Micromachining Microchannels on Cyclic Olefin Copolymer (COC) Substrates with the Taguchi Method

Abstract

:1. Introduction

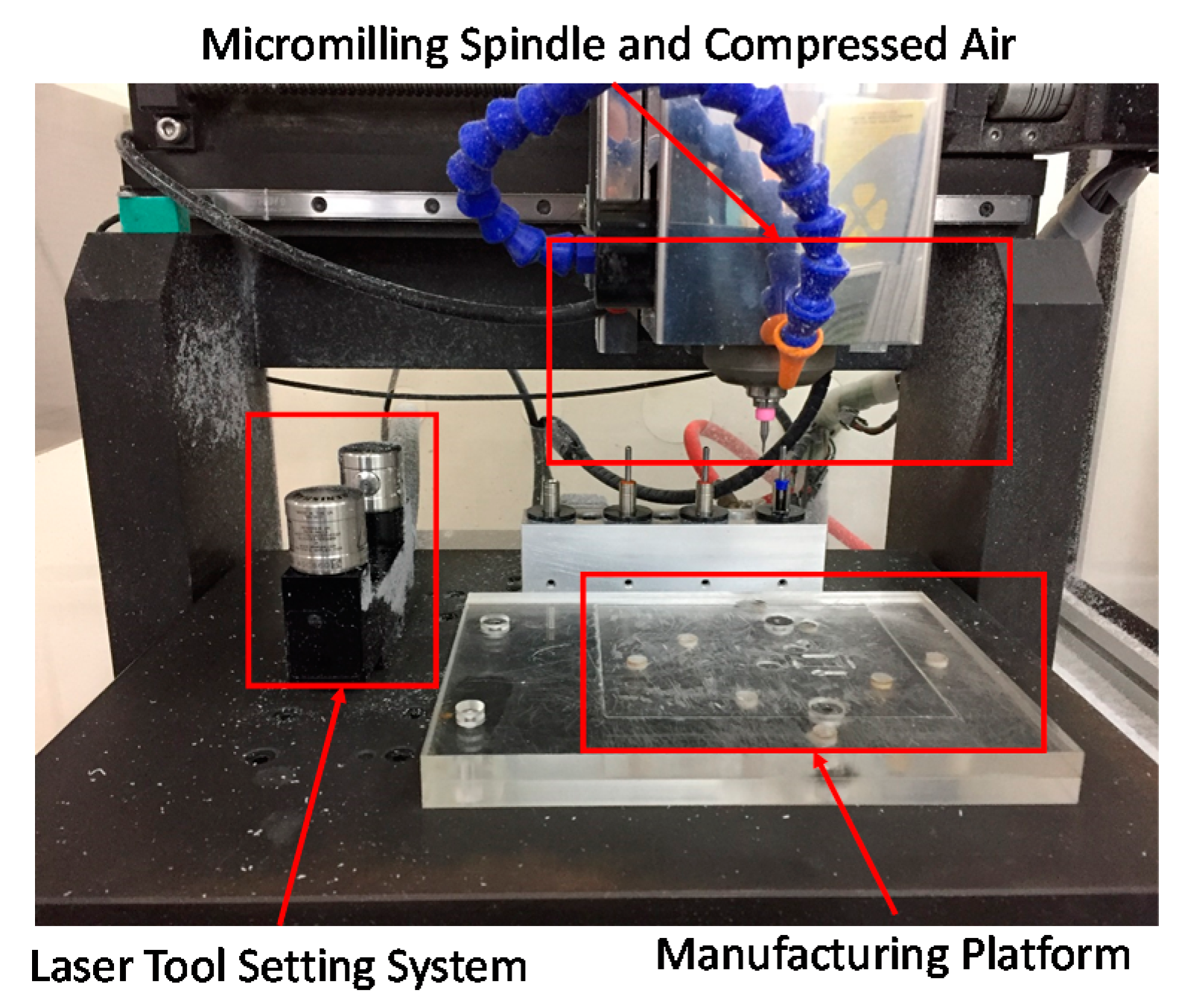

