3.1. Effects of Types and Loadings of Polyisocyanate

The mechanical behaviors of the bonding layer are crucial to the comprehensive understanding of the complicated deformation response of EPI adhesive in a moist environment. Therefore, a series of uniaxial tension tests under different RHs (0%, 20%, 40%, 60% and 80%) were carried out on the EPI cured samples, which were cross-linked by EMDI or p-MDI with 0%, 5%, 10%, 15% and 20% of loadings, respectively.

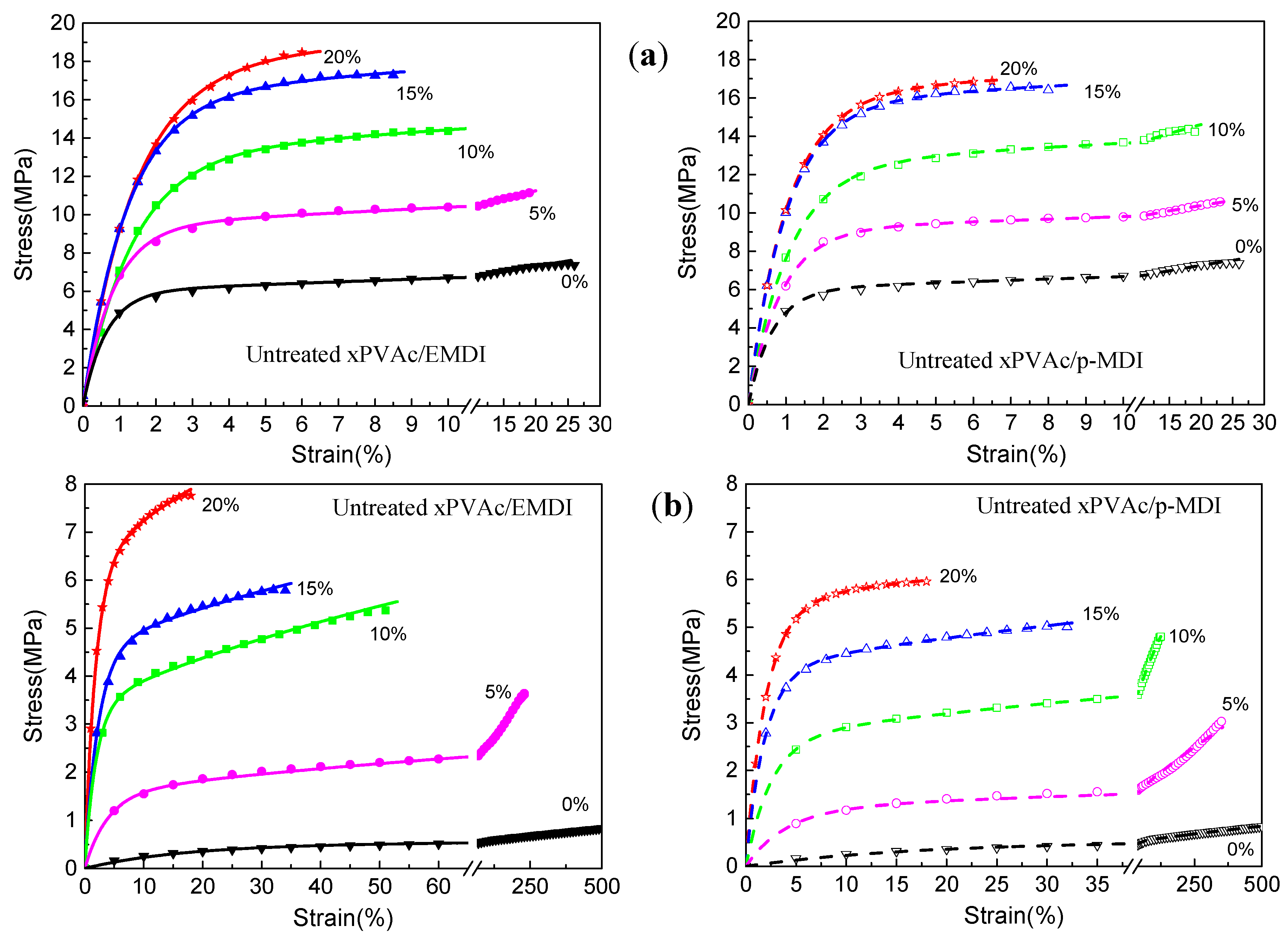

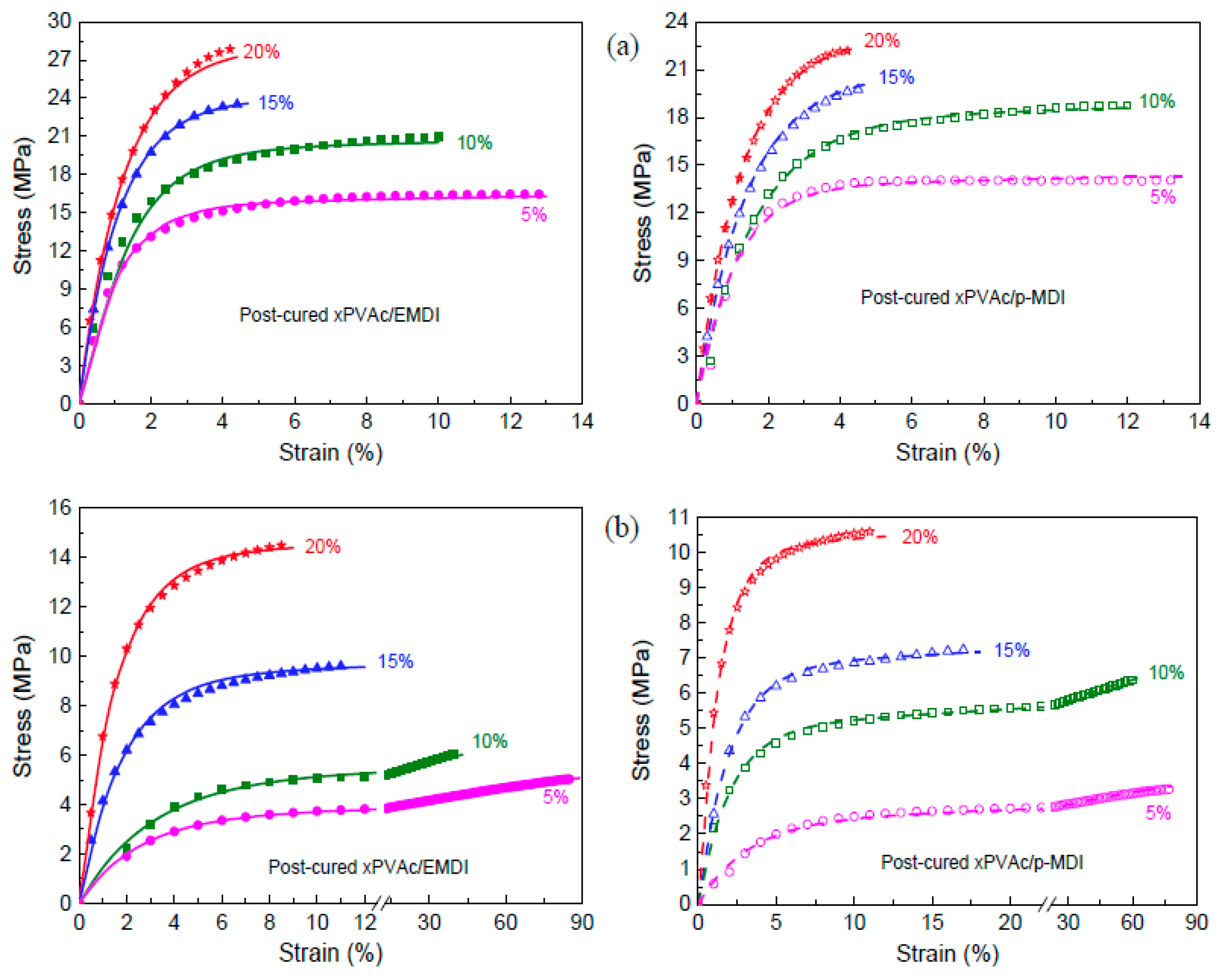

Figure 1a shows the mechanical behavior for dry EPI specimens. As the isocyanate content increases, the engineering stress-strain curves of polymer film have noticeably changed. For the low cross-linker loadings (0–5%), the raised strain causes the stress to quickly enlarge, followed by a relatively long period of minimal stress increase until rupture. With the addition of more isocyanate, the level of stress increases, and then plateau gradually shortens and disappears. This indicates that the cured films of aqueous vinyl emulsion are gradually transformed from a thermoplastic polymer to thermoset resin owing to the cross-link reaction between the hydroxyl groups (–OH) in polymer and isocyanate groups (–NCO). Moreover, compared to the standard version, the aqueous emulsifiable polymeric isocyanate exhibits better cross-linking effects, where the EPI films have relatively higher strength and stiffness.

Under high humidity conditions, due to the penetration of water molecules, scissioning of chain segments and the destruction of cross-links occur, resulting in the deterioration of the mechanical properties of the polymer. Thus, the tensile strength of the EPI films is greatly weakened, and the fracture strain increases considerably, as shown in

Figure 1b. Moreover, it can be observed that the aqueous polymer would undergo various kinds of intrinsic deformation as the amount of isocyanate increases. Similar to the main component (xPVAc), the EPI film with 5% cross-linker displays the typical behavior of a soft elastomer, of which the fracture happens at the point of very high strain value. The values of

for xPVAc/EMDI and xPVAc/

p-MDI are 240% and 350% at 80% RH, respectively, which are separately 12 times and 15 times of those when the compounds are in a dry state. However, within the range of higher cross-linker loading (15–20%), the polymers are neither rubber-like nor glassy, where the stress steeply goes up to the fracture point corresponding to a strain of 18–34%. It is much less than the value (240–500%) at low isocyanate addition levels (0–5%). At an intermediate cross-linker loading (10%), the specimen cross-linked by

p-MDI bears a notably hyperelastic material with

of 125%, which is far larger than that of EMDI. The influences of cross-linker type and loading on the moisture resistance of cured film are further compared in

Figure 2.

After EPI is applied on the substrate, as H

2O is evaporated into the environment and reacts with the isocyanate groups as shown in Equation (1), the water content in the adhesive layer decreases, and tiny particles of polymer gradually form a film; while –OH cross-links with –NCO, the result forms the urethane bond [

