Google Scholar] [CrossRef]

- Nakada, M.; Miyano, Y. Accelerated testing for long-term fatigue strength of various FRP laminates for marine use. Compos. Sci. Technol. 2009, 69, 805–813. [Google Scholar] [CrossRef]

- Silva, M.A.G.; Cidade, M.T.; Biscaia, H.; Marreiros, R. Composites and FRP-strengthened beams subjected to dry/wet and salt fog cycles. J. Mater. Civ. Eng. 2014, 26. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Abolhasani, M.M.; Shirvanimoghaddam, K.; Naebe, M. PVDF/graphene composite nanofibers with enhanced piezoelectric performance for development of robust nanogenerators. Compos. Sci. Technol. 2017, 138, 49–56. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.S.; Dong, Z.Q.; Zhang, G.C. Durability of basalt fibers and composites in corrosive environments. J. Compos. Mater. 2015, 49, 873–887. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G. Combined effects of sustained tensile loading and elevated temperatures on the mechanical properties of pultruded BFRP plates. Constr. Build. Mater. 2017, 150, 310–320. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Shi, J.Z.; Wang, X.; Wu, Z.S.; Zhu, Z.G. Creep behavior enhancement of a basalt fiber-reinforced polymer tendon. Constr. Build. Mater. 2015, 94, 750–757. [Google Scholar] [CrossRef]

- Alaimo, G.; Valenza, A.; Enea, D.; Fiore, V. The durability of basalt fibres reinforced polymer (BFRP) panels for cladding. Mater. Struct. 2016, 49, 2053–2064. [Google Scholar] [CrossRef]

- Quagliarini, E.; Monni, F.; Bondioli, F.; Lenci, S. Basalt fiber ropes and rods: Durability tests for their use in building engineering. J. Build. Eng. 2016, 5, 142–150. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM D3039 / D3039M-17). Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2000; pp. 1–10. Available online: http://www.astm.org/cgi-bin/resolver.cgi?D3039D3039M-14 (accessed on 2 December 2015).

- American Society for Testing and Materials (ASTM D638-14). Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2000; pp. 1–13. Available online: http://www.astm.org/cgi-bin/resolver.cgi?D638-14 (accessed on 2 December 2015).

- Wang, Z.; Zhao, C.; Pan, Z. Porous bead-on-string poly(lactic acid) fibrous membranes for air filtration. J. Colloid Interface Sci. 2015, 441, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Kafodya, I.; Xian, G.; Li, H. Durability study of pultruded CFRP plates immersed in water and seawater under sustained bending: Water uptake and effects on the mechanical properties. Compos. Part B 2015, 70, 138–148. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Xian, G. Hygrothermal effects on high VF pultruded unidirectional carbon/epoxy composites: Moisture uptake. Compos. Part B 2009, 40, 41–49. [Google Scholar] [CrossRef]

- Burkhard, D.J.M.; Scherer, T. The effect of initial oxidation state on crystallization of basaltic glass. J. Non-Cryst. Solids 2006, 352, 3961–3969. [Google Scholar] [CrossRef]

- Lu, Z.Y.; Xian, G.J.; Li, H. Effects of thermal aging on the water uptake behavior of pultruded BFRP plates. Polym. Degrad. Stab. 2014, 110, 216–224. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, K.; Hui, D.; Xu, F.; Liu, W.; Yang, S.; Wang, L. Monitoring of seawater immersion degradation in glass fibre reinforced polymer composites using quantum dots. Compos. Part B 2017, 112, 93–102. [Google Scholar] [CrossRef]

- Lu, Z.Y.; Xian, G.J.; Li, H. Effects of elevated temperatures on the mechanical properties of basalt fibers and BFRP plates. Constr. Build. Mater. 2016, 127, 1029–1036. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G. Resistance of basalt fibers to elevated temperatures and water or alkaline solution immersion. Polym. Compos. 2016. [Google Scholar] [CrossRef]

| Characteristic | R—Radius of Fillet | LO—Length Overall | WO—Width Overall | D—Distance between Grips | L—Length of Narrow Section | G—Gauge Length | WC—Width of Narrow Section | T—Thickness |

|---|---|---|---|---|---|---|---|---|

| Dimension (mm) | 76 | 165 | 19 | 115 | 57 | 50 | 13 | 3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Z.; Xie, J.; Zhang, H.; Li, J. Long-Term Durability of Basalt Fiber-Reinforced Polymer (BFRP) Sheets and the Epoxy Resin Matrix under a Wet–Dry Cyclic Condition in a Chloride-Containing Environment. Polymers 2017, 9, 652. https://doi.org/10.3390/polym9120652

Lu Z, Xie J, Zhang H, Li J. Long-Term Durability of Basalt Fiber-Reinforced Polymer (BFRP) Sheets and the Epoxy Resin Matrix under a Wet–Dry Cyclic Condition in a Chloride-Containing Environment. Polymers. 2017; 9(12):652. https://doi.org/10.3390/polym9120652

Chicago/Turabian StyleLu, Zhongyu, Jianhe Xie, Huan Zhang, and Jianglin Li. 2017. "Long-Term Durability of Basalt Fiber-Reinforced Polymer (BFRP) Sheets and the Epoxy Resin Matrix under a Wet–Dry Cyclic Condition in a Chloride-Containing Environment" Polymers 9, no. 12: 652. https://doi.org/10.3390/polym9120652