Development of Active Packaging to Extend the Shelf Life of Agaricus bisporus by Using Plasma Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

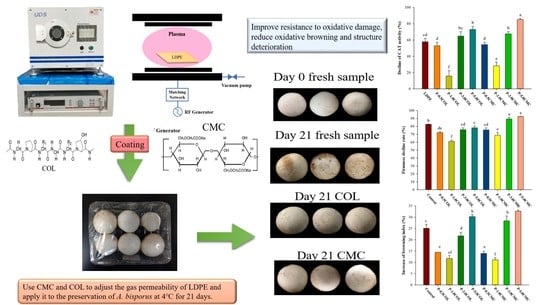

2.2. Preparation of Composite Films and Package

2.3. Properties of Films

2.3.1. ATR-FTIR Spectra

2.3.2. Film Thickness, Optical Properties, and Mechanical Properties

2.3.3. Water Vapor, Oxygen, and Carbon Dioxide Permeability of Films

2.4. Structural Deterioration

2.4.1. Firmness

2.4.2. β-1,3-Glucanase

2.4.3. Microstructure Evaluation

2.5. Oxidative Browning

2.5.1. Browning

2.5.2. Polyphenol Oxidase

2.6. Respiratory Injury

2.6.1. Electrolyte Leakage

2.6.2. Malondialdehyde

2.6.3. Catalase

2.6.4. Respiration Rate

2.7. Data Analysis

3. Results and Discussion

3.1. Properties of Different Packaging

3.2. Effects of Different Packaging on the Structure in A. bisporus during Storage

3.3. Effects of Different Packaging on Browning in A. bisporus during Storage

3.4. Effects of Different Packaging on Cell Membrane Damage in A. bisporus during Storage

3.5. Effects of Different Packaging on the Respiration in A. bisporus during Storage

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hu, Y.-H.; Chen, C.-M.; Xu, L.; Cui, Y.; Yu, X.-Y.; Gao, H.-J.; Wang, Q.; Liu, K.; Shi, Y.; Chen, Q.-X. Postharvest application of 4-methoxy cinnamic acid for extending the shelf life of mushroom (Agaricus bisporus). Postharvest Biol. Technol. 2015, 104, 33–41. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Sun, Y.; Wang, X.; Li, L. Combined antioxidant and sensory effects of active chitosan/zein film containing α-tocopherol on Agaricus bisporus. Food Packag. Shelf 2020, 24, 100470. [Google Scholar] [CrossRef]

- Mahajan, P.V.; Oliveira, F.; Macedo, I. Effect of temperature and humidity on the transpiration rate of the whole mushrooms. J. Food Eng. 2008, 84, 281–288. [Google Scholar] [CrossRef]

- Mittler, R. Oxidative stress, antioxidants and stress tolerance. Trends Plant Sci. 2002, 7, 405–410. [Google Scholar] [CrossRef]

- Gao, M.; Feng, L.; Jiang, T. Browning inhibition and quality preservation of button mushroom (Agaricus bisporus) by essential oils fumigation treatment. Food Chem. 2014, 149, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Zheng, X.; Li, J.; Jing, G.; Cai, L.; Ying, T. Integrated application of nitric oxide and modified atmosphere packaging to improve quality retention of button mushroom (Agaricus bisporus). Food Chem. 2011, 126, 1693–1699. [Google Scholar] [CrossRef] [PubMed]

- Willekens, H.; Chamnongpol, S.; Davey, M.; Schraudner, M.; Langebartels, C.; Van Montagu, M.; Inzé, D.; Van Camp, W. Catalase is a sink for H2O2 and is indispensable for stress defence in C3 plants. EMBO J. 1997, 16, 4806–4816. [Google Scholar] [CrossRef] [Green Version]

- Ares, G.; Lareo, C.; Lema, P. Modified atmosphere packaging for postharvest storage of mushrooms. A review. Fresh Prod. 2007, 1, 32–40. [Google Scholar]