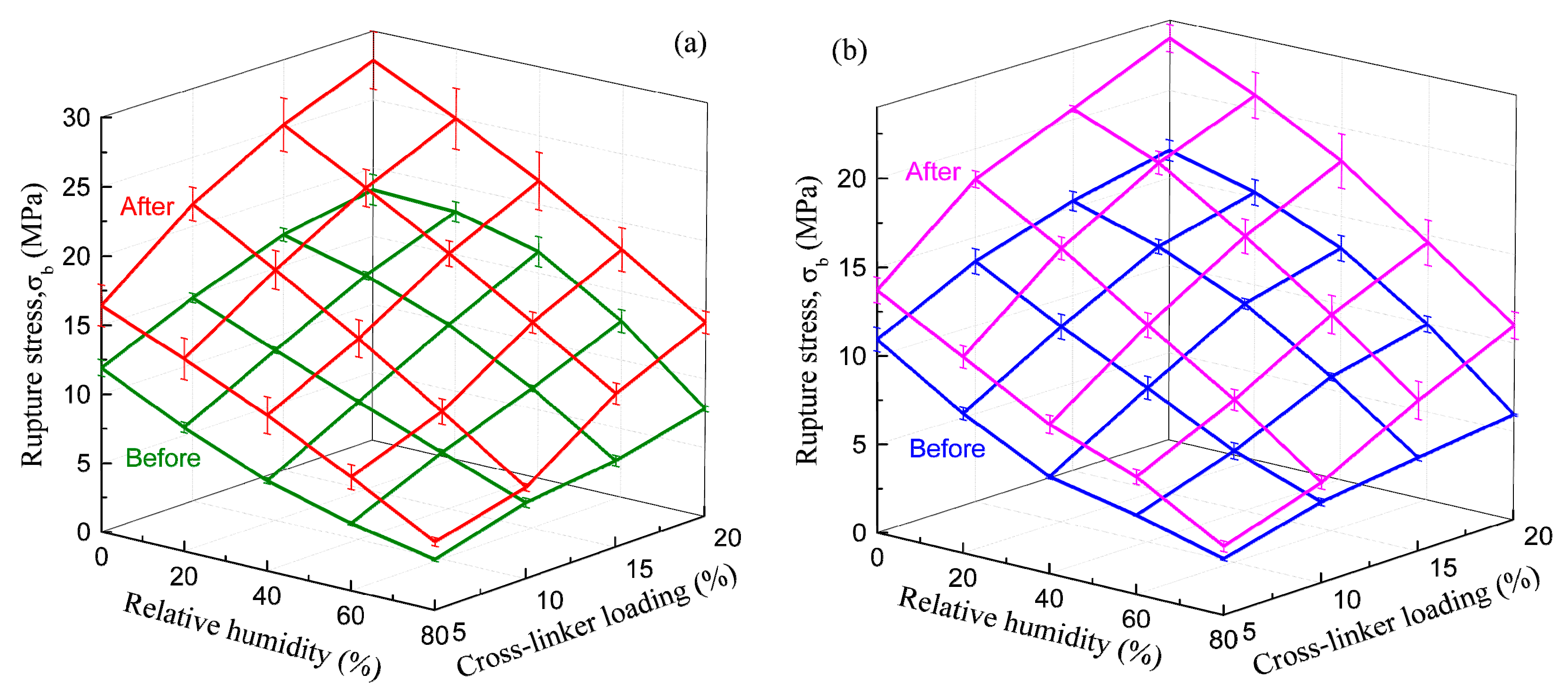

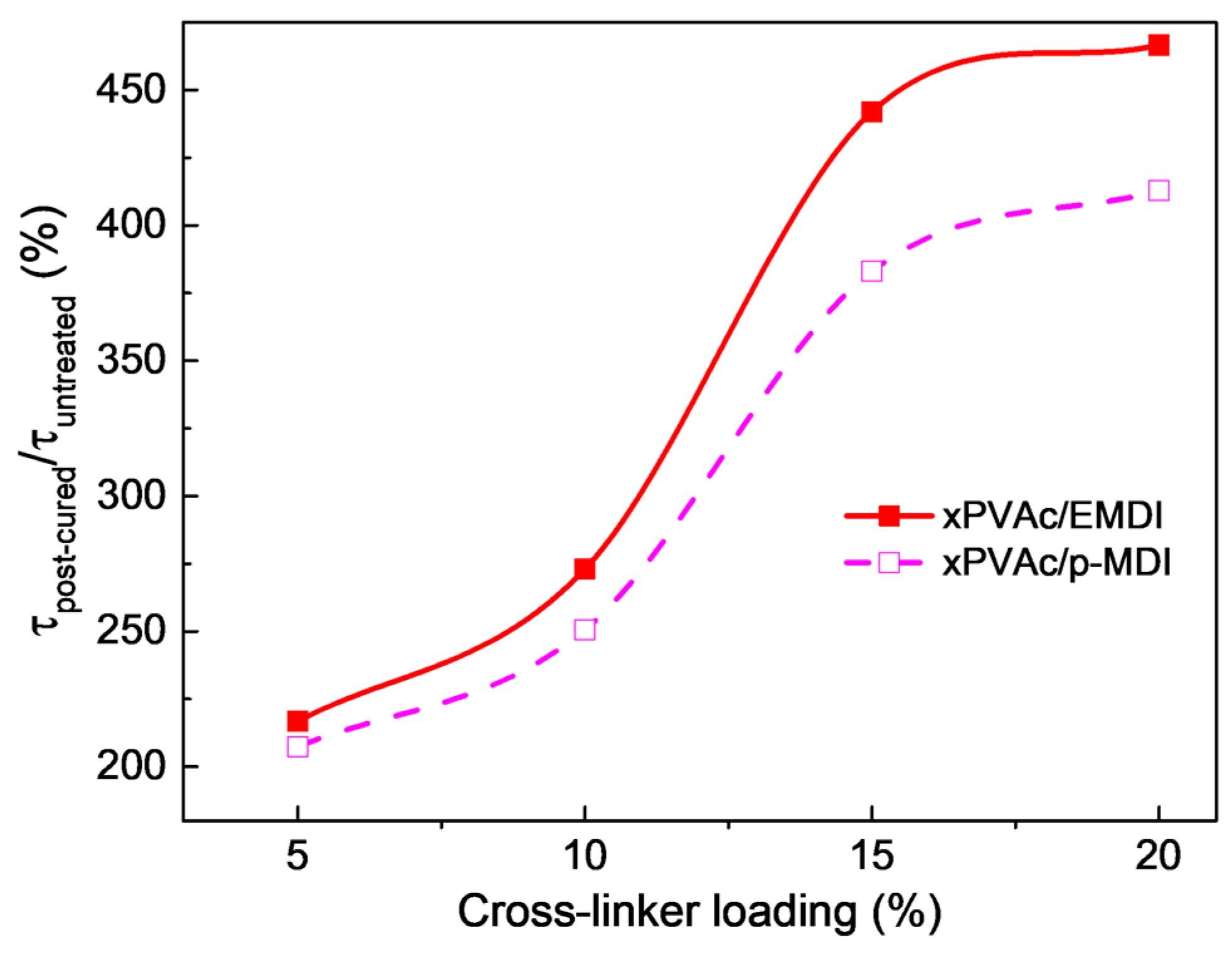

2]. These reactions and related chemical structures of the EPI films during curing the process are illustrated in Equations (2) and (3) respectively, by which not only xPVAc (vinyl acetate/butyl acrylate/hydroxypropyl methacrylate tri-copolymer latex), but also PVOH in the main component, can be cross-linked by the polyisocyanate to increase their molecular weights and establish the stable crosslinking networks after fabrication. As indicated in

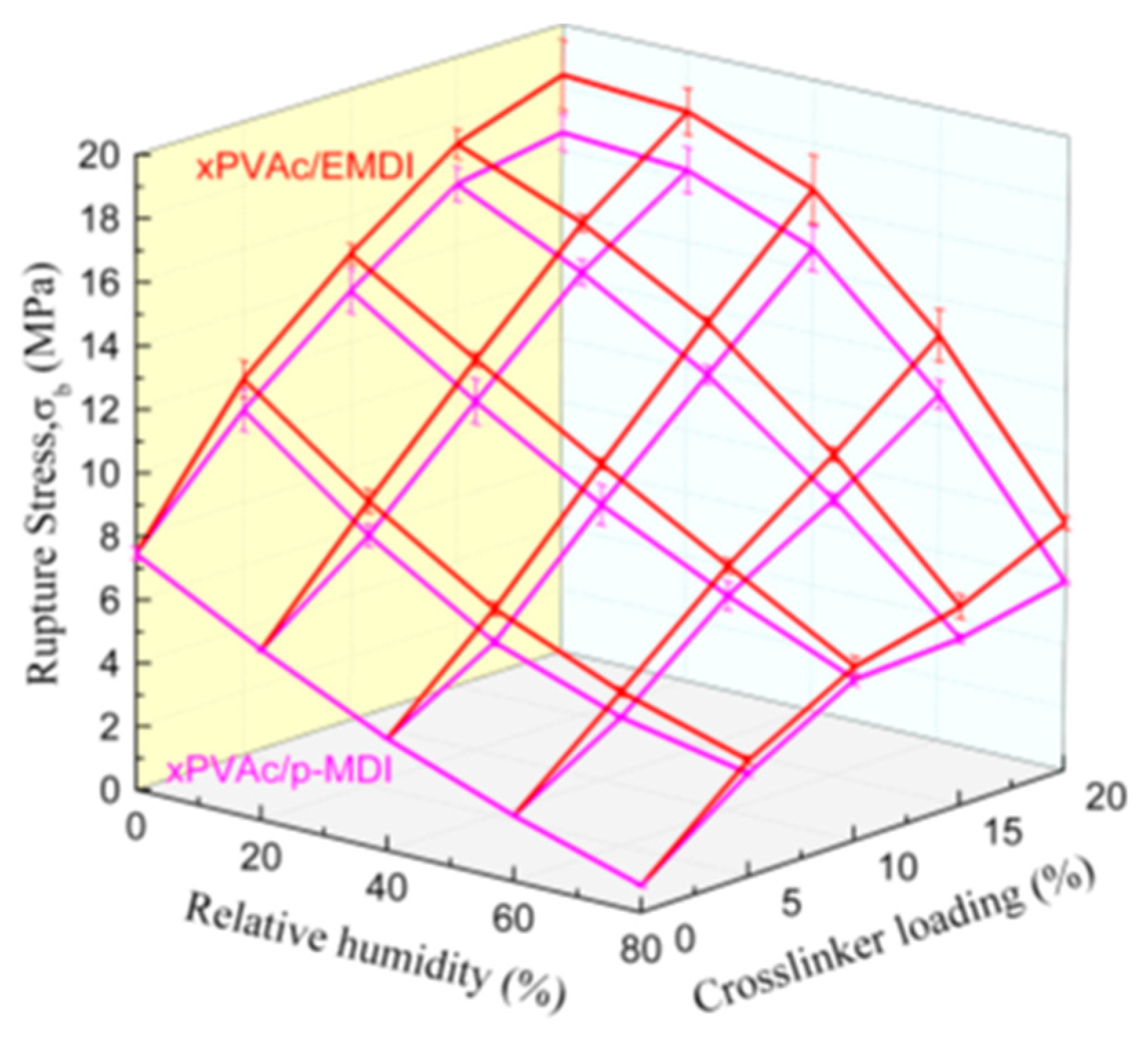

Figure 2, with the aid of polymeric isocyanate, the rupture stress (

) remarkably improves the adhesive film under different relative humidity conditions. The magnitude of

at 0% RH is 46.4% higher in the EPI film with 5.0 wt %

p-MDI compared to the neat xPVAc sample. As the weight ratio of cross-linker increases to 20%, the relative difference in

between EPI and its main component amplifies to 122.2%. Noticeably, with increasing EMDI or

p-MDI content, the strength of dry film continuously increases. This is different to the effect of polymeric isocyanate on the bonding performance of xPVAc-based EPI at ambient temperature, which first rises then descends as the weight ratio of cross-linker increases from 0 to 20.0% [

