Observation and Manipulation of a Capillary Jet in a Centrifuge-Based Droplet Shooting Device

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Analysis of the Jetting-Dripping Transition

2.3. Particle Fabrication in the Jetting Regime

2.4. Beads-On-A-String Structure Fabrication

3. Results and Discussion

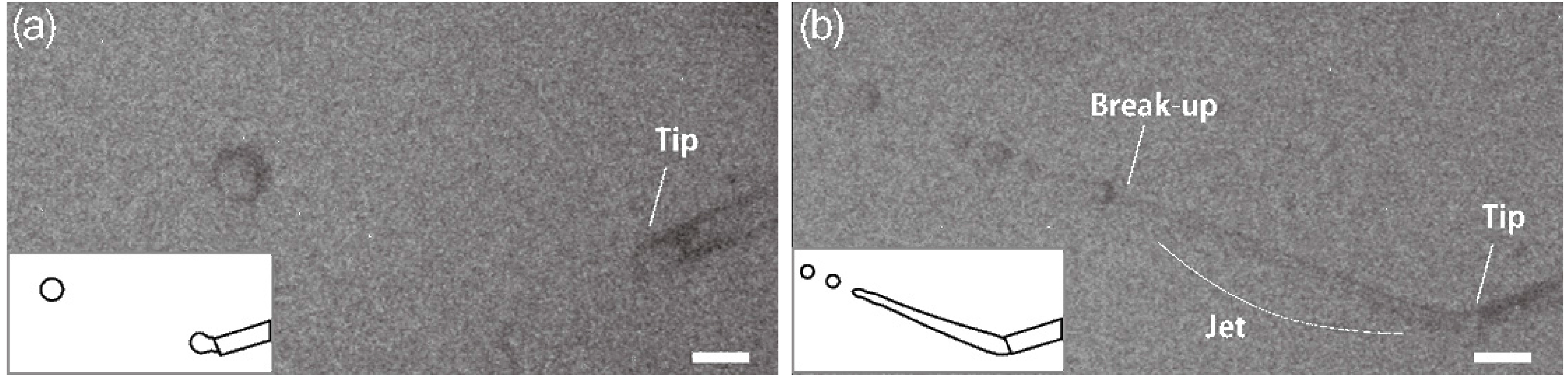

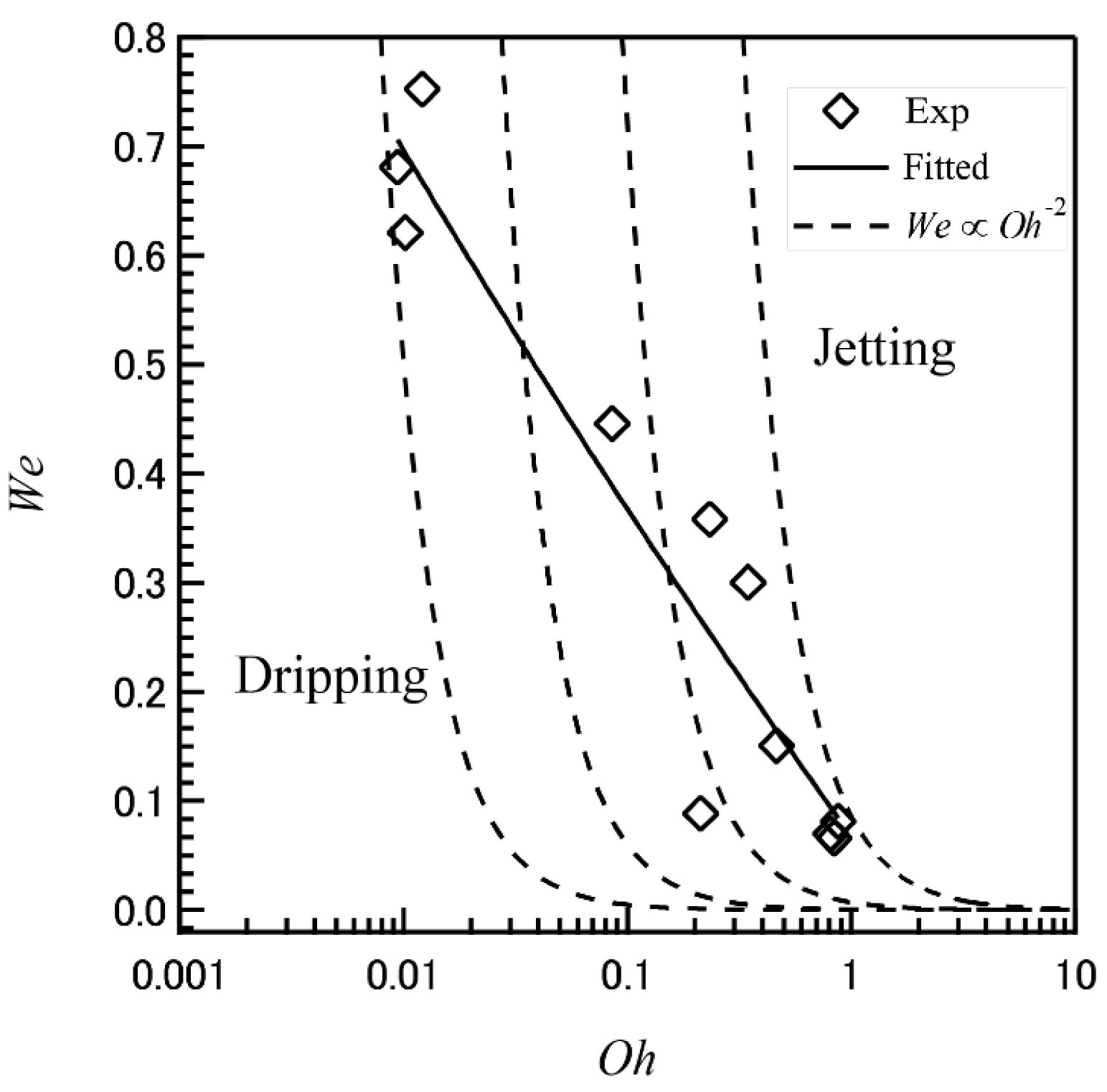

3.1. Analysis of the Dripping-Jetting Transition

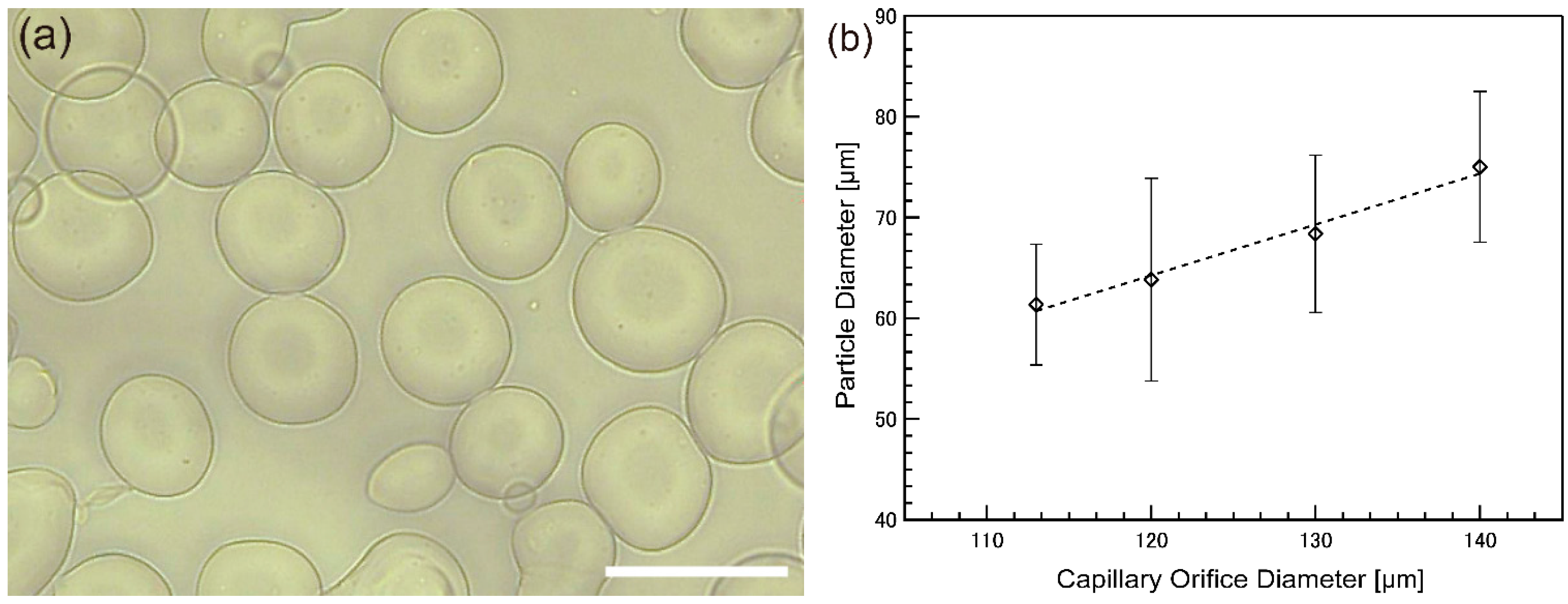

3.2. Particle Fabrication in the Jetting Regime

3.3. Beads-on-a-String Structure Fabrication

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pregibon, D.C.; Toner, M.; Doyle, P.S. Multifunctional encoded particles for high-throughput biomolecule analysis. Science 2007, 315, 1393–1396. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Rozhkova, E.A.; Ulasov, I.V.; Bader, S.D.; Rajh, T.; Lesniak, M.S.; Novosad, V. Biofunctionalized magnetic-vortex microdiscs for targeted cancer-cell destruction. Nat. Mater. 