Electroosmotic Flow in Microchannel with Black Silicon Nanostructures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication Methods

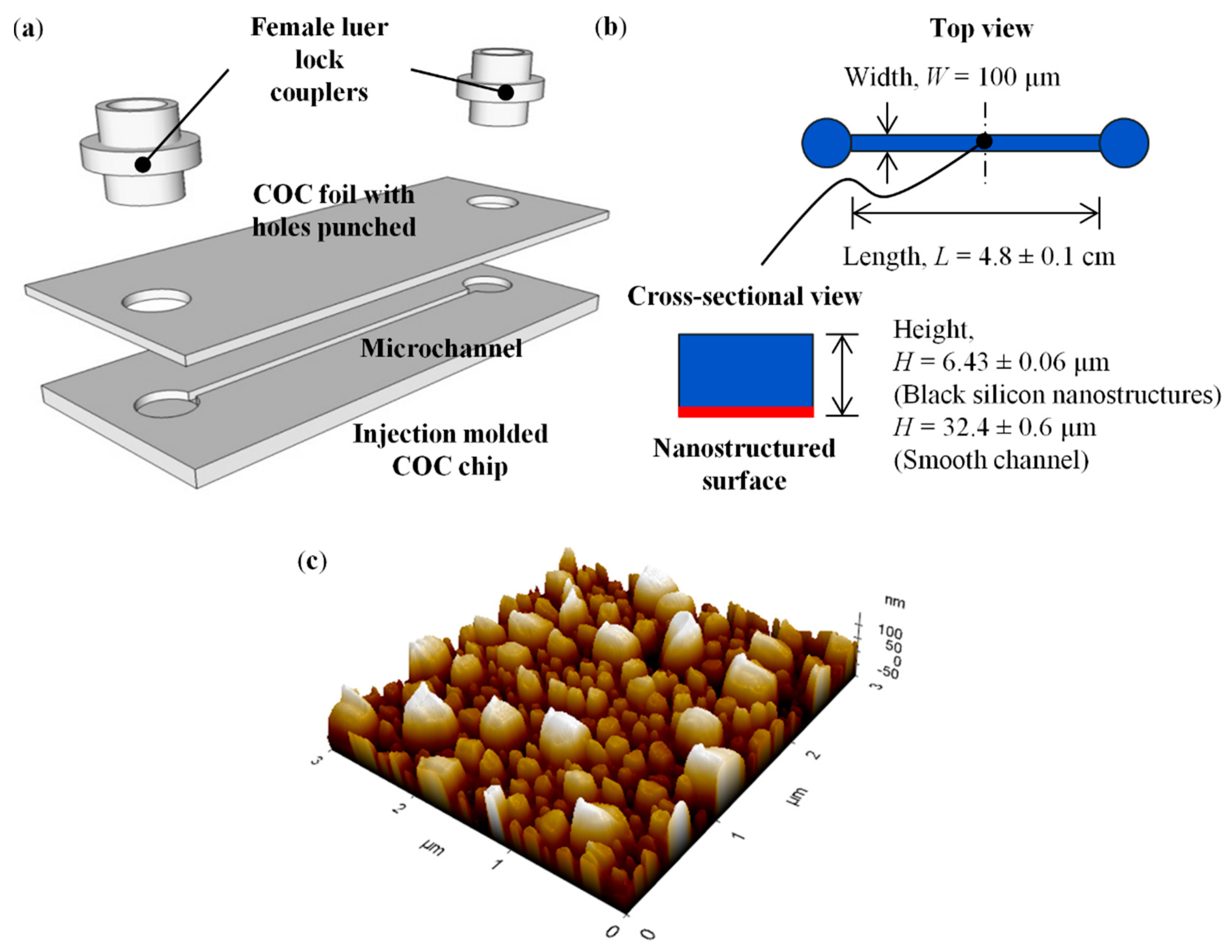

2.1.1. Microchannel Designs with/without Black Silicon Nanostructures

2.1.2. DEEMO Process for the Fabrication of Master Structures on Silicon Wafers

