Miscibility and Nanoparticle Diffusion in Ionic Nanocomposites

Abstract

:1. Introduction

2. Methodology

3. Results and Discussion

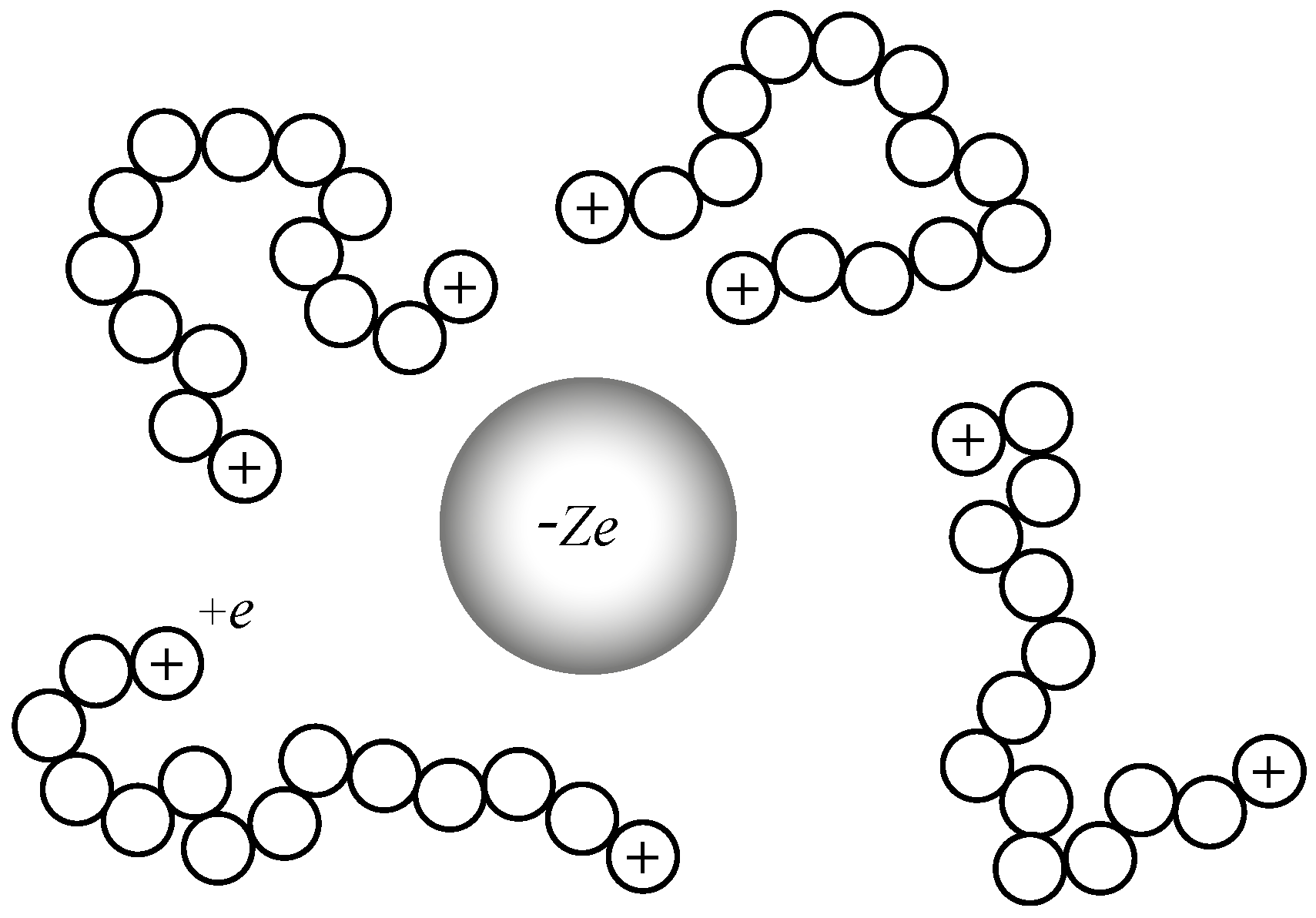

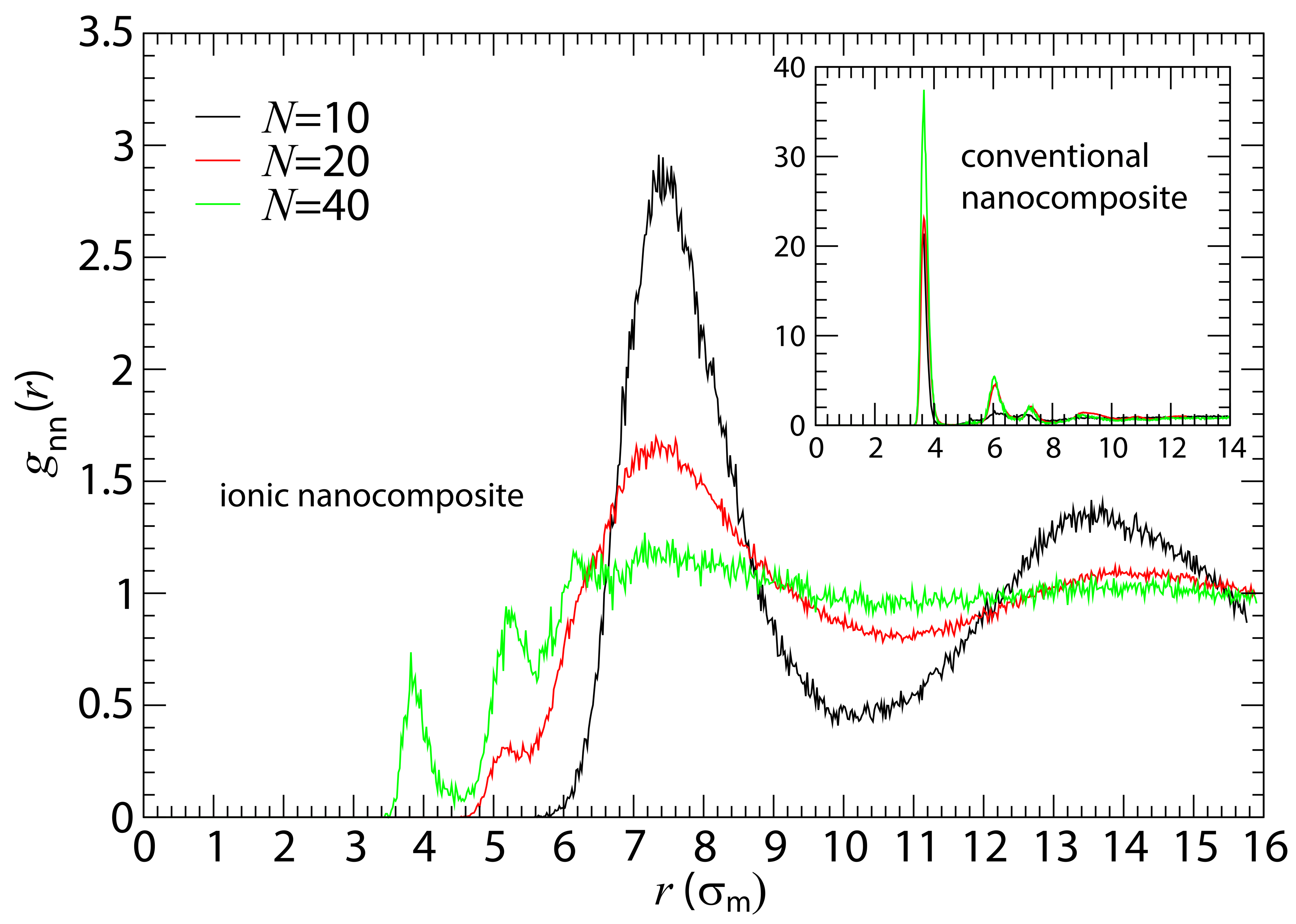

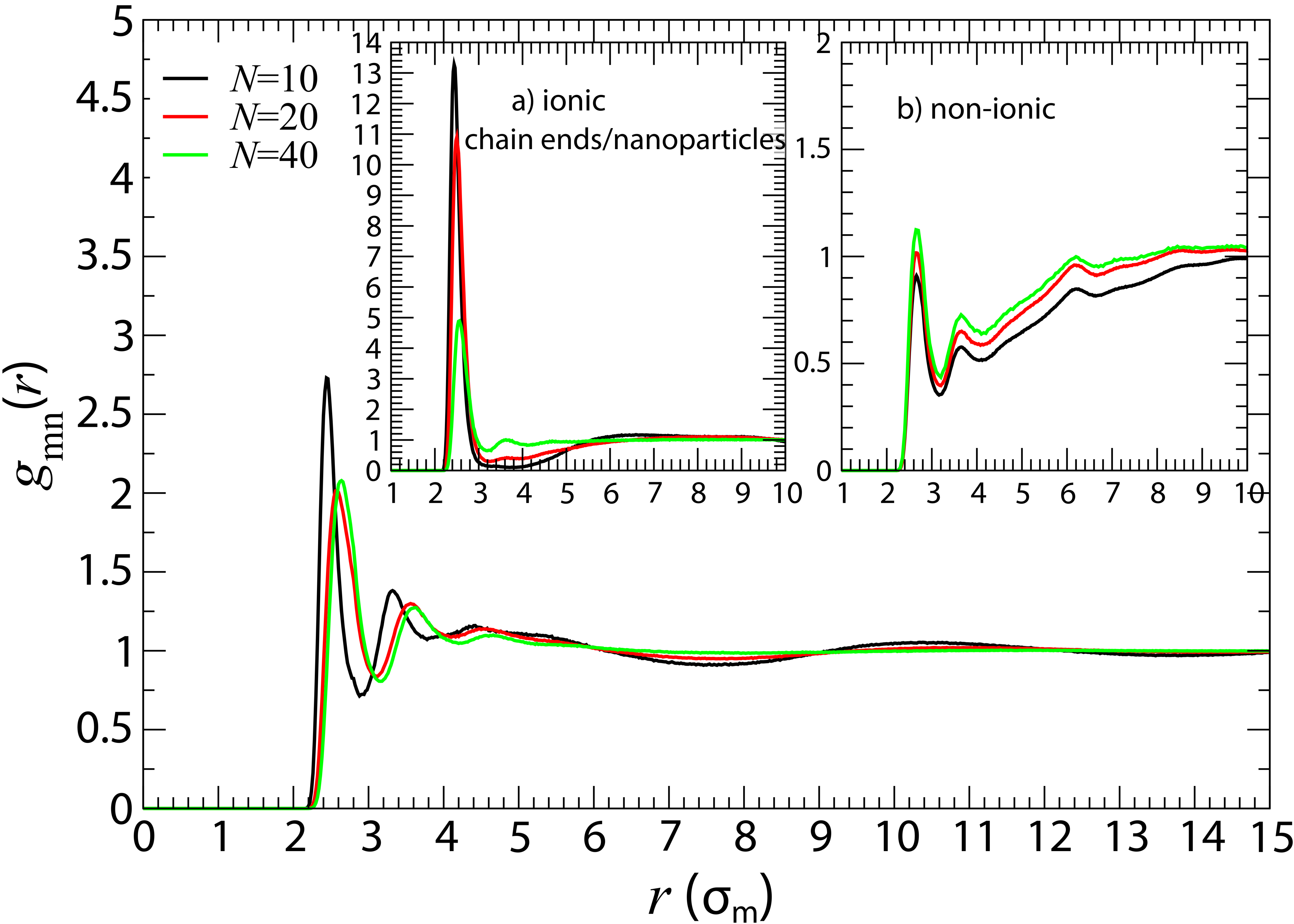

3.1. Nanoparticle and Polymer Structure

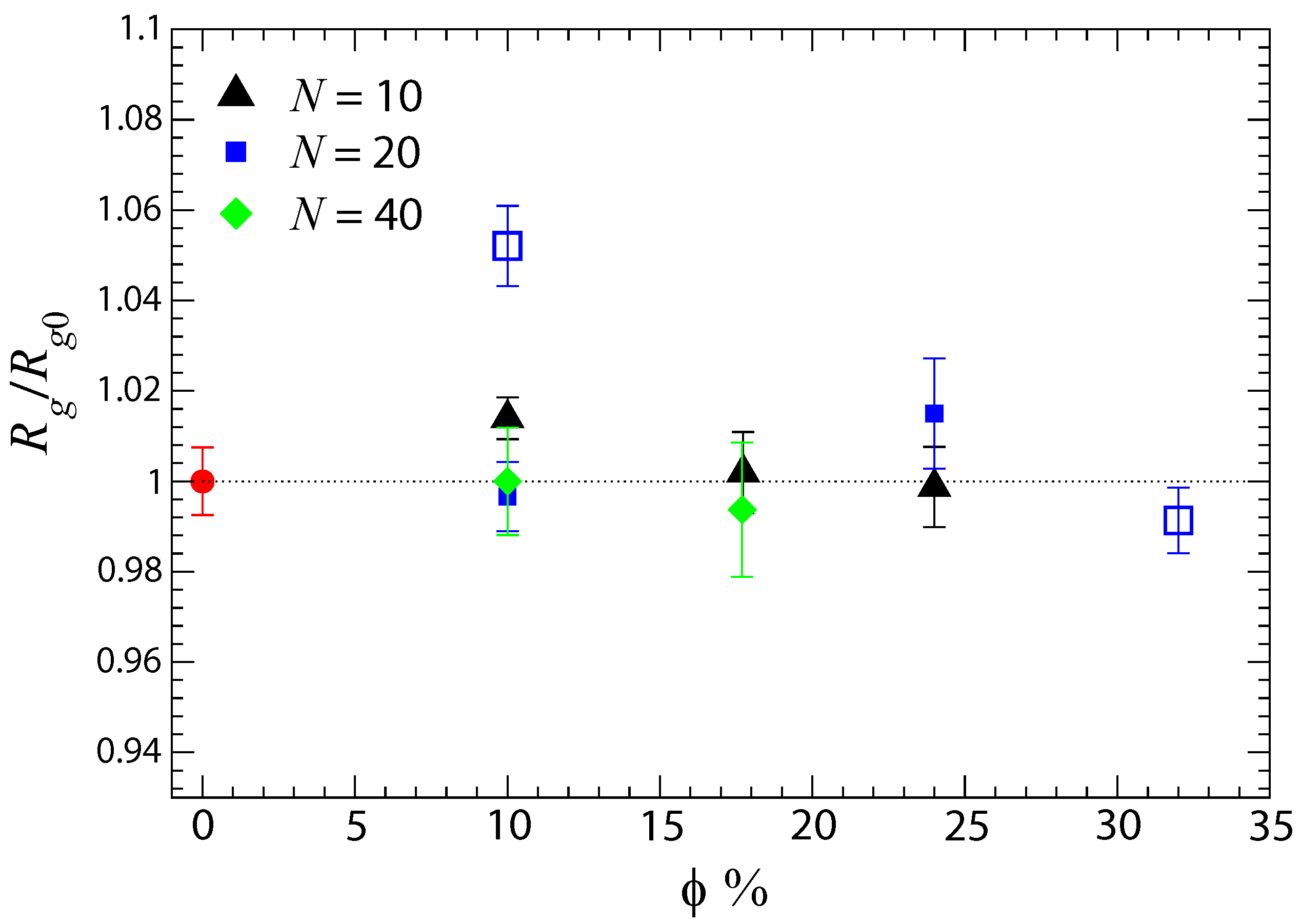

3.2. Polymer Dimensions

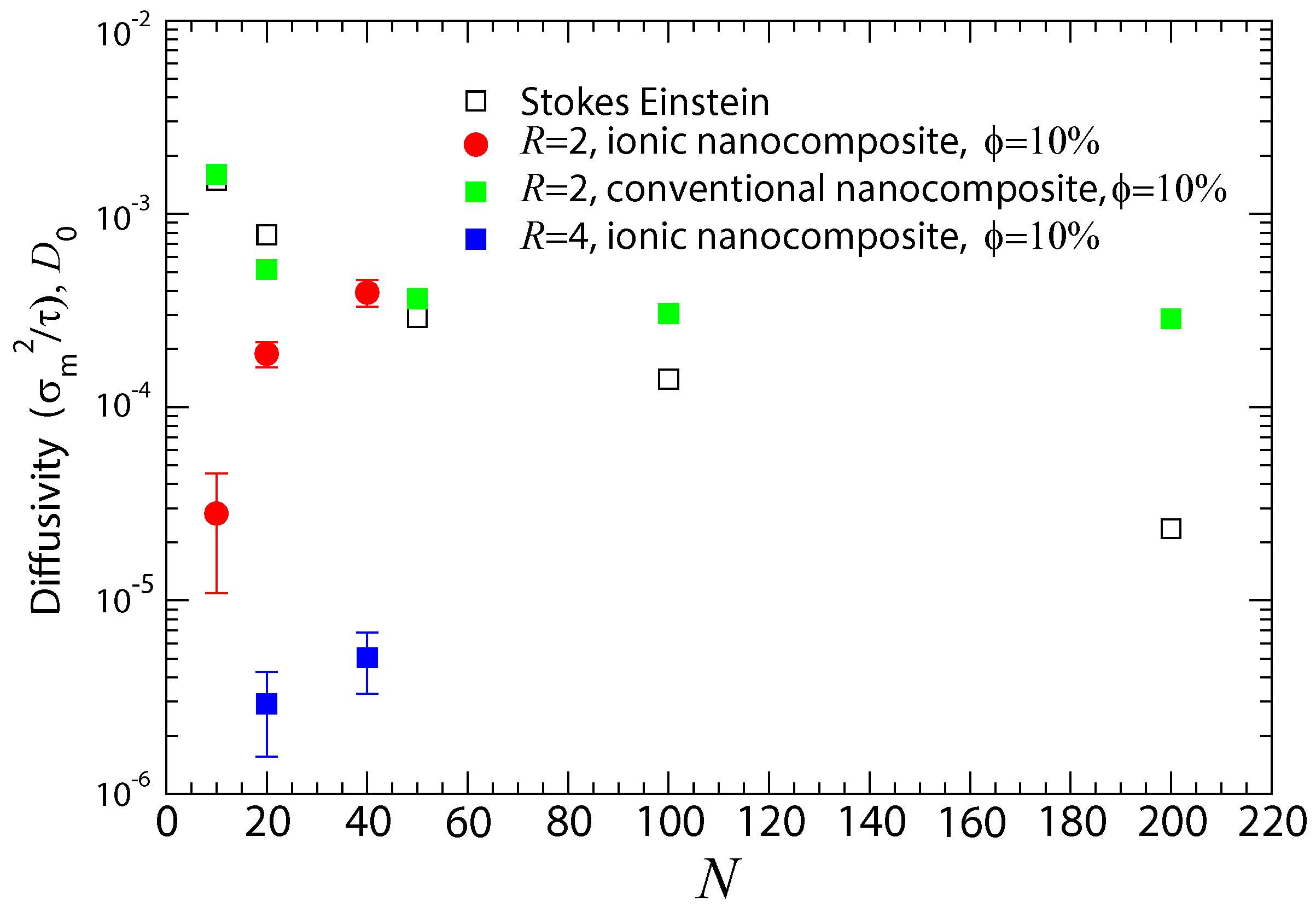

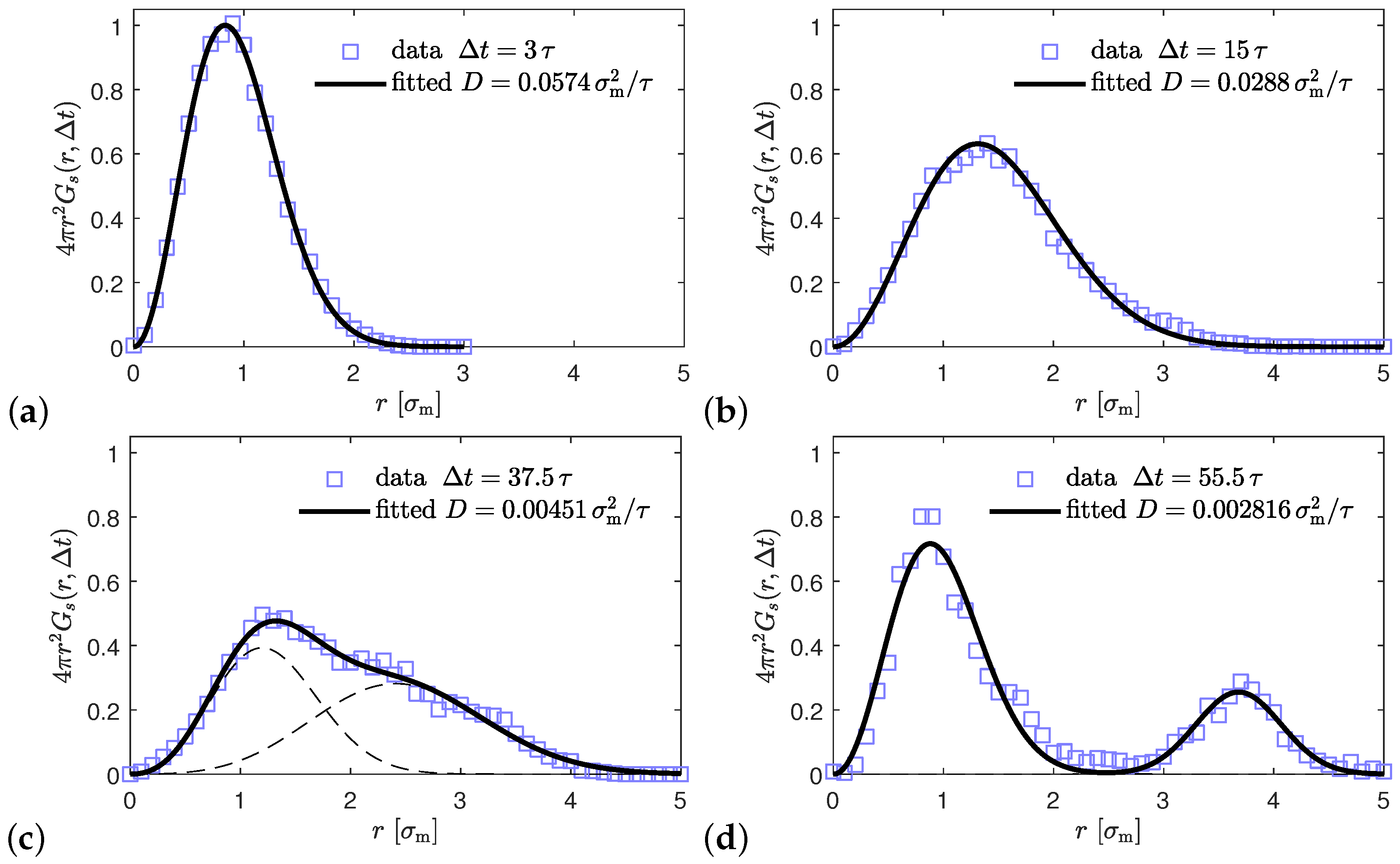

3.3. Nanoparticle Diffusion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, S.K.; Benicewicz, B.C.; Vaia, R.A.; Winey, K.I. 50th anniversary perspective: Are polymer nanocomposites practical for applications? Macromolecules 2017, 50, 714–731. [Google Scholar] [CrossRef]

- Winey, K.I.; Vaia, R.A. Polymer Nanocomposites. MRS Bull. 2007, 32, 314. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Winey, K.I. Polymer nanocomposites containing carbon nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Kumar, S.K.; Krishnamoorti, R. Nanocomposites: Structure, phase behavior, and properties. Annu. Rev. Chem. Biomol. Eng. 2010, 1, 37–58. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, N.J.; Akbarzadeh, J.; Peterlik, H.; Giannelis, E.P. Synthesis and properties of highly dispersed ionic silica-poly(ethylene oxide) nanohybrids. ACS Nano 2013, 7, 1265–1271. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, N.J.; Wallin, T.J.; Vaia, R.A.; Koerner, H.; Giannelis, E.P. Hairy nanoparticle assemblies as one-component functional polymer nanocomposites: Opportunities and challenges. MRS Commun. 2013, 3, 13–29. [Google Scholar] [CrossRef]

- Srivastava, S.; Choudhury, S.; Agrawal, A.; Archer, L.A. Self-suspended polymer grafted nanoparticles. Curr. Opin. Chem. Eng. 2017, 16, 92–101. [Google Scholar] [CrossRef]

- Crosby, A.; Lee, J.Y. Polymer nanocomposites: The nano effect on mechanical properties. Polym. Rev. 2007, 47, 217–229. [Google Scholar] [CrossRef]

- Hu, H.; Onyebueke, L.; Abatan, A. Characterizing and modeling mechanical properties of nanocomposites. Review and evaluation. J. Miner. Mater. Charact. Eng. 2010, 9, 275–319. [Google Scholar] [CrossRef]

- Suvorova, Y.V.; Alekseeva, S.I.; Fronya, M.A.; Viktorova, I.V. Investigations of physical and mechanical properties of polymeric nanocomposites (Review). Inorg. Mater. 2013, 49, 1357–1368. [Google Scholar] [CrossRef]

- Clancy, T.C.; Frankland, S.J.V.; Hinkley, J.A.; Gates, T.S. Multiscale modeling of thermal conductivity of polymer/carbon nanocomposites. Int. J. Therm. Sci. 2010, 49, 1555–1560. [Google Scholar] [CrossRef] [Green Version]

- Pereira, P.; Gaspar, H.; Fernardes, L.; Bernardo, G. Impact of fullerenes on the thermal stability of melt processed polystyrene and poly(methyl-methacrylate) composites. Polym. Test. 2015, 47, 130–136. [Google Scholar] [CrossRef]

