A Fast, Large-Stroke Electrothermal MEMS Mirror Based on Cu/W Bimorph

Abstract

:1. Introduction

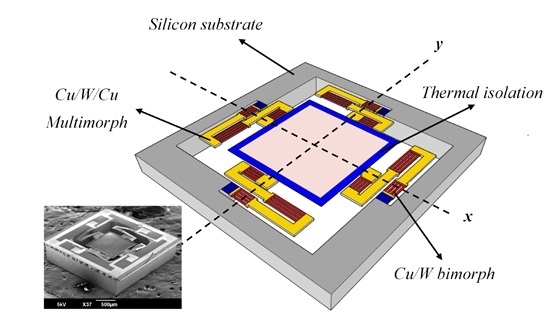

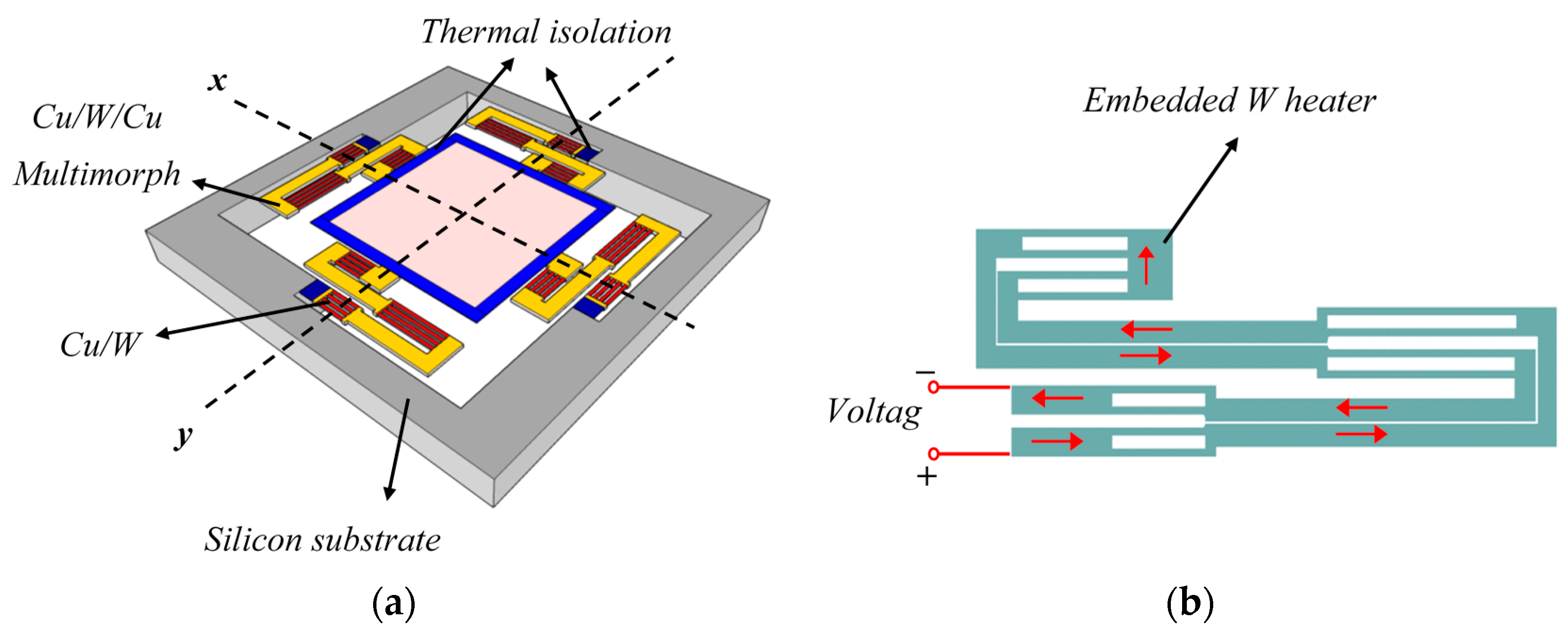

2. Working Principle

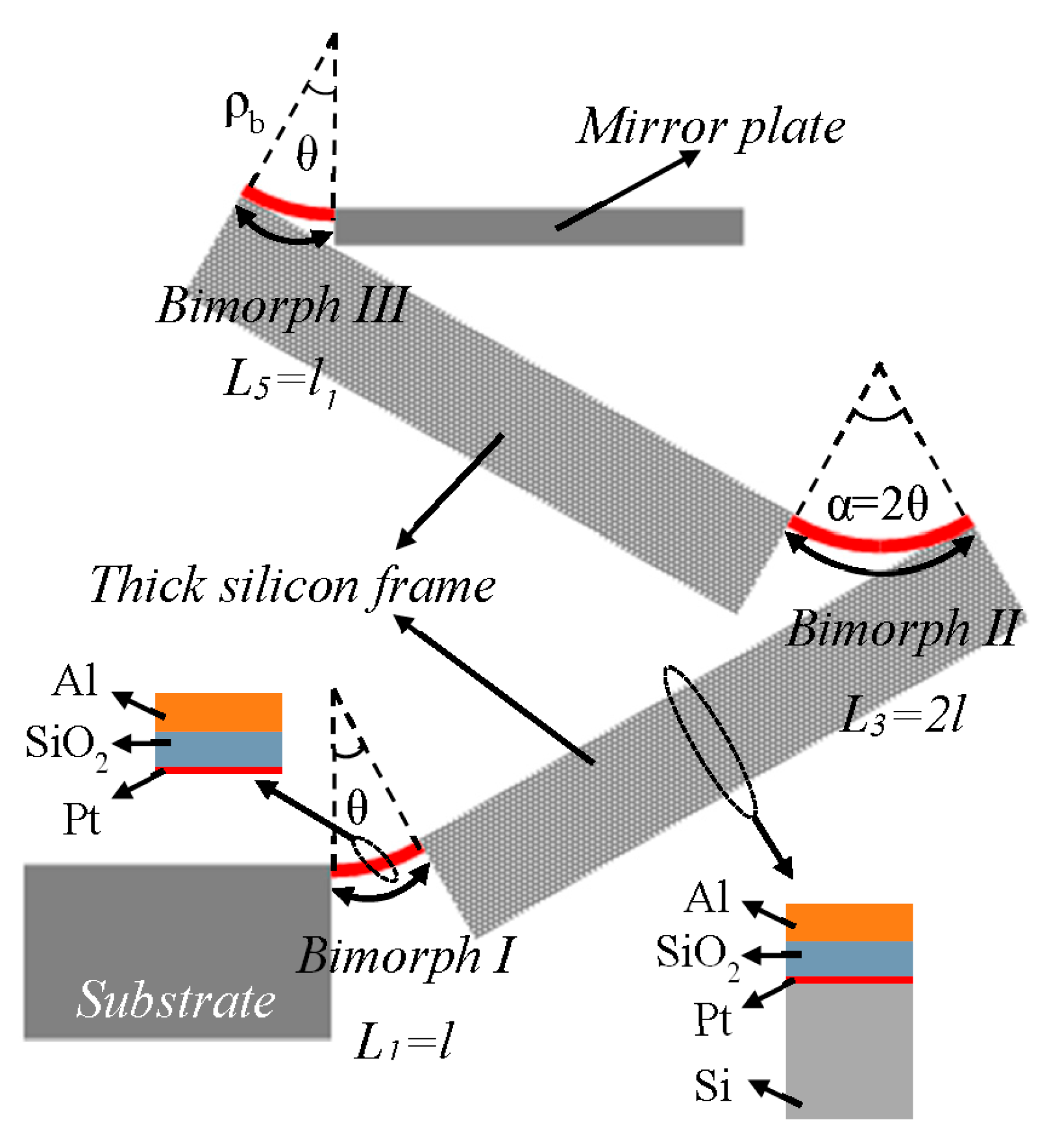

2.1. LSF Cu/W Bimorph Actuator Concept

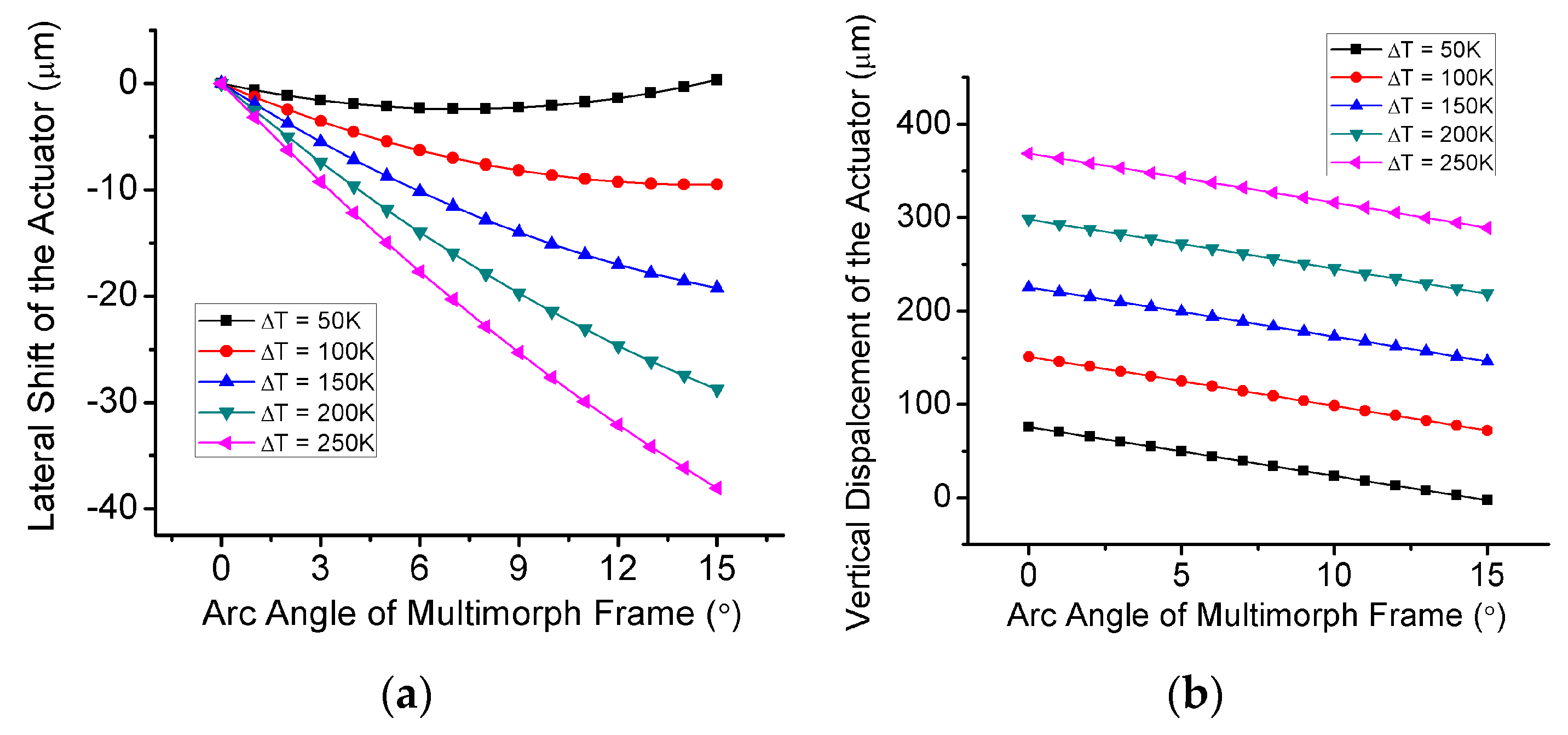

2.2. Tilt/Shift Analysis of the LSF Cu/W Bimorph Actuator

2.3. Thermal Response

3. Design of the Cu/W LSF-Based MEMS Mirror

| Structure Parameter | Value |

|---|---|