2]. This may be ascribed to the fact that more residual stress has arisen from the shrinkage of the adhesive layer due to the relatively higher curing rate as the EPI is coated on the surface of the dry wood specimen, where a great deal of water molecules are rapidly absorbed by the adherend. Meanwhile, not only noncovalent interactions, such as electrostatic interaction, hydrogen bonding, hydrophobic attraction, and van der Waals interaction [

23], but also chemical crosslinking occur on the interfaces between wood and EPI film. However, if the evaporation rate of water in the EPI adhesive is too low, the coalescence of particles in the emulsion would occur after the chemical cross-link between the isocyanate group and active hydrogen in the main component. Consequently, the crosslinking reactions on the surface of the particles may impede the formation of a continuous film. Therefore, it is important in the design of the robust EPI bond-line to control the water-loss speed and the crosslinking reactions well with the diffusion and coalescence of tiny particles, film formation, and emulsion migration into the porosity of the surface of the adherend.

When water-based polymer film is subjected to moisture, because of the strong attraction of the water molecules to the amorphous chains of aqueous polymer, the electrostatic forces create a mutually exclusive system, forcing molecular chains to become a looser framework, and leaving extra free volume. Therefore, the small molecules can penetrate into the non-crystalline zone and reduce the local density of the system, which results in the strength of the cured film decreasing through an increase in the relative humidity at isothermal conditions (see

Figure 2). As anticipated, polymeric isocyanate is helpful in alleviating plasticization. Furthermore, it was found that the moisture resistance of EPI film is strongly dependent upon the cross-linker content. That is, the more isocyanate that is added, the higher the rupture stress of the cured film in humid conditions. To explore the effect of the cross-linker content on the moisture resistance of the EPI films, the cross-link density was used to describe the degree of cross-linking between the isocyanate groups and functional groups in xPVAc. The cross-link density refers to the number of cross-linked bonds per unit volume, and can be calculated using the Young’s modulus from the stress-strain test [

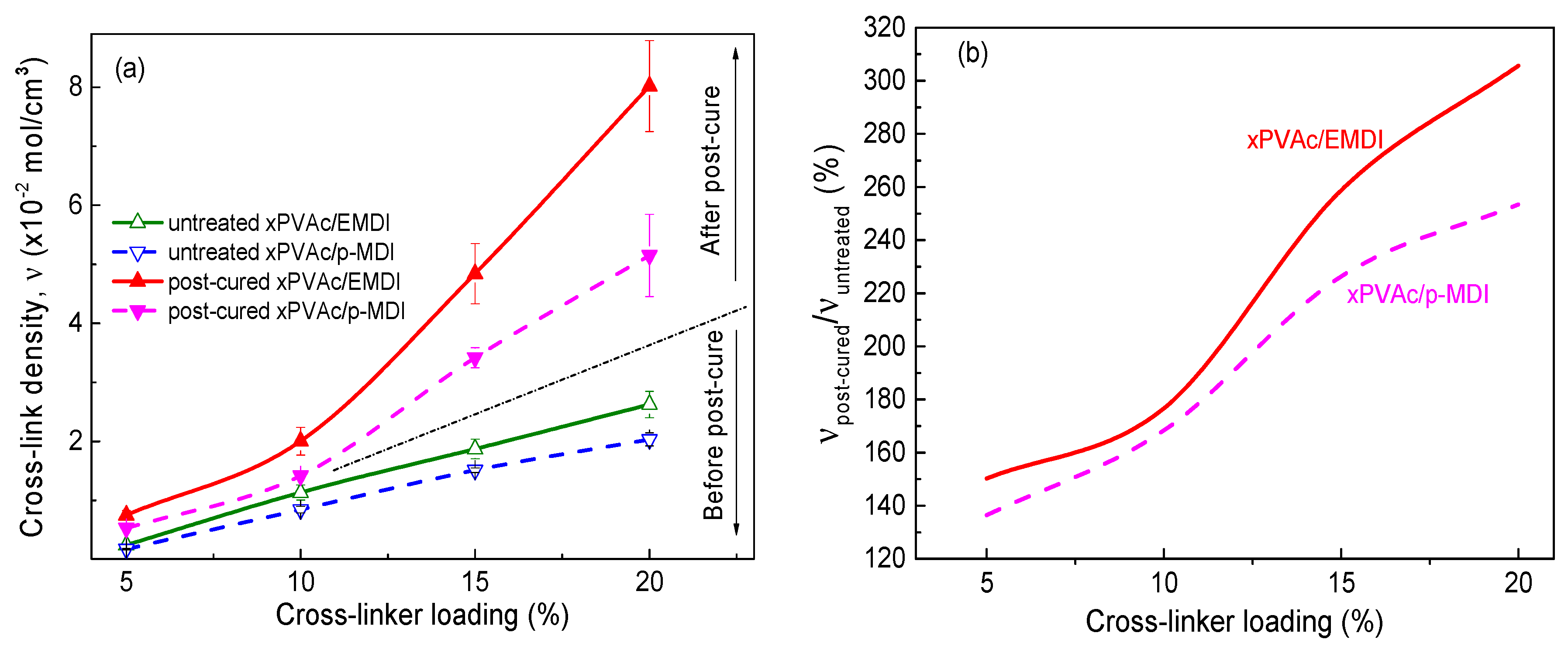

24]. The evolution of the crosslink density as a function of the isocyanate content is shown in

Figure 3.

As seen in

Figure 3, as the isocyanate content increases, the crosslink density rises at an almost uniform rate. Importantly, the cross-linked structure is a very powerful barrier to the penetration of water molecules: the greater the crosslink density, the greater the difficult of penetration of water molecules. A highly cross-linked structure can also cause massive restrictions on chain movement, which means that the relative content of amorphous chains in the EPI samples is greatly reduced, and that the free volume among the macromolecular chains is also decreased. Because fewer water molecules can penetrate into samples with a higher cross-linker content, their strength in a humid environment can be maintained at a higher value.

Figure 2 shows that xPVAc/EMDI films have much better moisture resistance than xPVAc/

p-MDI films with the same isocyanate, and that the difference tends to become more obvious as the cross-linker amount increases. This result may be interpreted as follows: On the one hand, as shown in

Figure 3, the crosslink density of xPVAc/EMDI films is greater than that of xPVAc/

p-MDI films throughout the cross-linker content range tested. Moreover, as the cross-linker addition increases, the gap in cross-link density between the two types of films gradually widens. Therefore, the water resistance of xPVAc/EMDI films is better. On the other hand, as the more non-polar cross-linker,

p-MDI in the form of small particles is not easy to disperse into the polar aqueous main polymer component, and this situation is further exacerbated at higher isocyanate ratios. In EMDI, where the polymeric isocyanate is modified with non-ionic surfactants, the interface between the hydrophilic and lyophilic groups in the EPI adhesive is optimized. Thus, EMDI will facilitate the dispersion of the isocyanate into xPVAc and PVOH, and thus, enhance the contact probability and cross-linking reaction between the –OH of the aqueous polymer and –NCO in the cross-linker. Consequently, the mechanical properties of the cured film are improved by the higher crosslink density through its effect on the molecular mobility and the glass transition relative humidity.

