Novel EMD-Based Extraction Approach of Electric Field Fringe Impacts on a Micro Capacitive Displacement Sensor

Abstract

:1. Introduction

2. Sensor Model against Fringe Effects

2.1. Sensor Mechanism

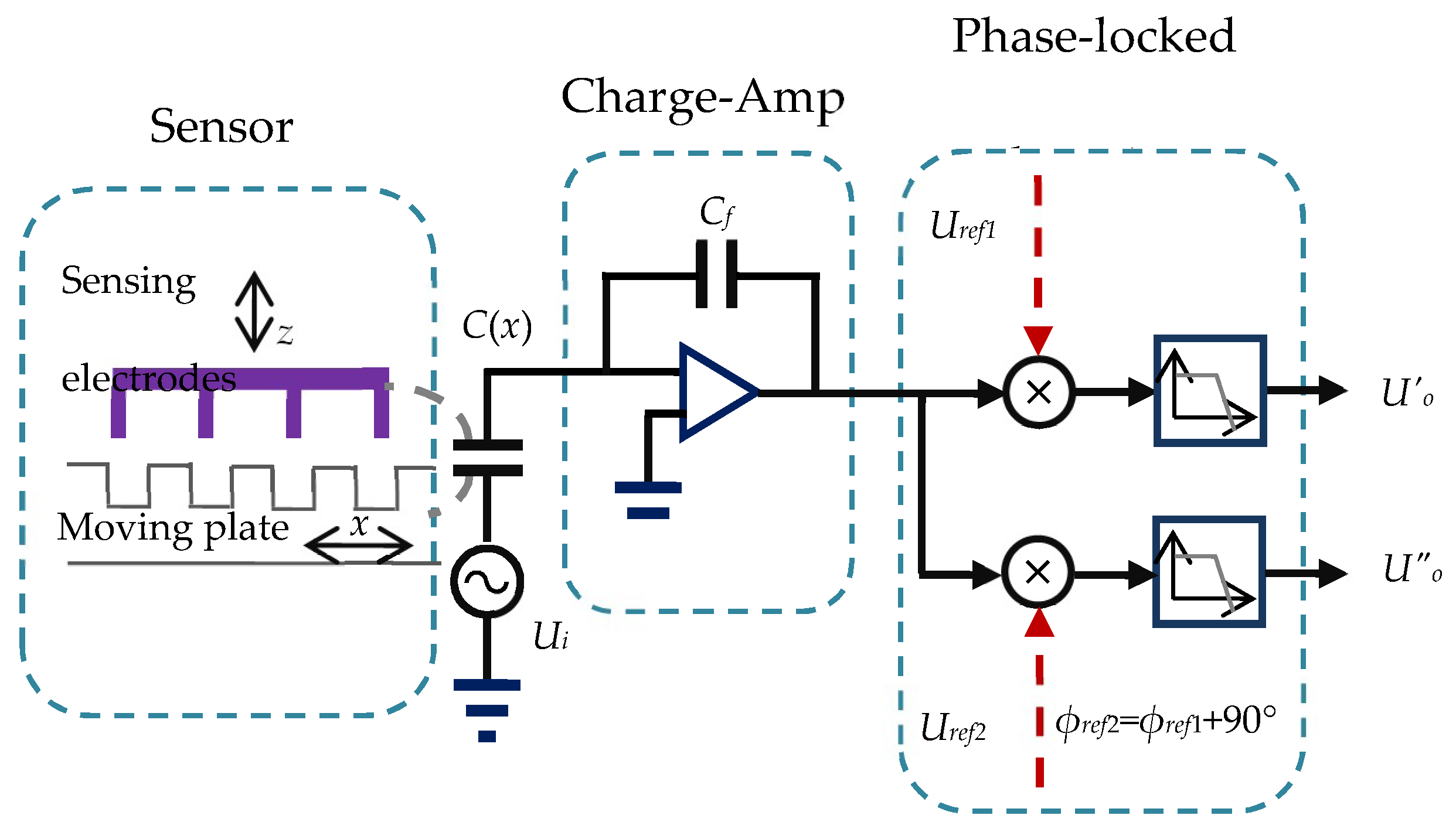

2.2. Measuring Operation against Fringe Effects

3. Theoretical Framework of EMD Filtering Method

- Define any signals from Equations (9) and (10) as x(k), where, k = 1.