| Device footprint | 2.5 mm × 2.5 mm |

| Mirror plate size | 0.9 mm × 0.9 mm |

| Length of Bimorph I, III | 150 μm |

| Length of Multimorph Frame | 450 μm |

| Width of Bimorphs | 12 μm × 4 |

| Width of Multimorph Frame | 70 μm |

| Thickness of Cu | 1 μm |

| Thickness of W | 0.7 μm |

| Thickness of protection SiO2 | 0.2 μm |

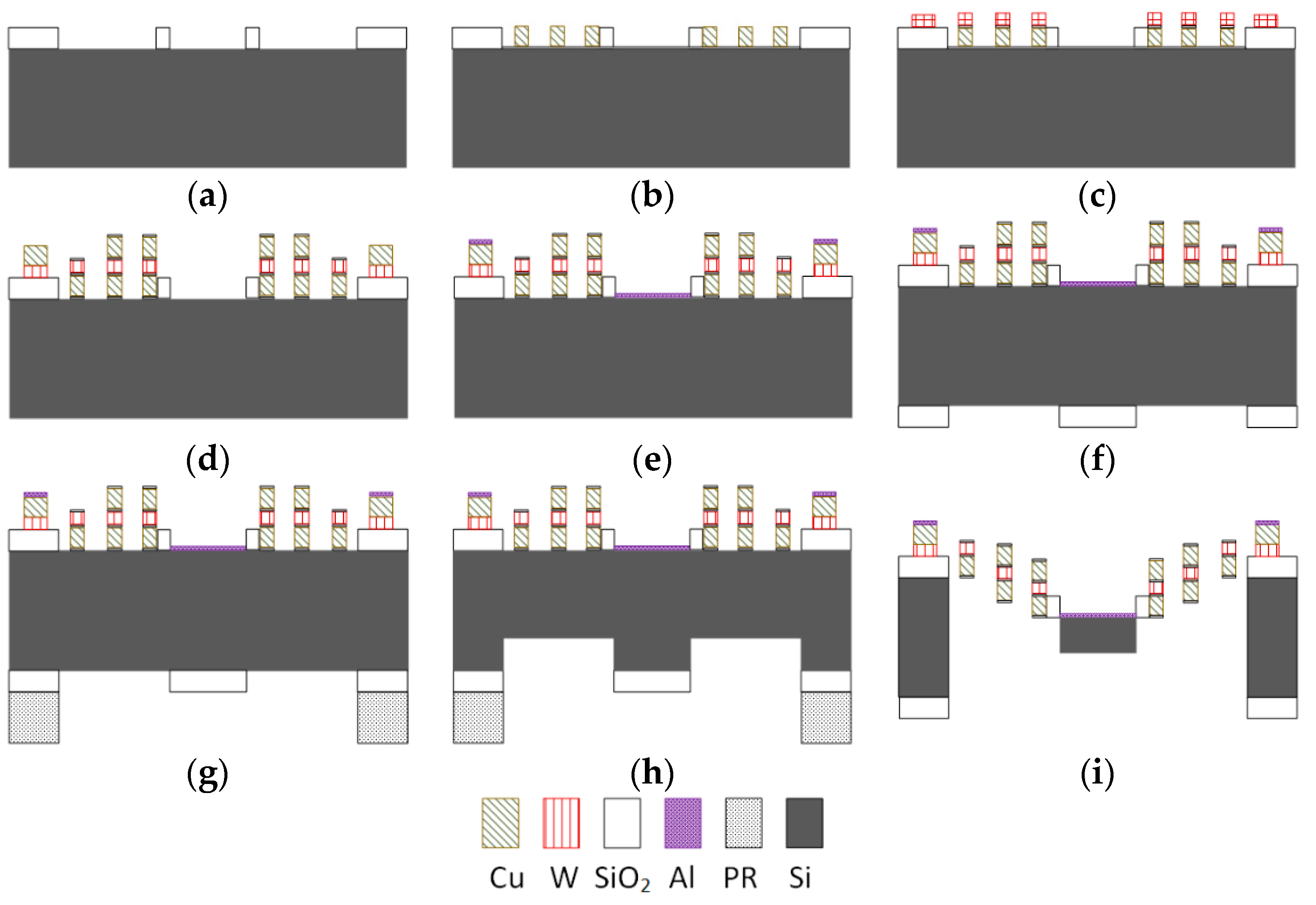

4. Fabrication Process

5. Experiment Results and Analysis

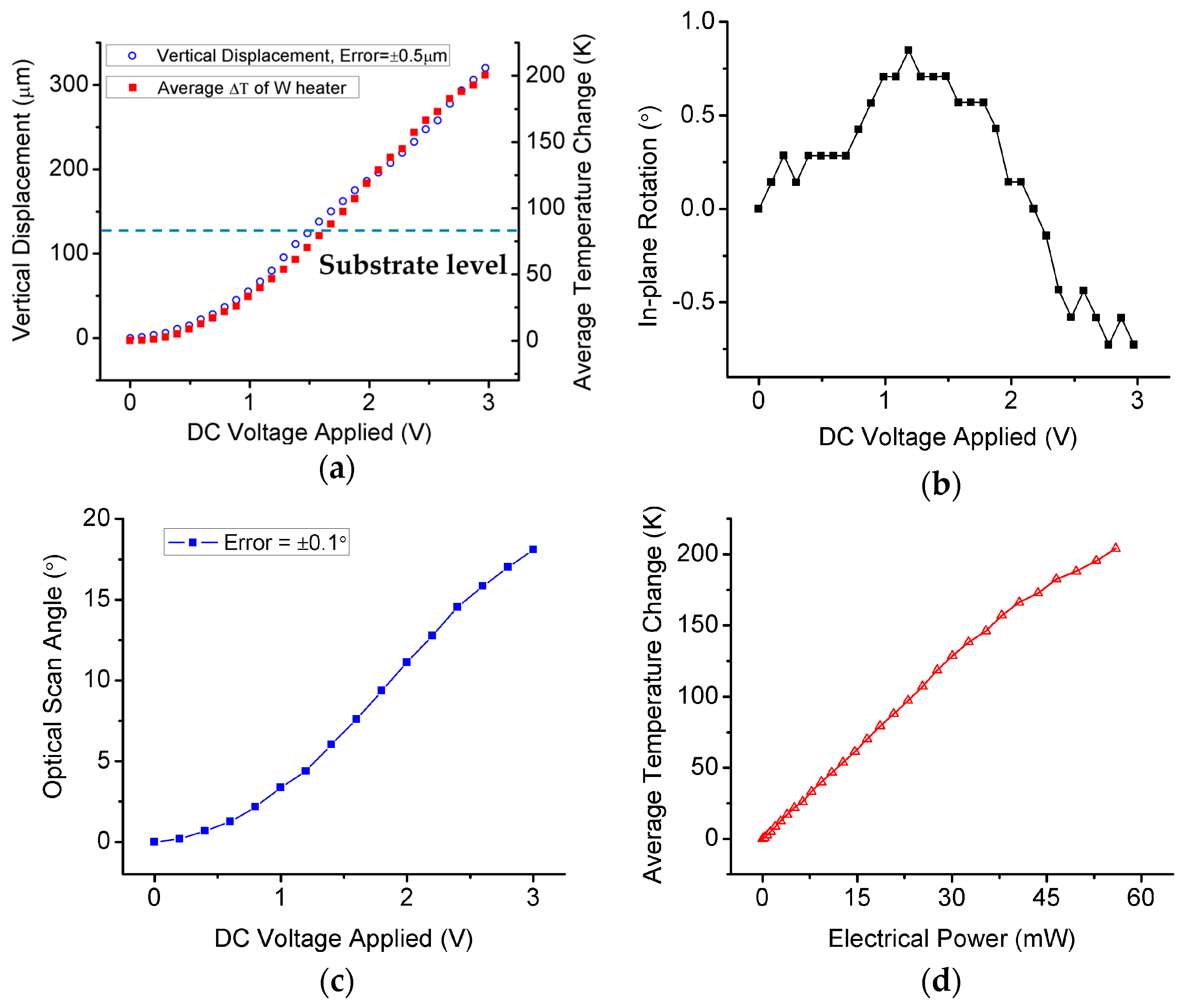

5.1. Static Response