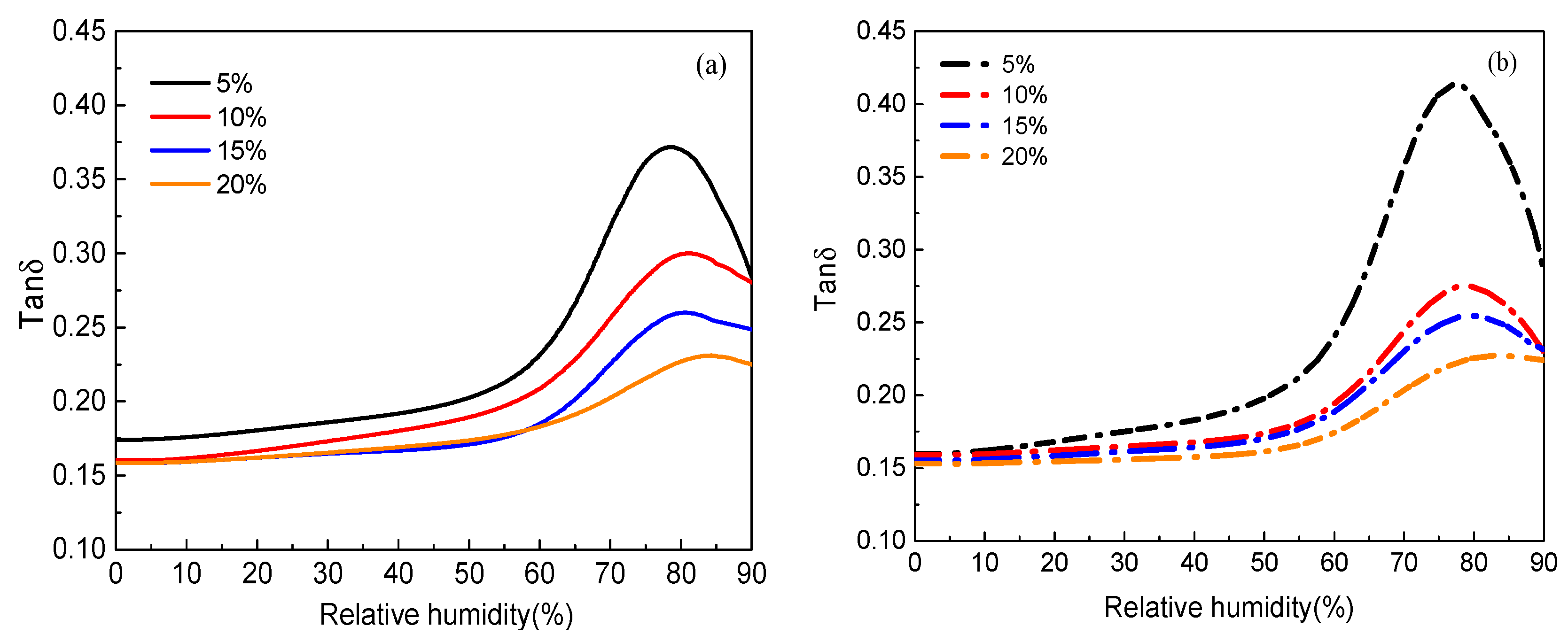

Analogous to the glass transition induced by temperature change, external relative humidity variation and the resulting change in water content can also lead to a remarked viscoelastic state change of the EPI film, as seen in

Figure 4. With the loading of cross-linker varying from 5 to 20%, the introduction of isocyanate group crosslinks increased the width of the RH-dependent tan

δ, and decreased the peak height, suggesting that the molecular weight increases and the molecular weight distribution broadens. It can be clearly observed that there exists the critical relative humidity denoted as RH

g, corresponding to the peak of loss tangent. Admittedly, the addition of polyisocyanate was helpful in increasing the glass transition relative humidity, causing a greater constraint on chain movement and a higher crosslink degree. Accordingly, the more isocyanate added, the higher the RH

g. As anticipated, the RH

g value of xPVAc/EMDI is higher than that of xPVAc/

p-MDI at the same cross-linker content.

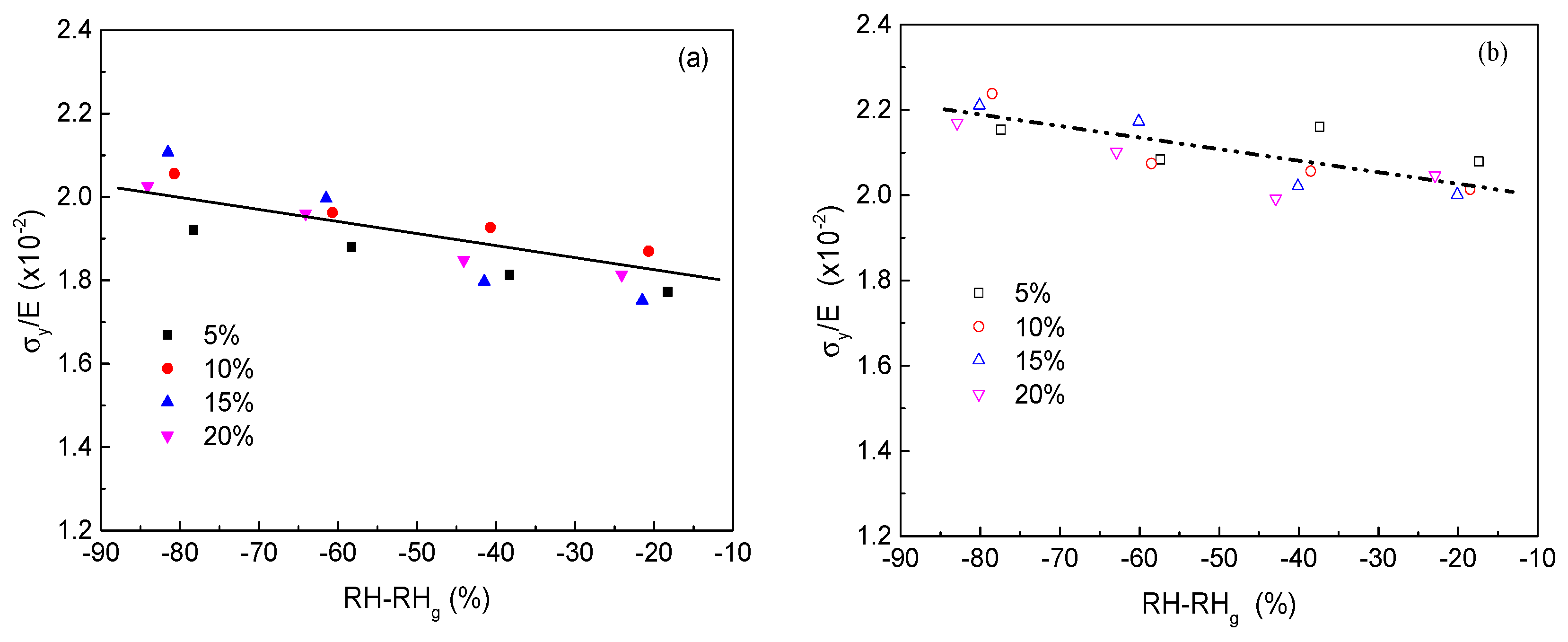

As stated above, experimental results show that an increase in relative humidity would lead to not only a decrease of mechanical properties, such as yield and rupture stress, but also of the glass transition of adhesive film. One may wonder whether there exists some connection between plastic behavior and the segmental mobility process. Inspired by the work of the Halary group [

15,

16,

17,

18], we have plotted the yield stress normalized by elastic modulus (

) of cured film versus departure from main mechanical relaxation relative humidity (

) in

Figure 5 for xPVAc/EMDI and xPVAc/

p-MDI. The value of

was defined as the point where the stress passed at the obvious ‘knee’ in the stress–strain curve (because a maximum in stress was not observed in

Figure 1). It can be seen that almost all the plots of

against

lie on a unique master curve for xPVAc/EMDI film with different isocyanate loadings; xPVAc/

p-MDI shows a similar trend. All the EPI cured films with various cross-link densities exhibit almost the same profile of evolution

as a function of (

), which implies there is a correlation between the yielding behavior and segmental mobility in the β-relaxation processes induced by moisture.