2.1.3. Electroplating of Negative Mold Inserts

2.1.4. Polymer Injection Molding

2.1.5. Thermal Bonding and Integration of Practical Inlet/Outlet Ports

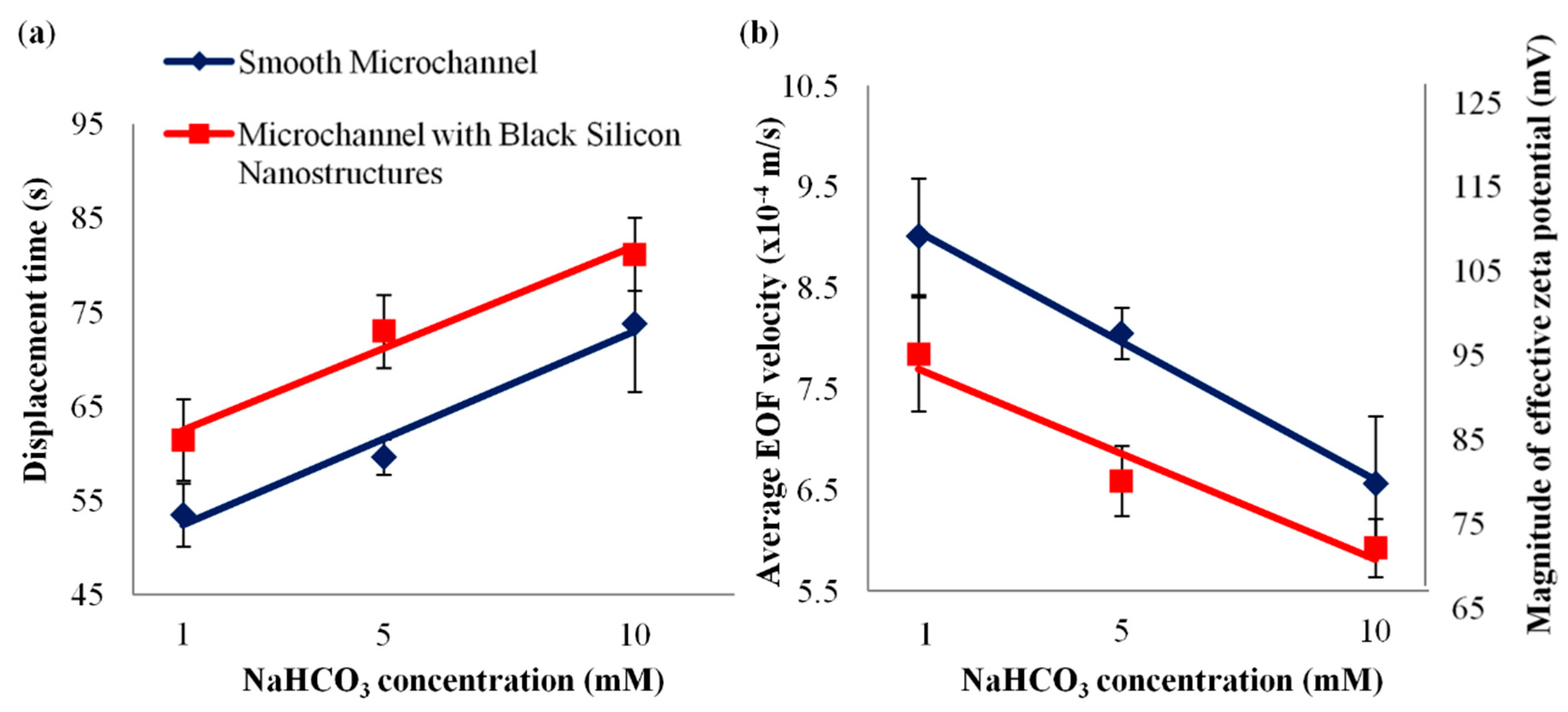

2.2. Current Monitoring Experiments

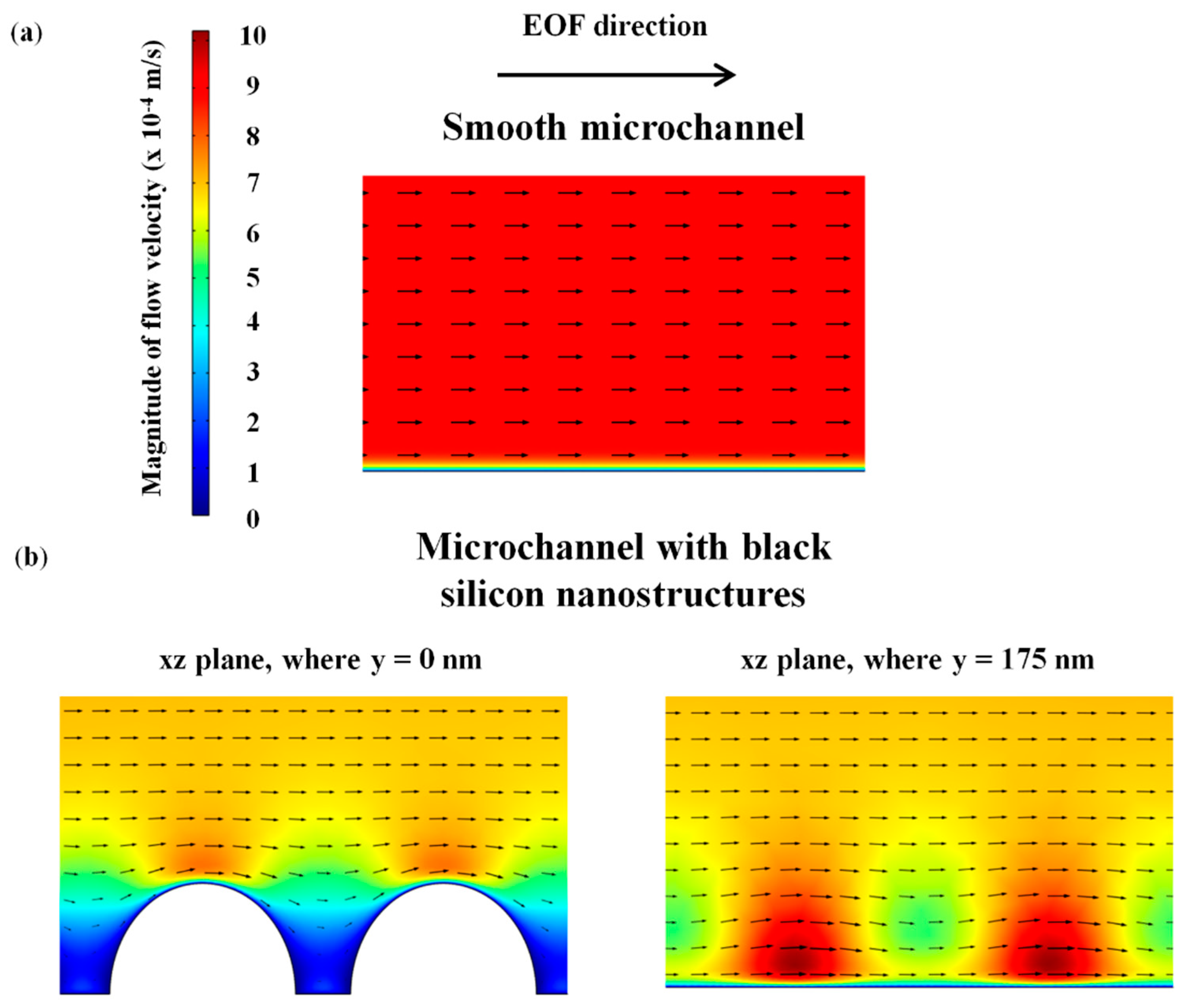

2.3. Numerical Simulations