- Koutsawa, Y.; Karatrantos, A.; Yu, W.; Ruch, D. A micromechanics approach for the effective thermal conductivity of composite materials with general linear imperfect interfaces. Compos. Struct. 2018, 200, 747–756. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, H.; Zeng, H.; Wetzel, B.; Friedrich, K. Microstructure and tribological behavior of polymeric nanocomposites. Ind. Lubric. Tribol. 2001, 53, 72–77. [Google Scholar] [CrossRef]

- Everaers, R. Topological versus rheological entanglement length in primitive-path analysis protocols, tube models, and slip-link models. Phys. Rev. E 2012, 86, 022801. [Google Scholar] [CrossRef] [PubMed]

- Winey, K.I.; Kashiwagi, T.; Mu, M.F. Improving electrical conductivity and thermal properties of polymers by the addition of carbon nanotubes as fillers. MRS Bull. 2007, 32, 348–53. [Google Scholar] [CrossRef]

- Mangal, R.; Srivastava, S.; Archer, L.A. Multiscale dynamics of polymers in particle-rich nanocomposites. Macromolecules 2016, 49, 5502. [Google Scholar] [CrossRef]

- Karatrantos, A.; Composto, R.J.; Winey, K.I.; Kröger, M.; Clarke, N. Entanglements and dynamics of polymer melts near a SWCNT. Macromolecules 2012, 45, 7274. [Google Scholar] [CrossRef]