- Spline interpolation is fitted to acquire the lower extrema and the upper extrema, which then defines the lower (LE) and upper envelopes (UE). This approach avoids poor numerical stability due to violent oscillation, and at the same time, keeps the acquired linear interpolation continuous and smooth.

- The average envelope, m(k), is calculated as the arithmetic mean value between UE and LE as Equation (13); where, xmax(k) represents the upper envelope, xmin(k) is the lower envelope.

- A candidate IMF, h(k), is estimated as the difference between x(k) and m(k). If h(k) satisfies the following two conditions, then an first IMF it is defined as imf(k). Otherwise, it is assigned as the new x(k) and steps 1–4 are repeated.

- (a)

- In the whole time-series, the number of extrema and the number of zero crossings must be either equal or differ at most by 1.

- (b)

- At any point in the time-series, the mean value of the upper envelope and the lower envelope is 0.

- A partial residue, r(k) comes along with every IMF as Equation (14)

- r(k) is estimated as a new x(k) and steps 1–4 are repeated until the stopping conditions—defined below—are reached, then the sifting process is finalized.

- (a)

- Define a maximum decomposition time, stops when residual component r(k) or the last component becomes smaller than the predetermined value.

- (b)

- Stops when the remaining components become monotonic functions, the intrinsic mode functions cannot be further selected.

4. Experiments and Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fleming, A.J. A review of nanometer resolution position sensors: Operation and performance. Sens. Actuators A Phys. 2013, 190, 106–126. [Google Scholar] [CrossRef]

- Ekinci, K.L.; Roukes, M.L. Nanoelectromechanical systems. Rev. Sci. Instrum. 2005, 76, 061101. [Google Scholar] [CrossRef]

- Gao, W.; Dejima, S.; Kiyono, S. A dual-mode surface encoder for position measurement. Sens. Actuators A Phys. 2005, 117, 95–102. [Google Scholar] [CrossRef]

- Huang, X.H.; Lee, J.I.; Ramakrishnan, N.; Bedillion, M.; Chu, P. Nano-positioning of an electromagnetic scanner with a MEMS capacitive sensor. Mechatronics 2010, 20, 27–34. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, L.; Shen, M. Novel capacitive displacement sensor based on interlocking stator electrodes with sequential commutating excitation. Sens. Actuators A Phys. 2015, 230, 94–101. [Google Scholar] [CrossRef]

- Carvalho, V.; Belsley, M.; Vasconcelos, R.; Soares, F. A comparison of mass parameters determination using capacitive and optical sensors. Sens. Actuators A Phys. 2011, 167, 327–331. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; de Jong, G.; Meijer, G.C.M. Influence of electric-field bending on the nonlinearity of capacitive sensors. IEEE Instrum. Meas. 2000, 49, 256–259. [Google Scholar] [CrossRef]

- Kang, D.; Moon, W. Electrode configuration method with surface profile effect in a contact-type area-varying capacitive displacement sensor. Sens. Actuators A Phys. 2013, 189, 33–44. [Google Scholar]

- Kuijpers, A.A.; Krijnen, G.J.M.; Wiegerink, R.J.; Lammerink, T.S.J.; Elwenspoek, M. A micromachined capacitive incremental position sensor: Part 1. Analysis and simulations. J. Micromech. Microeng. 2006, 16, S116–S124. [Google Scholar] [CrossRef]

