Application of the Improved Inclusion Core Model of the Indentation Process for the Determination of Mechanical Properties of Materials

Abstract

:1. Introduction

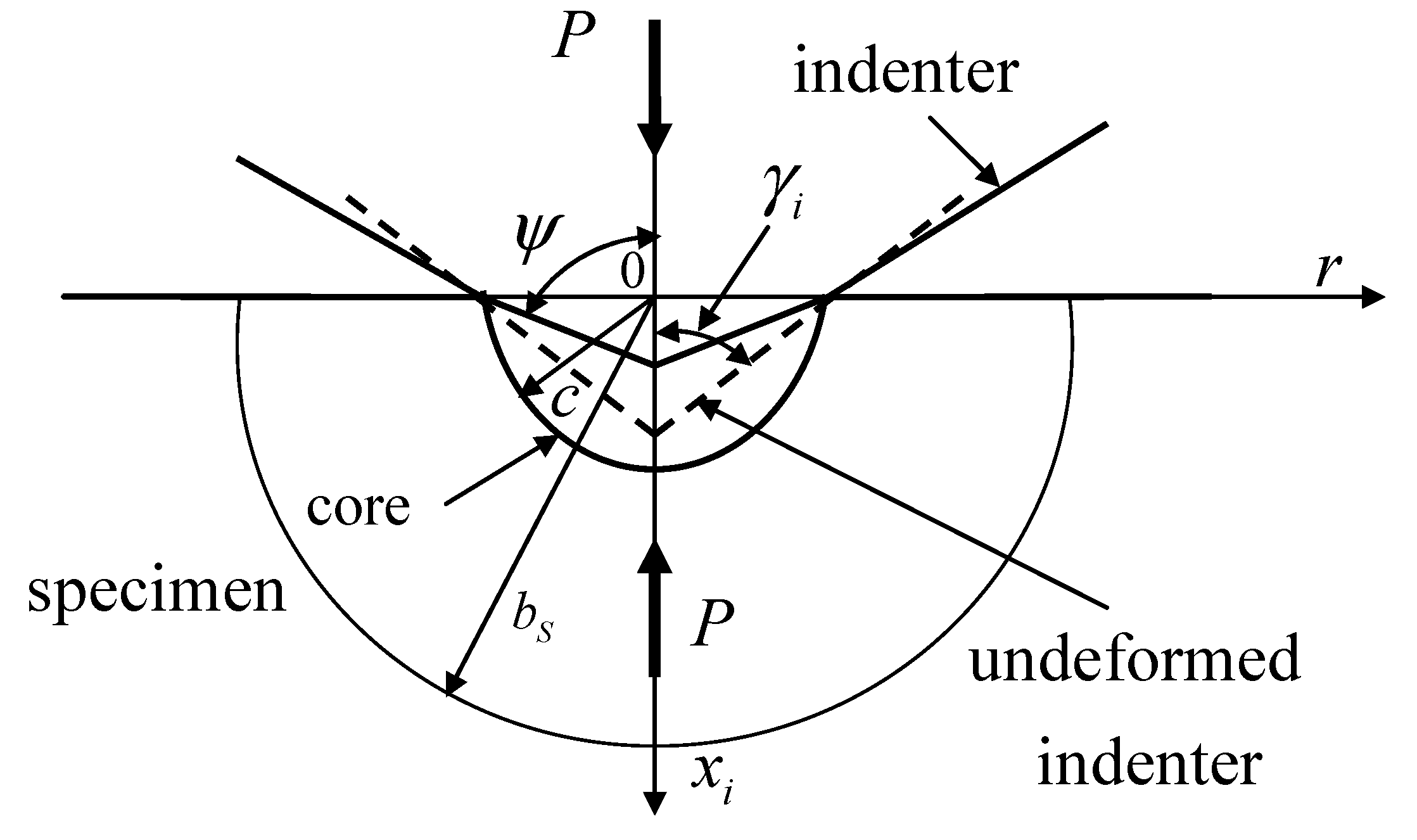

2. Theoretical Background. Scheme and Equations of the Improved Model

3. Results and Discussion

3.1. Comparative Analysis of the Deformation Process during Indentation of Materials with Different Types of Interatomic Bond and Different Crystalline Structures