3.2. Effect of Post-Cure Treatment

Although the NCO groups can be so reactive that they react with almost all polar substances in the wood and aqueous polymers such as water and hydroxyl groups, the isocyanate absorption band at 2270 cm

−1 was still detected in the spectrum of an EPI film stored for 60 days at ambient temperature [

14]. As a result, the residual NCO groups may further react with environmental moisture, leading to the presence of minor defects in the adhesive layer due to carbon dioxide (CO

2) gas arising from this reaction, as shown in Equation (1). Therefore, to improve the durability performance of EPI-bonded structures under operating conditions, reducing the amount of unreacted isocyanate in the glue-line is essential. Importantly, the post-curing treatment, i.e., by heating at 120–180 °C, could decrease the content of residual NCO groups in an EPI film sample, thereby contributing to the higher dynamic storage modulus [

14]. How the moisture resistance of EPI films with different cross-linker types and loadings would be affected, however, if this additional curing procedure is added, remains unclear. To answer this question, we compared the moisture-dependent rupture stress of xPVAc-based EPI films with and without the thermal treatment, and explored the evolution of the porosity on the film surface, the cross-link density, and residual isocyanate groups in the cured samples with different cross-linkers.

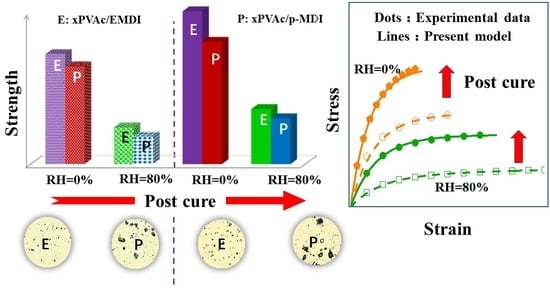

To decrease the content of residual NCO groups in polymer film, EPI specimens were heated in an oven at 140 °C for 24 h, and then subjected to the same uniaxial tensile test. The representative engineering stress-strain curves are shown in

Figure 6. Furthermore, to compare the effect of post-cure on the moisture resistance of EPI specimens with different cross-linker, the rupture stresses of xPVAc/EMDI and xPVAc/p-MDI films before and after the treatment were determined, as shown in

Figure 7a,b, respectively.

As shown in

Figure 7, in either a dry atmosphere or a humid environment, the rupture stress (

) of EPI films cross-linked by both EMDI and p-MDI after post-cure is significantly higher than that of untreated specimens, which indicates that the treatment can generally enhance the mechanical properties of EPI films. After heating,

of dry film with 5% EMD increases 38%. As the weight ratio of EMDI to the main component increases to 20%, it would boost by approximately 51%, which is considerably greater than that of the 5% EMD-cross-linked specimen. The EPI films containing

p-MDI also show the similar trend, but relatively less improvement. This observation indicates that the treatment effectively promotes the cross-linking reaction between the –OH and the functional groups in the main component, and may obtain additional intramolecular crosslinking, as indicated in Equation (4). As stated by Wei and Haag [

23], the intra-polymer interactions such as physical and chemical crosslinking can also substantially improve the stability of the coating. It is worth noting that all of the treated specimens in a dry environment show a monotonic strengthening as cross-linker loading increases, indicating that the post-cure would not result in over-crosslinking of EPI specimens, even with 20% polymeric isocyanate.

Due to plasticization effect of moisture, the rupture stress of the post-cured films also decreases as the relative humidity increases. As anticipated, heating treatment can significantly increase moisture resistance of EPI specimens. Certainly, the degree of improvement depends upon the water absorption in the polymer films. At 80% RH, the treated specimens with 5–10% cross-linker show increases by 20–30% in . However, with the aid of a higher cross-linker content (20%), there is a dramatic increase. The wet strength value of post-cured xPVAc/EMDI and xPVAc/p-MDI are increased by approximately 80% and 60% respectively, compared to their untreated specimens. It was also found that the treatment is more effective for the film cross-linked by EMDI than p-MDI at other loadings (5%, 10% and 15%).

To determine the effect mechanism of the post-cure on the mechanical behavior of EPI films, it is necessary to systematically analyze the changes in the structure and composition of the polymer. As the cross-linked structure is an effective barrier to water molecule infiltration, the higher the crosslink density, the more difficult the diffusion by water molecules. The first aim of the following discussion was the clarification of the changes in the cross-link density () of xPVAc cross-linked by EMDI or p-MDI, before and after post-curing treatment at various isocyanate loadings.

Figure 8 illustrates the effect of post-curing on the crosslink density (

) of two kinds of EPI specimen at 80% RH. Upon 24 h of heating at 140 °C, the value of

increases substantially as a consequence of post-curing and the formation of new crosslinking structures, and cured effect sharply enlarges as more cross-linker is added. Importantly, the degree of cross-link of post-cured film with 15% cross-linker is noticeably higher than that of the untreated one with 20% cross-linker. The result may be very helpful in developing cost-effective EPI-bonded wood products, especially as the price of polyisocyanate has increased to approximately USD 5000 per ton at present.

Good dispersion of EMDI in vinyl acetate-based tri-copolymer latex facilitates not only the chemical reaction of –NCO with active hydrogen in EPI in a humidity environment, but also potential intra-crosslinking of the polymer film, subsequently expediting the curing process and an increase in

. As seen in

Figure 8, it is reasonable to conclude that xPVAc/EMDI film subjected to moisture results in a higher crosslink degree, as compared with xPVAc/

p-MDI at the same isocyanate content. After being thermally treated for a day, it is observed that the ratio of the cross-link density (

) of xPVAc/EMDI is also larger than that of xPVAc/

p-MDI, and the difference enlarges as the cross-linker loading increases. The reason for this is that within the post-curing period, a much stronger cross-link reaction take places in the EPI film with EMDI, indicating that there may be more residual isocyanate in the untreated polymer. For the purpose of probing the difference in –NCO residue of the EPI films, the chemical structure was checked using FTIR. The peak value of CaCO

