Surface Instability of Bilayer Hydrogel Subjected to Both Compression and Solvent Absorption

Abstract

1. Introduction

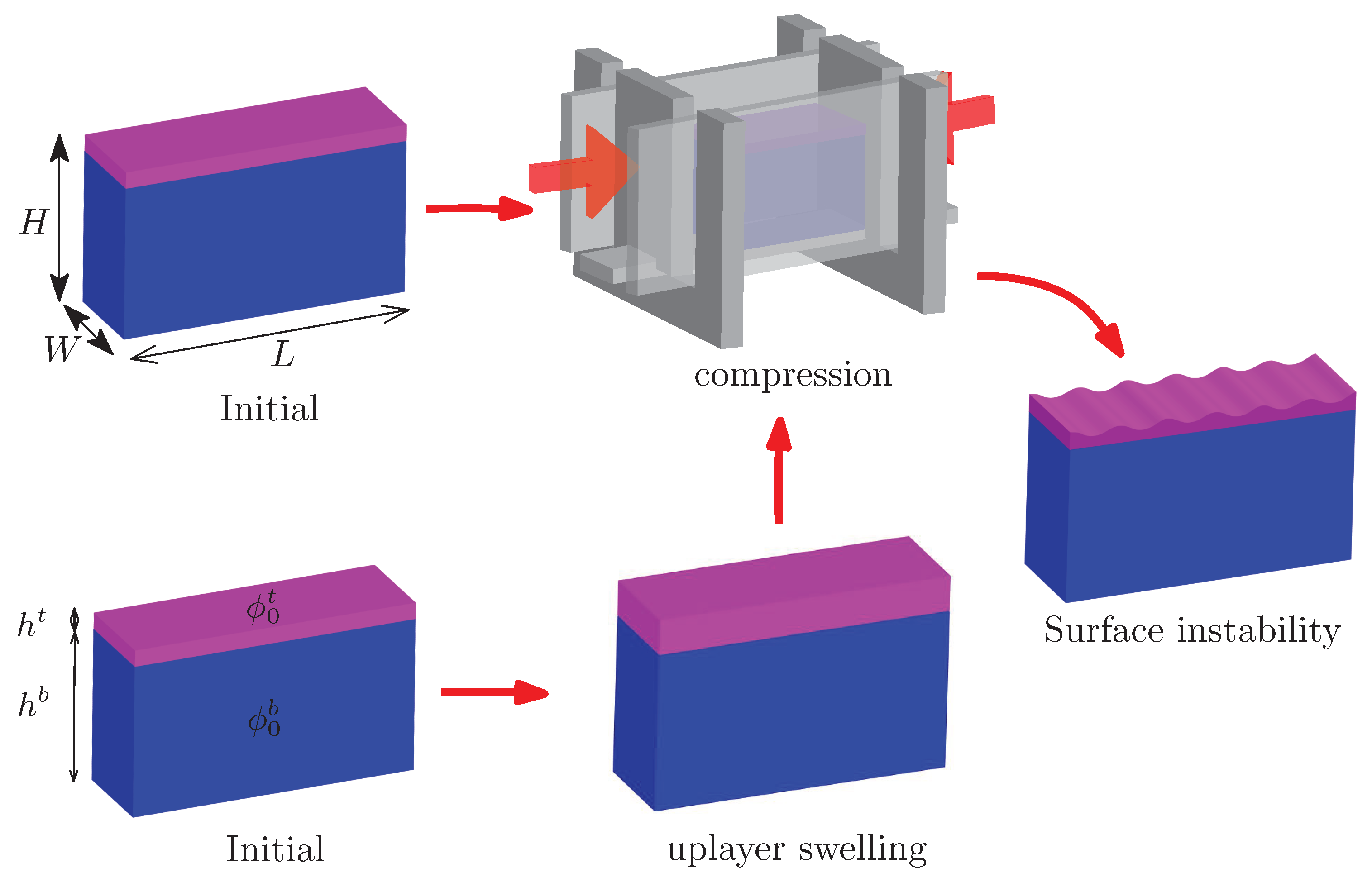