3.2. Relation between the Tabor Parameter С = НМ/YS and Plasticity Characteristic δН

3.2.1. Plasticity Characteristic δН Determined by Indentation

3.2.2. Relation between the Relative Size of the Elastoplastic Zone x = bS/c and the Plasticity Characteristic δН

3.2.3. Yield Strength YS and Tabor Parameter НМ/YS in the Considered Model

3.3. Physical Nature of Increase of the Tabor Parameter С = НМ/YS with Increase in the Plasticity δН

3.4. Relaxed Effective Apex Angle of a Hardness Indent γSR and Apex Angle of an Indenter under Load ψ

3.5. Simple Method of Determination of the Tabor Parameter С = НМ/YS and Yield Strength YS from the Hardness НМ Determined with a Pyramidal Indenter

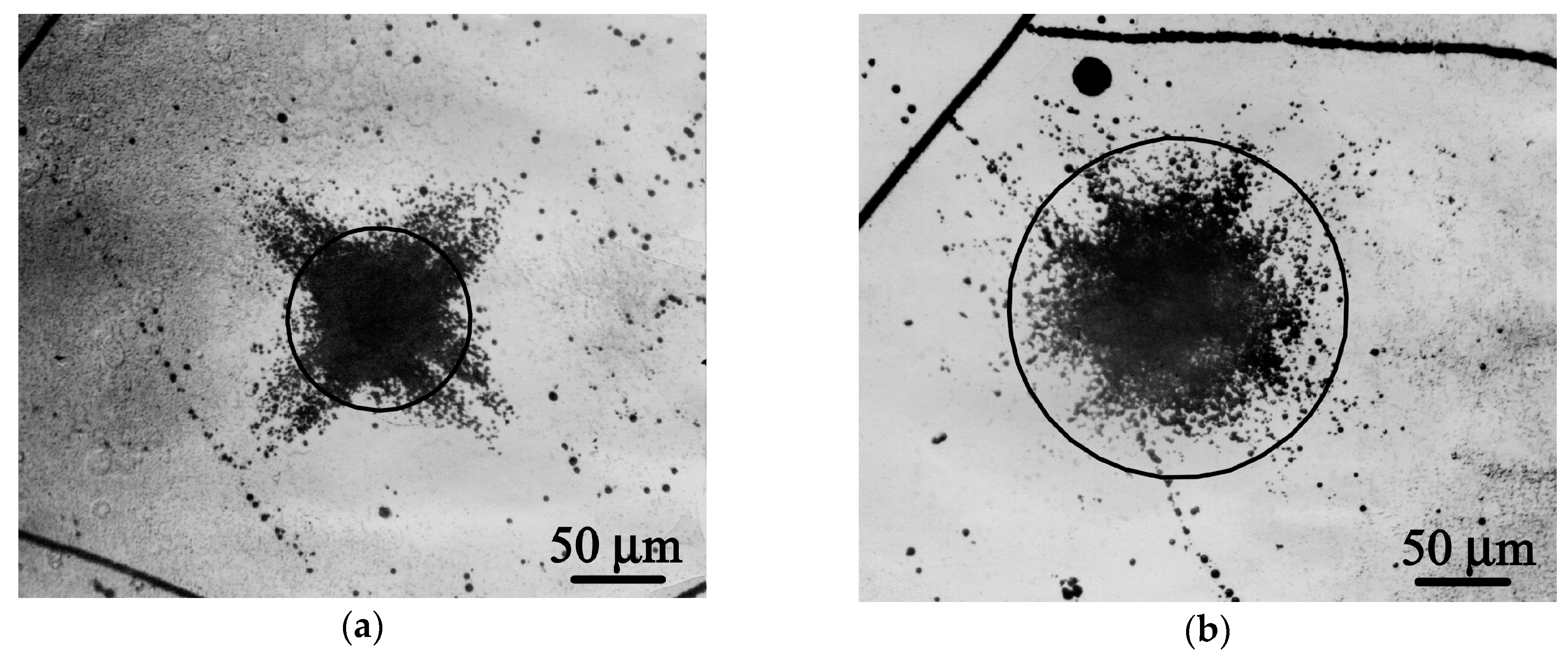

3.6. Experimental Check of the Values of the Tabor Parameter С = НМ/YS and the Radius of Elastoplastic Zone bS.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Walley, S.M. Historical origins of indentation hardness testing. Mater. Sci. Technol. 2012, 28, 1028–1044. [Google Scholar] [CrossRef]

- Walley, S.M. Addendum and correction to ‘Historical origins of indentation hardness testing’. Mater. Sci. Technol. 2013, 29, 1148. [Google Scholar] [CrossRef]

- Johnson, K.L. The correlation of indentation experiments. J. Mech. Phys. Solids 1970, 18, 115–126. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Tanaka, K. Elastic/plastic indentation hardness and indentation fracture toughness: The inclusion core model. J. Mater. Sci. 1987, 22, 1501–1508. [Google Scholar] [CrossRef]

- Mata, M.; Anglada, M.; Alcala, J. A hardness equation for sharp indentation of elastic-power-low strain-hardening materials. Philos. Mag. A 2002, 82, 1831–1839. [Google Scholar] [CrossRef]