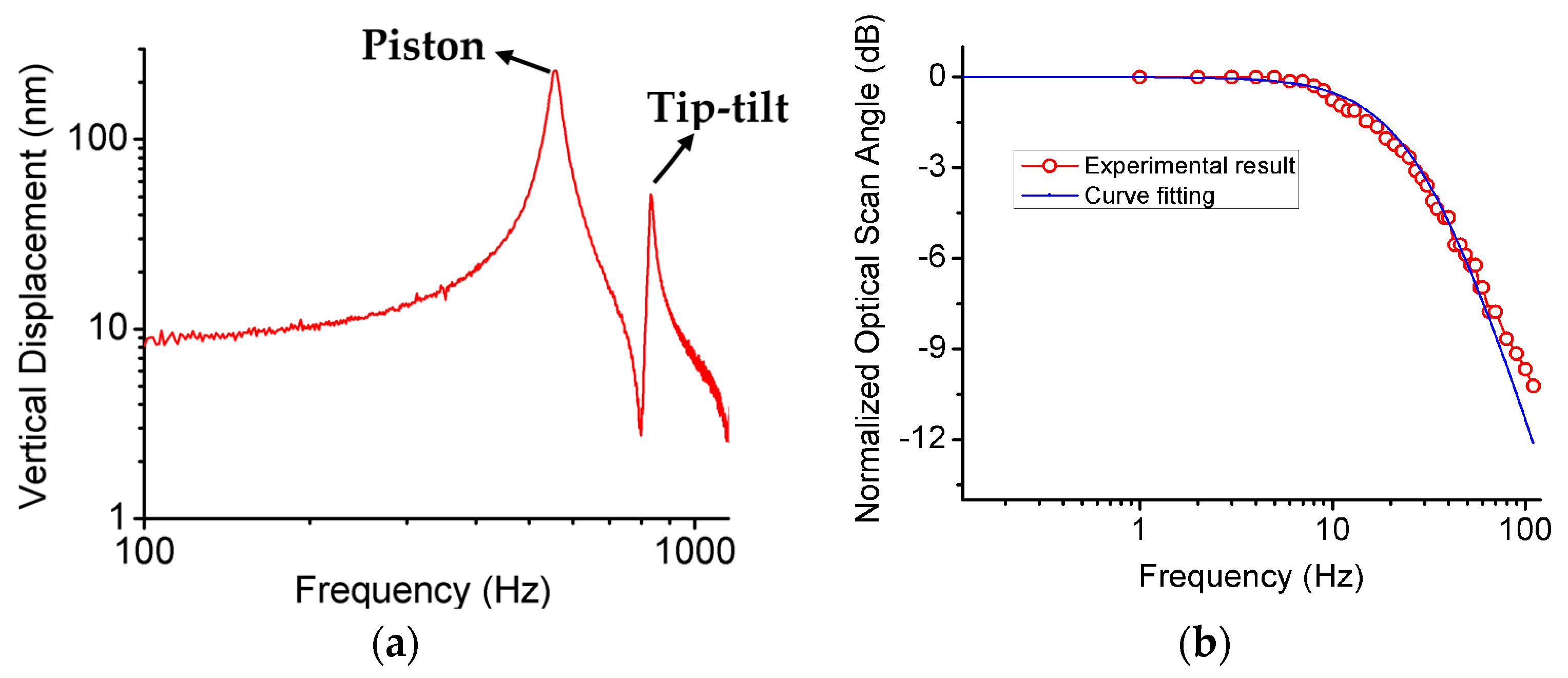

5.2. Dynamic Response

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Manzardo, O.; Herzig, H.P.; Marxer, C.R.; de Rooij, N.F. Miniaturized time-scanning Fourier transform spectrometer based on silicon technology. Opt. Lett. 1999, 24, 1705–1707. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Pais, A.; Samuelson, S.R.; Guo, S.; Xie, H. A mirror-tilt-insensitive Fourier transform spectrometer based on a large vertical displacement micromirror with dual