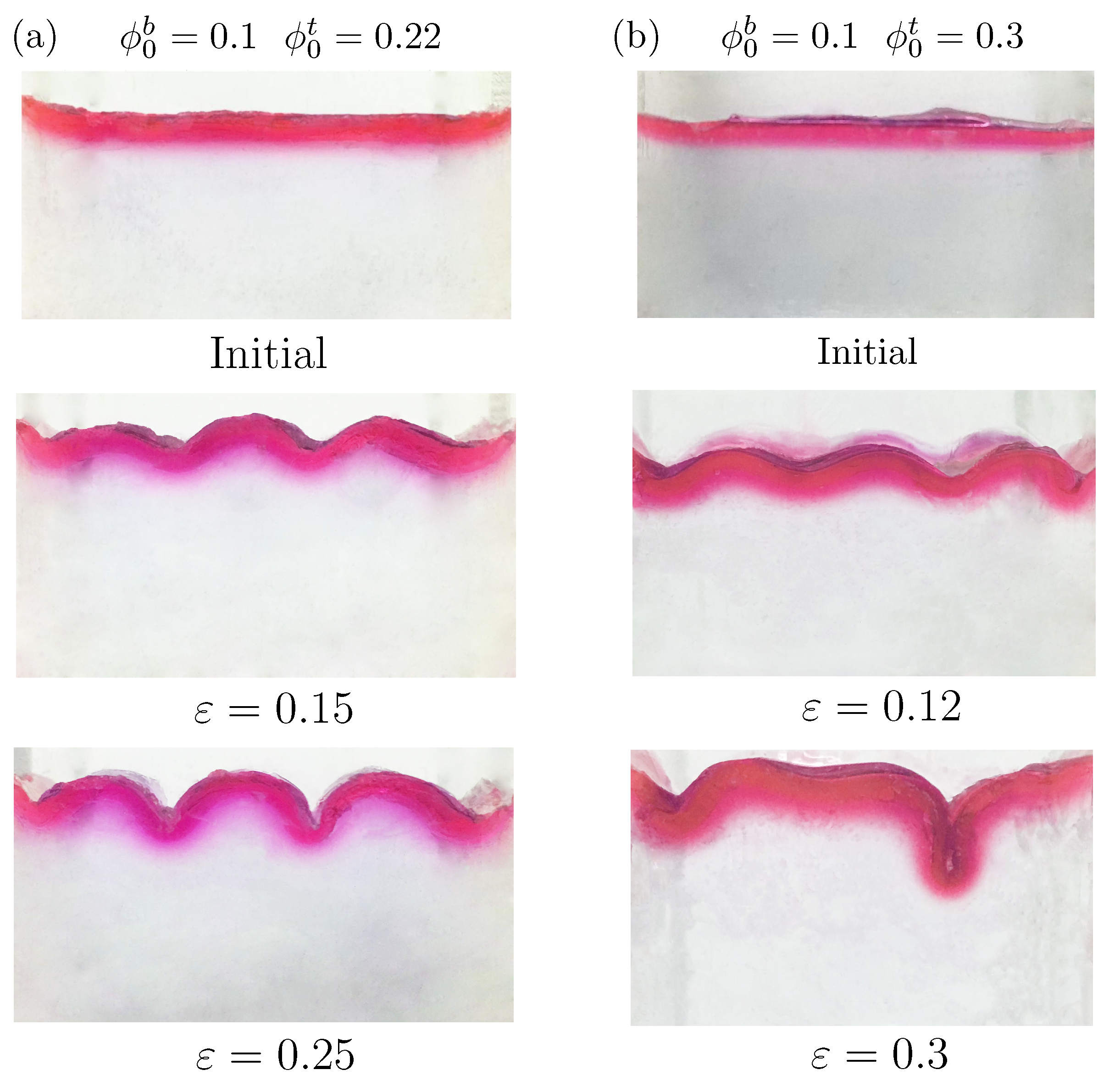

2. Experimental Setup

3. Numerical Analysis

3.1. Material Models

3.2. Surface Instability Analysis