- Paulsen, E.; Barrios, S.; Lema, P. Ready-to-eat cherry tomatoes: Passive modified atmosphere packaging conditions for shelf life extension. Food Packag. Shelf 2019, 22, 100407. [Google Scholar] [CrossRef]

- Villaescusa, R.; Gil, M. Quality improvement of Pleurotus mushrooms by modified atmosphere packaging and moisture absorbers. Postharvest Biol. Technol. 2003, 28, 169–179. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Wang, X.; Dong, S.; Sun, Y.; Zhao, Z. The properties of chitosan/zein blend film and effect of film on quality of mushroom (Agaricus bisporus). Postharvest Biol. Technol. 2019, 155, 47–56. [Google Scholar] [CrossRef]

- Tumwesigye, K.; Sousa, A.; Oliveira, J.; Sousa-Gallagher, M. Evaluation of novel bitter cassava film for equilibrium modified atmosphere packaging of cherry tomatoes. Food Packag. Shelf 2017, 13, 1–14. [Google Scholar] [CrossRef]

- Taghizadeh, M.; Gowen, A.; Ward, P.; O’Donnell, C.P. Use of hyperspectral imaging for evaluation of the shelf-life of fresh white button mushrooms (Agaricus bisporus) stored in different packaging films. Innov. Food Sci. Emerg. 2010, 11, 423–431. [Google Scholar] [CrossRef]

- Cheng, P.; Yun, X.; Xu, C.; Yang, Y.; Han, Y.; Dong, T. Use of poly (ε-caprolactone)-based films for equilibrium-modified atmosphere packaging to extend the postharvest shelf life of garland chrysanthemum. Food Sci. Nutr. 2019, 7, 1946–1956. [Google Scholar] [CrossRef] [PubMed]

- Koide, S.; Shi, J. Microbial and quality evaluation of green peppers stored in biodegradable film packaging. Food Control. 2007, 18, 1121–1125. [Google Scholar] [CrossRef]

- Gholami, R.; Ahmadi, E.; Farris, S. Shelf life extension of white mushrooms (Agaricus bisporus) by low temperatures conditioning, modified atmosphere, and nanocomposite packaging material. Food Packag. Shelf 2017, 14, 88–95. [Google Scholar] [CrossRef] [Green Version]

- Jancikova, S.; Dordevic, D.; Jamroz, E.; Behalova, H.; Tremlova, B. Chemical and physical characteristics of edible films, based on κ-and ι-carrageenans with the addition of lapacho tea extract. Foods 2020, 9, 357. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Liu, S.; Chen, Y.; Zhang, L.; Kan, J.; Jin, C. Physical, mechanical and antioxidant properties of chitosan films grafted with different hydroxybenzoic acids. Food Hydrocoll. 2017, 71, 176–186. [Google Scholar] [CrossRef]

- Imtiaz-Ul-Islam, M.; Hong, L.; Langrish, T. CO2 capture using whey protein isolate. Chem. Eng. J. 2011, 171, 1069–1081. [Google Scholar] [CrossRef]

- Ghadermazi, R.; Hamdipour, S.; Sadeghi, K.; Ghadermazi, R.; Khosrowshahi Asl, A. Effect of various additives on the properties of the films and coatings derived from hydroxypropyl methylcellulose—A review. Food Sci. Nutr. 2019, 7, 3363–3377. [Google Scholar] [CrossRef] [Green Version]

- Miremadi, S.I.; Shafiabadi, N.; Amini-Fazl, M.S. Gas separation properties of crosslinked and non-crosslinked carboxymethylcellulose (CMC) membranes. Sci. Iran. 2013, 20, 1921–1928. [Google Scholar]

- Gaikwad, K.K.; Singh, S.; Lee, Y.S. A pyrogallol-coated modified LDPE film as an oxygen scavenging film for active packaging materials. Prog. Org. Coat. 2017, 111, 186–195. [Google Scholar] [CrossRef]

- Gray, N.; Hamzeh, Y.; Kaboorani, A.; Abdulkhani, A. Influence of cellulose nanocrystal on strength and properties of low density polyethylene and thermoplastic starch composites. Ind. Crop Prod. 2018, 115, 298–305. [Google Scholar] [CrossRef]