reflective surface. In Proceedings of the 15th IEEE International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers ’09), Denver, CO, USA, 21–25 June 2009.

- Liu, L.; Wang, E.; Zhang, X.; Liang, W.; Li, X.; Xie, H. MEMS-based 3D confocal scanning microendoscope using MEMS scanners for both lateral and axial scan. Sens. Actuators A Phys. 2014, 215, 89–95. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.M.; Cobb, M.J.; Chen, Y.C.; Kimmey, M.B.; Li, X.D. Rapid-scanning forward-imaging miniature endoscope for real-time optical coherence tomography. Opt. Lett. 2004, 29, 1763–1765. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Guo, S.; Wu, L.; Liu, L.; Choe, S.-W.; Sorg, B.S.; Xie, H. 3D in vivo optical coherence tomography based on a low-voltage, large-scan-range 2D MEMS mirror. Opt. Express 2010, 18, 12065–12075. [Google Scholar] [CrossRef] [PubMed]

- Toshiyoshi, H.; Fujita, H. Electrostatic micro torsion mirrors for an optical switch matrix. J. Microelectromech. Syst. 1996, 5, 231–237. [Google Scholar] [CrossRef]

- Van Kessel, P.F.; Hornbeck, L.J.; Meier, R.E.; Douglass, M.R. A MEMS-based projection display. Proc. IEEE 1998, 86, 1687–1704. [Google Scholar] [CrossRef]

- Wang, W.; Chen, J.; Zivkovic, A.S.; Duan, C.; Xie, H. A silicon based Fourier transform spectrometer based on an open-loop controlled electrothermal MEMS mirror. In Proceedings of the 18th IEEE International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers ’15), Anchorage, AK, USA, 21–25 June 2015.