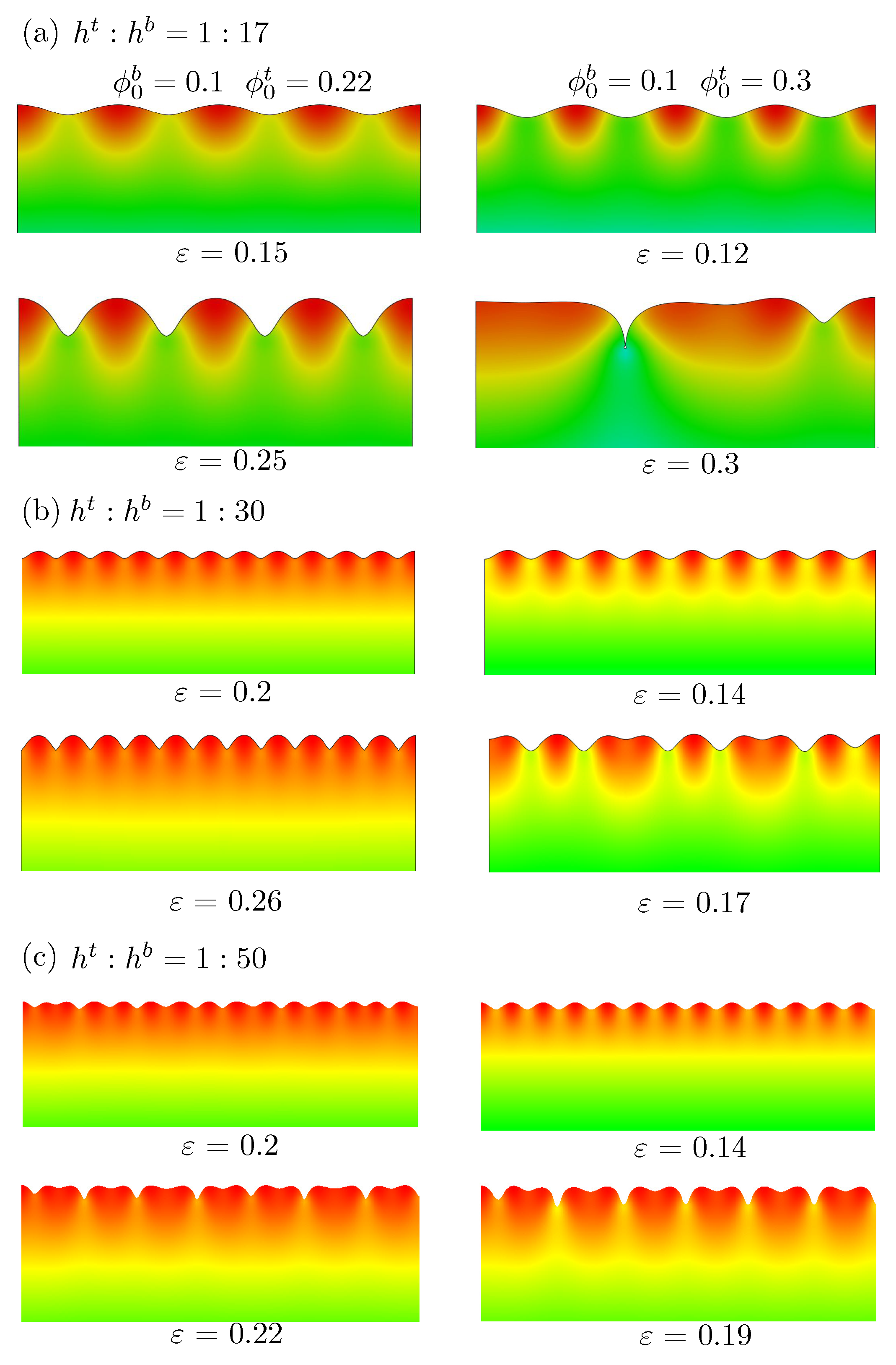

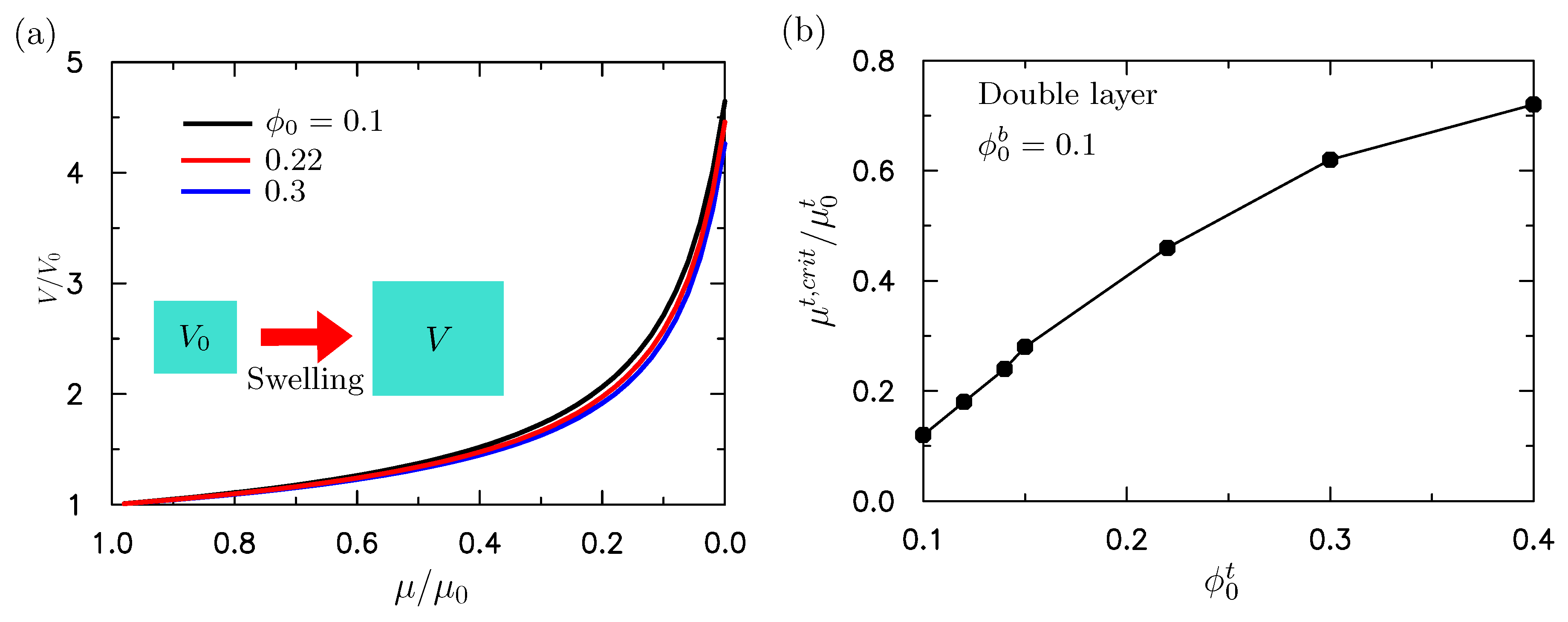

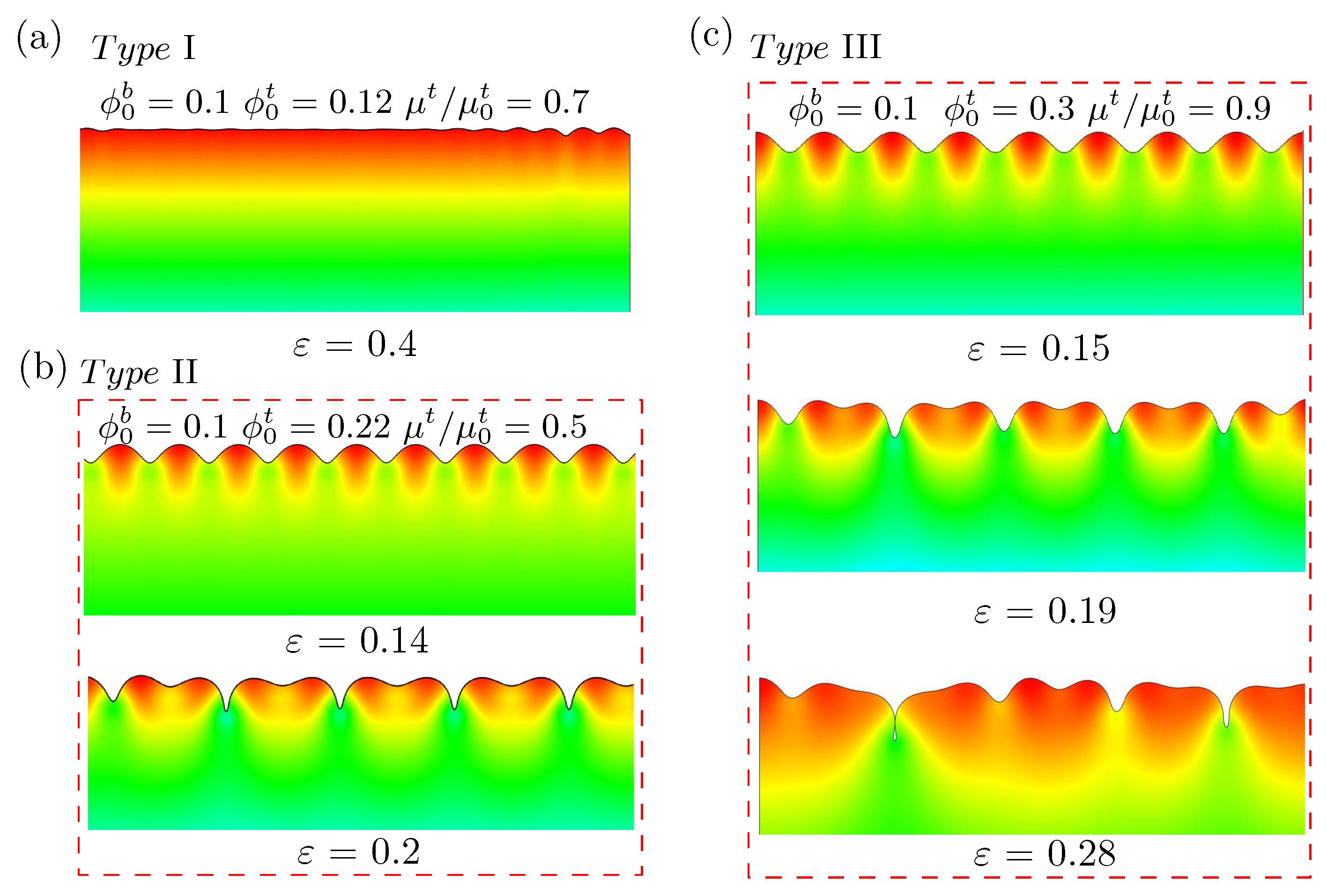

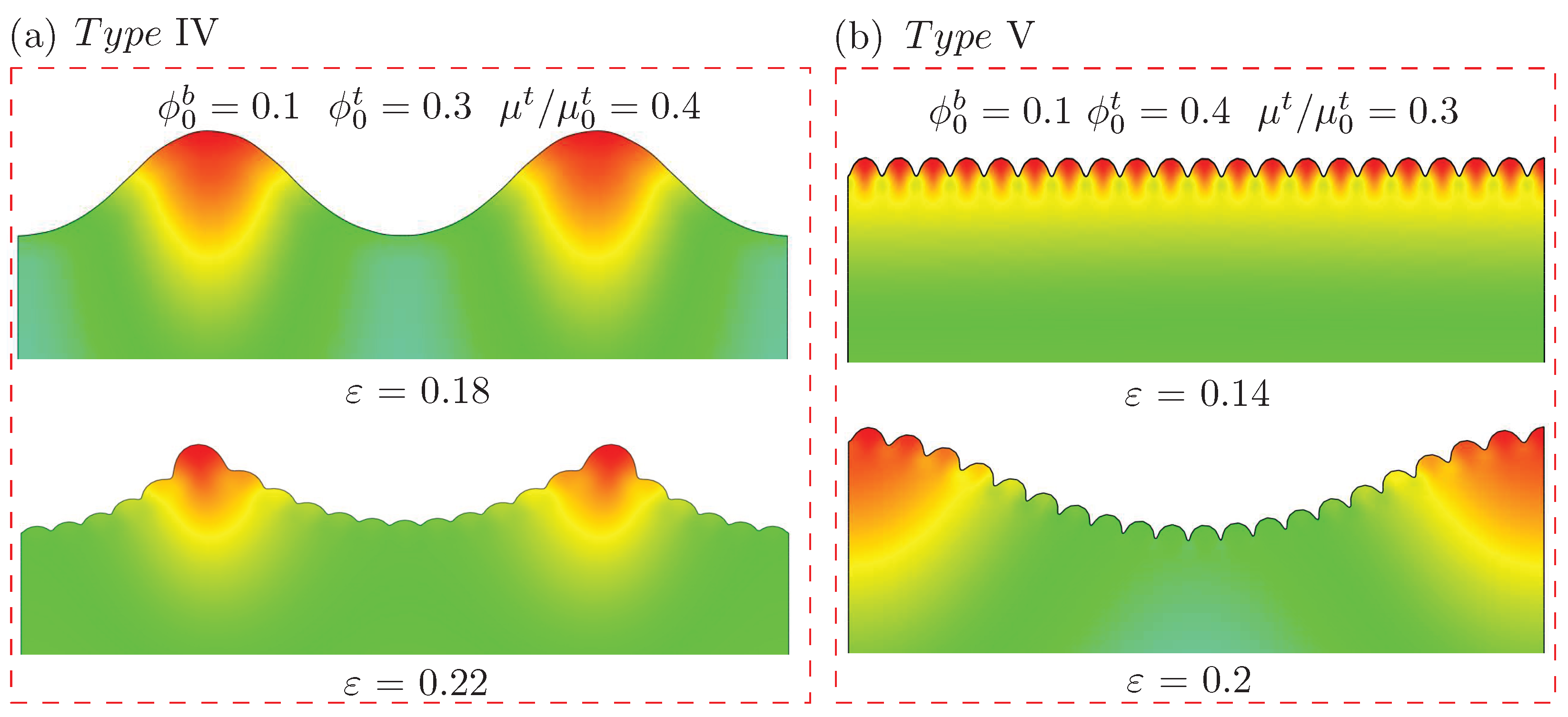