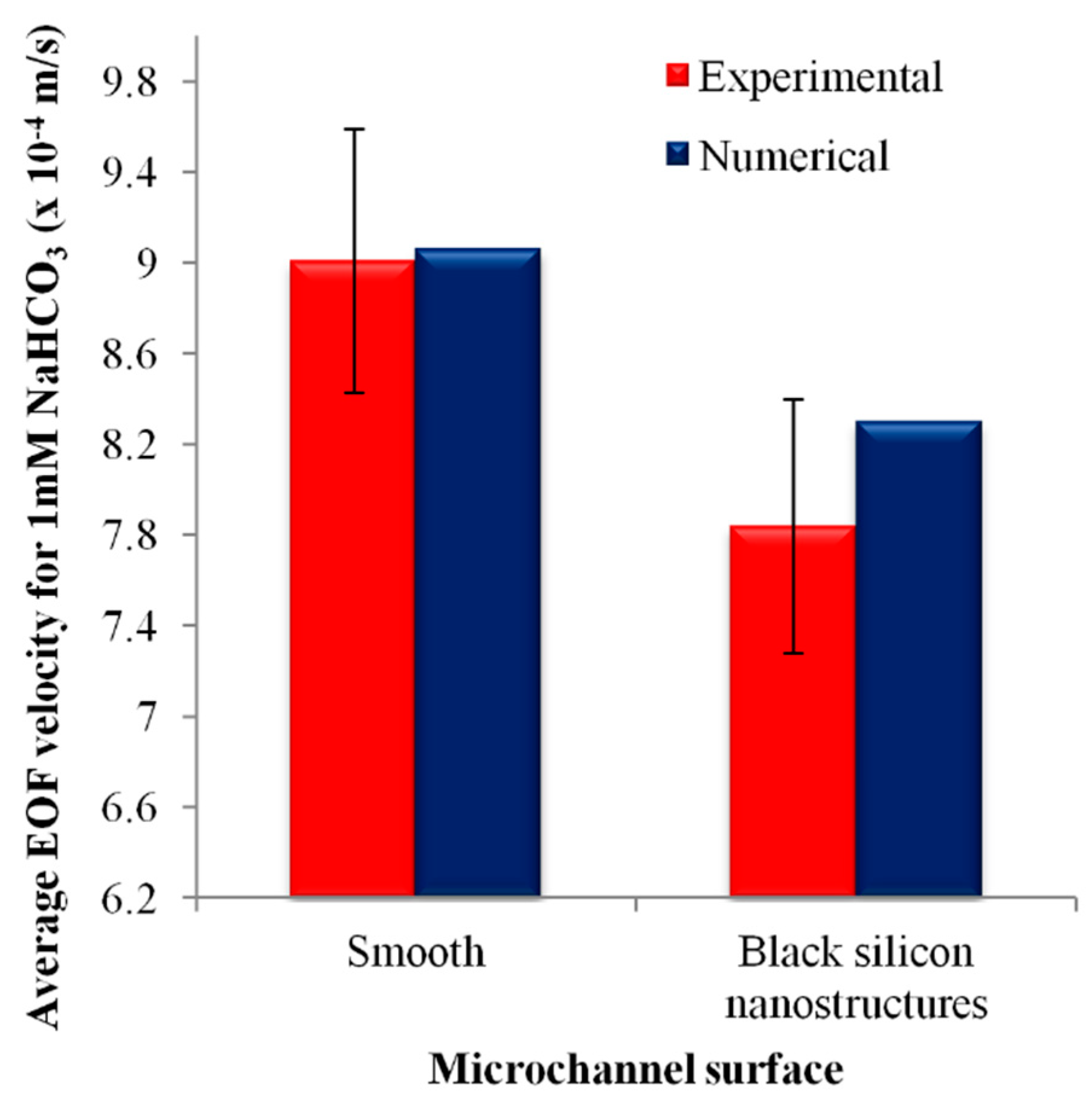

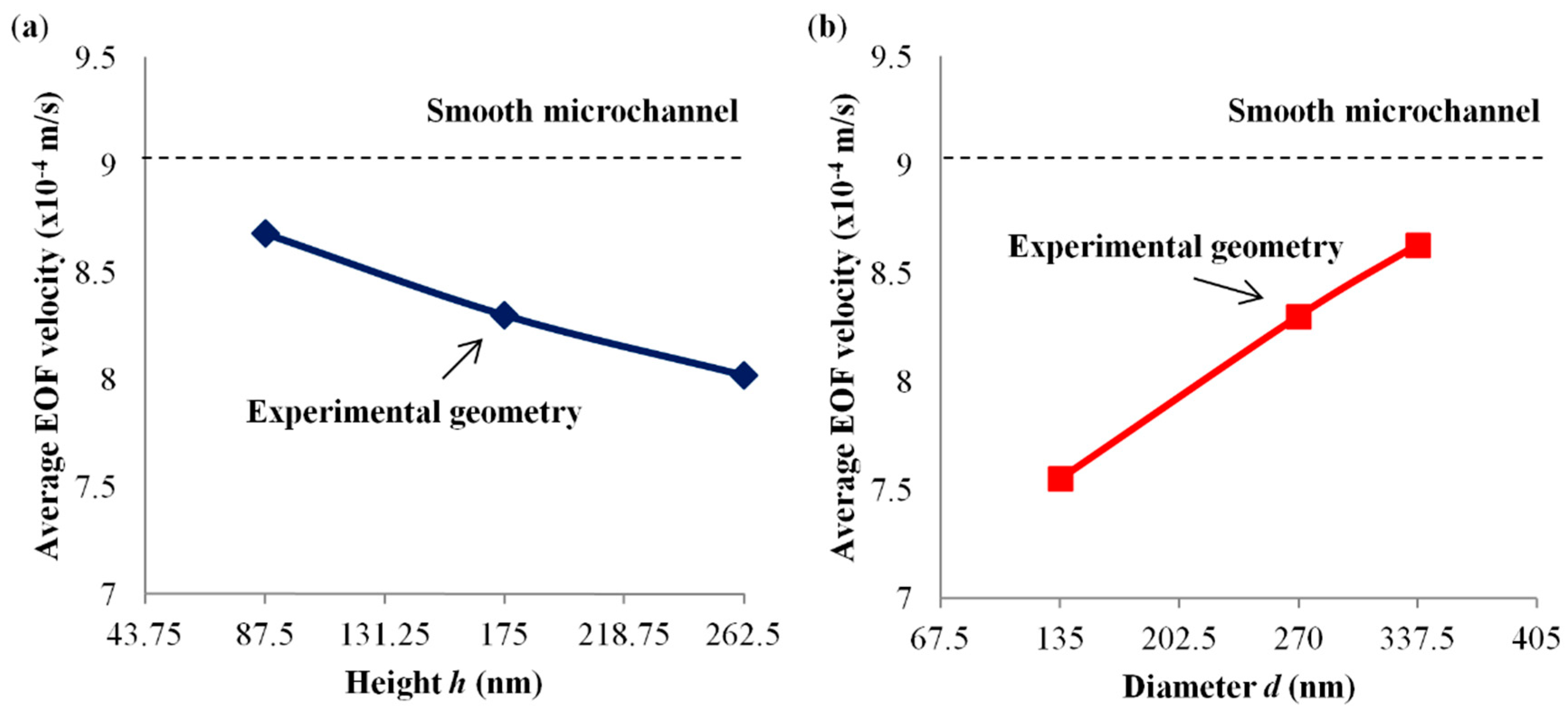

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, X.; Cheng, C.; Wang, S.; Liu, S. Electroosmotic pumps and their applications in microfluidic systems. Microfluid. Nanofluid. 2009, 6, 145–162. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Gui, L. A handy liquid metal based electroosmotic flow pump. Lab Chip 2014, 14, 1866–1872. [Google Scholar] [CrossRef] [PubMed]

- Lim, C.Y.; Lam, Y.C.; Yang, C. Mixing enhancement in microfluidic channel with a constriction under periodic electro-osmotic flow. Biomicrofluidics 2010, 4, 014101. [Google Scholar] [CrossRef] [PubMed]