- Wu, L.; Xie, H. A large vertical displacement electrothermal bimorph microactuator with very small lateral shift. Sens. Actuators A Phys. 2008, 145, 371–379. [Google Scholar] [CrossRef]

- Jain, A.; Kopa, A.; Pan, Y.; Feeder, G.K.; Xie, H. A two-axis electrothermal micromirror for endoscopic optical coherence tomography. IEEE J. Sel. Top. Quantum Electron. 2004, 10, 636–642. [Google Scholar] [CrossRef]

- Hao, Z.; Wingfield, B.; Whitley, M.; Brooks, J.; Hammer, J.A. A design methodology for a bulk-micromachined two-dimensional electrostatic torsion micromirror. J. Microelectromech. Syst. 2003, 12, 692–701. [Google Scholar]

- Sandner, T.; Grasshoff, T.; Schenk, H.; Kenda, A. Out-of-Plane Translatory MEMS actuator with extraordinary large stroke for optical path length modulation. Proc. SPIE MOEMS Miniat. Syst. X 2011, 7930, 79300I. [Google Scholar]

- Zhu, Y.; Liu, W.; Jia, K.; Liao, W.; Xie, H. A piezoelectric unimorph actuator based tip-tilt-piston micromirror with high fill factor and small tilt and lateral shift. Sens. Actuators A Phys. 2011, 67, 495–501. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, R.; Koppal, S.; Butler, L.; Cheng, X.; Xie, H. MEMS mirror submerged in liquid for wide-angle scanning. In Proceedings of the 18th IEEE International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers ’15), Anchorage, AK, USA, 21–25 June 2015.

- Garcia, E.; Lobontiu, N. Induced-strain multimorphs for microscale sensory actuation design. Smart Mater. Struct. 2004, 13, 725–732. [Google Scholar] [CrossRef]

- Chu, W.H.; Mehregany, M.; Mullen, R.L. Analysis of tip deflection and force of a bimetallic cantilever microactuator. J. Micromech. Microeng. 1993, 6, 4–7. [Google Scholar] [CrossRef]

- Ali, S.Z.; Udrea, F.; Milne, W.I.; Gardner, J.W.; Member, S. Tungsten-based SOI microhotplates for smart gas sensors. J. Microelectromech. Syst. 2008, 17, 1408–1417. [Google Scholar] [CrossRef]

- Ghodssi, R.; Lin, P. MEMS Materials and Processes Handbook; Springer: Berlin, Germany, 2011. [Google Scholar]

- Pal, S.; Xie, H. Fabrication of robust electrothermal MEMS devices using aluminum-tungsten bimorphs and polyimide thermal isolation. J. Micromech. Microeng. 2012, 22, 115036–115049. [Google Scholar] [CrossRef]

- Todd, S.T.; Xie, H. An electrothermomechanical lumped element model of an electrothermal bimorph actuator. J. Microelectromech. Syst. 2008, 17, 213–225. [Google Scholar] [CrossRef]

- Pike, A.; Gardner, J.W. Thermal modelling and characterisation of micropower chemoresistive silicon sensors. Sens. Actuators B Chem. 1997, 45, 19–26. [Google Scholar] [CrossRef]

- Zhang, X.; Duan, C.; Liu, L.; Li, X.; Xie, H. A non-resonant fiber scanner based on an electrothermally-actuated MEMS stage. Sens. Actuators A Phys. 2015, 233, 239–245. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Xie, H. A millimeter-tunable-range microlens for endoscopic biomedical imaging applications. IEEE J. Quantum Electron. 2010, 46, 1237–1244. [Google Scholar] [CrossRef]

- Yang, B.; Wang, S.; Li, H.; Zhou, B. Mechanical-thermal noise in drive-mode of a silicon microgyroscope. Sensors 2009, 9, 3357–3375. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhou, L.; Xie, H. A Fast, Large-Stroke Electrothermal MEMS Mirror Based on Cu/W Bimorph. Micromachines 2015, 6, 1876-1889. https://doi.org/10.3390/mi6121460

Zhang X, Zhou L, Xie H. A Fast, Large-Stroke Electrothermal MEMS Mirror Based on Cu/W Bimorph. Micromachines. 2015; 6(12):1876-1889. https://doi.org/10.3390/mi6121460

Chicago/Turabian StyleZhang, Xiaoyang, Liang Zhou, and Huikai Xie. 2015. "A Fast, Large-Stroke Electrothermal MEMS Mirror Based on Cu/W Bimorph" Micromachines 6, no. 12: 1876-1889. https://doi.org/10.3390/mi6121460