Study on Improving Thickness Uniformity of Microfluidic Chip Mold in the Electroforming Process

Abstract

:1. Introduction

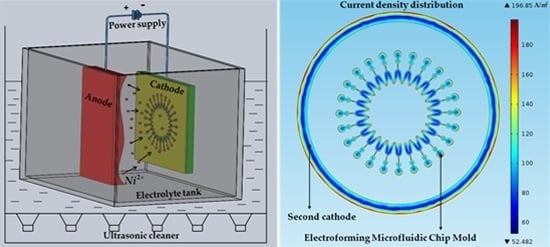

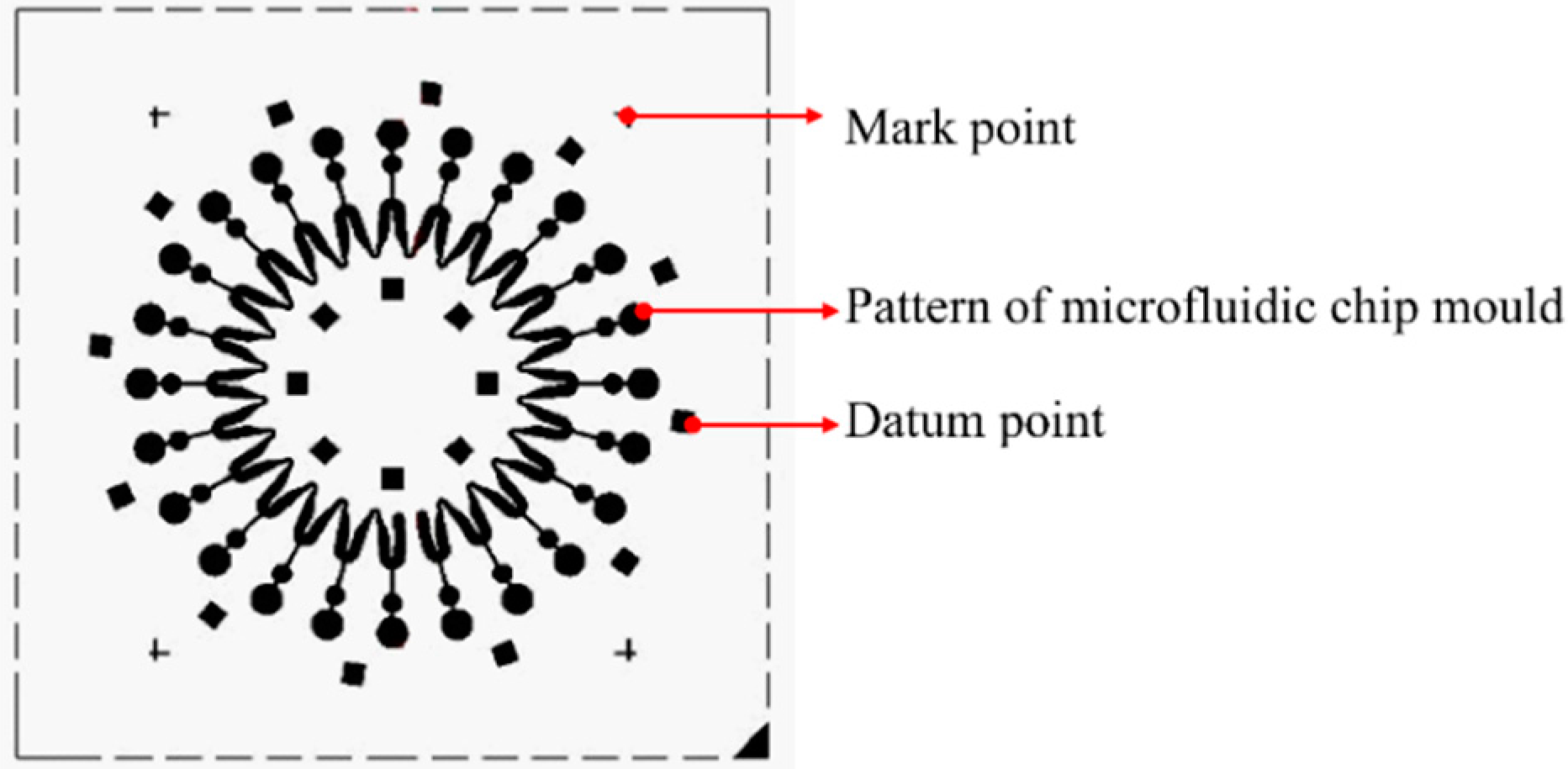

2. Experimental Study on Effect of Ultrasonic Agitation on Thickness Uniformity of the Mold

2.1. Electroforming Experiment

2.2. Results and Discussion