- Kogut, L.; Etsion, I. Elastic-plastic contact analysis of a sphere and a rigid flat. J. Appl. Mech. 2002, 69, 657–662. [Google Scholar] [CrossRef]

- Cheng, Y.-T.; Cheng, C.-M. Analysis of indentation loading curves obtained using conical indenters. Philos. Mag. Lett. 1998, 77, 39–47. [Google Scholar] [CrossRef]

- Cheng, Y.-T.; Cheng, C.-M. What is indentation hardness? Surf. Coat. Technol. 2000, 133–134, 417–424. [Google Scholar] [CrossRef]

- Galanov, B.; Milman, Yu.; Ivakhnenko, S.; Suprun, E.; Chugunova, S.; Golubenko, A.; Tkach, V.; Litvin, P.; Voskoboinik, I. Improved inclusion core model and its application for measuring the hardness of diamond. J. Superhard Mater. 2016, 38, 289–305. [Google Scholar] [CrossRef]

- Tabor, D. The Hardness of Metals; Clarendon Press: Oxford, UK, 1951. [Google Scholar]

- Chaudhri, M.M. Strain hardening around spherical indentations. Phys. Status Solidi A 2000, 182, 641–652. [Google Scholar] [CrossRef]

- Brown, L.M. Indentation size effect and the Hall-Petch ‘law’. Mater. Sci. Forum 2010, 662, 13–26. [Google Scholar] [CrossRef]

- Milman, Y.; Chugunova, S.; Goncharova, I. Plasticity at absolute zero as a fundamental characteristic of dislocation properties. Int. J. Mater. Sci. Appl. 2014, 3, 353–362. [Google Scholar] [CrossRef]

- Stelmashenko, N.A.; Walls, M.G.; Brown, L.M.; Milman, Y.V. Microindentation of W and Mo oriented single crystals: STM study. Acta Metall. Mater. 1993, 41, 2855–2865. [Google Scholar] [CrossRef]

- Nix, W.P.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- McLaughlin, K.K.; Clegg, W.J. Deformation underneath low-load indentations in copper. J. Phys. D Appl. Phys. 2008, 41, 074007. [Google Scholar] [CrossRef]