- Lim, C.Y.; Lam, Y.C. Analysis on micro-mixing enhancement through a constriction under time periodic electroosmotic flow. Microfluid. Nanofluid. 2012, 12, 127–141. [Google Scholar] [CrossRef]

- Chang, C.C.; Yang, R.J. Electrokinetic mixing in microfluidic systems. Microfluid. Nanofluid. 2007, 3, 501–525. [Google Scholar] [CrossRef]

- Chen, L.; Guan, Y.; Ma, J.; Luo, G.; Liu, K. Application of a high-pressure electro-osmotic pump using nanometer silica in capillary liquid chromatography. J. Chromatogr. A 2005, 1064, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Kawamata, T.; Yamada, M.; Yasuda, M.; Seki, M. Continuous and precise particle separation by electroosmotic flow control in microfluidic devices. Electrophoresis 2008, 29, 1423–1430. [Google Scholar] [CrossRef] [PubMed]

- Wong, P.K.; Chen, C.Y.; Wang, T.H.; Ho, C.M. Electrokinetic bioprocessor for concentrating cells and molecules. Anal. Chem. 2004, 76, 6908–6914. [Google Scholar] [CrossRef] [PubMed]

- Hua, Y.; Jemere, A.B.; Dragoljic, J.; Harrison, D.J. Multiplexed electrokinetic sample fractionation, preconcentration and elution for proteomics. Lab Chip 2013, 13, 2651–2659. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, M.; Madadi, H.; Casals-Terré, J. Microfluidic point-of-care blood panel based on a novel technique: Reversible electroosmotic flow. Biomicrofluidics 2015, 9, 054106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bazant, M.Z.; Ben, Y. Theoretical prediction of fast 3d ac electro-osmotic pumps. Lab Chip 2006, 6, 1455–1461. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.Y.; Zhu, J.; Sivan, V.; Gol, B.; Soffe, R.; Zhang, W.; Mitchell, A.; Khoshmanesh, K. Creation of liquid metal 3d microstructures using dielectrophoresis. Adv. Funct. Mater. 2015, 25, 4445–4452. [Google Scholar] [CrossRef]

- So, J.H.; Dickey, M.D. Inherently aligned microfluidic electrodes composed of liquid metal. Lab Chip 2011, 11, 905–911. [Google Scholar] [CrossRef] [PubMed]

- Viovy, J.L. Electrophoresis of DNA and other polyelectrolytes: Physical mechanisms. Rev. Mod. Phys. 2000, 72, 813–872. [Google Scholar] [CrossRef]

- Kuhn, R.; Hoffstetter-Kuhn, S. Capillary Electrophoresis: Principles and Practice; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Bharadwaj, R.; Santiago, J.G. Dynamics of field-amplified sample stacking. J. Fluid Mech. 2005, 543, 57–92. [Google Scholar] [CrossRef]

- Smejkal, P.; Bottenus, D.; Breadmore, M.C.; Guijt, R.M.; Ivory, C.F.; Foret, F.; Macka, M. Microfluidic isotachophoresis: A review. Electrophoresis 2013, 34, 1493–1509. [Google Scholar] [CrossRef] [PubMed]

- Horvath, J.; Dolnik, V. Polymer wall coatings for capillary electrophoresis. Electrophoresis 2001, 22, 644–655. [Google Scholar] [CrossRef]

- Steiner, F.; Hassel, M. Control of electroosmotic flow in nonaqueous capillary electrophoresis by polymer capillary coatings. Electrophoresis 2003, 24, 399–407. [Google Scholar] [CrossRef] [PubMed]

- Preisler, J.; Yeung, E.S. Characterization of nonbonded poly (ethylene oxide) coating for capillary electrophoresis via continuous monitoring of electroosmotic flow. Anal. Chem. 1996, 68, 2885–2889. [Google Scholar] [CrossRef] [PubMed]

- Iki, N.; Yeung, E.S. Non-bonded poly(ethylene oxide) polymer-coated column for protein separation by capillary electrophoresis. J. Chromatogr. A 1996, 731, 273–282. [Google Scholar] [CrossRef]

- Cuñat-Walter, M.; Bossú, E.; Engelhardt, H. Chiral separations with coated and uncoated capillaries. J. Capill. Electrophor. 1996, 3, 275–279. [Google Scholar]

- Belder, D.; Deege, A.; Husmann, H.; Kohler, F.; Ludwig, M. Cross-linked poly(vinyl alcohol) as permanent hydrophilic column coating for capillary electrophoresis. Electrophoresis 2001, 22, 3813–3818. [Google Scholar] [CrossRef]

- Lucy, C.A.; MacDonald, A.M.; Gulcev, M.D. Non-covalent capillary coatings for protein separations in capillary electrophoresis. J. Chromatogr. A 2008, 1184, 81–105. [Google Scholar] [CrossRef] [PubMed]

- Katayama, H.; Ishihama, Y.; Asakawa, N. Stable cationic capillary coating with successive multiple ionic polymer layers for capillary electrophoresis. Anal. Chem. 1998, 70, 5272–5277. [Google Scholar] [CrossRef] [PubMed]