2.2.1. Effect of Ultrasonic Frequency on Thickness Uniformity of the Mold

| f (kHz) | hmax (μm) | hmin (μm) | α (%) |

|---|---|---|---|

| 0 | 62.22 | 20.09 | 209.8 |

| 80 | 53.46 | 20.91 | 155.7 |

| 120 | 56.22 | 20.46 | 174.8 |

| 200 | 51.55 | 20.73 | 148.6 |

2.2.2. Effect of Ultrasonic Power on Thickness Uniformity of the Mold

| P (W) | hmax (μm) | hmin (μm) | α (%) |

|---|---|---|---|

| 0 | 61.92 | 20.08 | 208.3 |

| 100 | 60.86 | 21.26 | 186.3 |

| 200 | 54.39 | 21.71 | 150.5 |

| 500 | 53.47 | 22.19 | 141.0 |

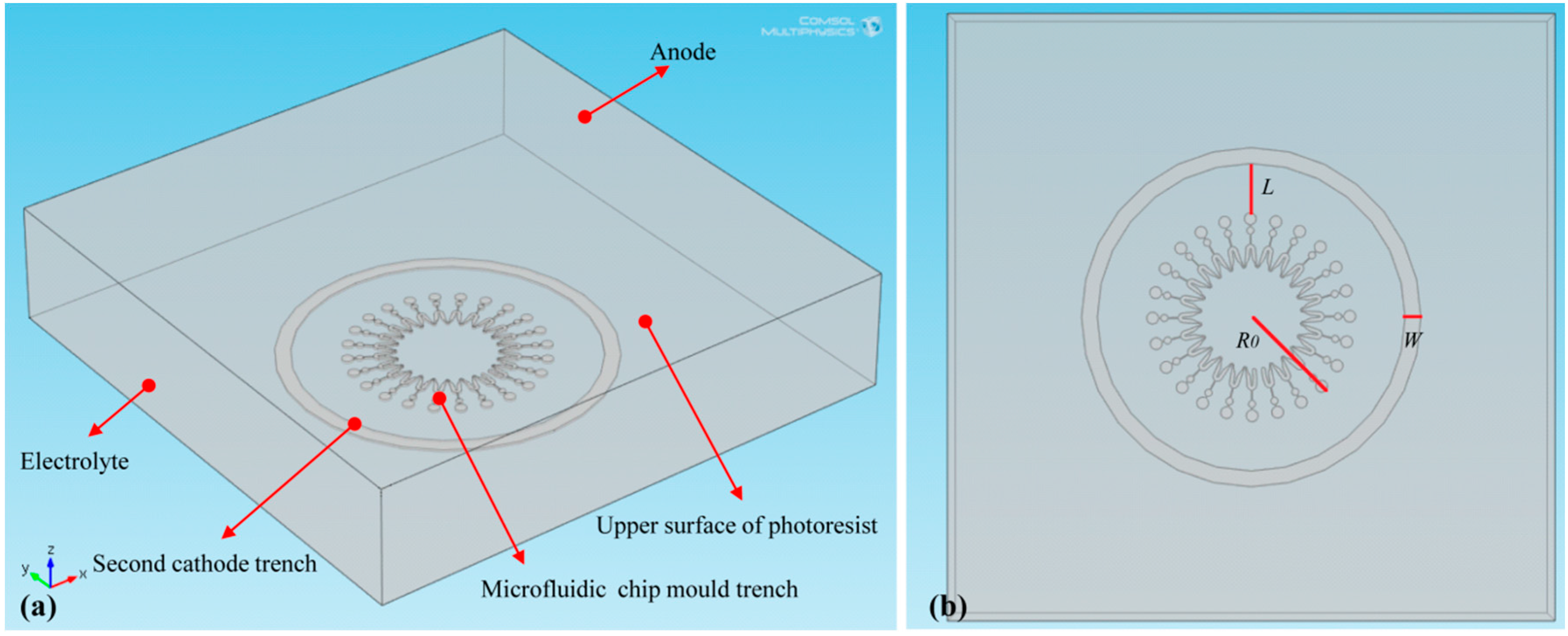

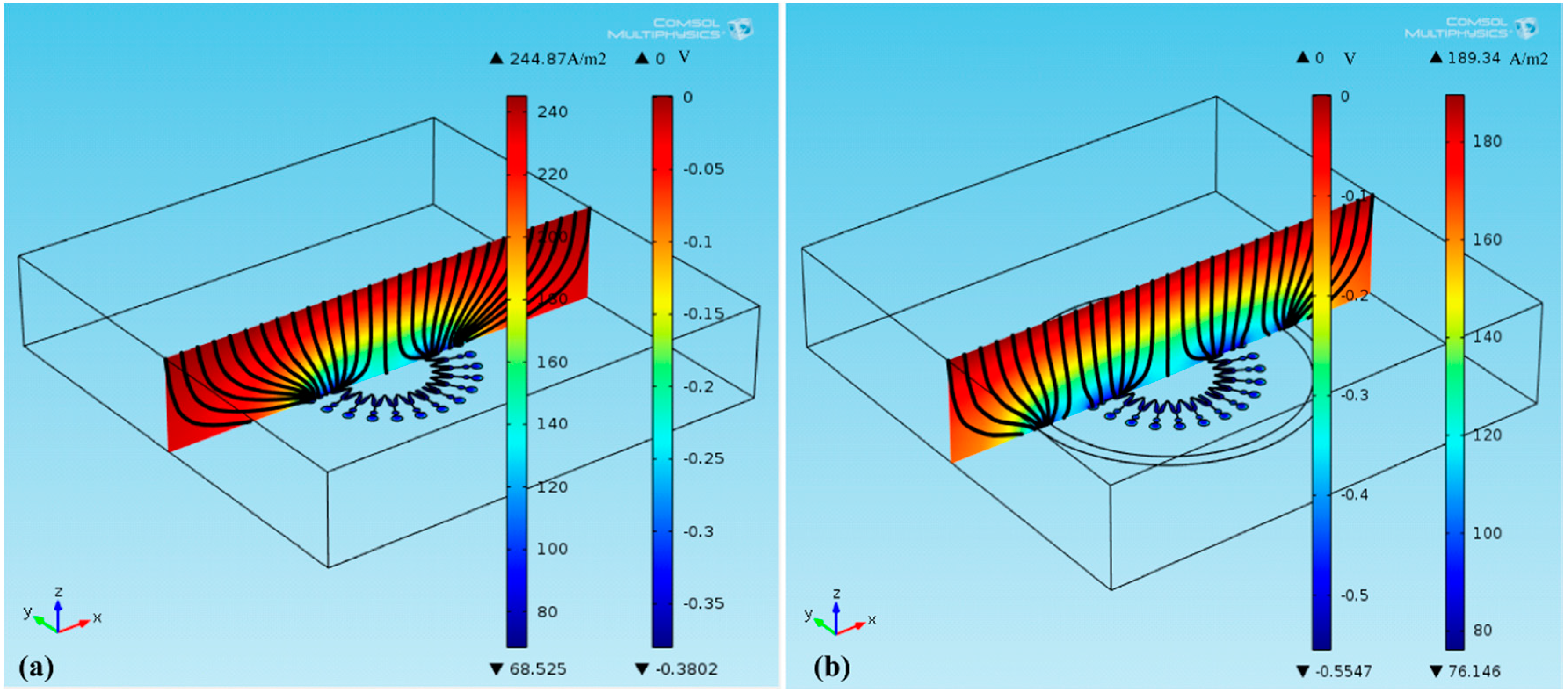

3. Simulation Study on Effect of a Second Cathode on Thickness Uniformity of the Mold

3.1. Geometric Model

3.2. Electrochemical Model

| σ (S/m) | i0 (A/m2) | αa | αc | T (K) | Eeq (V) | M (kg/mol) | ρ (kg/m3) | ν | n |