- Karatrantos, A.; Composto, R.J.; Winey, K.I.; Clarke, N. Primitive path network, structure and dynamics of SWCNT/polymer nanocomposites. IOP Conf. Ser. Mater. Sci. Eng. 2012, 40, 012027. [Google Scholar] [CrossRef]

- Karatrantos, A.; Clarke, N. A theoretical model for the prediction of diffusion in polymer/SWCNT nanocomposites. Soft Matter 2011, 7, 7334. [Google Scholar] [CrossRef]

- Chen, T.; Qian, H.J.; Zhu, Y.L.; Lu, Z.Y. Structure and dynamics properties at interphase region in the composite of polystyrene and cross-linked polystyrene soft nanoparticle. Macromolecules 2015, 48, 2751–2760. [Google Scholar] [CrossRef]

- Karatrantos, A.; Clarke, N.; Composto, R.J.; Winey, K.I. Structure, entanglements and dynamics of polymer nanocomposites containing spherical nanoparticles. IOP Conf. Ser. Mat. Sci. Eng 2014, 64, 012041. [Google Scholar] [CrossRef] [Green Version]

- Ghanbari, A.; Ndoro, T.V.M.; Leroy, F.; Rahimi, M.; Bohm, M.C.; Muller-Plathe, F. Interface structure in silica-polystyrene nanocomposites: A coarse-grained molecular dynamics study. Macromolecules 2012, 45, 572–584. [Google Scholar] [CrossRef]

- Jankar, J.; Douglas, J.F.; Starr, F.W.; Kumar, S.K.; Cassagnau, P.; Lesser, A.J.; Sternstein, S.S.; Buehler, M.J. Current issues in research on structure property relationships in polymer nanocomposites. Polymer 2010, 51, 3321–3343. [Google Scholar] [CrossRef]