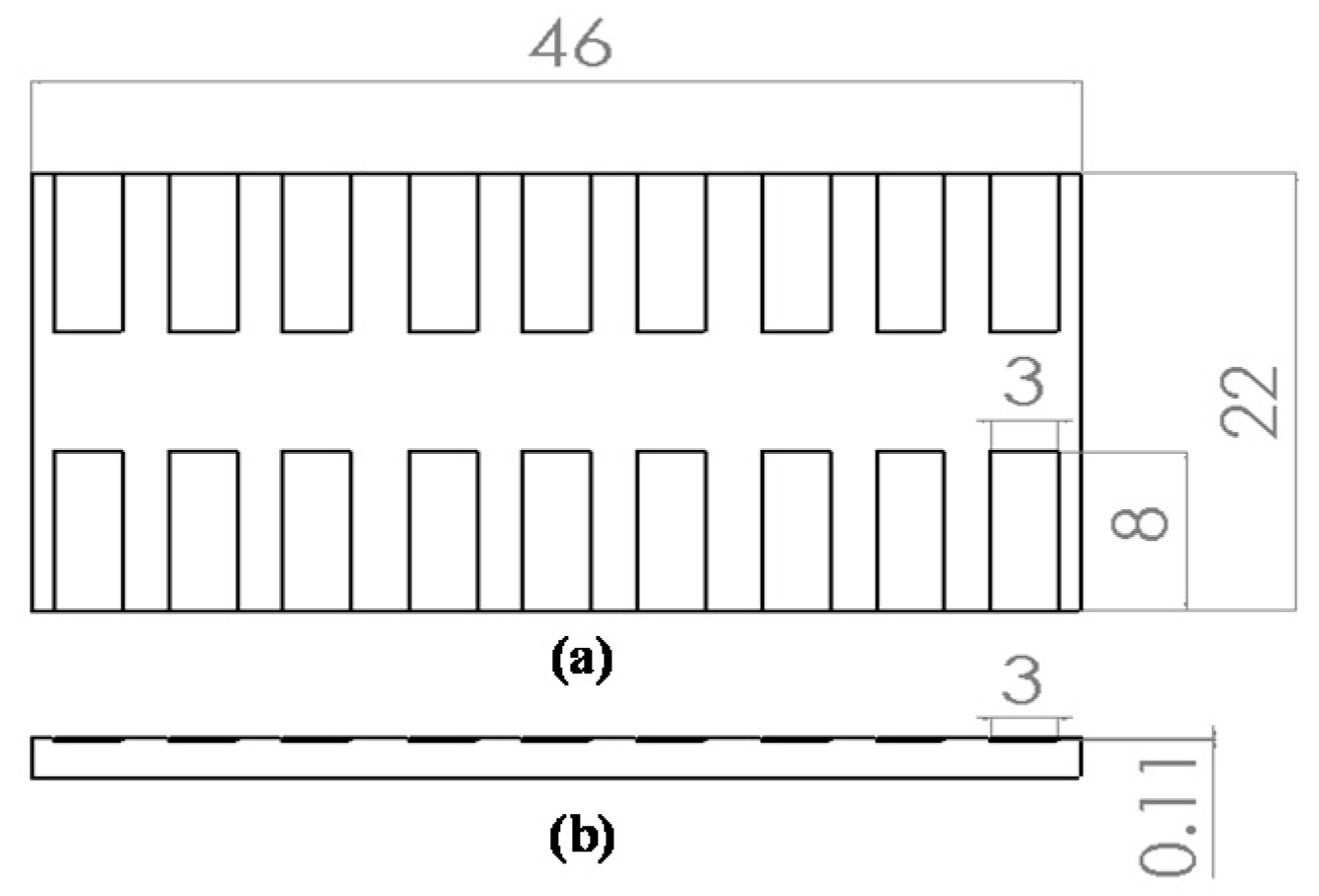

2. Experiment Design and Procedure

3. Results and Discussion

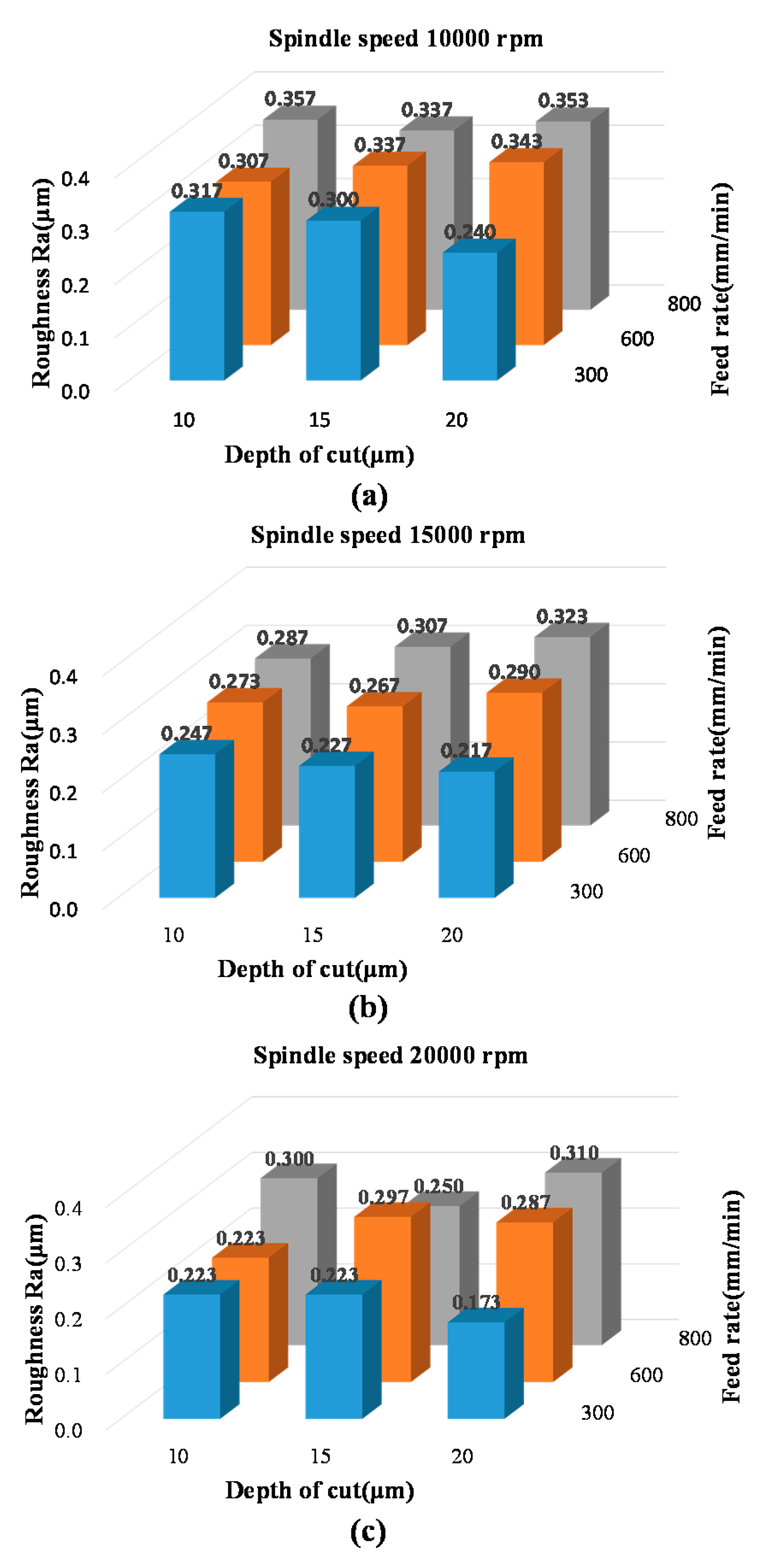

3.1. Experimental Result Analysis

