Fabrication and Characterization of Capacitive Micromachined Ultrasonic Transducers with Low-Temperature Wafer Direct Bonding

Abstract

:1. Introduction

2. Surface Properties by Activation Processes

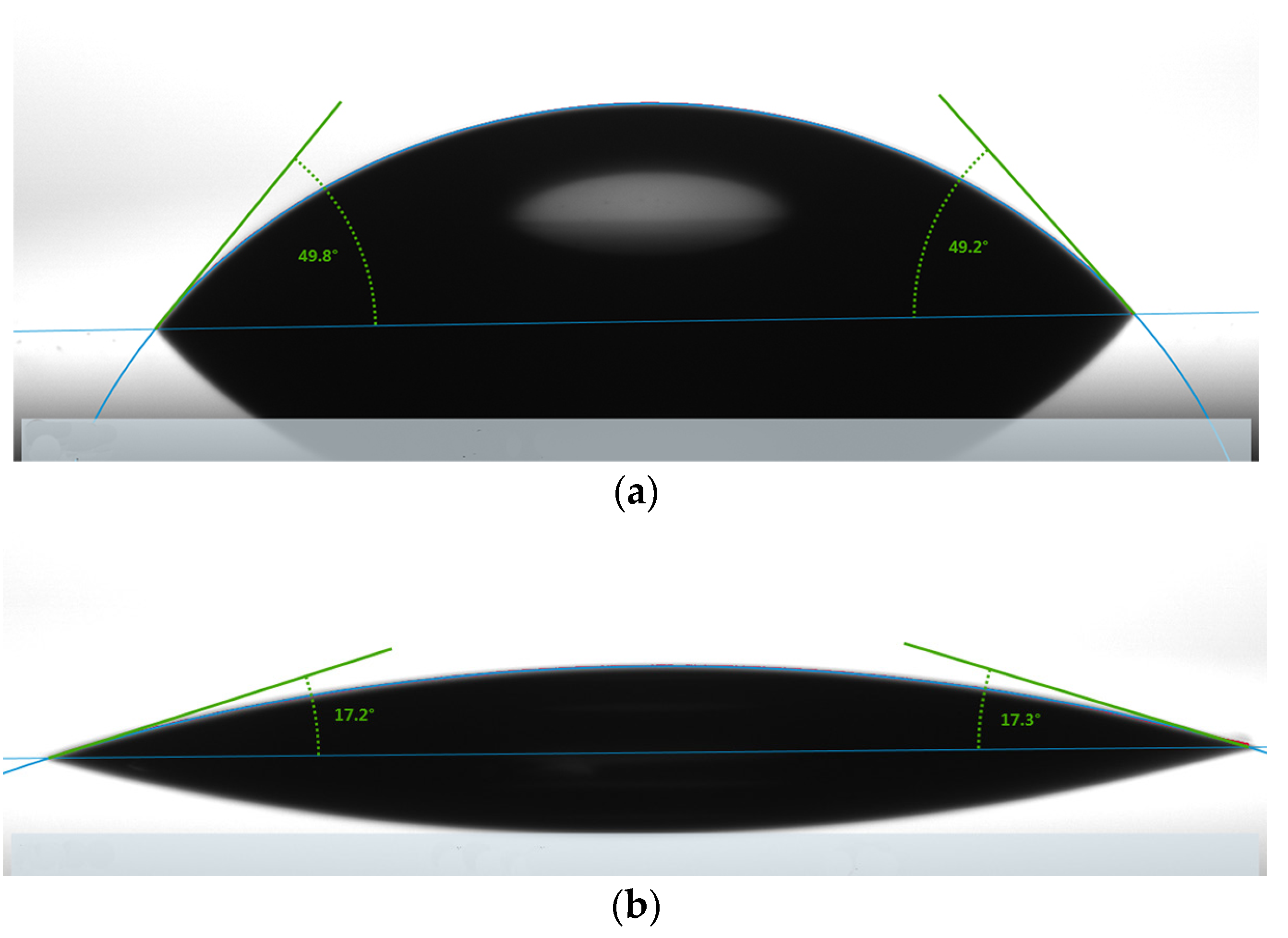

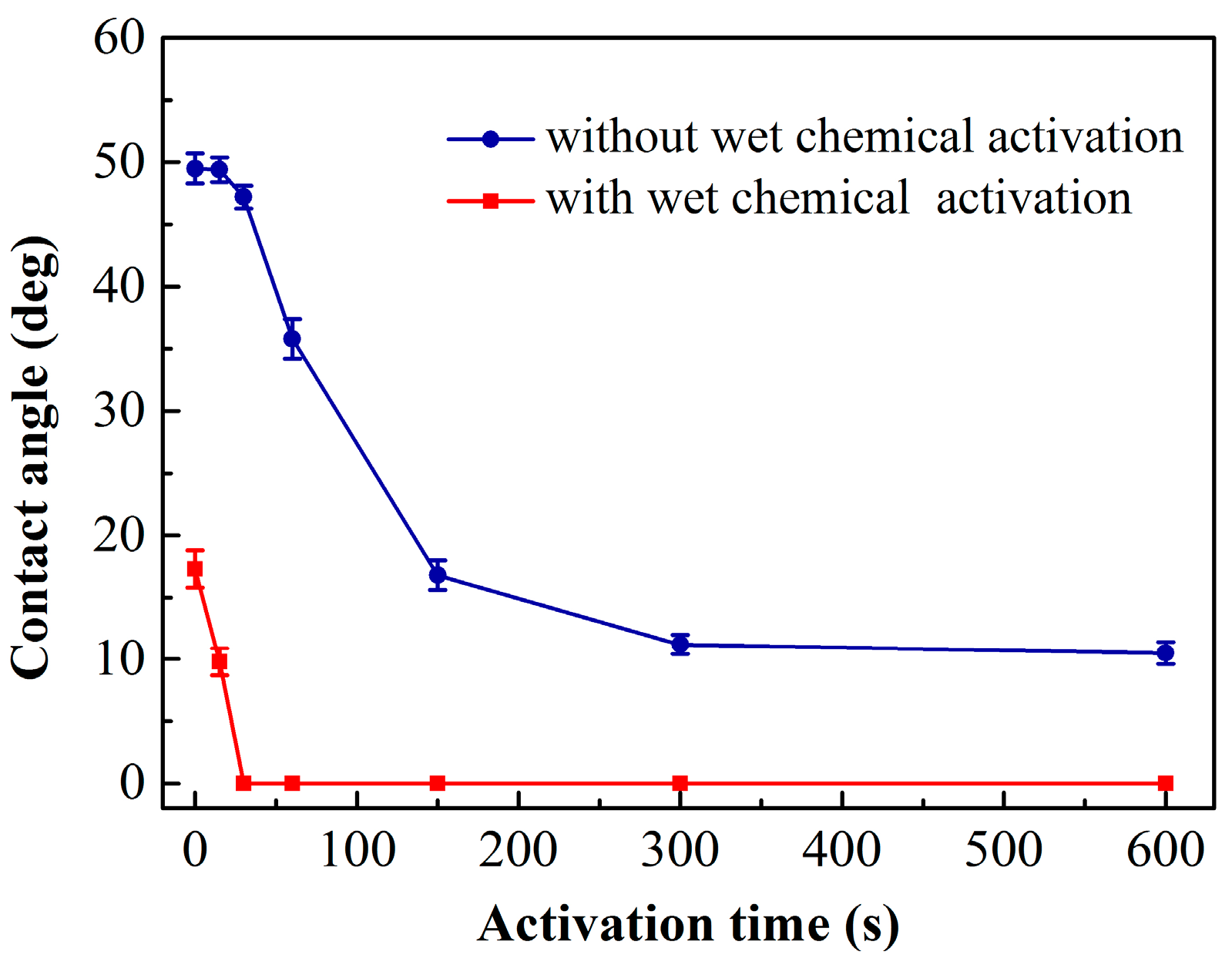

2.1. Contact Angle

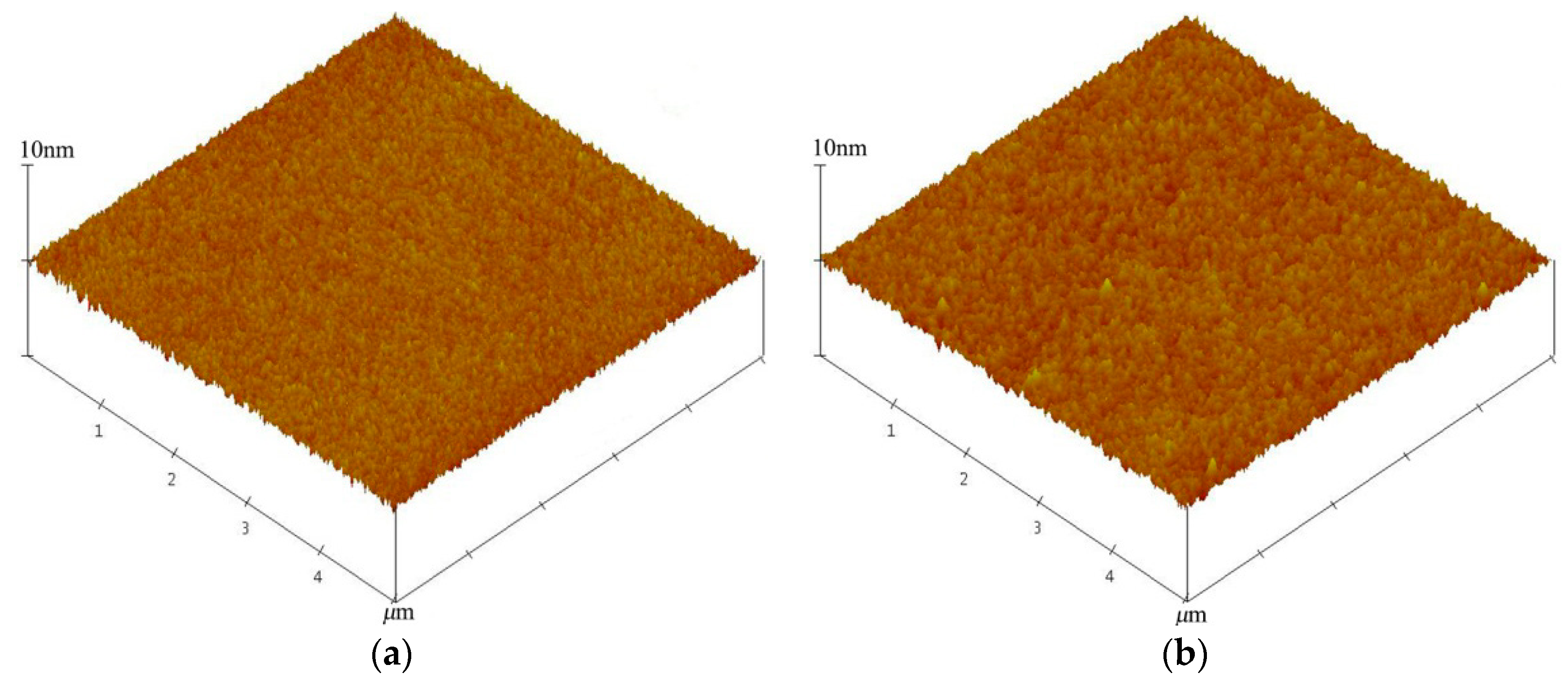

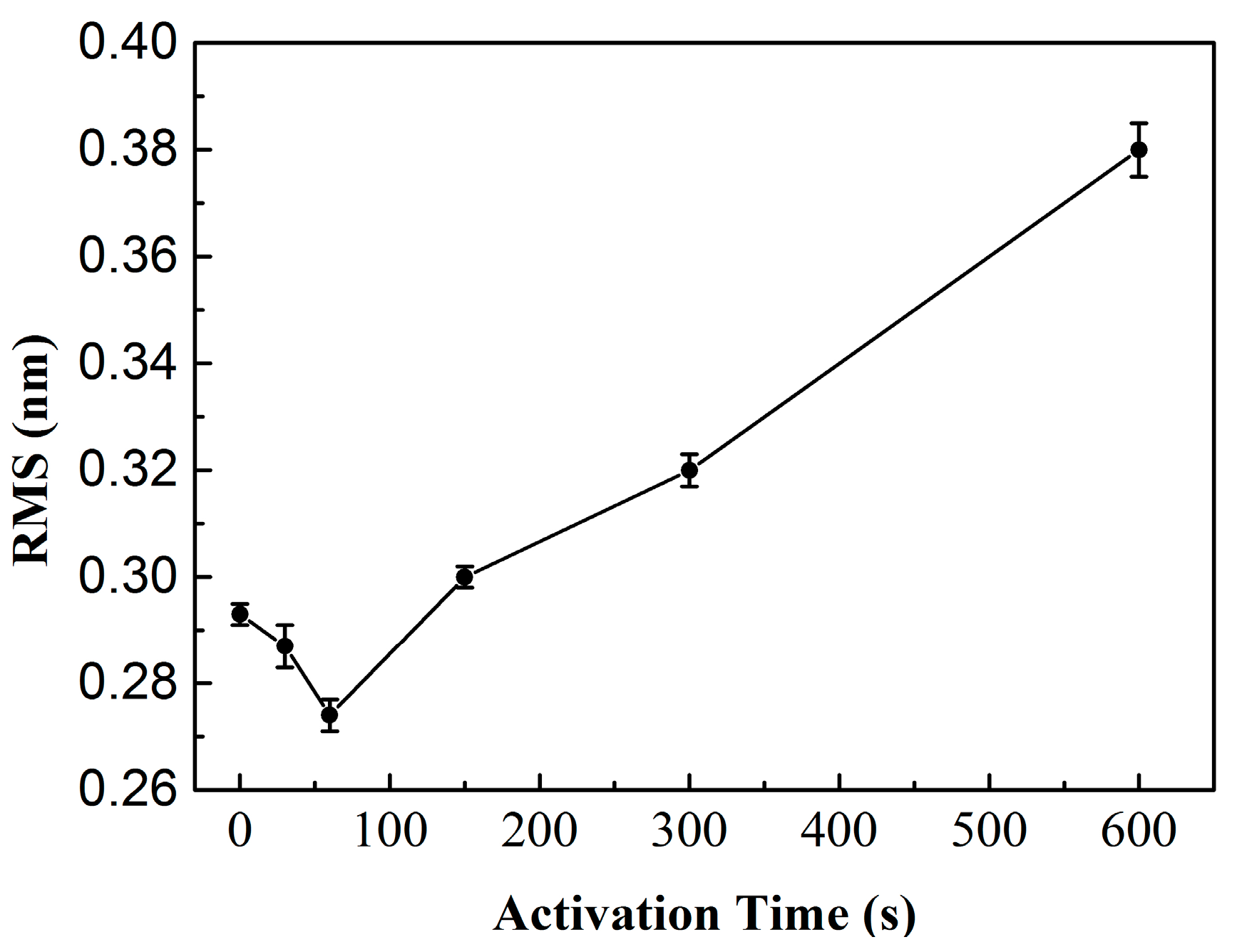

2.2. Surface Roughness

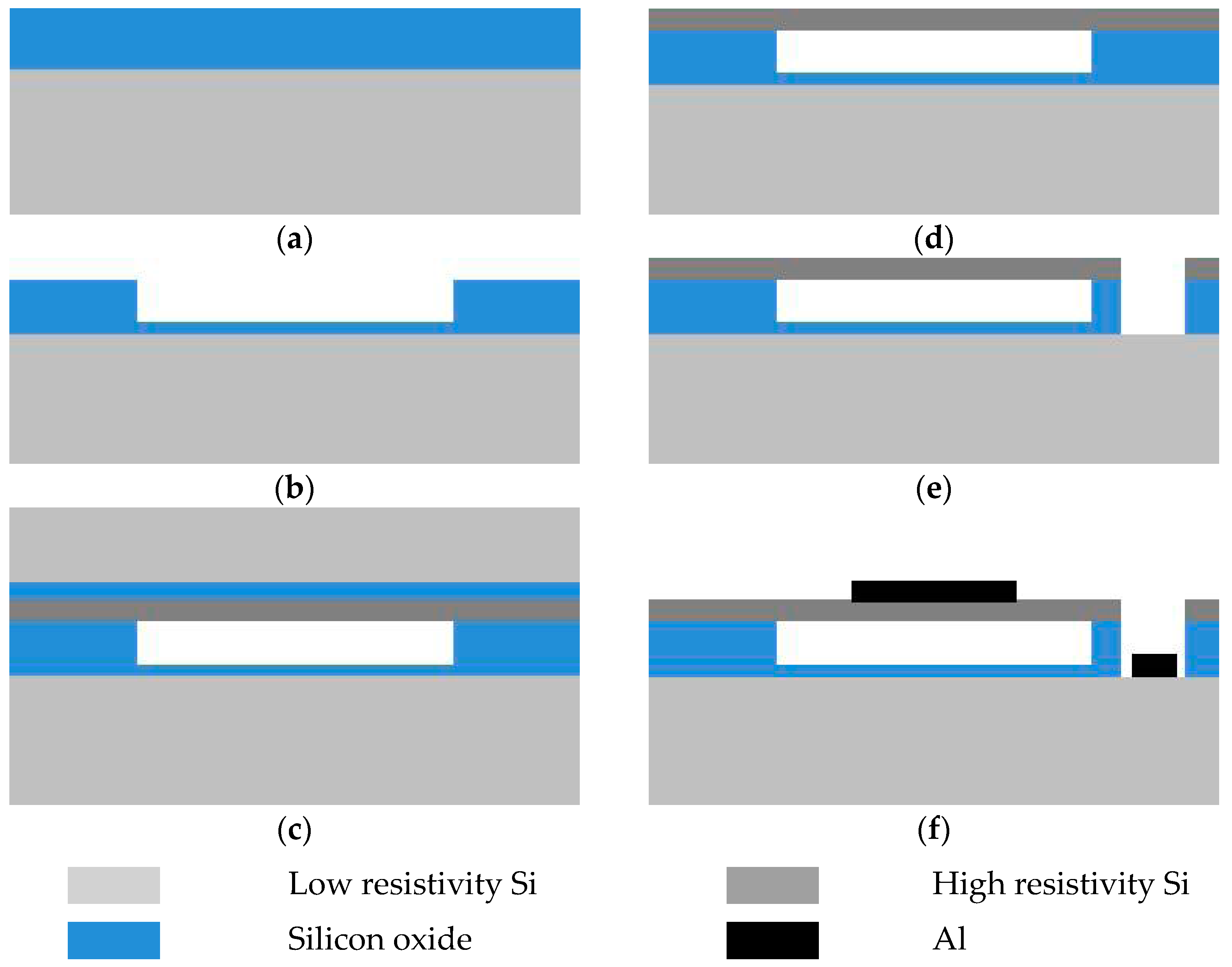

3. Low-Temperature CMUT Fabrication Process