- Ganesan, V.; Jayaraman, A. Theory and simulation studies of effective interactions, phase behavior and morphology in polymer nanocomposites. Soft Matter 2014, 10, 13–38. [Google Scholar] [CrossRef] [PubMed]

- Gaspar, H.; Teixeira, P.; Santos, R.; Fernardes, L.; Hilliou, L.; Weir, M.P.; Parnell, A.J.; Abrams, K.J.; Hill, C.J.; Bouwman, W.G.; et al. Impact of fullerenes on the thermal stability of melt processed polystyrene and poly(methyl-methacrylate) composites. A Journey along the Extruder with Polystyrene: C60 Nanocomposites: Convergence of Feeding Formulations into a Similar Nanomorphology. Macromolecules 2017, 50, 3301–3312. [Google Scholar] [CrossRef]

- Karatrantos, A.; Clarke, N.; Composto, R.J.; Winey, K.I. Structure, dynamics and primitive path network of polymer nanocomposites containing spherical nanoparticles. MRS Symp. Proc. 2014, 1619. [Google Scholar] [CrossRef]

- Karatrantos, A.; Clarke, N.; Kröger, M. Modeling of polymer structure and conformations in polymer nanocomposites from atomistic to mesoscale: A Review. Polym. Rev. 2016, 56, 385–428. [Google Scholar] [CrossRef]

- Lu, C.T.; Weerasinghe, A.; Maroudas, D.; Ramasubramaniam, A. A Comparison of the Elastic Properties of Graphene- and Fullerene-Reinforced Polymer Composites: The Role of Filler Morphology and Size. Sci. Rep. 2016, 6, 525. [Google Scholar] [CrossRef] [PubMed]

- Mangal, R.; Srivastava, S.; Archer, L.A. Phase stability and dynamics of entangled polymer-nanoparticles composites. Nat. Commun. 2015, 6, 7198. [Google Scholar] [CrossRef] [PubMed]

- Supova, M.; Martynkova, G.S.; Barabasyova, K. Effect of Nanofillers Dispersion in Polymer Matrices: A Review. Sci. Adv. Mater. 2011, 3, 1–25. [Google Scholar] [CrossRef]

- Bernardo, G.; Deb, N.; King, S.M.; Bucknall, D.G. Phase behavior of blends of PCBM with amorphous polymers with different aromaticity. J. Polym. Sci. B 2016, 54, 994–1001. [Google Scholar] [CrossRef]

- Mackay, M.E.; Tuteja, A.; Duxbury, P.M.; Hawker, C.J.; Van Horn, B.; Guan, Z.; Chen, G.H.; Krishnan, R.S. General strategies for nanoparticle dispersion. Science 2006, 311, 1740. [Google Scholar] [CrossRef] [PubMed]

- Ferdous, S.F.; Sarker, F.; Adnan, A. Role of nanoparticle dispersion and filler-matrix interface on the matrix dominated failure of rigid C60-PE nanocomposites: A molecular dynamics simulation study. Polymer 2013, 54, 2565–2576. [Google Scholar] [CrossRef]

- Cao, X.Z.; Merlitz, H.; Wu, C.X.; Ungar, G.; Sommer, J.U. A theoretical study of dispersion-to-aggregation of nanoparticles in adsorbing polymers using molecular dynamics simulations. Nanoscale 2016, 8, 6964–6968. [Google Scholar] [CrossRef] [PubMed]

- Jouault, N.; Dalmas, F.; Boue, F.; Jestin, J. Multiscale characterization of filler dispersion and origins of mechanical reinforcement in model nanocomposites. Polymer 2012, 53, 761–775. [Google Scholar] [CrossRef]

- Hore, M.J.A.; Composto, R.J. Strategies for dispersing, assembling, and orienting nanorods in polymers. Curr. Opin. Chem. Eng. 2013, 2, 95–102. [Google Scholar] [CrossRef]

- Kumar, S.K.; Jouault, N.; Benicewicz, B.; Neely, T. Nanocomposites with polymer grafted nanoparticles. Macromolecules 2013, 46, 3199–3214. [Google Scholar] [CrossRef]

- Akcora, P.; Liu, H.; Kumar, S.K.; Moll, J.; Li, Y.; Benicewicz, B.C.; Schadler, L.S.; Acehan, D.; Panagiotopoulos, A.Z.; Pryamitsyn, V.; et al. Anisotropic self-assembly of spherical polymer-grafted nanoparticles. Nat. Mater. 2009, 8, 354–359. [Google Scholar] [CrossRef] [PubMed]

- Chevigny, C.; Dalmas, F.; Di Cola, E.; Gigmes, D.; Bertin, D.; Boué, F.; Jestin, J. Polymer-grafted-nanoparticles nanocomposites: Dispersion, grafted chain conformation, and rheological behavior. Macromolecules 2011, 44, 122–133. [Google Scholar] [CrossRef]

- Crawford, M.K.; Smalley, R.J.; Cohen, G.; Hogan, B.; Wood, B.; Kumar, S.K.; Melnichenko, Y.B.; He, L.; Guise, W.; Hammouda, B. Chain conformation in polymer nanocomposites with uniformly dispersed nanoparticles. Phys. Rev. Lett. 2013, 110, 196001. [Google Scholar] [CrossRef] [PubMed]

- Jouault, N.; Crawford, M.K.; Chi, C.; Smalley, R.J.; Wood, B.; Jestin, J.; Melnichenko, Y.B.; He, L.; Guise, W.E.; Kumar, S.K. Polymer Chain Behavior in Polymer Nanocomposites with Attractive Interactions. ACS Macro Lett. 2016, 5, 523–527. [Google Scholar] [CrossRef]

- Blivi, A.S.; Benhui, F.; Bai, J.; Kondo, D.; Bédoui, F. Experimental evidence of size effect in nano-reinforced polymers: Case of silica reinforced PMMA. Polym. Test. 2016, 56, 337–343. [Google Scholar] [CrossRef]

- Robbes, A.S.; Cousin, F.; Meneau, F.; Jestin, J. Melt Chain Conformation in Nanoparticles/Polymer Nanocomposites Elucidated by the SANS Extrapolation Method: Evidence of the Filler Contribution. Macromolecules 2018, 51, 2216–2226. [Google Scholar] [CrossRef]

- Sen, S.; Xie, Y.; Kumar, S.K.; Yang, H.; Bansal, A.; Ho, D.L.; Hall, L.; Hooper, J.B.; Schweizer, K.S. Chain conformations and bound-layer correlations in polymer nanocomposites. Phys. Rev. Lett. 2007, 98, 128302. [Google Scholar] [CrossRef] [PubMed]

- Tuteja, A.; Duxbury, P.M.; Mackay, M.E. Polymer chain swelling induced by dispersed nanoparticles. Phys. Rev. Lett. 2008, 100, 077801. [Google Scholar] [CrossRef] [PubMed]

- Nusser, K.; Neueder, S.; Schneider, G.J.; Meyer, M.; Pyckhout-Hintzen, W.; Willner, L.; Radulescu, A.; Richter, D. Conformations of silica-poly(ethylene-propylene) nanocomposites. Macromolecules 2010, 43, 9837–9847. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.M.; Dubois, P.; Giannelis, E.P. Ultra-stretchable ionic nanocomposites: From dynamic bonding to multi-responsive behaviors. J. Mater. Chem. A 2017, 5, 13357–13363. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.M.; Samuel, C.; Barrau, S.; Enotiadis, A.; Dubois, P.; Giannelis, E.P. Shape-memory behavior of polylactide/silica ionic hybrids. Macromolecules 2017, 50, 2896. [Google Scholar] [CrossRef]