- Lee, J.I.; Huang, X.H.; Chu, P.B. Nanoprecision MEMS Capacitive Sensor for Linear and Rotational Positioning. J. Microelectromech. Syst. 2009, 18, 660–670. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, B.; Li, Z.; Liu, Z. A novel high voltage LDMOS for HVIC with the multiple step shaped equipotential rings. Solid-State Electron. 2007, 51, 394–397. [Google Scholar] [CrossRef]

- Benedek, P.; Silvester, P. Capacitance of Parallel Rectangular Plates Separated by a Dielectric Sheet. IEEE Trans. Microw. Theory 1972, MTT-20, 504–510. [Google Scholar] [CrossRef]

- Wolff, I.; Knoppik, N. Rectangular and Circular Microstrip Disk Capacitors and Resonators. IEEE Trans. Microw. Theory 1974, MT22, 857–864. [Google Scholar] [CrossRef]

- Wheeler, H.A. Transmission-Line Properties of Parallel Strips Separated by a Dielectric Sheet. IEEE Trans. Microw. Theory 1965, 13, 172–185. [Google Scholar] [CrossRef]

- Yu, J.P.; Wang, W.; Li, X.; Zhou, Z.Z. A Novel Quadrature Signal Estimation Method for a Planar Capacitive Incremental Displacement Sensor. Meas. Sci. Rev. 2016, 16, 127–133. [Google Scholar] [CrossRef]

- Zhuang, Y.; Wan, Y. Joint estimation of carrier frequency offset and in-phase/quadrature-phase imbalances for orthogonal frequency division multiplexing systems. Comput. Electr. Eng. 2015, 48, 1–11. [Google Scholar] [CrossRef]

- Trusiak, M.; Wielgus, M.; Patorski, K. Advanced processing of optical fringe patterns by automated selective reconstruction and enhanced fast empirical mode decomposition. Opt. Laser. Eng. 2014, 52, 230–240. [Google Scholar] [CrossRef]

- Yaslan, Y.; Bican, B. Empirical mode decomposition based denoising method with support vector regression for time series prediction: A case study for electricity load forecasting. Measurement 2017, 103, 52–61. [Google Scholar] [CrossRef]

- Kizilkaya, A.; Elbi, M.D. Optimal signal reconstruction based on time-varying weighted empirical mode decomposition. Comput. Electr. Eng. 2017, 57, 28–42. [Google Scholar] [CrossRef]

- Han, G.; Lin, B.; Xu, Z. Electrocardiogram signal denoising based on empirical mode decomposition technique: An overview. J. Instrum. 2017, 12, P03010. [Google Scholar] [CrossRef]

- Brookhuis, R.A.; Lammerink, T.S.J.; Wiegerink, R.J. Differential capacitive sensing circuit for a multi-electrode capacitive force sensor. Sens. Actuators A Phys. 2015, 234, 168–179. [Google Scholar] [CrossRef]

- Singh, T.; Saether, T.; Ytterdal, T. Current-Mode Capacitive Sensor Interface Circuit with Single-Ended to Differential Output Capability. IEEE Trans. Instrum. Meas. 2009, 58, 3914–3920. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.-P.; Du, H.-L.; Li, X. Novel EMD-Based Extraction Approach of Electric Field Fringe Impacts on a Micro Capacitive Displacement Sensor. Micromachines 2018, 9, 211. https://doi.org/10.3390/mi9050211

Yu J-P, Du H-L, Li X. Novel EMD-Based Extraction Approach of Electric Field Fringe Impacts on a Micro Capacitive Displacement Sensor. Micromachines. 2018; 9(5):211. https://doi.org/10.3390/mi9050211

Chicago/Turabian StyleYu, Jian-Ping, Hui-Lin Du, and Xin Li. 2018. "Novel EMD-Based Extraction Approach of Electric Field Fringe Impacts on a Micro Capacitive Displacement Sensor" Micromachines 9, no. 5: 211. https://doi.org/10.3390/mi9050211