- Gaikwad, K.K.; Singh, S.; Lee, Y.S. Antimicrobial and improved barrier properties of natural phenolic compound-coated polymeric films for active packaging applications. J. Coat. Technol. Res. 2019, 16, 147–157. [Google Scholar] [CrossRef]

- Kim, J.E.; Lee, D.-U.; Min, S.C. Microbial decontamination of red pepper powder by cold plasma. Food Microbiol. 2014, 38, 128–136. [Google Scholar] [CrossRef]

- Lu, P.; Guo, M.; Xu, Z.; Wu, M. Application of nanofibrillated cellulose on BOPP/LDPE film as oxygen barrier and antimicrobial coating based on cold plasma treatment. Coatings 2018, 8, 207. [Google Scholar] [CrossRef] [Green Version]

- Loke, X.-J.; Chang, C.-K.; Hou, C.-Y.; Cheng, K.-C.; Hsieh, C.-W. Plasma-treated polyethylene coated with polysaccharide and protein containing cinnamaldehyde for active packaging films and applications on tilapia (Orechromis niloticus) fillet preservation. Food Control 2021, 125, 108016. [Google Scholar] [CrossRef]

- Wong, L.-W.; Hou, C.-Y.; Hsieh, C.-C.; Chang, C.-K.; Wu, Y.-S.; Hsieh, C.-W. Preparation of antimicrobial active packaging film by capacitively coupled plasma treatment. LWT 2020, 117, 108612. [Google Scholar] [CrossRef]

- Rojas, A.; Velásquez, E.; Garrido, L.; Galotto, M.J.; de Dicastillo, C.L. Design of active electrospun mats with single and core-shell structures to achieve different curcumin release kinetics. J. Food Eng. 2020, 273, 109900. [Google Scholar] [CrossRef]

- Rojas, A.; Velásquez, E.; Piña, C.; Galotto, M.J.; de Dicastillo, C.L. Designing active mats based on cellulose acetate/polycaprolactone core/shell structures with different release kinetics. Carbohyd. Polym. 2021, 261, 117849. [Google Scholar] [CrossRef]

- Velásquez, E.; Rojas, A.; Piña, C.; Galotto, M.J.; López de Dicastillo, C. Development of bilayer biodegradable composites containing cellulose nanocrystals with antioxidant properties. Polymers 2019, 11, 1945. [Google Scholar] [CrossRef] [Green Version]

- López de Dicastillo, C.; Garrido, L.; Velásquez, E.; Rojas, A.; Gavara, R. Designing Biodegradable and Active Multilayer System by Assembling an Electrospun Polycaprolactone Mat Containing Quercetin and Nanocellulose between Polylactic Acid Films. Polymers 2021, 13, 1288. [Google Scholar] [CrossRef]

- Theapsak, S.; Watthanaphanit, A.; Rujiravanit, R. Preparation of chitosan-coated polyethylene packaging films by DBD plasma treatment. ACS Appl. Mater. Inter. 2012, 4, 2474–2482. [Google Scholar] [CrossRef] [PubMed]

- Hamaguchi, P.Y.; WuYin, W.; Tanaka, M. Effect of pH on the formation of edible films made from the muscle proteins of Blue marlin (Makaira mazara). Food Chem. 2007, 100, 914–920. [Google Scholar] [CrossRef]

- Sobral, P.d.A.; Menegalli, F.; Hubinger, M.; Roques, M. Mechanical, water vapor barrier and thermal properties of gelatin based edible films. Food Hydrocoll. 2001, 15, 423–432. [Google Scholar] [CrossRef]

- Wood, T.M.; Bhat, K.M. Methods for measuring cellulase activities. Method Enzymol. 1988, 160, 87–112. [Google Scholar] [CrossRef]

- Kaya, C.; Kirnak, H.; Higgs, D.; Saltali, K. Supplementary calcium enhances plant growth and fruit yield in strawberry cultivars grown at high (NaCl) salinity. Sci. Hortic. 2002, 93, 65–74. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X. Changes in color, antioxidant, and free radical scavenging enzyme activity of mushrooms under high oxygen modified atmospheres. Postharvest Biol. Technol. 2012, 69, 1–6. [Google Scholar] [CrossRef]