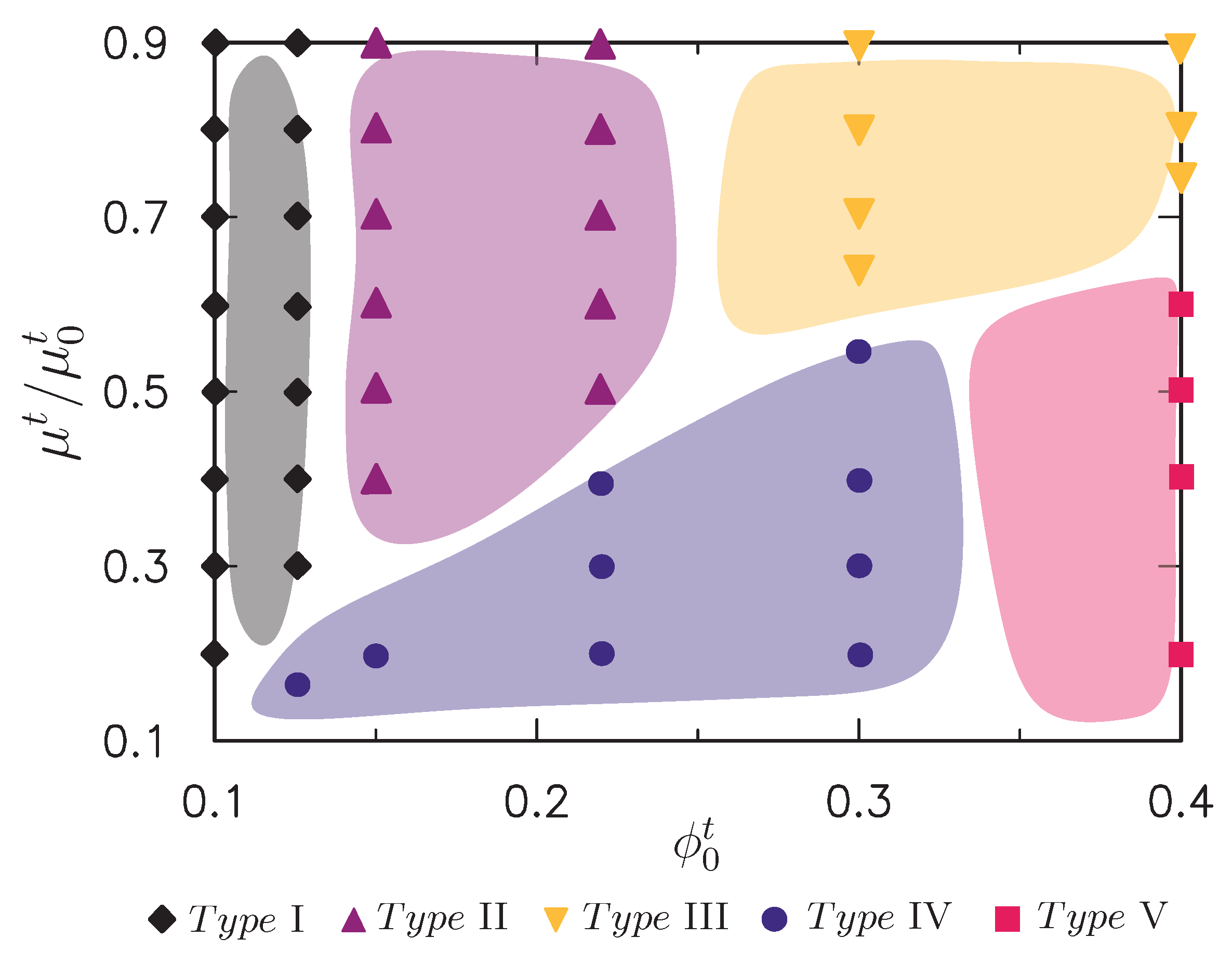

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, D.; Yoon, J.; Chandra, D.; Crosby, A.J.; Hayward, R.C. Stimuli-responsive buckling mechanics of polymer films. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 1441–1461. [Google Scholar] [CrossRef]