|---|---|---|---|---|---|---|---|---|---|

| 0.95 | 17.1 | 1.5 | 0.5 | 324 | −0.257 | 0.0586 | 8900 | 1 | 2 |

3.3. Results and Discussion

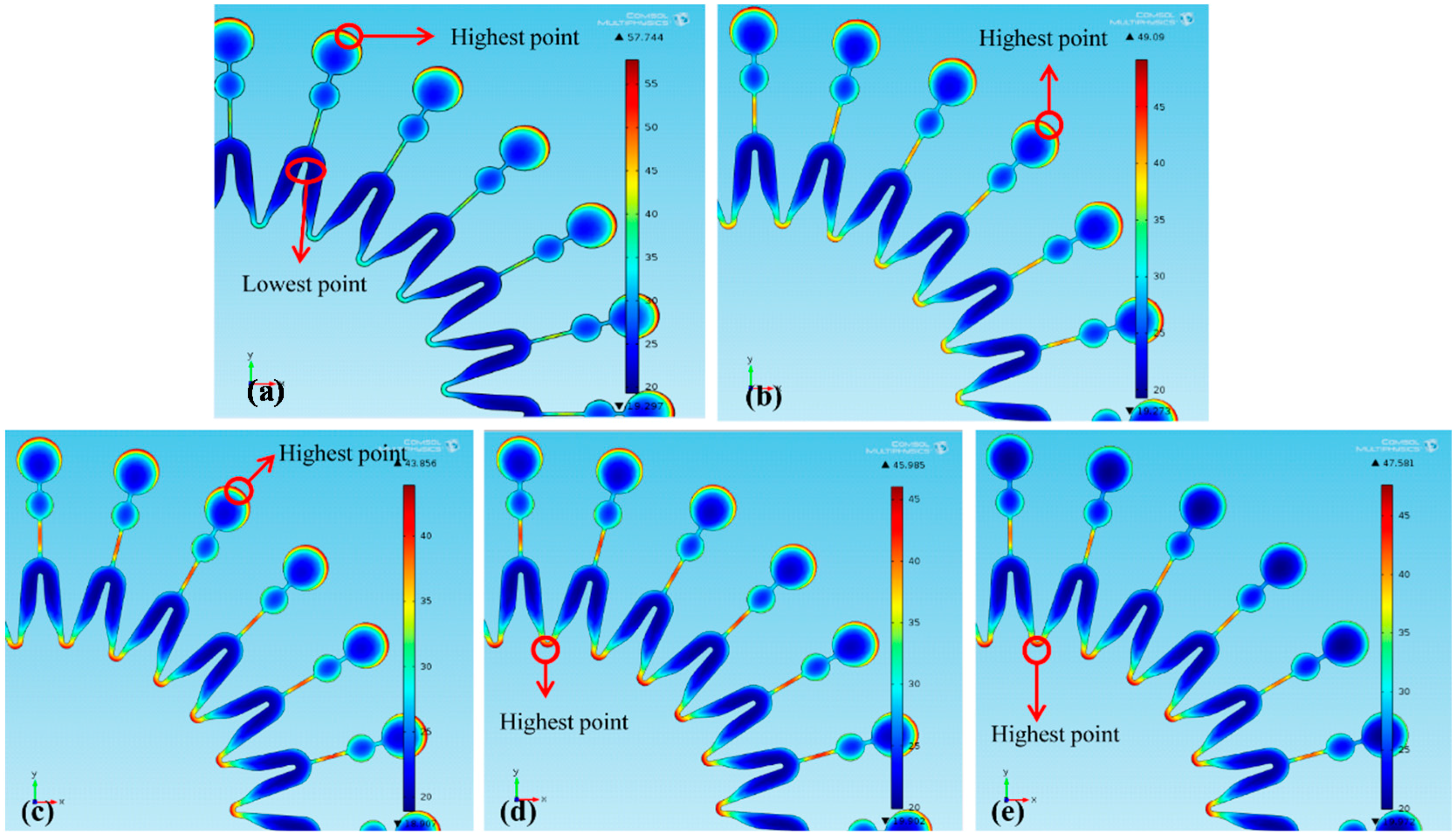

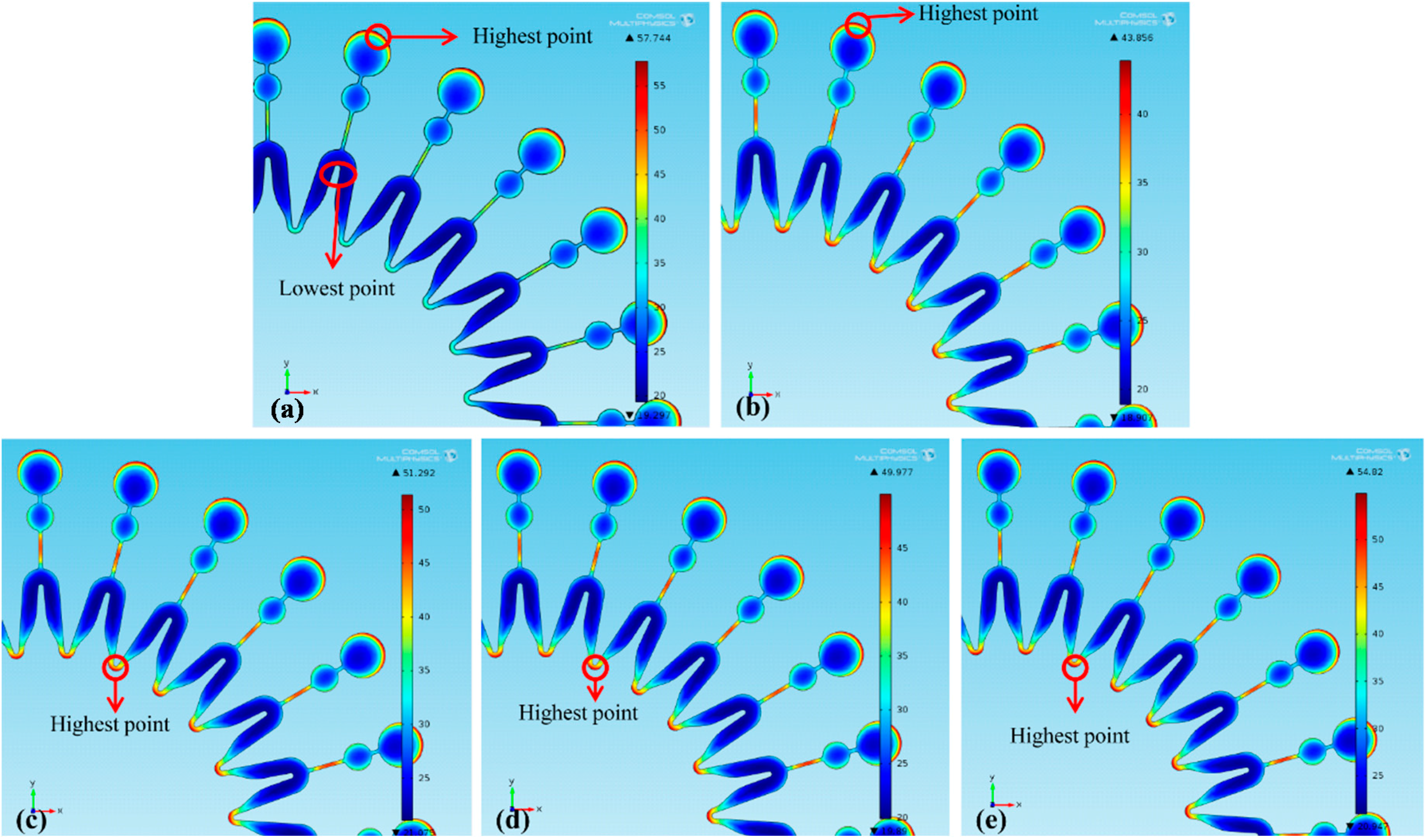

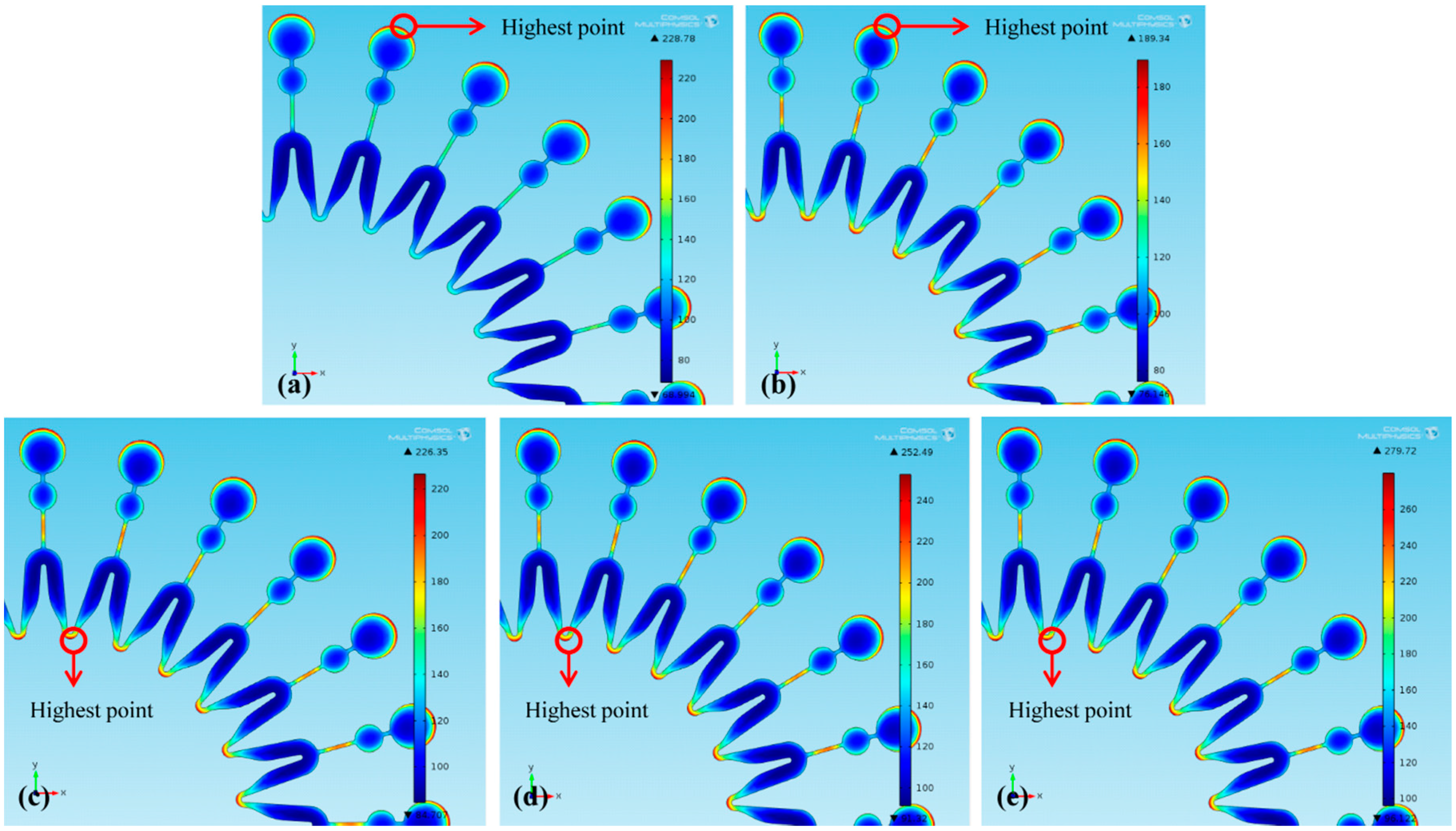

3.3.1. Effect of Distance between Second Cathode and Microstructure of the Mold on Thickness Uniformity of the Mold

| (L, W) (mm) | hmax (μm) | hmin (μm) | α (%) |

|---|---|---|---|

| (0, 0) | 57.74 | 19.30 | 199.3 |

| (13, 4) | 49.09 | 19.27 | 154.8 |

| (9, 4) | 43.86 | 18.91 | 131.9 |

| (5, 4) | 45.99 | 19.90 | 131.1 |

| (1, 4) | 47.58 | 19.97 | 138.3 |

3.3.2. Effect of Second Cathode Width on Thickness Uniformity of the Mold

| (L, W) (mm) | hmax (μm) | hmin (μm) | α (%) |

|---|---|---|---|

| (0, 0) | 57.74 | 19.29 | 199.3 |

| (9, 4) | 43.86 | 18.91 | 132.0 |

| (9, 5) | 51.29 | 21.08 | 143.3 |

| (9, 6) | 49.98 | 19.89 | 151.3 |