- Kaji, N.; Tezuka, Y.; Takamura, Y.; Ueda, M.; Nishimoto, T.; Nakanishi, H.; Horiike, Y.; Baba, Y. Separation of long DNA molecules by quartz nanopillar chips under a direct current electric field. Anal. Chem. 2004, 76, 15–22. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, M.; Kaneno, J.; Kohama, R.; Uehara, M.; Kanno, K.; Fujii, M.; Shimizu, H.; Maeda, H. Preparation of functionalized nanostructures on microchannel surface and their use for enzyme microreactors. Chem. Eng. J. 2004, 101, 277–284. [Google Scholar] [CrossRef]

- Kusakabe, K.; Morooka, S.; Maeda, H. Development of a microchannel catalytic reactor system. Korean J. Chem. Eng. 2001, 18, 271–276. [Google Scholar] [CrossRef]

- Li, D.; Wu, G.S.; Wang, W.; Wang, Y.D.; Liu, D.; Zhang, D.C.; Chen, Y.F.; Peterson, G.P.; Yang, R. Enhancing flow boiling heat transfer in microchannels for thermal management with monolithically-integrated silicon nanowires. Nano Lett. 2012, 12, 3385–3390. [Google Scholar] [CrossRef] [PubMed]

- Nagayama, G.; Sibuya, S.; Kawagoe, M.; Tsuruta, T. Heat transfer enhancement at nanostructured surface in parallel-plate microchannel. In Challenges of Power Engineering and Environment; Cen, K., Chi, Y., Wang, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Ng, E.; Chen, K.; Hang, A.; Syed, A.; Zhang, J.X.J. Multi-dimensional nanostructures for microfluidic screening of biomarkers: From molecular separation to cancer cell detection. Ann. Biomed. Eng. 2016, 44, 847–862. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yin, H.; Que, L. A microfluidic nanostructured fluorescence sensor for biomolecular binding detection. In Proceedings of the IEEE Sensors, Baltimore, MD, USA, 3–6 November 2013. [Google Scholar]

- Yasui, T.; Kaji, N.; Mohamadi, M.R.; Okamoto, Y.; Tokeshi, M.; Horiike, Y.; Baba, Y. Electroosmotic flow in microchannels with nanostructures. ACS Nano 2011, 5, 7775–7780. [Google Scholar] [CrossRef] [PubMed]

- Koga, Y.; Kuriyama, R.; Sato, Y.; Hishida, K.; Miki, N. Effects of micromachining processes on electro-osmotic flow mobility of glass surfaces. Micromachines 2013, 4, 67–79. [Google Scholar] [CrossRef]

- Kang, S.; Suh, Y.K. Numerical analysis on electroosmotic flows in a microchannel with rectangle-waved surface roughness using the poisson–nernst–planck model. Microfluid. Nanofluid. 2009, 6, 461–477. [Google Scholar] [CrossRef]

- Messinger, R.J.; Squires, T.M. Suppression of electro-osmotic flow by surface roughness. Phys. Rev. Lett. 2010, 105, 144503. [Google Scholar] [CrossRef] [PubMed]

- Lim, A.E.; Lim, C.Y.; Lam, Y.C.; Taboryski, R.; Wang, S.R. Effect of nanostructures orientation on electroosmotic flow in a microfluidic channel. Nanotechnology 2017, 28, 255303. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Avouris, P.; Bucchignano, J.; Martel, R.; Sun, S.; Michl, J. Simple fabrication scheme for sub-10 nm electrode gaps using electron-beam lithography. Appl. Phys. Lett. 2002, 80, 865–867. [Google Scholar] [CrossRef]

- Grigorescu, A.E.; Hagen, C.W. Resists for sub-20-nm electron beam lithography with a focus on hsq: State of the art. Nanotechnology 2009, 20, 292001. [Google Scholar] [CrossRef] [PubMed]

- Burn Jeng, L. Deep uv lithography. J. Vac. Sci. Technol. 1975, 12, 1317–1320. [Google Scholar]

- Kawamura, Y.; Toyoda, K.; Namba, S. Deep uv submicron lithography by using a pulsed high-power excimer laser. J. Appl. Phys. 1982, 53, 6489–6490. [Google Scholar] [CrossRef]

- Jansen, H.V.; De Boer, M.J.; Unnikrishnan, S.; Louwerse, M.C.; Elwenspoek, M.C. Black silicon method x: A review on high speed and selective plasma etching of silicon with profile control: An in-depth comparison between bosch and cryostat drie processes as a roadmap to next generation equipment. J. Micromech. Microeng. 2009, 19, 033001. [Google Scholar] [CrossRef]

- Steglich, M.; Käsebier, T.; Zilk, M.; Pertsch, T.; Kley, E.B.; Tünnermann, A. The structural and optical properties of black silicon by inductively coupled plasma reactive ion etching. J. Appl. Phys. 2014, 116, 173503. [Google Scholar] [CrossRef]