- Lin, C.C.; Gam, S.; Meth, J.S.; Clarke, N.; Winey, K.I. Do attractive polymer-nanoparticle interactions retard polymer diffusion in nanocomposites. Macromolecules 2013, 46, 4502. [Google Scholar] [CrossRef]

- Gam, S.; Meth, J.S.; Zane, S.G.; Chi, C.; Wood, B.A.; Seitz, M.E.; Winey, K.I.; Clarke, N.; Composto, R.J. Macromolecules diffusion in a crowded polymer nanocomposite. Macromolecules 2011, 44, 3494. [Google Scholar] [CrossRef]

- Gam, S.; Meth, J.S.; Zane, S.G.; Chi, C.; Wood, B.A.; Winey, K.I.; Clarke, N.; Composto, R.J. Polymer Diffusion in a polymer nanocomposite:effect of nanoparticle size and polydispersity. Soft Matter 2012, 8, 6512. [Google Scholar] [CrossRef]

- Jouault, N.; Kumar, S.K.; Smalley, R.J.; Chi, C.; Moneta, R.; Wood, B.; Salerno, H.; Melnichenko, Y.B.; He, L.; Guise, W.E.; et al. Do Very Small POSS Nanoparticles Perturb s-PMMA Chain Conformations? Macromolecules 2018, 51, 5278–5293. [Google Scholar] [CrossRef]

- Jouault, N.; Dalmas, F.; Said, S.; Schweins, R.; Jestin, J.; Boue, F. Direct measurement of polymer chain conformation in well-controlled model nanocomposites by combining SANS and SAXS. Macromolecules 2010, 43, 9881–9891. [Google Scholar] [CrossRef]

- Pimer, D.; Dulle, M.; Forster, S. Viscoelastic properties and reinforcement of non-aggregated and aggregated nanocomposites. Polymer 2018, 145, 101–107. [Google Scholar]

- Shen, J.; Liu, J.; Gao, Y.; Cao, D.; Zhang, L. Revisiting the dispersion mechanism of grafted nanoparticles in polymer matrix: A detailed molecular dynamics simulation. Langmuir 2011, 27, 15213–15222. [Google Scholar] [CrossRef] [PubMed]

- Teh, S.L.; Linton, D.; Sumpter, B.; Dadmun, M.D. Controlling Non-covalent interactions to modulate the dispersion of fullerenes in polymer nanocomposites. Macromolecules 2011, 44, 7737–7745. [Google Scholar] [CrossRef]

- Hore, M.J.A.; Frischknecht, A.L.; Composto, R.J. Nanorod assemblies in polymer films and their dispersion-dependent optical properties. ACS Macro Lett. 2012, 1, 115–121. [Google Scholar] [CrossRef]

- Sampath, J.; Hall, L. Influence of a nanoparticle on the structure and dynamics of model ionomer melts. Soft Matter 2018, 14, 4621–4632. [Google Scholar] [CrossRef] [PubMed]

- Shah, D.; Maiti, P.; Jiang, D.D.; Batt, C.A.; Giannelis, E.P. Effect of nanoparticle mobility on toughness of polymer nanocomposites. Adv. Mater. 2005, 17, 525. [Google Scholar] [CrossRef]

- Karatrantos, A.; Composto, R.J.; Winey, K.I.; Clarke, N. Polymer and spherical nanoparticle diffusion in nanocomposites. J. Chem. Phys. 2017, 146, 203331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, C.C.; Parrish, E.; Composto, R.J. Macromolecule and particle dynamics in confined media. Macromolecules 2016, 49, 5755–5772. [Google Scholar] [CrossRef]

- Lungova, M.; Krutyeva, M.; Pyckhout-Hintzen, W.; Wischnewski, A.; Monkenbusch, M.; Allgaier, J.; Ohl, M.; Sharp, M.; Richter, D. Nanoscale motion of soft nanoparticles in unentangled and entangled polymer matrices. Phys. Rev. Lett. 2016, 117, 147803. [Google Scholar] [CrossRef] [PubMed]

- Grabowski, C.A.; Mukhopadhyay, A. Size effect of nanoparticle diffusion in a polymer melt. Macromolecules 2014, 47, 7238–7242. [Google Scholar] [CrossRef]

- Grabowski, C.A.; Adhikari, B.; Mukhopadhyay, A. Dynamics of gold nanoparticles in a polymer melt. Appl. Phys. Lett. 2009, 94, 021903. [Google Scholar] [CrossRef]

- Karatrantos, A.; Composto, R.J.; Winey, K.I.; Clarke, N. Structure and conformations of polymer/SWCNT nanocomposites. Macromolecules 2011, 44, 9830–9838. [Google Scholar] [CrossRef]

- Mangal, R.; Srivastava, S.; Narayanan, S.; Archer, L.A. Size-dependent particle dynamics in entangled polymer nanocomposites. Langmuir 2016, 32, 596–603. [Google Scholar] [CrossRef] [PubMed]

- Karatrantos, A.; Clarke, N.; Composto, R.J.; Winey, K.I. Polymer conformations in polymer nanocomposites containing spherical nanoparticles. Soft Matter 2015, 11, 382. [Google Scholar] [CrossRef] [PubMed]

- Einstein, A. Eine neue Bestimmung der Moleküldimensionen. Ann. Phys. (Leipzig) 1906, 19, 289. [Google Scholar] [CrossRef]

- Griffin, P.J.; Bocharova, V.; Middleton, L.R.; Composto, R.J.; Clarke, N.; Schweizer, K.S.; Winey, K. Influence of the bound polymer layer on nanoparticle diffusion in polymer melts. ACS Macro Lett. 2016, 5, 1141. [Google Scholar] [CrossRef]

- Wyart, F.B.; de Gennes, P.G. Viscosity at small scales in polymer melts. Eur. Phys. J. E 2000, 1, 93–97. [Google Scholar] [CrossRef]

- Everaers, R.; Sukumaran, S.K.; Grest, G.S.; Svaneborg, C.; Sivasubramanian, A.; Kremer, K. Rheology and microscopic topology of entangled polymeric liquids. Science 2004, 303, 823. [Google Scholar] [CrossRef] [PubMed]

- Kalathi, J.T.; Yamamoto, U.; Schweizer, K.S.; Grest, G.S.; Kumar, S.K. Nanoparticle diffusion in polymer nanocomposites. Phys. Rev. Lett. 2014, 112, 108301. [Google Scholar] [CrossRef] [PubMed]

- Ge, T.; Grest, G.; Rubinstein, M. Nanorheology of Entangled Polymer Melts. Phys. Rev. Lett. 2018, 120, 057801. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Cao, D.; Zhang, L. Molecular Dynamics study on nanoparticle diffusion in polymer melts: A test of the Stokes–Einstein Law. J. Phys. Chem. C 2008, 112, 6653–6661. [Google Scholar] [CrossRef]