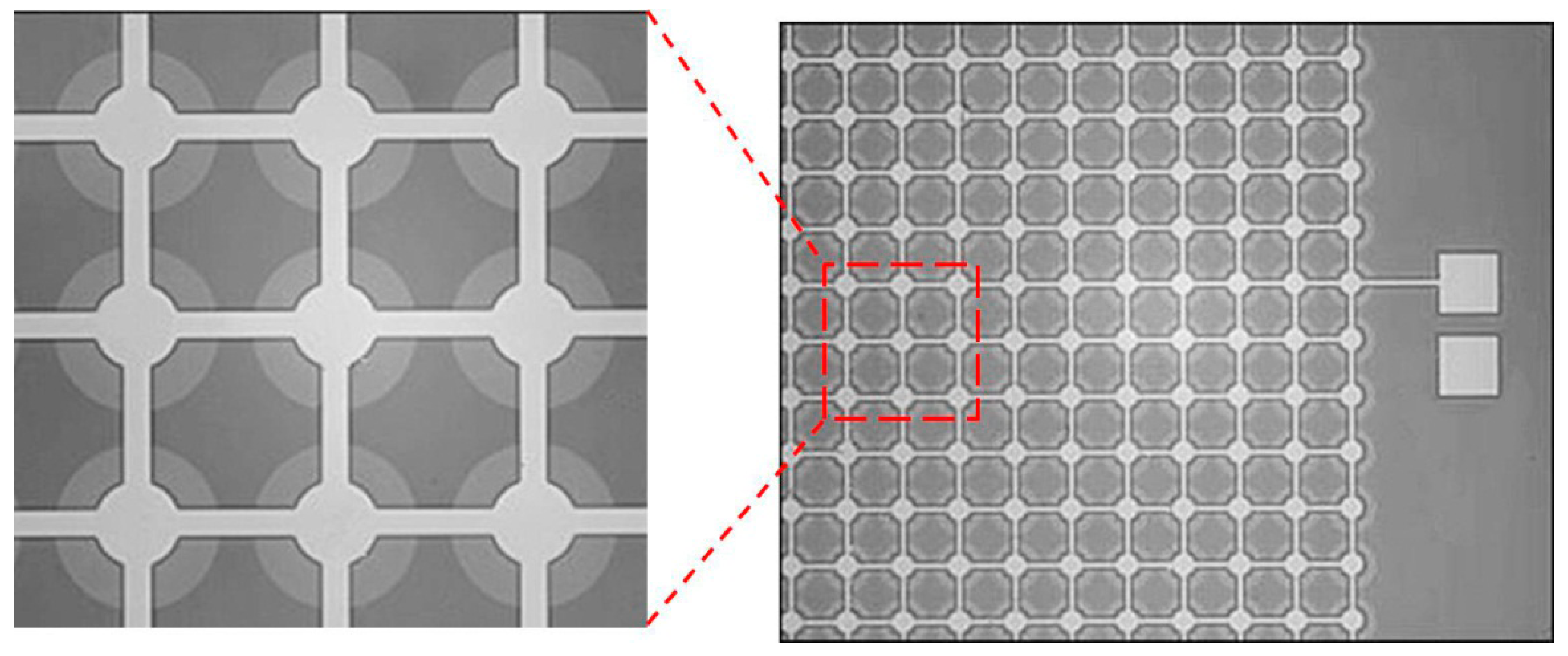

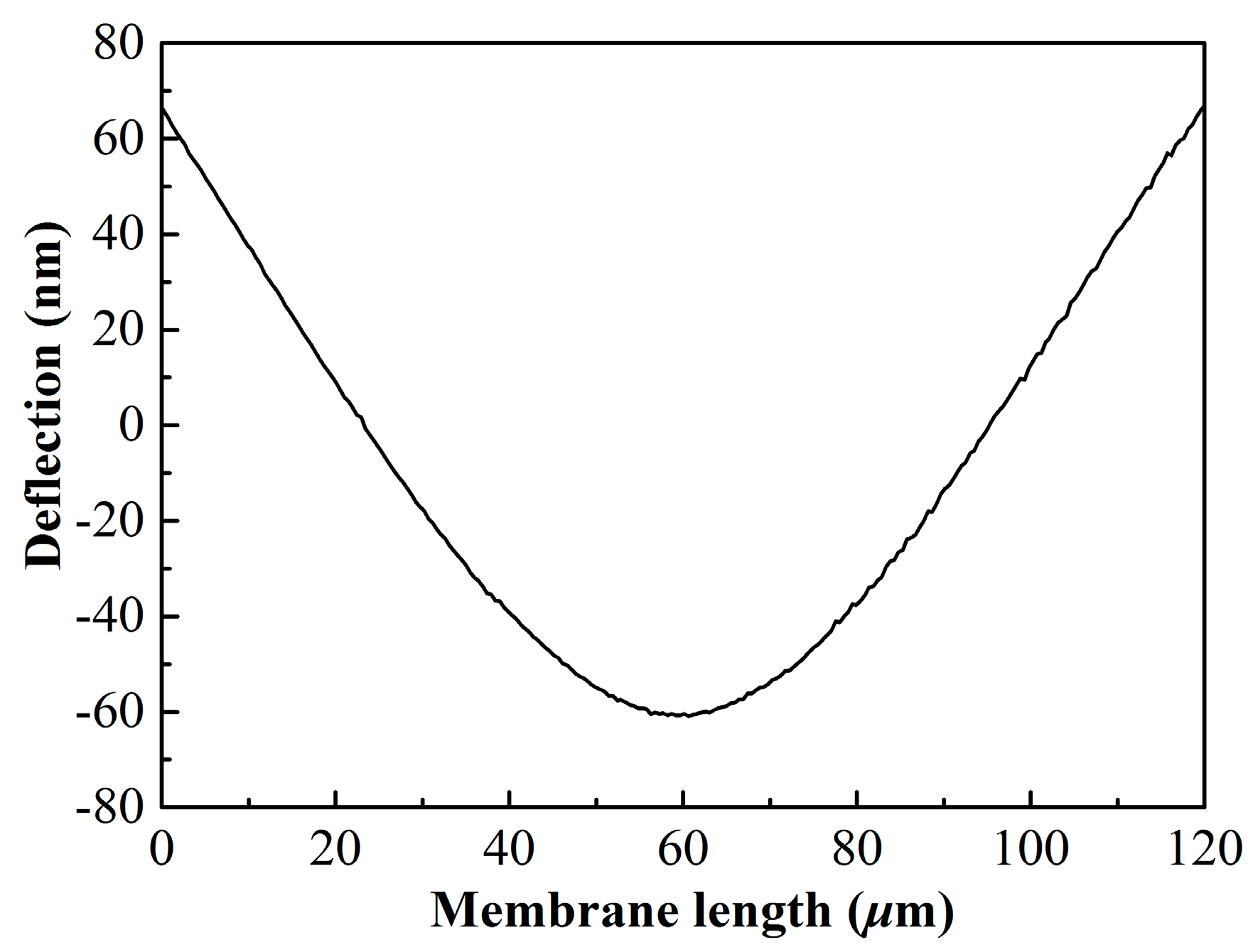

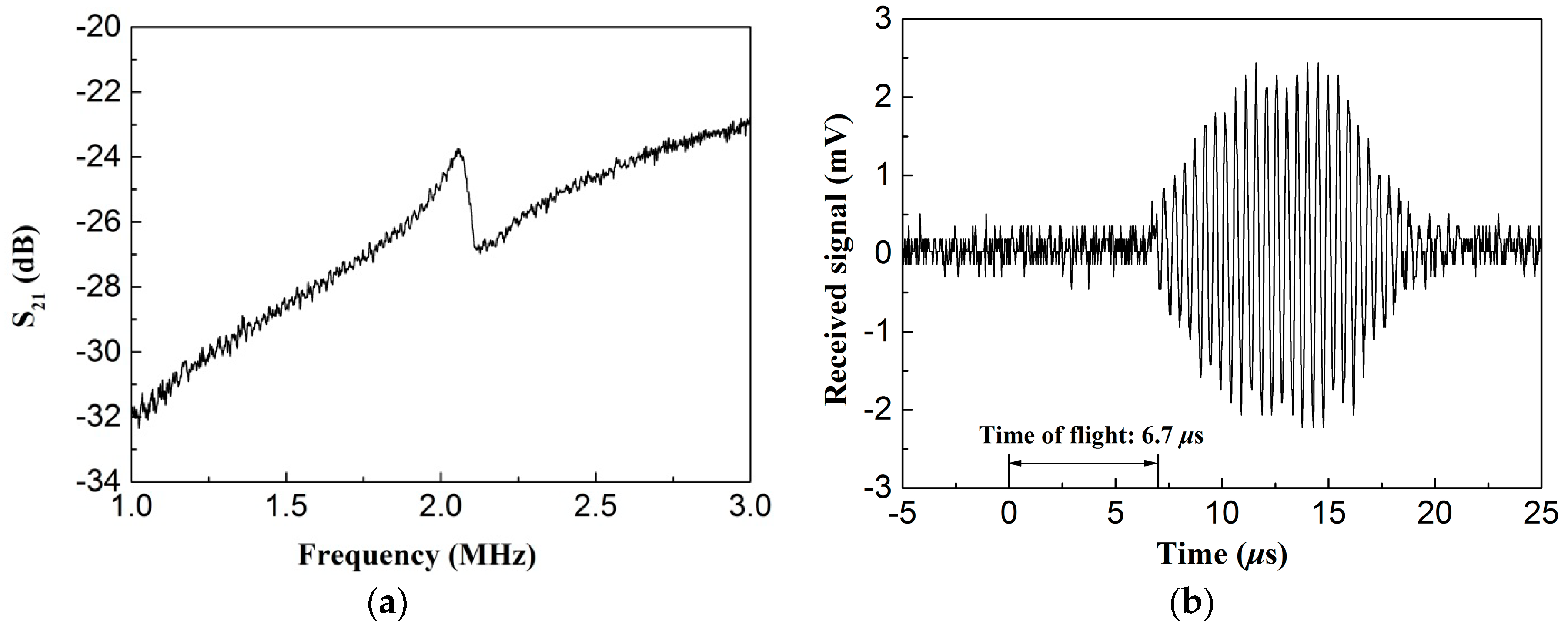

4. Device Characterizations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Oralkan, Ö.; Ergun, A.S.; Johnson, J.A.; Karaman, M.; Demirci, U.; Kaviani, K.; Lee, T.H.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers: Next-generation arrays for acoustic imaging? IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 1596–1610. [Google Scholar] [CrossRef] [PubMed]