- Ltters, J.C.; Olthuis, W.; Veltink, P.H.; Bergveld, P. The mechanical properties of the rubber elastic polymer polydimethylsiloxane for sensor applications. J. Micromech. Microeng. 1997, 797, 145–147. [Google Scholar] [CrossRef]

- Bashir, R.; Hilt, J.Z.; Elibol, O.; Gupta, A.; Peppas, N.A. Micromechanical cantilever as an ultrasensitive pH microsensor. Appl. Phys. Lett. 2002, 81, 3091–3093. [Google Scholar] [CrossRef]

- Kim, D.H.; Ahn, J.H.; Choi, W.M.; Kim, H.S.; Kim, T.H.; Song, J.; Huang, Y.Y.; Liu, Z.; Lu, C.; Rogers, J.A. Stretchable and foldable silicon integrated circuits. Science 2008, 320, 507–511. [Google Scholar] [CrossRef] [PubMed]

- Khang, D.Y.; Jiang, H.; Huang, Y.; Rogers, J.A. A stretchable form of single-crystal silicon for high-performance electronics on rubber substrates. Science 2006, 311, 208–212. [Google Scholar] [CrossRef] [PubMed]

- Ohzono, T.; Monobe, H. Morphological transformation of a liquid micropattern on dynamically tunable microwrinkles. Langmuir 2010, 26, 6127–6132. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Crosby, A.J. Solvent-Responsive Surface via Wrinkling Instability. Adv. Mater. 2011, 23, 4188–4192. [Google Scholar] [CrossRef] [PubMed]

- Schwalm, R.; Häußling, L.; Reich, W.; Beck, E.; Enenkel, P.; Menzel, K. Tuning the mechanical properties of UV coatings towards hard and flexible systems. Prog. Org. Coat. 1997, 32, 191–196. [Google Scholar] [CrossRef]

- Jeong, H.E.; Kwak, M.K.; Suh, K.Y. Stretchable, Adhesion-Tunable Dry Adhesive by Surface Wrinkling. Langmuir 2010, 26, 2223–2226. [Google Scholar] [CrossRef] [PubMed]

- Hammer, D.A.; Tirrell, M. Biological Adhesion at Interfaces. Mater. Res. 1996, 26, 651–691. [Google Scholar] [CrossRef]

- Shivapooja, P.; Wang, Q.; Orihuela, B.; Rittschof, D.; López, G.P.; Zhao, X. Bioinspired surfaces with dynamic topography for active control of biofouling. Adv. Mater. 2013, 25, 1430–1434. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, X.S.; Meng, X.K. Buckling behavior of metal film/substrate structure under pure bending. Appl. Phys. Lett. 2008, 92, 131902. [Google Scholar] [CrossRef]

- Xu, B.; Chen, D.; Hayward, R.C. Mechanically gated electrical switches by creasing of patterned metal/elastomer bilayer films. Adv. Mater. 2014, 26, 4381–4385. [Google Scholar] [CrossRef] [PubMed]

- Sanii, B.; Smith, A.M.; Butti, R.; Brozell, A.M.; Parikh, A.N. Bending membranes on demand: Fluid phospholipid bilayers on topographically deformable substrates. Nano Lett. 2008, 8, 866–871. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Yang, Y.; Peng, X.H.; Liu, W.K.; Huang, X.X.; Elkhodary, K. A semi-numerical algorithm for instability of compressible multilayered structures. Comput. Mech. 2015, 56, 63–75. [Google Scholar] [CrossRef]

- Guvendiren, M.; Burdick, J.A.; Yang, S. Solvent induced transition from wrinkles to creases in thin film gels with depth-wise crosslinking gradients. Soft Matter 2010, 6, 5795–5801. [Google Scholar] [CrossRef]

- Bae, H.J.; Bae, S.; Park, C.; Han, S.; Kim, J.; Kim, L.N.; Kim, K.; Song, S.H.; Park, W.; Kwon, S. Biomimetics: Biomimetic Microfingerprints for Anti-Counterfeiting Strategies. Adv. Mater. 2015, 27, 2083–2089. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Khare, K.; Lin, P.C. Harnessing surface wrinkle patterns in soft matter. Adv. Funct. Mater. 2010, 20, 2550–2564. [Google Scholar] [CrossRef]

- Chen, X.; Yin, J. Buckling patterns of thin films on curved compliant substrates with applications to morphogenesis and three-dimensional micro-fabrication. Soft Matter 2010, 6, 5667–5680. [Google Scholar] [CrossRef]

- Hong, K.S. Tunable microfluidic optical devices with an integrated microlens array. J. Micromech. Microeng. 2006, 16, 1660–1666. [Google Scholar] [CrossRef]