3 at 875 cm

−1 [

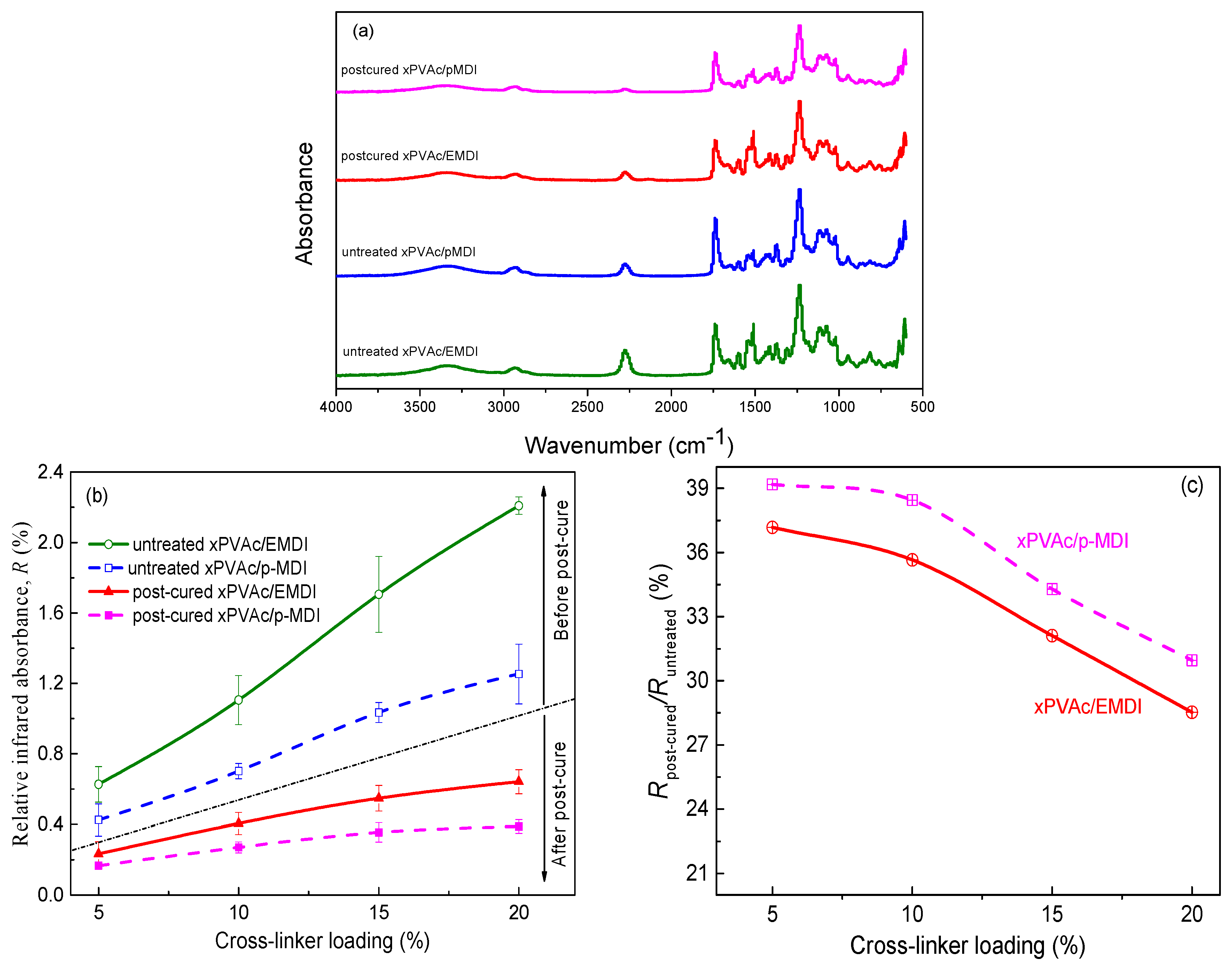

25] was used as the benchmark for spectrum normalization, and the normalized curves are represented in

Figure 9a. Seemingly, the reaction from the isocyanate can be perceived due to the presence of absorption bands in the C=O stretching in the range of 1740–1620 cm

−1 and N-H stretching around 3300 cm

−1 [

14]. However, these characteristic bands could not be distinguished because the C=O stretching region was covered with a huge band due to CaCO

3 being centered at 1400 cm

−1, and the N-H stretching bands overlapped with the broad band assignable to water [

26]. The following therefore focuses on the evolution of the relative intensity of the peak at 2270 cm

−1 assigned to an asymmetric isocyanate stretching; the relative absorption ratio of the peaks,

, interpreted as the amount of residual NCO groups in cured EPI film before and after post-cured treatment, was plotted as shown in

Figure 9b.

From

Figure 9b, under the same cross-linker loading, xPVAc/p-MDI films reveal markedly lower relative infrared absorbance (

) than xPVAc/EMDI before post-curing, indicating that the –NCO depleted much faster for the

p-MDI based EPI film during the preparing process. As its cross-link density is evidently smaller compared to that of the film with EMDI, it may be deduced that more of the cross-linker of xPVAc/

p-MDI reacted with H

2O in this stage. The inference can be further verified by the higher porosity in this type of specimen (see

Figure 10). After post-cure, the magnitude of

drops sharply, while the ratio of relative infrared absorbance (

) for –NCO in the xPVAc/EMDI and xPVAc/

p-MDI films after and before thermal treatment at 24 h is about 37% and 39%, respectively, and it gradually decreases as the cross-linker loading increases. Therefore, post-curing treatment is necessary for EPI, especially with high isocyanate content. Furthermore, the treated xPVAc/EMDI still has relatively higher residual isocyanate. However, it can be seen from

Figure 9c that the value of

is lower than the EPI film with

p-MDI, demonstrating that more isocyanate reacted in post-cured xPVAc/EMDI films than in xPVAc/

p-MDI. This may be attributed to the fact the water vapor from the environment can also expediently penetrate into the relaxed EPI with EMDI in treatment at 140 °C, resulting in there being almost no difference in the reactivity of water molecules with the two kinds of polyisocyanate. Meanwhile, due to the uniformly distributed particles and higher concentration of residual isocyanate, more –NCO in xPVAc/EMDI was consumed by the functional group in the polymer than in xPVAc/

p-MDI. Hence, the post-curing effect on EMDI-crosslinked films is stronger than on that containing

p-MDI, and the treated film is more densely cross-linked, contributing to a more obvious increase in moisture resistance.

As the post-cured cross-linking of EPI film is accompanied by the reaction between isocyanate and water as described in Equation (1), the micropore magnitude on the specimen surface will be considerably changed due to the released carbon dioxide gas. Therefore, the change in micropore distribution may reflect the extent of this reaction. Based on this hypothesis, we used a 3D optical microscope to observe the morphologies of the micropores on the surface of the EPI specimens with different cross-linkers before and after heat treatment, as shown in

Figure 10. Distinct micropore distribution and morphology were observed on the film surface. Before post-curing, the micropores are very small and sparsely distributed, and the specimens with EMDI show smaller micropores than

p-MDI, indicating that less isocyanate was consumed by water molecules during EPI film preparation. After treatment, some larger pores appear, and the number of micropores increases rapidly due to the reaction of residual NCO and moisture of the surroundings; there is also a comparative increase of micropores on the film surface for both types of EPI. This observation may confirm that post-cure facilitates residual isocyanate in xPVAc/EMDI preferentially reacting with the available group in the polymer, resulting in a higher degree of chemical cross-linking.

3.3. Model Analysis on the Moisture-Dependent Mechanical Response

In the previous section, EPI films with different cross-linkers were systematically subjected to quasi-static tensile tests in a variety of humid environments, and the corresponding stress-strain curves were obtained. However, the experiments could not encompass all relative humidity, making it necessary to establish a theoretical model that can predict the mechanical behavior of adhesive films. This section offers a constitutive model to quantitatively describe the moisture-dependent stress-strain curves of cured films; calculated relaxation time is used to determine the effect mechanism of cross-linker and post-curing on the water resistance of EPI.