- Milman, Y.V.; Galanov, B.A.; Chugunova, S.I. Plasticity characteristic obtained through hardness measurement. Acta Metall. Mater. 1993, 41, 2523–2532. [Google Scholar] [CrossRef]

- Gridneva, I.V.; Milman, Y.V.; Trefilov, V.I.; Chugunova, S.I. Analysis of dislocation mobility under concentrated loads at indentations of single crystals. Phys. Status Solidi A 1979, 54, 195–206. [Google Scholar] [CrossRef]

- Trefilov, V.I.; Milman, Y.V.; Grigoriev, O.N. Deformation and rupture of crystals with covalent interatomic bonds. Prog. Cryst. Growth. Charact. Mater. 1988, 16, 225–277. [Google Scholar] [CrossRef]

- Galanov, B.A.; Milman, Y.V.; Chugunova, S.I.; Goncharova, I.V. Investigation of mechanical properties of high-hardness materials by indentation. J. Superhard Mater. 1999, 3, 23. [Google Scholar]

- Milman, Y.V.; Chugunova, S.I.; Goncharova, I.V. Plasticity characteristic obtained by indentation technique for crystalline and noncrystalline materials in the wide temperature range. High Temp. Mater. Process. 2006, 25, 39–46. [Google Scholar] [CrossRef]

- Milman, Y.V.; Miracle, D.B.; Chugunova, S.I.; Voskoboinik, I.V.; Korzhova, N.P.; Legkaya, T.N.; Podrezov, Y.N. Mechanical behaviour of Al3Ti intermetallic and L12 phases on its basis. Intermetallics 2001, 9, 839–845. [Google Scholar] [CrossRef]

- Milman, Y.V. The effect of structural state and temperature on mechanical properties and deformation mechanisms of WC-Co hard alloy. J. Superhard Mater. 2014, 36, 65–81. [Google Scholar] [CrossRef]

- Milman, Y.V.; Luyckx, S.; Goncharuck, A.V.; Northrop, J.T. Results from bending tests on submicron and micron WC-Co grades at elevated temperatures. Int. J. Refract. Met. Hard Mater. 2002, 20, 71–79. [Google Scholar] [CrossRef]

- Gridneva, I.V.; Milman, Y.V.; Trefilov, V.I. Phase transition in diamond structure crystals at hardness measurement. Phys. Status Solidi A 1972, 14, 177–182. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Milman, Y.V. On the cracks self-healing mechanism at ductile mode cutting of silicon. Tribol. Int. 2014, 80, 166–171. [Google Scholar] [CrossRef]

- Orlov, A.N.; Regel, V.R. Plasticity. In Physical Encyclopedic Dictionary; Soviet Encyclopaedia: Moscow, Russia, 1965; p. 39. (In Russian) [Google Scholar]

- Plasticity (Physics), Wikipedia. Available online: https://en.wikipedia.org/wiki/Plasticity_%28physics%29 (accessed on 15 March 2017).

- Milman, Y.V.; Chugunova, S.I.; Goncharova, I.V. Plasticity determined by indentation and theoretical plasticity of materials. Bull. Russ. Acad. Sci. Phys. 2009, 73, 1215–1221. [Google Scholar] [CrossRef]

- Bozzini, B.; Boniardi, M.; Fanigliulo, A.; Bogani, F. Tribological properties of electroless Ni-P/diamond composite films. Mater. Res. Bull. 2001, 36, 1889–1902. [Google Scholar] [CrossRef]

- Boldt, P.H.; Weatherly, G.C.; Embury, J.D. A transmission electron microscope study of hardness indentations in MoSi2. J. Mater. Res. 2000, 15, 1025–1031. [Google Scholar] [CrossRef]

- Qiang, J.B.; Zhang, W.; Xie, G.; Kimura, H.; Dong, C.; Inoue, A. An in situ bulk Zr58Al9Ni9Cu14Nb10 quasicrystal-glass composite with superior room temperature mechanical properties. Intermetallics 2007, 15, 1197–1201. [Google Scholar] [CrossRef]