- Yue, Z.; Shen, H.; Jiang, Y. Antireflective nanostructures fabricated by reactive ion etching method on pyramid-structured silicon surface. Appl. Sci. Res. 2013, 271, 402–406. [Google Scholar] [CrossRef]

- Telecka, A.; Murthy, S.; Schneider, L.; Pranov, H.; Taboryski, R. Superhydrophobic properties of nanotextured polypropylene foils fabricated by roll-to-roll extrusion coating. ACS Macro Lett. 2016, 5, 1034–1038. [Google Scholar] [CrossRef]

- Schneider, L.; Laustsen, M.; Mandsberg, N.; Taboryski, R. The influence of structure heights and opening angles of micro-and nanocones on the macroscopic surface wetting properties. Sci. Rep. 2016, 6, 21400. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elders, J.; Jansen, H.V.; Elwenspoek, M.; Ehrfeld, W. Deemo: A new technology for the fabrication of microstructures. In Proceedings of the IEEE Micro Electro Mechanical Systems, MEMS’95, Amsterdam, The Netherlands, 29 January–2 February 1995; pp. 238–243. [Google Scholar]

- Tanzi, S.; Ostergaard, P.F.; Matteucci, M.; Christiansen, T.L.; Cech, J.; Marie, R.; Taboryski, R. Fabrication of combined-scale nano- and microfluidic polymer systems using a multilevel dry etching, electroplating and molding process. J. Micromech. Microeng. 2012, 22, 115008. [Google Scholar] [CrossRef]

- Tanzi, S.; Matteucci, M.; Christiansen, T.L.; Friis, S.; Christensen, M.T.; Garnaes, J.; Wilson, S.; Kutchinsky, J.; Taboryski, R. Ion channel recordings on an injection-molded polymer chip. Lab Chip 2013, 13, 4784–4793. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Østergaard, P.F.; Lopacinska-Jørgensen, J.; Pedersen, J.N.; Tommerup, N.; Kristensen, A.; Flyvbjerg, H.; Silahtaroglu, A.; Marie, R.; Taboryski, R. Optical mapping of single-molecule human DNA in disposable, mass-produced all-polymer devices. J. Micromech. Microeng. 2015, 25, 105002. [Google Scholar] [CrossRef]

- Omasu, F.; Nakano, Y.; Ichiki, T. Measurement of the electrophoretic mobility of sheep erythrocytes using microcapillary chips. Electrophoresis 2005, 26, 1163–1167. [Google Scholar] [CrossRef] [PubMed]

- Matteucci, M.; Christiansen, T.L.; Tanzi, S.; Ostergaard, P.F.; Larsen, S.T.; Taboryski, R. Fabrication and characterization of injection molded multi level nano and microfluidic systems. Microelectron. Eng. 2013, 111, 294–298. [Google Scholar] [CrossRef]

- Chang, H.C.; Yeo, L.Y. Electrokinetically Driven Microfluidics and Nanofluidics; Cambridge University Press: New York, NY, USA, 2010. [Google Scholar]

- Kirby, B.J. Micro- and Nanoscale Fluid Mechanics: Transport in Microfluidic Devices; Cambridge University Press: New York, NY, USA, 2010. [Google Scholar]

- Andresen, K.Ø.; Hansen, M.; Matschuk, M.; Jepsen, S.T.; Sørensen, H.S.; Utko, P.; Selmeczi, D.; Hansen, T.S.; Larsen, N.B.; Rozlosnik, N.; et al. Injection molded chips with integrated conducting polymer electrodes for electroporation of cells. J. Micromech. Microeng. 2010, 20, 055010. [Google Scholar] [CrossRef]

- Cech, J.; Taboryski, R. Stability of fdts monolayer coating on aluminum injection molding tools. Appl. Sci. Res. 2012, 259, 538–541. [Google Scholar] [CrossRef]

- Bernard, M.; Jubeli, E.; Bakar, J.; Tortolano, L.; Saunier, J.; Yagoubi, N. Biocompatibility assessment of cyclic olefin copolymers: Impact of two additives on cytotoxicity, oxidative stress, inflammatory reactions, and hemocompatibility. J. Biomed. Mater. Res. A 2017, 105, 3333–3349. [Google Scholar] [CrossRef] [PubMed]

- Persson, F.; Tegenfeldt, J.O. DNA in nanochannels—Directly visualizing genomic information. Chem. Soc. Rev. 2010, 39, 985–999. [Google Scholar] [CrossRef] [PubMed]

- Koh, C.G.; Tan, W.; Zhao, M.-Q.; Ricco, A.J.; Fan, Z.H. Integrating polymerase chain reaction, valving, and electrophoresis in a plastic device for bacterial detection. Anal. Chem. 2003, 75, 4591–4598. [Google Scholar] [CrossRef] [PubMed]

- Søgaard, E.; Andersen, N.K.; Smistrup, K.; Larsen, S.T.; Sun, L.; Taboryski, R. Study of transitions between wetting states on microcavity arrays by optical transmission microscopy. Langmuir 2014, 30, 12960–12968. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Gordon, M.J.; Zare, R.N. Current-monitoring method for measuring the electroosmotic flow-rate in capillary zone electrophoresis. Anal. Chem. 1988, 60, 1837–1838. [Google Scholar] [CrossRef]