| (9, 7) | 54.82 | 20.95 | 161.7 |

3.3.3. Effect of Electroforming Time on Thickness Uniformity of the Mold

| t (h) | 2 | 5 | 10 | 15 | 22 |

|---|---|---|---|---|---|

| αwithout (%) | 76.5 | 80.6 | 88.9 | 100 | 123.8 |

| αwith (%) | 52.6 | 53.9 | 57.6 | 61.6 | 67.5 |

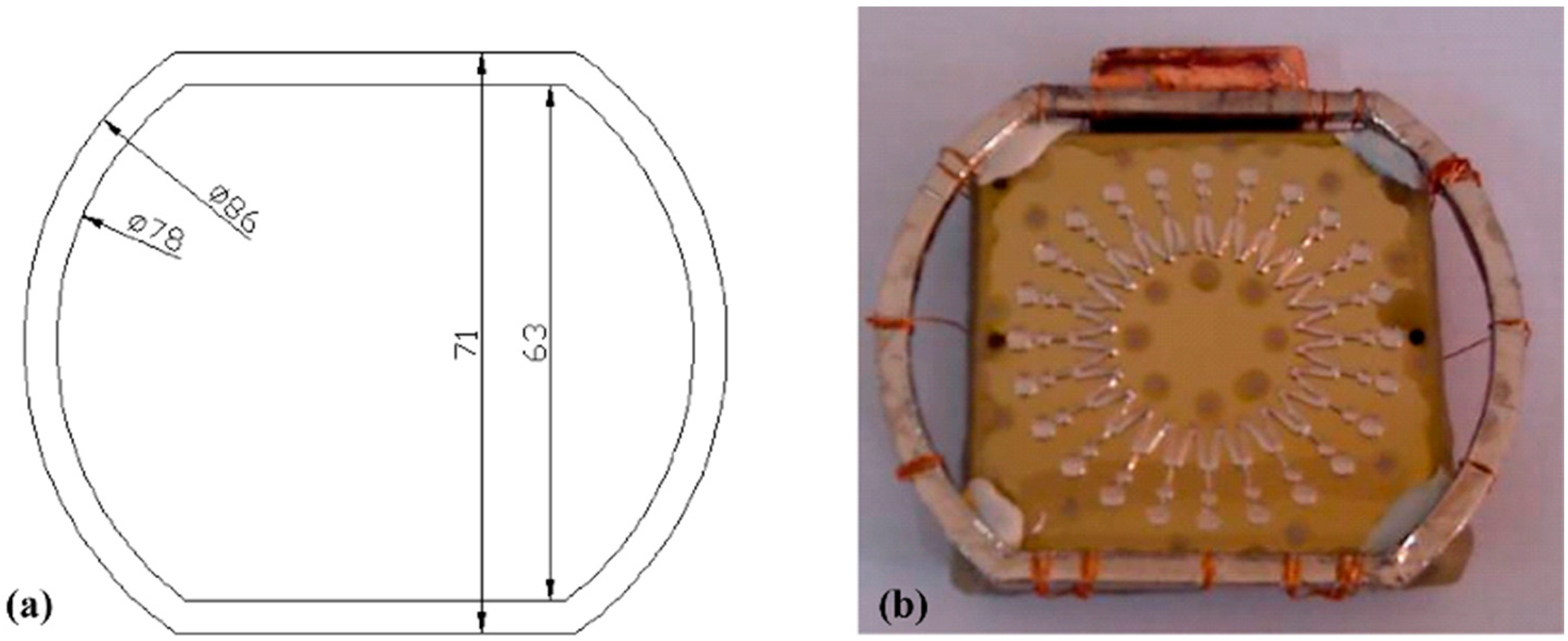

4. Fabrication of the Microfluidic Chip Mold

4.1. Fabrication of the Mold by Electroforming with a Second Cathode Present

4.2. Uniformity Analysis of the Mold Thickness

| Electroforming Condition | hmax (μm) | hmin (μm) | α (%) |

|---|---|---|---|

| Without the Second Cathode | 503.4 | 208.0 | 142.0 |

| With the Second Cathode | 344.8 | 204.1 | 68.9 |

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Alley, W.R., Jr.; Madera, M.; Mechref, Y.; Novotny, M.V. Chip-based reversed-phase liquid chromatography-mass spectrometry of permethylated N-linked glycans: A potential methodology for cancer-biomarker discovery. Anal. Chem. 2010, 82, 5095–5106. [Google Scholar] [CrossRef] [PubMed]