- Goswami, M.; Sumpter, B.G. Anomalous chain diffusion in polymer nanocomposites for varying polymer-filler interaction strengths. Phys. Rev. E 2010, 81, 041801. [Google Scholar] [CrossRef] [PubMed]

- Mu, M.; Seitz, M.E.; Clarke, N.; Composto, R.J.; Winey, K. Polymer tracer diffusion exhibits a minimum in nanocomposites containing spherical nanoparticles. Macromolecules 2011, 44, 191–193. [Google Scholar] [CrossRef]

- Lin, C.C.; Cargnello, M.; Murray, C.B.; Clarke, N.; Winey, K.I.; Riggleman, R.A.; Composto, R.J. Nanorod mobility influences polymer diffusion in polymer nanocomposites. ACS Macro Lett. 2017, 6, 869–874. [Google Scholar] [CrossRef]

- Hong, B.; Chremos, A.; Panagiotopoulos, A.Z. Simulations of the structure and dynamics of nanoparticle-based ionic liquids. Faraday Discuss. 2011, 154, 29. [Google Scholar] [CrossRef]

- Hong, B.; Panagiotopoulos, A.Z. Diffusivities, viscosities, and conductivities of solvent-free ionically grafted nanoparticles. Soft Matter 2013, 9, 6091–6102. [Google Scholar] [CrossRef] [Green Version]

- Babayekhorasani, F.; Dunstan, D.E.; Krishnamoorti, R.; Conrad, J.C. Nanoparticle diffusion in crowded and confined media. Soft Matter 2016, 12, 8407–8416. [Google Scholar] [CrossRef] [PubMed]

- Nath, P.; Mangal, R.; Kohle, F.F.E.; Choudhury, S.; Narayanan, S.; Wiesner, U.B.; Archer, L.A. Dynamics of nanoparticles in entangled polymer solutions. Langmuir 2017, 50, 2896. [Google Scholar] [CrossRef] [PubMed]

- Poling-Skutvik, R.; Krishnamoorti, R.; Conrad, J.C. Size-dependent dynamics of nanoparticles in unentangled polyelectrolyte solutions. ACS Macro Lett. 2015, 4, 1169–1173. [Google Scholar] [CrossRef]

- Wu, S.; Xiao, C.; Zhang, Z.; Chen, Q.; Matsumiya, Y.; Watanabe, H. Molecular design of highly stretchable ionomers. Macromolecules 2018, 51, 4735–4746. [Google Scholar] [CrossRef]

- Pandav, G.; Pryamitsyn, V.; Ganesan, V. Interactions and Aggregation of Charged Nanoparticles in Uncharged Polymer Solutions. Langmuir 2015, 31, 12328–12338. [Google Scholar] [CrossRef] [PubMed]

- Pandav, G.; Pryamitsyn, V.; Errington, J.; Ganesan, V. Multibody Interactions, Phase Behavior, and Clustering in Nanoparticle–Polyelectrolyte Mixtures. J. Phys. Chem. B 2015, 119, 14536–14550. [Google Scholar] [CrossRef] [PubMed]

- Parrish, E.; Caporizzo, M.A.; Composto, R.J. Network confinement and heterogeneity slows nanoparticle diffusion in polymer gels. J. Chem. Phys. 2017, 146, 203318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parrish, E.; Seeger, S.C.; Composto, R.J. Temperature-Dependent Nanoparticle Dynamics in Poly(N-isopropylacrylamide) Gels. Macromolecules 2018, 51, 3597–3607. [Google Scholar] [CrossRef]

- Bekker, H.; Berendsen, H.J.C.; Dijkstra, E.J.; Achterop, S.; van Drunen, R.; van der Spoel, D.; Sijbers, A.; Keegstra, H.; Reitsma, B.; Renardus, M.K.R. Gromacs: A parallel computer for molecular dynamics simulations. Phys. Comput. 1993, 92, 252. [Google Scholar]

- Berendsen, H.J.C.; van der Spoel, D.; van Drunen, R. GROMACS: A message-passing parallel molecular dynamics implementation. Comput. Phys. Commun. 1995, 91, 43–56. [Google Scholar] [CrossRef] [Green Version]

- Lindahl, E.; Hess, B.; van der Spoel, D. Gromacs 3.0: A package for molecular simulation and trajectory analysis. J. Mol. Mod. 2001, 7, 306–317. [Google Scholar] [CrossRef]

- Van der Spoel, D.; Lindahl, E.; Hess, B.; Groenhof, G.; Mark, A.E.; Berendsen, H.J.C. GROMACS: Fast, Flexible and Free. J. Comp. Chem. 2005, 26, 1701–1718. [Google Scholar] [CrossRef] [PubMed]

- Kremer, K.; Grest, G.S. Dynamics of entangled linear polymer melts: A molecular-dynamics simulation. J. Chem. Phys. 1990, 92, 5057. [Google Scholar] [CrossRef]

- Karatrantos, A.; Clarke, N.; Composto, R.J.; Winey, K.I. Entanglements in polymer nanocomposites containing spherical nanoparticles. Soft Matter 2016, 12, 2567. [Google Scholar] [CrossRef] [PubMed]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon Press: Oxford, UK, 1987. [Google Scholar]

- Hatlo, M.; Karatrantos, A.; Lue, L. One-component plasma of point charges and of charged rods. Phys. Rev. E 2009, 80, 061107. [Google Scholar] [CrossRef] [PubMed]

- Karatrantos, A. Isotropic-nematic transition and dynamics of rigid charged molecules. Chem. Phys. Lett. 2016, 647, 89–94. [Google Scholar] [CrossRef]

- Karatrantos, A.; Cai, Q. Effect of pore size and surface charge on sodium ion storage in carbon nanopores. Phys. Chem. Chem. Phys. 2016, 18, 30761–30769. [Google Scholar] [CrossRef] [PubMed]

- Bocharova, V.; Wojnarowska, Z.; Cao, P.F.; Fu, Y.; Kumar, R.; Li, B.; Novikov, S.; Zhao, S.; Kisliuk, A.; Saito, T.; et al. The influence of chain rigidity and dielectric constant on the glass transition temperature in polymerized ionic liquids. J. Phys. Chem. B 2017, 121, 11511–11519. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Bocharova, V.; Ma, M.; Sokolov, A.P.; Sumpter, B.G.; Kumar, R. Effects of counterion size and backbone rigidity on dynamics of ionic polymer melts and glasses. Phys. Chem. Chem. Phys. 2017, 19, 27442–27451. [Google Scholar] [CrossRef] [PubMed]

- Bulacu, M.; van der Giessen, E. Effect of bending and torsion rigidity on self-diffusion in polymer melts: A molecular-dynamics study. J. Chem. Phys. 2005, 123, 114901. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karatrantos, A.; Clarke, N.; Composto, R.J.; Winey, K.I. Topological entanglement length in polymer melts and nanocomposites by a DPD polymer model. Soft Matter 2013, 9, 3877–3884. [Google Scholar] [CrossRef]

- Van Gunsteren, W.F.; Berendsen, H.C.J. A leap-frog algorithm for stochastic dynamics. Mol. Simul. 1988, 1, 173–185. [Google Scholar] [CrossRef]

- Cheng, S.; Carroll, B.; Borachova, V.; Carrillo, J.M.; Sumpter, B.; Sokolov, A.P. Focus: Structure and dynamics of the interfacial layer in polymer nanocomposites with attractive interactions. J. Chem. Phys. 2017, 146, 203201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rubinstein, M.; Colby, R.H. Polymer Physics; Oxford University Press Inc.: New York, NY, USA, 2003. [Google Scholar]