2010, 9, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Morimoto, Y.; Tan, W.H.; Tsuda, Y.; Takeuchi, S. Monodisperse semi-permeable microcapsules for continuous observation of cells. Lab Chip 2009, 9, 2217–2223. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Jeon, S.J.; Jeong, W.C.; Park, H.S.; Yang, S.M. Optofluidic synthesis of electroresponsive photonic janus balls with isotropic structural colors. Adv. Mater. 2008, 20, 4129–4134. [Google Scholar] [CrossRef]

- Xu, Q.B.; Hashimoto, M.; Dang, T.T.; Hoare, T.; Kohane, D.S.; Whitesides, G.M.; Langer, R.; Anderson, D.G. Preparation of monodisperse biodegradable polymer microparticles using a microfluidic flow-focusing device for controlled drug delivery. Small 2009, 5, 1575–1581. [Google Scholar] [CrossRef] [PubMed]

- Matsunaga, Y.T.; Morimoto, Y.; Takeuchi, S. Molding cell beads for rapid construction of macroscopic 3d tissue architecture. Adv. Mater. 2011, 23, H90–H94. [Google Scholar] [CrossRef] [PubMed]

- Garstecki, P.; Fuerstman, M.J.; Stone, H.A.; Whitesides, G.M. Formation of droplets and bubbles in a microfluidic t-junction—Scaling and mechanism of break-up. Lab Chip 2006, 6, 437–446. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, S.; Garstecki, P.; Weibel, D.B.; Whitesides, G.M. An axisymmetric flow-focusing microfluidic device. Adv. Mater. 2005, 17, 1067–1072. [Google Scholar] [CrossRef]

- Maeda, K.; Onoe, H.; Takinoue, M.; Takeuchi, S. Controlled synthesis of 3D multi-compartmental particles with centrifuge-based microdroplet formation from a multi-barrelled capillary. Adv. Mater. 2012, 24, 1340–1346. [Google Scholar] [CrossRef] [PubMed]

- Ambravaneswaran, B.; Subramani, H.J.; Phillips, S.D.; Basaran, O.A. Dripping-jetting transitions in a dripping faucet. Phys. Rev. Lett. 2004, 93, 034501. [Google Scholar] [CrossRef] [PubMed]