- Khuri-Yakub, B.T.; Oralkan, Ö. Capacitive micromachined ultrasonic transducers for medical imaging and therapy. J. Micromech. Microeng. 2011, 21, 054004–054014. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhang, H.; Jin, S.J.; Zeng, Z.M. An analytical model for CMUTs with square multilayer membranes using the Ritz method. Micromachines 2016, 7, 55–74. [Google Scholar] [CrossRef]

- Gurun, G.; Tekes, C.; Zahorian, J.; Xu, T.; Satir, S.; Karaman, M.; Hasler, J.; Degertekin, F.L. Single-chip CMUT-on-CMOS front-end system for real-time volumetric IVUS and ICE imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 239–250. [Google Scholar] [CrossRef] [PubMed]

- Ergun, A.S.; Huang, Y.L.; Zhuang, X.F.; Oralkan, Ö.; Yarahoğlu, G.G.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers: Fabrication technology. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2242–2258. [Google Scholar] [PubMed]

- Bagolini, A.; Savoia, A.S.; Picciotto, A.; Boscardin, M.; Bellutti, P.; Lamberti, N.; Caliano, G. PECVD low stress silicon nitride analysis and optimization for the fabrication of CMUT devices. J. Micromech. Microeng. 2015, 25, 15012–15023. [Google Scholar] [CrossRef]

- Jeong, B.G.; Kim, D.K.; Hong, S.W.; Chung, S.W.; Shin, H.J. Performance and reliability of new CMUT design with improved efficiency. Sens. Actuators A Phys. 2013, 199, 325–333. [Google Scholar] [CrossRef]

- Zhang, P.Y.; Fitzpatrick, G.; Harrison, T.; Moussa, W.A.; Zemp, R.J. Double-SOI wafer-bonded CMUTs with improved electrical safety and minimal roughness of dielectric and electrode surfaces. J. Microelectromech. Syst. 2012, 21, 668–680. [Google Scholar] [CrossRef]

- Ladabaum, I.; Jin, X.C.; Soh, H.T.; Atalar, A.; Khuri-Yakub, B.T. Surface micromachined capacitive ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 678–690. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, Y.L.; Ergun, A.S.; Hæggström, E.; Badi, M.H.; Khuri-Yakub, B.T. Fabricating capacitive micromachined ultrasonic transducers with wafer-bonding technology. J. Microelectromech. Syst. 2003, 12, 128–137. [Google Scholar] [CrossRef]

- Belgacem, B.; Alquier, D.; Muralt, P.; Baborowski, J.; Lucas, S.; Jerisian, R. Optimization of the fabrication of sealed capacitive transducers using surface micromachining. J. Micromech. Microeng. 2004, 14, 299–304. [Google Scholar] [CrossRef]

- Salim, M.S.; AdbMalek, M.F.; Heng, R.B.W.; Juni, K.M.; Sabri, N. Capacitive micromachined ultrasonic transducers: Technology and application. J. Med. Ultrasound 2012, 20, 8–31. [Google Scholar] [CrossRef]