- Ren, L.; Escobedo, C.; Li, D. A new method of evaluating the average electro-osmotic velocity in microchannels. J. Colloid Interface Sci. 2002, 250, 238–242. [Google Scholar] [CrossRef] [PubMed]

- Ren, L.; Masliyah, J.; Li, D. Experimental and theoretical study of the displacement process between two electrolyte solutions in a microchannel. J. Colloid Interface Sci. 2003, 257, 85–92. [Google Scholar] [CrossRef]

- Pittman, J.L.; Henry, C.S.; Gilman, S.D. Experimental studies of electroosmotic flow dynamics in microfabricated devices during current monitoring experiments. Anal. Chem. 2003, 75, 361–370. [Google Scholar] [CrossRef] [PubMed]

- Lim, A.E.; Lim, C.Y.; Lam, Y.C. Electroosmotic flow hysteresis for dissimilar ionic solutions. Biomicrofluidics 2015, 9, 024113. [Google Scholar] [CrossRef] [PubMed]

- Lim, A.E.; Lim, C.Y.; Lam, Y.C. Electroosmotic flow hysteresis for dissimilar anionic solutions. Anal. Chem. 2016, 88, 8064–8073. [Google Scholar] [CrossRef] [PubMed]

- Lim, C.Y.; Lim, A.E.; Lam, Y.C. Ionic origin of electro-osmotic flow hysteresis. Sci. Rep. 2016, 6, 22329. [Google Scholar] [CrossRef] [PubMed]

- Lim, C.Y.; Lam, Y.C. Direction dependence of displacement time for two-fluid electroosmotic flow. Biomicrofluidics 2012, 6, 012816. [Google Scholar] [CrossRef] [PubMed]

- Lim, C.Y.; Lim, A.E.; Lam, Y.C. pH change in electroosmotic flow hysteresis. Anal. Chem. 2017, 89, 9394–9399. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, I.; Chandrasekhar, N. Experimental study and numerical estimation of current changes in electroosmotically pumped microfluidic devices. Electrophoresis 2005, 26, 1114–1121. [Google Scholar] [CrossRef] [PubMed]

- Yan, D.G.; Yang, C.; Huang, X.Y. Effect of finite reservoir size on electroosmotic flow in microchannels. Microfluid. Nanofluid. 2007, 3, 333–340. [Google Scholar] [CrossRef]

- Corstjens, H.; Billiet, H.A.H.; Frank, J.; Luyben, K.C.A.M. Variation of the ph of the background electrolyte due to electrode reactions in capillary electrophoresis: Theoretical approach and in situ measurement. Electrophoresis 1996, 17, 137–143. [Google Scholar] [CrossRef] [PubMed]

- Tang, G.; Yan, D.; Yang, C.; Gong, H.; Chai, J.C.; Lam, Y.C. Assessment of joule heating and its effects on electroosmotic flow and eletrophoretic transport of solutes in microfluidic channels. Electrophoresis 2006, 27, 628–639. [Google Scholar] [CrossRef] [PubMed]

- Arulanandam, S.; Li, D. Determining ζ potential and surface conductance by monitoring the current in electro-osmotic flow. J. Colloid Interface Sci. 2000, 225, 421–428. [Google Scholar] [CrossRef] [PubMed]

- Dorrer, C.; Rühe, J. Wetting of silicon nanograss: From superhydrophilic to superhydrophobic surfaces. Adv. Mater. 2008, 20, 159–163. [Google Scholar] [CrossRef]

| Solution (NaHCO3) | Conductivity (µS/cm) | pH |

|---|---|---|

| 0.95 mM | 96.2 ± 0.2 | 8.40 ± 0.01 |

| 1 mM | 99.7 ± 0.1 | 8.32 ± 0.03 |

| 4.75 mM | 436.6 ± 0.5 | 8.72 ± 0.02 |

| 5 mM | 469.4 ± 0.5 | 8.71 ± 0.01 |

| 9.5 mM | 851.2 ± 1.1 | 9.11 ± 0.01 |

| 10 mM | 912.8 ± 0.4 | 9.14 ± 0.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, A.E.; Lim, C.Y.; Lam, Y.C.; Taboryski, R. Electroosmotic Flow in Microchannel with Black Silicon Nanostructures. Micromachines 2018, 9, 229. https://doi.org/10.3390/mi9050229

Lim AE, Lim CY, Lam YC, Taboryski R. Electroosmotic Flow in Microchannel with Black Silicon Nanostructures. Micromachines. 2018; 9(5):229. https://doi.org/10.3390/mi9050229

Chicago/Turabian StyleLim, An Eng, Chun Yee Lim, Yee Cheong Lam, and Rafael Taboryski. 2018. "Electroosmotic Flow in Microchannel with Black Silicon Nanostructures" Micromachines 9, no. 5: 229. https://doi.org/10.3390/mi9050229