- Clanet, C.; Lasheras, J.C. Transition from dripping to jetting. J. Fluid Mech. 1999, 383, 307–326. [Google Scholar] [CrossRef]

- Rubio-Rubio, M.; Sevilla, A.; Gordillo, J.M. On the thinnest steady threads obtained by gravitational stretching of capillary jets. J. Fluid Mech. 2013, 729, 471–483. [Google Scholar] [CrossRef]

- Tate, T. XXX. On the magnitude of a drop of liquid formed under different circumstances. Philos. Mag. Ser. 4 1864, 27, 176–180. [Google Scholar]

- Rayleigh, L. On the capillary phenomena of jets. Proc. R. Soc. Lond. 1879, 29, 71–97. [Google Scholar] [CrossRef]

- Utada, A.S.; Fernandez-Nieves, A.; Stone, H.A.; Weitz, D.A. Dripping to jetting transitions in coflowing liquid streams. Phys. Rev. Lett. 2007, 99, 094502. [Google Scholar] [CrossRef] [PubMed]

- Ambravaneswaran, B.; Wilkes, E.D.; Basaran, O.A. Drop formation from a capillary tube: Comparison of one-dimensional and two-dimensional analyses and occurrence of satellite drops. Phys. Fluids 2002, 14, 2606–2621. [Google Scholar] [CrossRef]

- Lister, J.R.; Stone, H.A. Capillary breakup of a viscous thread surrounded by another viscous fluid. Phys. Fluids 1998, 10, 2758–2764. [Google Scholar] [CrossRef]

- Scheele, G.F.; Meister, B.J. Drop formation at low velocities in liquid-liquid systems.I. Prediction of drop volume.2. Prediction of jetting velocity. Aiche J. 1968, 14, 9–15. [Google Scholar] [CrossRef]

- Batchelor, G.K. An Introduction in Fluid Dynamics; Cambridge University Press: Cambridge, UK, 1967. [Google Scholar]

- Tan, W.H.; Takeuchi, S. Monodisperse alginate hydrogel microbeads for cell encapsulation. Adv. Mater. 2007, 19, 2696–2701. [Google Scholar] [CrossRef]

- Sahni, V.; Blackledge, T.A.; Dhinojwala, A. Changes in the adhesive properties of spider aggregate glue during the evolution of cobwebs. Sci. Rep. 2011, 1, 41. [Google Scholar] [CrossRef] [PubMed]

- Meister, B.J.; Scheele, G.F. Drop formation from cylindrical jets in immiscible liquid systems. AIChE J. 1969, 15, 700–706. [Google Scholar] [CrossRef]

- Eggers, J. Nonlinear dynamics and breakup of free-surface flows. Rev. Modern Phys. 1997, 69, 865–929. [Google Scholar] [CrossRef]

- Ganan-Calvo, A.M.; DePonte, D.P.; Herrada, M.A.; Spence, J.C.H.; Weierstall, U.; Doak, R.B. Liquid capillary micro/nanojets in free-jet expansion. Small 2010, 6, 822–824. [Google Scholar] [CrossRef] [PubMed]

- Sevilla, A. The effect of viscous relaxation on the spatiotemporal stability of capillary jets. J. Fluid Mech. 2011, 684, 204–226. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maeda, K.; Onoe, H.; Takinoue, M.; Takeuchi, S. Observation and Manipulation of a Capillary Jet in a Centrifuge-Based Droplet Shooting Device. Micromachines 2015, 6, 1526-1533. https://doi.org/10.3390/mi6101436

Maeda K, Onoe H, Takinoue M, Takeuchi S. Observation and Manipulation of a Capillary Jet in a Centrifuge-Based Droplet Shooting Device. Micromachines. 2015; 6(10):1526-1533. https://doi.org/10.3390/mi6101436

Chicago/Turabian StyleMaeda, Kazuki, Hiroaki Onoe, Masahiro Takinoue, and Shoji Takeuchi. 2015. "Observation and Manipulation of a Capillary Jet in a Centrifuge-Based Droplet Shooting Device" Micromachines 6, no. 10: 1526-1533. https://doi.org/10.3390/mi6101436