- Bailly, C.; Benamar, A.; Corbineau, F.; Côme, D. Changes in malondialdehyde content and in superoxide dismutase, catalase and glutathione reductase activities in sunflower seeds as related to deterioration during accelerated aging. Physiol. Plant. 1996, 97, 104–110. [Google Scholar] [CrossRef]

- Cody, R.P.; Smith, J.K. Applied statistics and the SAS programming language. N. Jersey 1997. [Google Scholar] [CrossRef]

- Mohajer, S.; Rezaei, M.; Hosseini, S.F. Physico-chemical and microstructural properties of fish gelatin/agar bio-based blend films. Carbohyd. Polym. 2017, 157, 784–793. [Google Scholar] [CrossRef] [Green Version]

- Chi, K.; Catchmark, J.M. Improved eco-friendly barrier materials based on crystalline nanocellulose/chitosan/carboxymethyl cellulose polyelectrolyte complexes. Food Hydrocoll. 2018, 80, 195–205. [Google Scholar] [CrossRef]

- Abugoch, L.E.; Tapia, C.; Villamán, M.C.; Yazdani-Pedram, M.; Díaz-Dosque, M. Characterization of quinoa protein–chitosan blend edible films. Food Hydrocoll. 2011, 25, 879–886. [Google Scholar] [CrossRef]

- Giteru, S.G.; Ali, M.A.; Oey, I. Solvent strength and biopolymer blending effects on physicochemical properties of zein-chitosan-polyvinyl alcohol composite films. Food Hydrocoll. 2019, 87, 270–286. [Google Scholar] [CrossRef]

- Tongnuanchan, P.; Benjakul, S.; Prodpran, T.; Pisuchpen, S.; Osako, K. Mechanical, thermal and heat sealing properties of fish skin gelatin film containing palm oil and basil essential oil with different surfactants. Food Hydrocoll. 2016, 56, 93–107. [Google Scholar] [CrossRef]

- Liu, J.; Liu, S.; Zhang, X.; Kan, J.; Jin, C. Effect of gallic acid grafted chitosan film packaging on the postharvest quality of white button mushroom (Agaricus bisporus). Postharvest Biol. Technol. 2019, 147, 39–47. [Google Scholar] [CrossRef]

- Singh, S.; Gaikwad, K.K.; Lee, M.; Lee, Y.S. Thermally buffered corrugated packaging for preserving the postharvest freshness of mushrooms (Agaricus bispours). J. Food Eng. 2018, 216, 11–19. [Google Scholar] [CrossRef]

- Lyn, F.H.; Adilah, Z.M.; Nor-Khaizura, M.; Jamilah, B.; Hanani, Z.N. Application of modified atmosphere and active packaging for oyster mushroom (Pleurotus ostreatus). Food Packag. Shelf 2020, 23, 100451. [Google Scholar] [CrossRef]

- Jiang, T.; Wang, Q.; Xu, S.; Jahangir, M.M.; Ying, T. Structure and composition changes in the cell wall in relation to texture of shiitake mushrooms (Lentinula edodes) stored in modified atmosphere packaging. J. Sci. Food Agric. 2010, 90, 742–749. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, C.-C.; Chang, C.-K.; Wong, L.-W.; Hu, C.-C.; Lin, J.-A.; Hsieh, C.-W. Alternating current electric field inhibits browning of Pleurotus ostreatus via inactivation of oxidative enzymes during postharvest storage. LWT 2020, 134, 110212. [Google Scholar] [CrossRef]

- Sandhya, Modified atmosphere packaging of fresh produce: Current status and future needs. LWT 2010, 43, 381–392. [CrossRef]