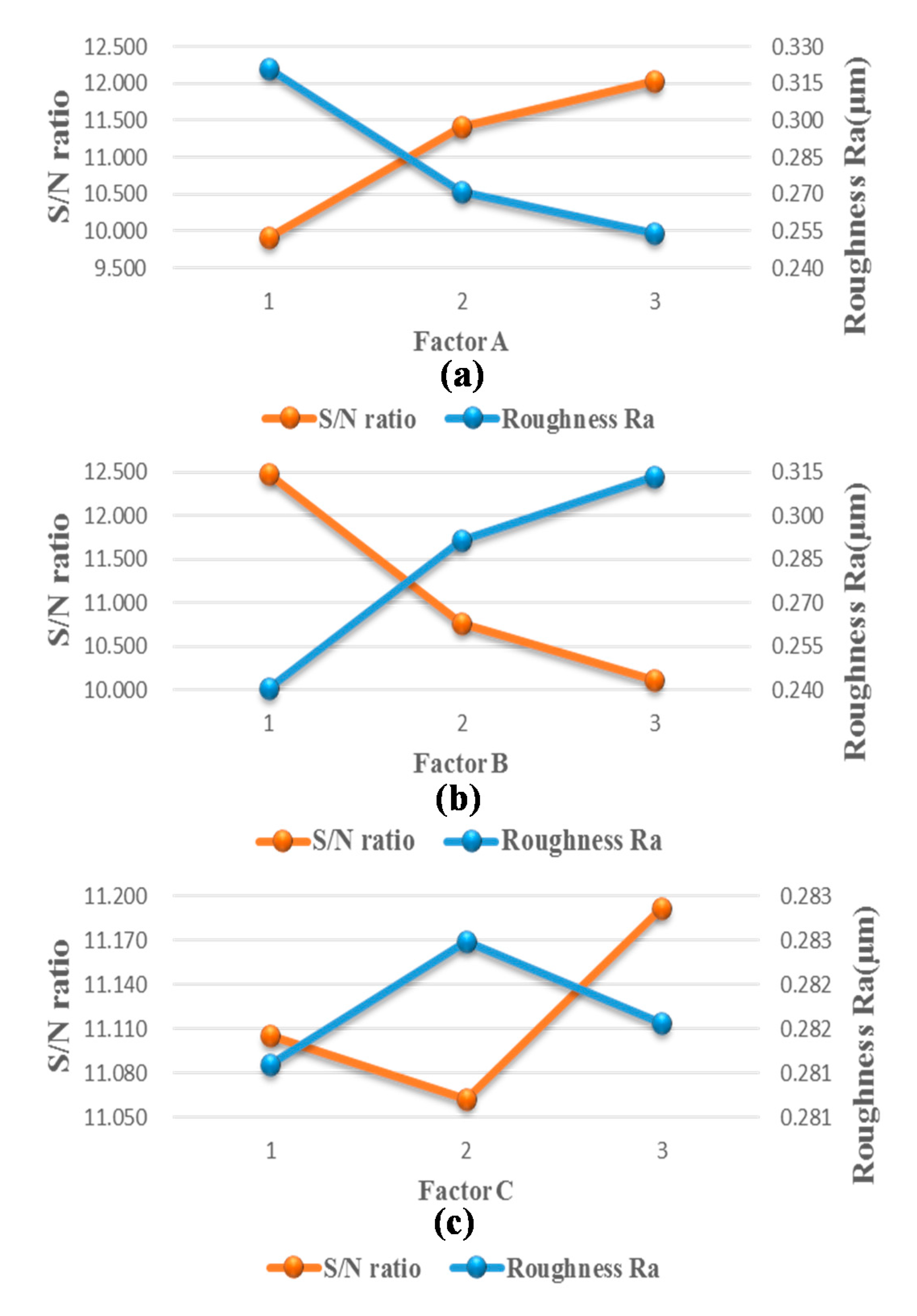

3.2. Factor Analysis

3.3. Confirmation Run

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Terry, S.C.; Jerman, J.H.; Angell, J.B. A gas chromatographic air analyzer fabricated on a silicon wafer. IEEE Trans. Electron Devices 1979, 26, 1880–1886. [Google Scholar] [CrossRef]