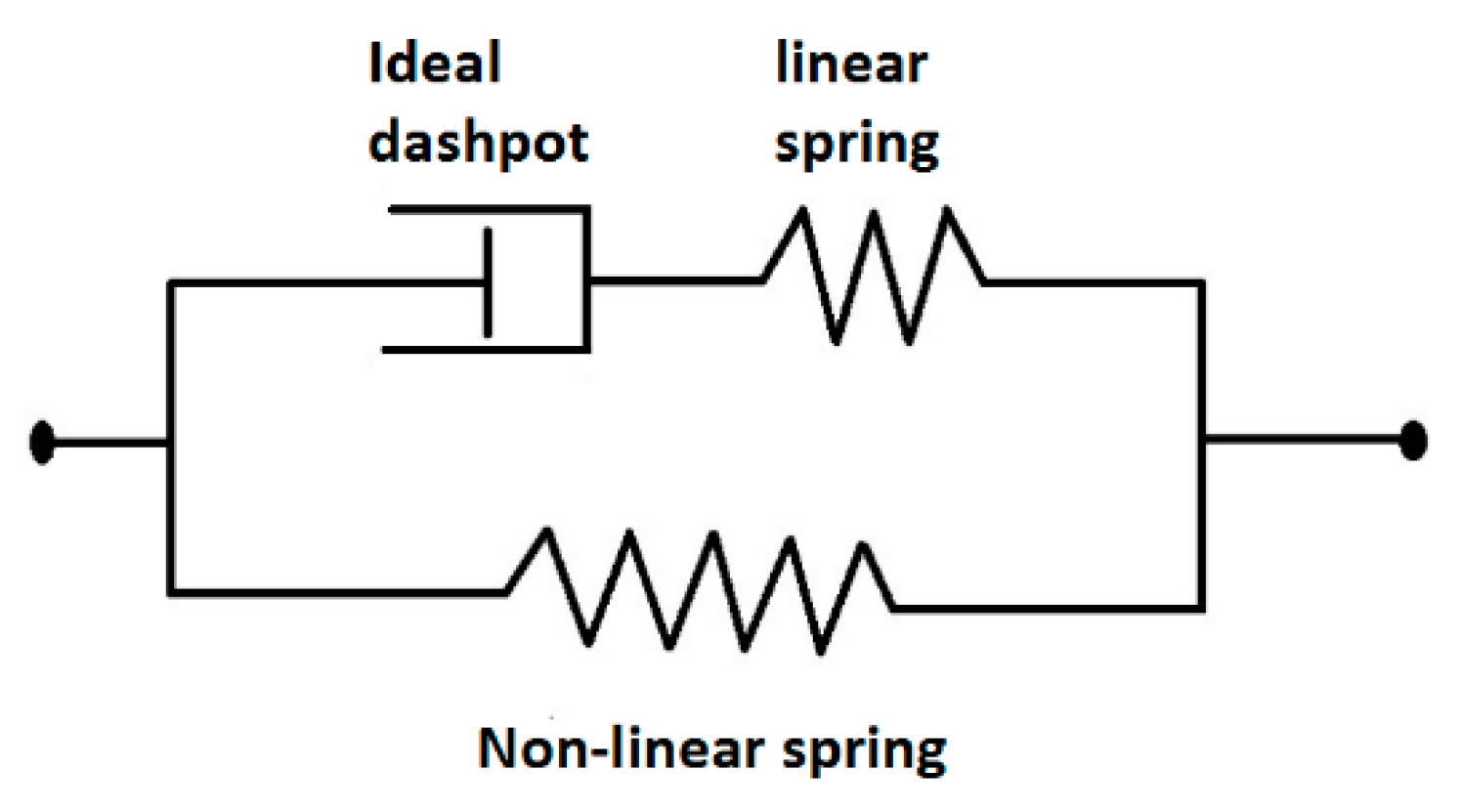

As shown in

Figure 1, the moisture-absorbed EPI samples display typical behavior of thermoplastic materials. Therefore, it is feasible to derive a viscoelastic constitutive equation based on the rheological model composed of two Maxwell elements in parallel (see

Figure 11), and we can obtain the relationship between stress (

) and strain (

) in the equation below (2).

where

is the stiffness of a non-linear spring,

is the stiffness of a linear spring,

is the viscosity of an ideal dashpot, and

is the strain rate.

Equation (5) was used to describe all the uniaxial tensile test curves of the dry and wet specimen cross-linked by EMDI or

p-MDI. The representative results are shown in

Figure 1 and

Figure 6, where the calculated values (solid lines) were in agreement with the experimental data (dots). The correlation coefficient close to 1 indicated that the constitutive model was accurate for calculating the mechanical behavior of EPI films in humid surroundings. As elaborated in the published works [

27,

28,

29,

30], relaxation time is an intrinsic property describing the hysteresis of chain segments of polymer or its composites under external stress. In order to investigate the moisture influence on the mechanical behaviors of EPI film in greater depth, we attempted to determine the relaxation time of a cured sample at 0–80% RH as follows.

The relaxation time (

) of a viscoelastic solid is defined as the ratio of the system viscosity to the system stiffness. Therefore, we can use the material parameters

,

and

obtained by the fitted experimental stress-strain curves to determine the

value of the EPI films in various conditions according to the Equation (6):

The change in relaxation time (

τ) against RH for EPI film with different crosslinkers before and after the post-curing treatment is shown in

Figure 12. The water molecules penetrating into EPI films form hydrogen bonds with the hydroxyl groups in the main component [

31], by which the interchain and intra-chain bonding among amorphous chains in the polymer may be broken [

32], and the

magnitude descends by about 30–50% as RH increases from 0 to 80%. Furthermore, it was found that the relaxation time of EPI film lengthens with the increased polyisocyanate content, also verifying the effective cross-linking between NCO groups and active hydrogen in EPI. Adding more cross-linker or post-curing would cause a stronger interaction force due to the remarkable substantial increase in the number of cross-link bonds among molecular chains, meaning that the film would shrink further and the space around the network chains would be compressed. Under such a steric hindrance effect, the conformational transition of molecular chains is inhibited, and the motion of cross-links is more strictly constrained [

33]. As anticipated, xPVAc/EMDI exhibits a slower relaxation process than xPVAc/

p-MDI of the same cross-linker ratio, owing to the higher crosslinking capacity of emulsified polyisocyanate. Meanwhile, the relaxation times of all EPI specimens can be also greatly increased by post-curing.

In order to further compare the responses of different EPI specimens to post-cured treatment, we calculated the relaxation time and cross-link density of a post-cured film divided by those of an untreated one, as shown in

Figure 13. With the increased loading of polyisocyanate, both the ratio of relaxation time (

) and the ratio of crosslink density (

), as shown in

Figure 8b, of the polymer films is noticeably enlarged. That is to say, the higher the cross-linker loading, the better the treated effects. Moreover, the relative increment of both material properties for xPVAc/EMDI is higher compared to xPVAc/

p-MDI at the same cross-linker loading, also validating the fact that the EMDI-crosslinked films is more sensitive to the post-curing process in terms of chain segments relaxation. Notably, due to coupling the variation of stiffness and viscosity of cured polymer film, the value of

is significantly larger than

for the identical EPI. Therefore, the relaxation time may be the best intrinsic parameter for characterizing the influence of isocyanate, of post-curing treatment, and of environmental conditions on the EPI polymer.