- Lanin, A.G.; Lotsko, D.V.; Milman, Y.V.; Sibirtsev, S.A.; Fedorova, V.N.; Chugunova, S.I. The effect of temperature on the mobility of dislocations at the penetration of the indenter into a single crystal of molybdenum (001). Phys. Met. 1989, 11, 50–55. (In Russian) [Google Scholar]

| Materials | НМ, GPa | ES, GPa | νS | C = HM/Ys | Ys, GPa | δН | x = bS/c | ψ, deg. | γSR, deg. | |

|---|---|---|---|---|---|---|---|---|---|---|

| FCC metals | Al | 0.173 | 71 | 0.35 | 4.02 | 0.043 | 0.99 | 5.33 | 68.01 | 68.12 |

| Au | 0.270 | 78 | 0.42 | 3.86 | 0.07 | 0.99 | 4.84 | 68.02 | 68.27 | |

| Cu | 0.486 | 130 | 0.343 | 3.74 | 0.13 | 0.98 | 4.47 | 68.04 | 68.32 | |

| Ni | 0.648 | 210 | 0.29 | 3.81 | 0.17 | 0.98 | 4.68 | 68.05 | 68.29 | |

| BCC metals | Cr | 1.404 | 298 | 0.31 | 3.42 | 0.41 | 0.97 | 3.98 | 68.10 | 68.47 |

| Ta | 0.972 | 185 | 0.342 | 3.35 | 0.29 | 0.97 | 3.88 | 68.07 | 68.48 | |

| V | 0.864 | 127 | 0.365 | 3.20 | 0.27 | 0.97 | 3.54 | 68.06 | 68.58 | |

| Мо (111) | 1.998 | 324 | 0.293 | 3.17 | 0.63 | 0.96 | 3.52 | 68.14 | 68.64 | |

| Nb | 0.972 | 104 | 0.397 | 2.94 | 0.33 | 0.96 | 3.16 | 68.07 | 68.76 | |

| Fe | 1.512 | 211 | 0.28 | 3.02 | 0.50 | 0.95 | 3.29 | 68.11 | 68.69 | |

| W (001) | 4.320 | 420 | 0.28 | 2.73 | 1.58 | 0.92 | 2.80 | 68.31 | 69.15 | |

| HCP metals | Ti | 1.112 | 120 | 0.36 | 2.93 | 0.38 | 0.95 | 3.09 | 68.08 | 68.79 |

| Zr | 1.156 | 98 | 0.38 | 2.75 | 0.42 | 0.95 | 2.83 | 68.08 | 68.97 | |

| Re | 3.024 | 466 | 0.26 | 3.09 | 0.63 | 0.95 | 3.38 | 68.22 | 68.75 | |

| Mg | 0.324 | 44.7 | 0.291 | 2.94 | 0.11 | 0.95 | 3.3 | 68.02 | 68.60 | |

| Be | 1.620 | 318 | 0.024 | 3.05 | 0.53 | 0.94 | 3.35 | 68.12 | 68.56 | |

| Co | 1.836 | 211 | 0.32 | 2.91 | 0.63 | 0.94 | 3.10 | 68.13 | 68.82 | |

| Intermetallics (IM) | Al66Mn11Ti23 (IM3) | 2.203 | 168 | 0.19 | 2.42 | 0.91 | 0.87 | 2.42 | 68.16 | 69.27 |

| Al61Cr12Ti27 (IM2) | 3.456 | 178 | 0.19 | 2.08 | 1.66 | 0.81 | 2.03 | 68.25 | 69.90 | |

| Al3Ti (IM1) | 5.335 | 156 | 0.30 | 1.67 | 3.19 | 0.76 | 1.65 | 68.38 | 71.16 | |

| Metallic glasses (MG) | Fe40Ni38Mo4B18 (MG2) | 7.992 | 152 | 0.30 | 1.25 | 6.39 | 0.62 | 1.34 | 68.58 | 72.90 |