- Pinto, E.; Faustino, V.; Rodrigues, R.O.; Pinho, D.; Garcia, V.; Miranda, J.M.; Lima, R. A Rapid and Low-Cost Nonlithographic Method to Fabricate. Micromachines 2015, 6, 121–135. [Google Scholar] [CrossRef]

- Liu, Z.H.; Xu, W.C.; Hou, Z.N.; Wu, Z.G. A Rapid Prototyping Technique for Microfluidics with High Robustness and Flexibility. Micromachines 2016, 7, 201. [Google Scholar] [CrossRef]

- Pinto, V.C.; Sousa, P.J.; Cardoso, V.F.; Minas, G. Optimized SU-8 Processing for Low-Cost Microstructures. Micromachines 2014, 5, 738–755. [Google Scholar] [CrossRef] [Green Version]

- Jang, H.; Haq, M.R.; Ju, J.; Kim, Y.; Kim, S.M.; Lim, J. Fabrication of All Glass Bifurcation Microfluidic Chip. Micromachines 2017, 8, 67. [Google Scholar] [CrossRef]

- Faustino, V.; Catarino, S.O.; Lima, R.; Minas, G. Biomedical microfluidic devices by using low-cost fabrication techniques: A review. J. Biomech. 2016, 49, 2280–2292. [Google Scholar] [CrossRef] [PubMed]

- Dornfeld, D.; Min, S.; Takeuchi, Y. Recent advances in mechanical micromachining. CIRP Ann.-Manuf. Technol. 2006, 55, 745–768. [Google Scholar] [CrossRef]

- Xu, B.Y.; Yan, X.N.; Zhang, J.D.; Xu, J.J.; Chen, H.Y. Glass etching to bridge micro- and nanofluidics. Lab Chip 2012, 12, 381–386. [Google Scholar] [CrossRef] [PubMed]

- Park, D.S.; Chen, P.C.; You, B.H.; Kim, N.; Park, T.; Lee, T.Y.; Datta, P.; Desta, Y.; Soper, S.A.; Nikitopoulos, D.E.; et al. Titer-plate formatted continuous flow thermal reactors for highthroughput applications: Fabrication and test. J. Micromech. Microeng. 2010, 20, 055003. [Google Scholar] [CrossRef]

- Chen, P.C.; Park, D.S.; You, B.H.; Kim, N.; Park, T.; Soper, S.A.; Nikitopoulos, D.E.; Murphy, M.C. Titer-plate formatted continuous flow thermal reactors: Design and performance of a nanoliter reactor. Sens. Actuators B-Chem. 2010, 149, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.A.; Lee, J.Y.; Seong, S.; Cha, S.H.; Lee, S.H.; Kim, J.J.; Park, T.H. Fabrication and characterization of a PDMS-glass hybrid continuous flow PCR chip. Biochem. Eng. J. 2006, 29, 91–97. [Google Scholar] [CrossRef]

- Mecomber, J.S.; Hurd, D.; Limbach, P.A. Enhanced machining of micron-scale features in microchip molding masters by CNC milling. Int. J. Mach. Tools Manuf. 2005, 45, 1542–1550. [Google Scholar] [CrossRef]

- Mecomber, J.S.; Stalcup, A.M.; Hurd, D.; Halsall, H.B.; Heineman, W.R.; Seliskar, C.J.; Wehmeyer, K.R.; Limbach, P.A. Analytical performance of polymer-based microfluidic devices fabricated by computer numerical controlled machining. Anal. Chem. 2006, 78, 936–941. [Google Scholar] [CrossRef] [PubMed]