- Cretich, M.; Di Carlo, G.; Giudici, C.; Pokoj, S.; Lauer, I.; Scheurer, S.; Chiari, M. Detection of allergen specific i mmunoglobulins by microarrays coupled to microfluidics. Proteomics 2009, 9, 2098–2107. [Google Scholar] [CrossRef] [PubMed]

- Stybayeva, G.; Mudanyali, O.; Seo, S.; Silangcruz, J.; Macal, M.; Ramanculov, E.; Dandekar, S.; Erlinger, A.; Ozcan, A.; Revzin, A. Lensfree holographic imaging of antibody microarrays for high-throughput detection of leukocyte numbers and function. Anal. Chem. 2010, 82, 3736–3744. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Yin, X.F.; Fang, Z.L. Integration of single cell injection, cell lysis, separation and detection of intracellular constituents on a microfluidic chip. Lab Chip 2004, 4, 47–52. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.B. Study on Electric Driven Bidirectional Bistable Micro Relay and Its Integrated Manufacturing Process; Shanghai Jiao Tong University: Shanghai, China, 2011. (In Chinese) [Google Scholar]

- Yeh, Y.M.; Tu, G.C.; Fu, M.N. Simulation analysis and experimental verification of UV-LIGA process for high-aspect-ratio Ni-Fe micro-mold insert. Jpn. J. Appl. Phys. 2003, 42, 6683. [Google Scholar] [CrossRef]

- Tsai, T.H.; Yang, H.; Chein, R. New electroforming technology pressure aid for LIGA process. Microsyst. Technol. 2004, 10, 351–356. [Google Scholar] [CrossRef]

- Du, L.; Liu, H.; Liu, C.; Zhu, S.; Qin, J. Study on the Uniformity of Micro Electroforming Mold Insert Used in Micro Fluidic-Chip Fabrication. In Proceedings of the 2007 1st International Conference on Integration and Commercialization of Micro and Nanosystems, Sanya, China, 10–13 January 2007; pp. 329–334.