- Khare, K.; Zhou, J.; Shu, Y. Tunable Open-Channel Microfluidics on Soft Poly (dimethylsiloxane) (PDMS) Substrates with Sinusoidal Grooves. Langmuir 2009, 25, 12794–12799. [Google Scholar] [CrossRef] [PubMed]

- Lin, P.C.; Vajpayee, S.; Jagota, A.; Hui, C.Y.; Yang, S. Mechanically tunable dry adhesive from wrinkled elastomers. Soft Matter 2008, 4, 1830–1835. [Google Scholar] [CrossRef]

- Chan, E.; Smith, E.; Hayward, R.; Crosby, A. Surface Wrinkles for Smart Adhesion. Adv. Mater. 2008, 20, 711–716. [Google Scholar] [CrossRef]

- Chung, J.Y.; Youngblood, J.P.; Stafford, C.M. Anisotropic wetting on tunable micro-wrinkled surfaces. Soft Matter 2007, 3, 1163–1169. [Google Scholar] [CrossRef]

- Lin, P.C.; Yang, S. Mechanically switchable wetting on wrinkled elastomers with dual-scale roughness. Soft Matter 2009, 5, 1011–1018. [Google Scholar] [CrossRef]

- Pocivavsek, L. Stress and fold localization in thin elastic membranes. Science 2008, 320, 912–916. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Li, Y.; Liu, W.K.; Hu, N.; Peng, X.H.; Guo, Z. Tensile Stress-Driven Surface Wrinkles on Cylindrical Core–Shell Soft Solids. J. Appl. Mech. 2015, 82, 121002. [Google Scholar] [CrossRef]

- Tanaka, T.; Sun, S.T.; Hirokawa, Y.; Katayama, S.; Kucera, J.; Hirose, Y.; Amiya, T. Mechanical instability of gels at the phase transition. Nature 1987, 325, 796–798. [Google Scholar] [CrossRef]

- Tang, S.; Gao, B.; Zhou, Z.; Gu, Q.; Guo, T. Dimension-controlled formation of crease patterns on soft solids. Soft Matter 2016, 13, 619–626. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Zhou, Z.; Li, Y.; Tang, S. Cyclic loading effects on creasing behavior of soft solids. Polymers 2017, 9, 148. [Google Scholar] [CrossRef]

- Cao, Y.; Hutchinson, J.W. Wrinkling phenomena in neo-Hookean film/substrate bilayers. J. Appl. Mech. 2012, 79, 031019. [Google Scholar] [CrossRef]

- Lin, P.C.; Yang, S. Spontaneous formation of one-dimensional ripples in transit to highly ordered two-dimensional herringbone structures through sequential and unequal biaxial mechanical stretching. Appl. Phys. Lett. 2007, 90, 505–515. [Google Scholar] [CrossRef]

- Tang, S.; Li, Y.; Liu, W.K.; Huang, X.X. Surface Ripples of Polymeric Nanofibers under Tension: The Crucial Role of Poisson’s Ratio. Macromolecules 2014, 47, 6503–6514. [Google Scholar] [CrossRef]

- Chen, X.; Hutchinson, J.W. A family of herringbone patterns in thin films. Scr. Mater. 2004, 50, 797–801. [Google Scholar] [CrossRef]

- Li, Y. Reversible wrinkles of monolayer graphene on a polymer substrate: Toward stretchable and flexible electronics. Soft Matter 2016, 12, 3202–3213. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Li, Y.; Yang, Y.; Guo, Z. The effect of mechanical-driven volumetric change on instability patterns of bilayered soft solids. Soft Matter 2015, 11, 7911–7919. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Zhao, X. Beyond wrinkles: Multimodal surface instabilities for multifunctional patterning. MRS Bull. 2016, 41, 115–122. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.S.; Fan, Q. Effects of elastic anisotropy on the surface stability of thin film/substrate system. Int. J. Eng. Sci. 2008, 46, 1325–1333. [Google Scholar] [CrossRef]

- Li, B.; Cao, Y.P.; Feng, X.Q.; Gao, H. Mechanics of morphological instabilities and surface wrinkling in soft materials: A review. Soft Matter 2012, 8, 5728–5745. [Google Scholar] [CrossRef]

- Xu, B.; Hayward, R.C. Low-voltage switching of crease patterns on hydrogel surfaces. Adv. Mater. 2013, 25, 5555–5559. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Kim, J.; Hayward, R.C. Nucleation, growth, and hysteresis of surface creases on swelled polymer gels. Soft Matter 2010, 6, 5807–5816. [Google Scholar] [CrossRef]

- Yoon, J.; Bian, P.; Kim, J.; Mccarthy, T.J.; Hayward, R.C. Local switching of chemical patterns through light-triggered unfolding of creased hydrogel surfaces. Angew. Chem. Int. Ed. 2012, 51, 7258–7261. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, L.; Zhao, X. Creasing to cratering instability in polymers under ultrahigh electric fields. Phys. Rev. Lett. 2011, 106, 118301. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wang, Q. Harnessing large deformation and instabilities of soft dielectrics: Theory, experiment, and application. Appl. Phys. Rev. 2014, 1, 021304. [Google Scholar] [CrossRef]

- Allen, W. The immunological measurement of pregnant mare serum gonadotrophin. J. Endocrinol. 1969, 43, 593–598. [Google Scholar] [CrossRef] [PubMed]