- Becker, H.; Heim, U. Hot embossing as a method for the fabrication of polymer high aspect ratio structures. Sens. Actuators A Phys. 2000, 83, 30–135. [Google Scholar] [CrossRef]

- Becker, H.; Gartner, C. Polymer based micro-reactors. Rev. Mol. Biotechnol. 2001, 82, 89–99. [Google Scholar] [CrossRef]

- Hupert, M.L.; Guy, W.J.; Llopis, S.D.; Shadpour, H.; Rani, S.; Nikitopoulos, D.E.; Soper, S.A. Valuation of micromilled metal mold masters for the replication of microchip electrophoresis devices. Microfluid. Nanofluid. 2007, 3, 1–11. [Google Scholar] [CrossRef]

- Park, C.H.; Song, C.K.; Hwang, J.; Kim, B.S. Development of an ultra precision machine tool for micromachining on large surfaces. Int. J. Precis. Eng. Manuf. 2009, 10, 85–91. [Google Scholar] [CrossRef]

- Vazquez, E.; Rodriguez, C.A.; Elias-Zuniga, A.; Ciurana, J. An experimental analysis of process parameters to manufacture metallic micro-channels by micro-milling. Int. J. Adv. Manuf. Technol. 2010, 51, 945–955. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Chen, J.C.; Kirby, E.D. Surface roughness optimization in an end-milling operation using the Taguchi design method. J. Mater. Process. Technol. 2007, 184, 233–239. [Google Scholar] [CrossRef]

- Chung, Y.C.; Lai, L.W.; Yang, L.J.; Liao, W.J. Comparison of Different Metal Film Thicknesses of COC-Substrate Polymerase Chain Reaction Chips With Single-Side and Double-Side Heaters. In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009; Volume 149, pp. 435–437. [Google Scholar]

- Yu, H.H.; Hwang, S.J.; Hwang, K.C. Preparation and characterization of a novel flexible substrate for OLED. Opt. Commun. 2005, 248, 51–57. [Google Scholar] [CrossRef]

- Ma, K.S.; Reza, F.; Saaem, I.; Tian, J. Versatile surface functionalization of cyclic olefin copolymer (COC) with sputtered SiO2 thin film for potential BioMEMS applications. J. Mater. Chem. 2009, 19, 7914–7920. [Google Scholar] [CrossRef]

- Yoon, H.S.; Wu, R.; Lee, T.M.; Ahn, S.H. Geometric optimization of micro drills using Taguchi methods and response surface methodology. Int. J. Precis. Eng. Manuf. 2011, 12, 871–875. [Google Scholar] [CrossRef]

| Factor | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Spindle speed (N) (mm/min) | 10,000 | 15,000 | 20,000 |