- Broadbent, E.K. Shields are disposed in the electroplating apparatus to selectively alter the electric field characteristics between the anode and the cathode to adjust or control the electrodepositin rate at selected areas of plating surface. U.S. Patent 6,027,631, 22 February 2000. [Google Scholar]

- Yang, H.; Kang, S.W. Improvement of thickness uniformity in nickel electroforming for the LIGA process. Int. J. Mach. Tools Manuf. 2000, 40, 1065–1072. [Google Scholar] [CrossRef]

- Li, J.; Zhang, P.; Wu, Y.; Liu, Y.; Xuan, M. Uniformity study of nickel thin-film microstructure deposited by electroplating. Microsyst. Technol. 2009, 15, 505–510. [Google Scholar] [CrossRef]

- Ming, P.M.; Zhu, D.; Hu, Y.Y.; Zeng, Y.B. Experimental research on microelectroforming with ultrasonic agitation. Key Eng. Mater. 2008, 375, 253–257. [Google Scholar] [CrossRef]

- Jensen, J.A.D.; Pocwiardowski, P.; Persson, P.O.Å.; Hultman, L.; Møller, P. Acoustic streaming enhanced electrodeposition of nickel. Chem. Phys. Lett. 2003, 368, 732–737. [Google Scholar] [CrossRef]

- Du, L.; Zhao, M.; Wang, A.; Chen, S.; Nie, W. Fabrication of novel MEMS inertial switch with six layers on a metal substrate. Microsyst. Technol. 2015, 21, 2025–2032. [Google Scholar] [CrossRef]

- Hume, E.C.; Deen, W.M.; Brown, R.A. Mass transfer analysis of electrodeposition through polymeric masks. J. Electrochem. Soc. 1984, 131, 1251–1258. [Google Scholar] [CrossRef]

- Luo, J.K.; Chu, D.P.; Flewitt, A.J.; Spearing, S.M.; Fleck, N.A.; Milne, W.I. Uniformity control of Ni thin-film microstructures deposited by through-mask plating. J. Electrochem. Soc. 2005, 152, C36–C41. [Google Scholar] [CrossRef]

- Sadhal, S.S. Acoustofluidics 13: Analysis of acoustic streaming by perturbation methods. Lab Chip 2012, 12, 2292–2300. [Google Scholar] [CrossRef] [PubMed]

- Mason, T.J. Sonochemistry: A technology for tomorrow. Chem. Ind. 1993, 1, 47–50. [Google Scholar]

- Beckett, M.A.; Hua, I. Impact of ultrasonic frequency on aqueous sonoluminescence and sonochemistry. J. Phys. Chem. A. 2001, 105, 3796–3802. [Google Scholar] [CrossRef]

- Nilson, R.H.; Griffiths, S.K. Enhanced transport by acoustic streaming in deep trench-like cavities. J. Electrochem. Soc. 2002, 149, G286–G296. [Google Scholar] [CrossRef]

- Tang, J.; Wang, H.; Liu, R.; Mao, S.; Li, X.; Wang, Z.; Ding, G. Finite element simulation on uniformity of MEMS electroforming microstructure. Microfabr. Technol. 2008, 5, 3–4. (In Chinese) [Google Scholar]

- Suslick, K.S.; Didenko, Y.; Fang, M.M.; Hyeon, T.; Kolbeck, K.J.; McNamara, W.B.; Mdleleni, M.M.; Wong, M. Acoustic cavitation and its chemical consequences. Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 1999, 357, 335–353. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Co mmons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, L.; Yang, T.; Zhao, M.; Tao, Y.; Luo, L.; Wang, L.; Liu, C. Study on Improving Thickness Uniformity of Microfluidic Chip Mold in the Electroforming Process. Micromachines 2016, 7, 7. https://doi.org/10.3390/mi7010007

Du L, Yang T, Zhao M, Tao Y, Luo L, Wang L, Liu C. Study on Improving Thickness Uniformity of Microfluidic Chip Mold in the Electroforming Process. Micromachines. 2016; 7(1):7. https://doi.org/10.3390/mi7010007

Chicago/Turabian StyleDu, Liqun, Tong Yang, Ming Zhao, Yousheng Tao, Lei Luo, Lei Wang, and Chong Liu. 2016. "Study on Improving Thickness Uniformity of Microfluidic Chip Mold in the Electroforming Process" Micromachines 7, no. 1: 7. https://doi.org/10.3390/mi7010007