- Huang, Y.L.; Zhuang, X.F.; Haeggstrom, E.O.; Ergun, A.S.; Cheng, C.H.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers (CMUTs) with isolation posts. Ultrasonics 2008, 48, 74–81. [Google Scholar] [CrossRef] [PubMed]

- Wygant, I.O.; Kupnik, M.; Windsor, J.C.; Wright, W.M.; Wochner, M.S.; Yaralioglu, G.G.; Hamilton, M.F.; Khuri-Yakub, B.T. Capacitive micromachined ultrasonic transducers for generation of highly directional sound with a parametric array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 193–203. [Google Scholar] [CrossRef] [PubMed]

- Park, K.K.; Lee, H.; Kupnik, M.; Khuri-Yakub, B.T. Fabrication of capacitive micromachined ultrasonic transducers via local oxidation and direct wafer bonding. J. Microelectromech. Syst. 2011, 20, 95–103. [Google Scholar] [CrossRef]

- Kowal, J.; Nixon, T.; Aitken, N.; Braithwaite, N.S.J. Surface activation for low temperature wafer fusion bonding by radicals produced in an oxygen discharge. Sens. Actuators A Phys. 2009, 155, 145–151. [Google Scholar] [CrossRef]

- Tsuji, Y.; Kupnik, M.; Khuri-Yakub, B.T. Low temperature process for CMUT fabrication with wafer bonding technique. In Proceedings of the IEEE International Ultrasonics Symposium, San Diego, CA, USA, 11–14 October 2010; pp. 551–554.

- Tong, Q.-Y.; Gan, Q.; Fountain, G.; Enquist, P.; Scholz, R.; Gösele, U. Fluorine-enhanced low-temperature wafer bonding of native-oxide covered Si wafers. Appl. Phys. Lett. 2004, 85, 3731–3733. [Google Scholar] [CrossRef]

- Bengtsson, S.; Amirfeiz, P. Room temperature wafer bonding of silicon, oxidized silicon, and crystalline quartz. J. Electron. Mater. 2000, 29, 909–915. [Google Scholar] [CrossRef]

- Wygant, I.O.; Kupnik, M.; Khuri-Yakub, B.T. Analytically calculating membrane displacement and the equivalent circuit model of a circular CMUT cell. In Proceedings of the IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 2111–2114.

- Mukhiya, R.; Sinha, A.; Prabakar, K.; Raghuramaiah, M.; Jayapandian, J.; Gopal, R.; Khanna, V.K.; Shekhar, C. Fabrication of capacitive micromachined ultrasonic transducer arrays with isolation trenches using anodic wafer bonding. IEEE Sens. J. 2015, 15, 5177–5184. [Google Scholar] [CrossRef]

- Martinussen, H.; Aksnes, A.; Leirset, E.; Engan, H.E. CMUT characterization by interferometric and electric measurements. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 2711–2721. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Cicek, P.V.; Allidina, K.; Nabki, F.; E1-Gamal, M.N. Surface-micromachined CMUT using low-temperature deposited silicon carbide membranes for above-IC integration. J. Microelectromech. Syst. 2014, 23, 482–493. [Google Scholar] [CrossRef]

- Toan, N.V.; Hahng, S.; Song, Y.; Ono, T. Fabrication of vacuum-sealed capacitive micromachined ultrasonic transducer arrays using glass reflow process. Micromachines 2016, 7, 76–84. [Google Scholar] [CrossRef]

- Cetin, A.M.; Bayram, B. Diamond-based capacitive micromachined ultrasonic transducers in immersion. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 414–420. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Value |

|---|---|

| Membrane radius (μm) | 60 |

| Membrane thickness (μm) | 2 |

| Electrode radius (μm) | 30 |

| Electrode thickness (μm) | 0.3 |

| Number of cells | 256 |

| Insulation layer thickness (μm) | 0.2 |

| Cavity depth (μm) | 0.6 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Yu, Y.; Ning, J. Fabrication and Characterization of Capacitive Micromachined Ultrasonic Transducers with Low-Temperature Wafer Direct Bonding. Micromachines 2016, 7, 226. https://doi.org/10.3390/mi7120226

Wang X, Yu Y, Ning J. Fabrication and Characterization of Capacitive Micromachined Ultrasonic Transducers with Low-Temperature Wafer Direct Bonding. Micromachines. 2016; 7(12):226. https://doi.org/10.3390/mi7120226

Chicago/Turabian StyleWang, Xiaoqing, Yude Yu, and Jin Ning. 2016. "Fabrication and Characterization of Capacitive Micromachined Ultrasonic Transducers with Low-Temperature Wafer Direct Bonding" Micromachines 7, no. 12: 226. https://doi.org/10.3390/mi7120226