| Co50Ni10Fe5Si12B17 (MG3) | 9.288 | 167 | 0.30 | 1.19 | 7.80 | 0.60 | 1.30 | 68.67 | 73.25 | |

| Fe83B17 (MG1) | 10.044 | 171 | 0.30 | 1.14 | 8.84 | 0.58 | 1.26 | 68.73 | 73.58 | |

| Quasicrystalls (QC) | Al70Pd20Mn10 (QC2) | 7.560 | 200 | 0.28 | 1.55 | 4.88 | 0.71 | 1.55 | 68.54 | 71.67 |

| Al63Cu25Fe12 (QC1) | 8.024 | 113 | 0.28 | 0.97 | 8.30 | 0.48 | 1.16 | 68.58 | 74.54 | |

| Refractory compounds | WC (0001) | 18.036 | 700 | 0.31 | 1.89 | 9.56 | 0.81 | 1.84 | 69.31 | 71.40 |

| NbC (100) | 25.920 | 550 | 0.21 | 1.22 | 21.26 | 0.54 | 1.32 | 69.89 | 74.02 | |

| LaB6 (001) | 23.220 | 439 | 0.20 | 1.13 | 20.51 | 0.50 | 1.26 | 69.69 | 74.34 | |

| TiC (100) | 25.920 | 465 | 0.191 | 1.08 | 24.07 | 0.46 | 1.23 | 69.89 | 74.83 | |

| ZrC (100) | 23.760 | 410 | 0.196 | 1.06 | 22.48 | 0.46 | 1.22 | 69.73 | 74.85 | |

| Al2O3 (0001) | 22.032 | 323 | 0.23 | 0.94 | 23.40 | 0.41 | 1.15 | 69.60 | 75.56 | |

| α-SiC (0001) | 32.400 | 457 | 0.22 | 0.87 | 37.24 | 0.36 | 1.11 | 70.38 | 76.77 | |

| Covalent crystals | Ge (111) | 7.776 | 130 | 0.21 | 1.10 | 7.06 | 0.49 | 1.24 | 68.56 | 73.75 |

| Si (111) | 11.340 | 160 | 0.22 | 0.96 | 11.84 | 0.42 | 1.16 | 68.82 | 74.99 | |

| Industrial alloys | Steel 0.45%C | 1.890 | 204 | 0.285 | 2.74 | 0.69 | 0.93 | 2.79 | 68.14 | 68.88 |

| Al alloy #5083 | 1.030 | 70.1 | 0.33 | 2.51 | 0.41 | 0.91 | 2.49 | 68.07 | 69.23 | |

| Material | Y7.6%, GPa | Cexp |

|---|---|---|

| Al | 0.041 | 4.21 |

| Al alloy #5083 | 0.373 | 2.76 |

| Steel 0.45%C | 0.64 | 2.95 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galanov, B.A.; Milman, Y.V.; Chugunova, S.I.; Goncharova, I.V.; Voskoboinik, I.V. Application of the Improved Inclusion Core Model of the Indentation Process for the Determination of Mechanical Properties of Materials. Crystals 2017, 7, 87. https://doi.org/10.3390/cryst7030087

Galanov BA, Milman YV, Chugunova SI, Goncharova IV, Voskoboinik IV. Application of the Improved Inclusion Core Model of the Indentation Process for the Determination of Mechanical Properties of Materials. Crystals. 2017; 7(3):87. https://doi.org/10.3390/cryst7030087

Chicago/Turabian StyleGalanov, Boris A., Yuly V. Milman, Svetlana I. Chugunova, Irina V. Goncharova, and Igor V. Voskoboinik. 2017. "Application of the Improved Inclusion Core Model of the Indentation Process for the Determination of Mechanical Properties of Materials" Crystals 7, no. 3: 87. https://doi.org/10.3390/cryst7030087