| Feed rate (F) (mm/min) | 300 | 600 | 800 |

| Depth of cut (DOC) (μm) | 10 | 15 | 20 |

| No. | N | F | DOC | Average Ra | S | S/N Ratio |

|---|---|---|---|---|---|---|

| 1 | 10,000 | 300 | 10 | 0.317 | 0.021 | 9.975 |

| 2 | 10,000 | 600 | 15 | 0.337 | 0.021 | 9.445 |

| 3 | 10,000 | 800 | 20 | 0.353 | 0.021 | 9.026 |

| 4 | 15,000 | 300 | 10 | 0.247 | 0.006 | 12.156 |

| 5 | 15,000 | 600 | 15 | 0.267 | 0.006 | 11.479 |

| 6 | 15,000 | 800 | 20 | 0.323 | 0.012 | 9.803 |

| 7 | 20,000 | 300 | 10 | 0.223 | 0.006 | 13.019 |

| 8 | 20,000 | 600 | 15 | 0.297 | 0.015 | 10.547 |

| 9 | 20,000 | 800 | 20 | 0.310 | 0.000 | 10.173 |

| 10 | 10,000 | 300 | 15 | 0.300 | 0.026 | 10.435 |

| 11 | 10,000 | 600 | 20 | 0.343 | 0.006 | 9.285 |

| 12 | 10,000 | 800 | 10 | 0.357 | 0.006 | 8.954 |

| 13 | 15,000 | 300 | 15 | 0.227 | 0.006 | 12.890 |

| 14 | 15,000 | 600 | 20 | 0.290 | 0.035 | 10.711 |

| 15 | 15,000 | 800 | 10 | 0.287 | 0.006 | 10.851 |

| 16 | 20,000 | 300 | 15 | 0.223 | 0.006 | 13.019 |

| 17 | 20,000 | 600 | 20 | 0.287 | 0.023 | 10.834 |

| 18 | 20,000 | 800 | 10 | 0.300 | 0.017 | 10.448 |

| 19 | 10,000 | 300 | 20 | 0.240 | 0.010 | 12.391 |

| 20 | 10,000 | 600 | 10 | 0.307 | 0.006 | 10.266 |

| 21 | 10,000 | 800 | 15 | 0.337 | 0.023 | 9.442 |

| 22 | 15,000 | 300 | 20 | 0.217 | 0.006 | 13.282 |

| 23 | 15,000 | 600 | 10 | 0.273 | 0.006 | 11.265 |

| 24 | 15,000 | 800 | 15 | 0.307 | 0.006 | 10.266 |

| 25 | 20,000 | 300 | 20 | 0.173 | 0.006 | 15.219 |

| 26 | 20,000 | 600 | 10 | 0.223 | 0.012 | 13.013 |

| 27 | 20,000 | 800 | 15 | 0.250 | 0.010 | 12.037 |

| Levels and Response | A (Spindle Speed) | B (Feed Rate) | C (Depth of Cut) |

|---|---|---|---|

| Level 1 | 9.913 | 12.487 | 11.105 |

| Level 2 | 11.412 | 10.760 | 11.062 |

| Level 3 | 12.034 | 10.111 | 11.192 |

| Range | 2.121 | 2.376 | 0.129 |

| Rank | 2 | 1 | 3 |

| No. | 1 | 2 | 3 | Average (Ra) µm |

|---|---|---|---|---|

| 1 | 0.14 | 0.14 | 0.15 | 0.143 |

| 2 | 0.18 | 0.19 | 0.18 | 0.183 |

| 3 | 0.20 | 0.20 | 0.20 | 0.200 |

| 4 | 0.15 | 0.14 | 0.15 | 0.147 |

| 5 | 0.18 | 0.20 | 0.19 | 0.190 |

| 6 | 0.21 | 0.20 | 0.20 | 0.203 |

| 7 | 0.17 | 0.17 | 0.18 | 0.173 |

| 8 | 0.19 | 0.19 | 0.18 | 0.187 |

| 9 | 0.19 | 0.20 | 0.20 | 0.197 |

| 10 | 0.20 | 0.22 | 0.21 | 0.210 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.-C.; Zhang, R.-H.; Aue-u-lan, Y.; Chang, G.-E. Micromachining Microchannels on Cyclic Olefin Copolymer (COC) Substrates with the Taguchi Method. Micromachines 2017, 8, 264. https://doi.org/10.3390/mi8090264

Chen P-C, Zhang R-H, Aue-u-lan Y, Chang G-E. Micromachining Microchannels on Cyclic Olefin Copolymer (COC) Substrates with the Taguchi Method. Micromachines. 2017; 8(9):264. https://doi.org/10.3390/mi8090264

Chicago/Turabian StyleChen, Pin-Chuan, Ren-Hao Zhang, Yingyot Aue-u-lan, and Guo-En Chang. 2017. "Micromachining Microchannels on Cyclic Olefin Copolymer (COC) Substrates with the Taguchi Method" Micromachines 8, no. 9: 264. https://doi.org/10.3390/mi8090264