- Toepperwein, G.N.; Karayiannis, N.C.; Riggleman, R.A.; Kröger, M.; de Pablo, J.J. Influence of nanorod inclusions on structure and primitive path network of polymer nanocomposites at equilibrium and under deformation. Macromolecules 2011, 44, 1034. [Google Scholar] [CrossRef]

- Kröger, M. Shortest multiple disconnected path for the analysis of entanglements in two- and three-dimensional polymeric systems. Comput. Phys. Commun. 2005, 168, 209–232. [Google Scholar] [CrossRef]

- Hoy, R.S.; Foteinopoulou, K.; Kröger, M. Topological analysis of polymeric melts: Chain-length effects and fast-converging estimators for entanglement length. Phys. Rev. E 2009, 80, 031803. [Google Scholar] [CrossRef] [PubMed]

- Sorichetti, V.; Hugouvieux, V.; Kob, W. Structure and Dynamics of a Polymer-Nanoparticle Composite: Effect of Nanoparticle Size and Volume Fraction. Macromolecules 2018, 51, 5375–5391. [Google Scholar] [CrossRef]

- Volgin, I.G.; Larin, S.V.; Abad, E.; Lyulin, S.V. Molecular Dynamics Simulations of Fullerene Diffusion in Polymer Melts. Macromolecules 2017, 50, 2207–2218. [Google Scholar] [CrossRef]

- Carroll, B.; Bocharova, V.; Carrillo, J.M.Y.; Kisliuk, A.; Cheng, S.; Yamamoto, U.; Schweizer, K.S.; Sumpter, B.G.; Sokolov, A.P. Diffusion of sticky nanoparticles in a polymer melt: Crossover from suppressed to enhanced transport. Macromolecules 2018, 51, 2268–2275. [Google Scholar] [CrossRef]

- Ren, K.X.; Jia, X.M.; Jiao, G.S.; Chen, T.; Qian, H.J.; Lu, Z.Y. Interfacial Properties and Hopping Diffusion of Small Nanoparticle in Polymer/Nanoparticle Composite with Attractive Interaction on Side Group. Polymers 2018, 10, 598. [Google Scholar] [CrossRef]

- Yamamoto, U.; Schweizer, K.S. Spatially dependent relative diffusion of nanoparticles in polymer melts. J. Chem. Phys. 2013, 139, 064907. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, U.; Schweizer, K.S. Microscopic theory of the long-time diffusivity and intermediate-time anomalous transport of a nanoparticle in polymer melts. Macromolecules 2015, 48, 152. [Google Scholar] [CrossRef]

- Yamamoto, U.; Carrillo, J.M.Y.; Bocharova, V.; Sokolov, A.P.; Sumpter, B.G.; Schweizer, K.S. Theory and simulation of attractive nanoparticle transport in polymer melts. Macromolecules 2018, 51, 2258–2267. [Google Scholar] [CrossRef]

- De Gennes, P.G. Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 1971, 55, 572. [Google Scholar] [CrossRef]

- Choi, J.; Cargnello, M.; Murrey, C.B.; Clarke, N.; Winey, K.I.; Composto, R.J. Fast nanorod diffusion through entangled polymer melts. Macromolecules 2015, 4, 952–956. [Google Scholar] [CrossRef]

- Cai, L.; Panyukov, S.; Rubinstein, M. Hopping diffusion of nanoparticles in polymer matrices. Macromolecules 2015, 48, 847–862. [Google Scholar] [CrossRef] [PubMed]

| R | Z | N | Dispersion | ||||

|---|---|---|---|---|---|---|---|

| 10.0% | 2 | 100 | 48 | 10 | 2400 | 0.96 | ✓ |

| 10.0% | 2 | 100 | 24 | 20 | 1200 | 0.48 | ✓ |

| 10.0% | 2 | 100 | 12 | 40 | 600 | 0.24 | ✓ |

| 10.0% | 2 | 100 | 2.4 | 200 | 120 | 0.048 | — |

| 10.0% | 4 | 8 | 150 | 20 | 600 | 3 | ✓ |

| 10.0% | 4 | 8 | 75 | 40 | 300 | 1.5 | ✓ |

| 17.7% | 2 | 100 | 24 | 10 | 1200 | 0.48 | ✓ |

| 17.7% | 2 | 100 | 12 | 20 | 600 | 0.24 | ✓ |

| 17.7% | 2 | 100 | 6 | 40 | 300 | 0.12 | — |

| 24.0% | 2 | 300 | 8 | 20 | 1200 | 0.16 | ✓ |

| 24.0% | 2 | 300 | 4 | 40 | 600 | 0.08 | — |

| 32.0% | 4 | 50 | 48 | 20 | 1200 | 0.96 | ✓ |

| 32.0% | 4 | 50 | 24 | 40 | 600 | 0.48 | — |

| System | R | 20 | 40 | |||

|---|---|---|---|---|---|---|

| (melt) | 0% | – | 1.574 | 2.363 | 3.466 | |

| (conventional) | 10.0% | 2 | 1.570 | 2.353 | – | |

| (charged) | 10.0% | 2 | 1.596 | 2.355 | 3.454 | |

| (charged) | 10.0% | 4 | – | 2.486 | – | |

| (charged) | 17.7% | 2 | 1.578 | 2.353 | 3.445 | |

| (charged) | 24.0% | 2 | 1.572 | 2.393 | – | |

| (charged) | 32.0% | 4 | – | 2.342 | – |

| Coil-Based | Kink-Based | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| System | |||||||||||

| melt | 0% | – | 40 | 8.5 ± 0.1 | 9.9 ± 0.1 | 7.3 | 28.8 ± 0.6 | 74.8 ± 4.5 | 1.07 ± 0.04 | 19.1 ± 0.4 | 37.6 ± 1.5 |

| charged | 10.0% | 2 | 40 | 8.7 ± 0.2 | 10.1 ± 0.2 | 7.4 | 28.8 ± 0.6 | 75.3 ± 4.4 | 1.03 ± 0.04 | 19.5 ± 0.4 | 39.0 ± 1.5 |

| charged | 10.0% | 4 | 40 | 8.9 ± 0.2 | 10.5 ± 0.2 | 7.6 | 28.1 ± 0.6 | 72.0 ± 4.8 | 1.12 ± 0.05 | 18.6 ± 0.4 | 35.7 ± 1.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karatrantos, A.; Koutsawa, Y.; Dubois, P.; Clarke, N.; Kröger, M. Miscibility and Nanoparticle Diffusion in Ionic Nanocomposites. Polymers 2018, 10, 1010. https://doi.org/10.3390/polym10091010

Karatrantos A, Koutsawa Y, Dubois P, Clarke N, Kröger M. Miscibility and Nanoparticle Diffusion in Ionic Nanocomposites. Polymers. 2018; 10(9):1010. https://doi.org/10.3390/polym10091010

Chicago/Turabian StyleKaratrantos, Argyrios, Yao Koutsawa, Philippe Dubois, Nigel Clarke, and Martin Kröger. 2018. "Miscibility and Nanoparticle Diffusion in Ionic Nanocomposites" Polymers 10, no. 9: 1010. https://doi.org/10.3390/polym10091010