- Wang, C.T.; Wang, C.T.; Cao, Y.P.; Nout, M.R.; Sun, B.G.; Liu, L. Effect of modified atmosphere packaging (MAP) with low and superatmospheric oxygen on the quality and antioxidant enzyme system of golden needle mushrooms (Flammulina velutipes) during postharvest storage. Eur. Food Res. Technol. 2011, 232, 851–860. [Google Scholar] [CrossRef]

| Thickness (mm) | Transparency | Tensile strength (MPa) | WVP (×10–7 g∙mm∙m−2∙h−1∙Pa−1) | OP (×10–12 g∙m∙m−2∙s−1∙Pa−1) | CDP (×10–12 g∙m∙m−2∙s−1∙Pa−1) | |

|---|---|---|---|---|---|---|

| Control | 0.033 ± 0.001 f | 1.500 ± 0.021 e | 19.25 ± 0.10 f | 0.29 ± 0.10 d | 4.18 ± 0.24 a | 8.98 ± 0.48 a |

| P-0.5COL | 0.034 ± 0.001 f | 1.508 ± 0.079 e | 24.52 ± 0.67 c | 0.61 ± 0.31 cd | 2.42 ± 0.14 d | 2.42 ± 1.45 d |

| P-1.0COL | 0.037 ± 0.002 e | 1.614 ± 0.031 de | 28.38 ± 0.30 a | 0.79 ± 0.28 cd | 2.38 ± 0.12 d | 3.17 ± 0.03 d |

| P-3.0COL | 0.045 ± 0.002 d | 1.662 ± 0.072 de | 25.99 ± 0.28 b | 1.61 ± 0.14 c | 2.40 ± 0.09 d | 3.64 ± 0.59 d |

| P-5.0COL | 0.059 ± 0.002 c | 1.659 ± 0.066 de | 21.17 ± 0.26 e | 8.63 ± 1.35 a | 2.67 ± 0.22 c | 5.88 ± 0.06 bc |

| P-0.5CMC | 0.036 ± 0.002 ef | 1.523 ± 0.006 e | 26.23 ± 1.19 b | 0.36 ± 0.12 cd | 2.69 ± 0.11 c | 2.67 ± 0.11 d |

| P-1.0CMC | 0.043 ± 0.002 d | 1.733 ± 0.011 c | 29.30 ± 0.55 a | 0.37 ± 0.25 cd | 2.77 ± 0.23 b | 3.54 ± 0.28 d |

| P-3.0CMC | 0.065 ± 0.001 b | 1.947 ± 0.069 b | 22.42 ± 0.93 d | 1.05 ± 0.18 cd | 2.80 ± 0.30 b | 5.63 ± 0.30 c |

| P-5.0CMC | 0.069 ± 0.002 a | 2.591 ± 0.325 a | 15.34 ± 0.24 g | 4.57 ± 1.51 b | 3.87 ± 0.56 a | 6.85 ± 0.49 b |

| Day 0 | Day 21 | ||||

|---|---|---|---|---|---|

| Control | Control | P-0.5COL | P-1.0COL | P-3.0COL | P-5.0COL |

|  |  |  |  |  |

| P-0.5CMC | P-1.0CMC | P-3.0CMC | P-5.0CMC | ||

|  |  |  | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.-K.; Cheng, K.-C.; Hou, C.-Y.; Wu, Y.-S.; Hsieh, C.-W. Development of Active Packaging to Extend the Shelf Life of Agaricus bisporus by Using Plasma Technology. Polymers 2021, 13, 2120. https://doi.org/10.3390/polym13132120

Chang C-K, Cheng K-C, Hou C-Y, Wu Y-S, Hsieh C-W. Development of Active Packaging to Extend the Shelf Life of Agaricus bisporus by Using Plasma Technology. Polymers. 2021; 13(13):2120. https://doi.org/10.3390/polym13132120

Chicago/Turabian StyleChang, Chao-Kai, Kuan-Chen Cheng, Chih-Yao Hou, Yi-Shan Wu, and Chang-Wei Hsieh. 2021. "Development of Active Packaging to Extend the Shelf Life of Agaricus bisporus by Using Plasma Technology" Polymers 13, no. 13: 2120. https://doi.org/10.3390/polym13132120