- Brau, F.; Vandeparre, H.; Sabbah, A.; Poulard, C.; Boudaoud, A.; Damman, P. Multiple-length-scale elastic instability mimics parametric resonance of nonlinear oscillators. Nat. Phys. 2011, 7, 56. [Google Scholar] [CrossRef]

- Cai, S.; Breid, D.; Crosby, A.J.; Suo, Z.; Hutchinson, J.W. Periodic patterns and energy states of buckled films on compliant substrates. J. Mech. Phys. Solids 2011, 59, 1094–1114. [Google Scholar] [CrossRef]

- Ebata, Y.; Croll, A.B.; Crosby, A.J. Wrinkling and strain localizations in polymer thin films. Soft Matter 2012, 8, 9086–9091. [Google Scholar] [CrossRef]

- Auguste, A.; Jin, L.; Suo, Z.; Hayward, R. The role of substrate pre-stretch on post-wrinkling bifurcations. Soft Matter 2014, 10, 6520–6529. [Google Scholar] [CrossRef] [PubMed]

- Shao, Z.C.; Zhao, Y.; Zhang, W.; Cao, Y.; Feng, X.Q. Curvature induced hierarchical wrinkling patterns in soft bilayers. Soft Matter 2016, 12, 7977–7982. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Li, Y.; Wong, W.; Guo, T.; Tang, S.; Luo, J. Transition of surface-interface creasing in bilayer hydrogels. Soft Matter 2017, 13, 6011–6020. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Tang, S.; Abberton, B.C.; Kröger, M.; Burkhart, C.; Jiang, B.; Papakonstantopoulos, G.J.; Poldneff, M.; Liu, W.K. A predictive multiscale computational framework for viscoelastic properties of linear polymers. Polymer 2012, 53, 5935–5952. [Google Scholar] [CrossRef]

- Li, Y.; Tang, S.; Kröger, M.; Liu, W.K. Molecular simulation guided constitutive modeling on finite strain viscoelasticity of elastomers. J. Mech. Phys. Solids 2016, 88, 204–226. [Google Scholar]

- Tang, S.; Greene, M.S.; Liu, W.K. Two-scale mechanism-based theory of nonlinear viscoelasticity. J. Mech. Phys. Solids 2012, 60, 199–226. [Google Scholar] [CrossRef]

- Hong, W.; Zhao, X.; Zhou, J.; Suo, Z. A theory of coupled diffusion and large deformation in polymeric gels. J. Mech. Phys. Solids 2008, 56, 1779–1793. [Google Scholar] [CrossRef]

- Hong, W.; Liu, Z.; Suo, Z. Inhomogeneous swelling of a gel in equilibrium with a solvent and mechanical load. Int. J. Solids Struct. 2009, 46, 3282–3289. [Google Scholar] [CrossRef]

- ABAQUS. User’s Manual Version 6.10; ABAQUS: Providence, RI, USA, 2010. [Google Scholar]

- Milner, S.T.; Lacasse, M.D.; Graessley, W.W. Why χ Is Seldom Zero for Polymer? Solvent Mixtures. Macromolecules 2009, 42, 876–886. [Google Scholar] [CrossRef]

- Tang, S.; Greene, M.S.; Peng, X.H.; Liu, W.K.; Guo, Z.Y. Chain confinement drives the mechanical properties of nanoporous polymers. Europhys. Lett. 2014, 106, 36002. [Google Scholar] [CrossRef]

- Li, Y.; Qiu, X.M.; Yang, F.; Wang, X.S.; Yin, Y.; Fan, Q. Chirality independence in critical buckling forces of super carbon nanotubes. Solid State Commun. 2008, 148, 63–68. [Google Scholar] [CrossRef]

- Lee, W.K.; Engel, C.J.; Huntington, M.D.; Hu, J.; Odom, T.W. Controlled three-dimensional hierarchical structuring by memory-based, sequential wrinkling. Nano Lett. 2015, 15, 5624–5629. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Sun, Q.; Xiao, J. Simultaneous formation of multiscale hierarchical surface morphologies through sequential wrinkling and folding. Appl. Phys. Lett. 2018, 112, 081602. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Li, Y.; Guo, T.F.; Guo, X.; Tang, S. Surface Instability of Bilayer Hydrogel Subjected to Both Compression and Solvent Absorption. Polymers 2018, 10, 624. https://doi.org/10.3390/polym10060624

Zhou Z, Li Y, Guo TF, Guo X, Tang S. Surface Instability of Bilayer Hydrogel Subjected to Both Compression and Solvent Absorption. Polymers. 2018; 10(6):624. https://doi.org/10.3390/polym10060624

Chicago/Turabian StyleZhou, Zhiheng, Ying Li, Tian Fu Guo, Xu Guo, and Shan Tang. 2018. "Surface Instability of Bilayer Hydrogel Subjected to Both Compression and Solvent Absorption" Polymers 10, no. 6: 624. https://doi.org/10.3390/polym10060624

APA StyleZhou, Z., Li, Y., Guo, T. F., Guo, X., & Tang, S. (2018). Surface Instability of Bilayer Hydrogel Subjected to Both Compression and Solvent Absorption. Polymers, 10(6), 624. https://doi.org/10.3390/polym10060624