Characterization of Sand and Dust Pollution Degradation Based on Sensitive Structure of Microelectromechanical System Flow Sensor †

Abstract

:1. Introduction

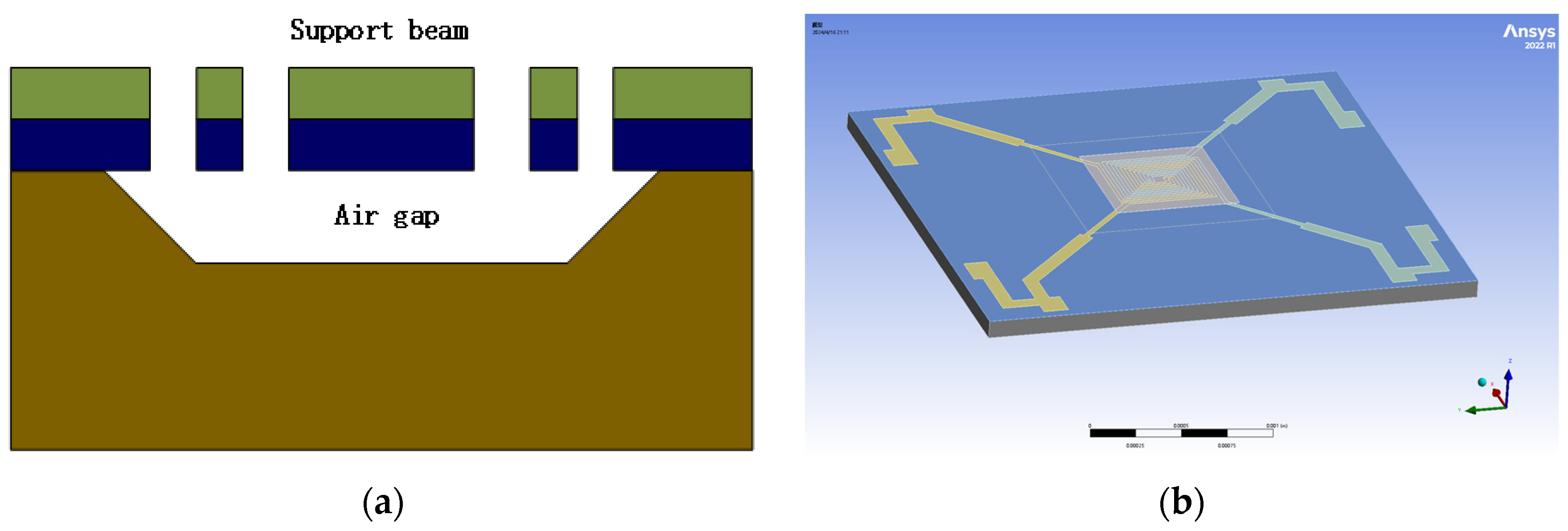

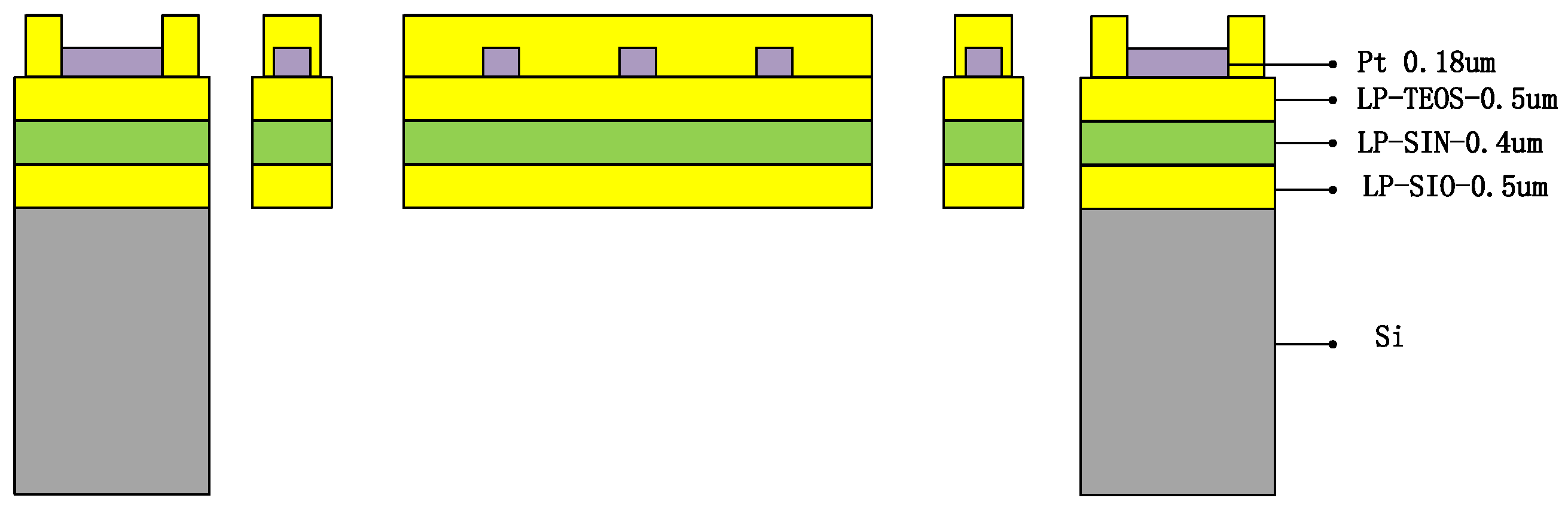

2. Design and Principle

2.1. Dust-Falling Principle

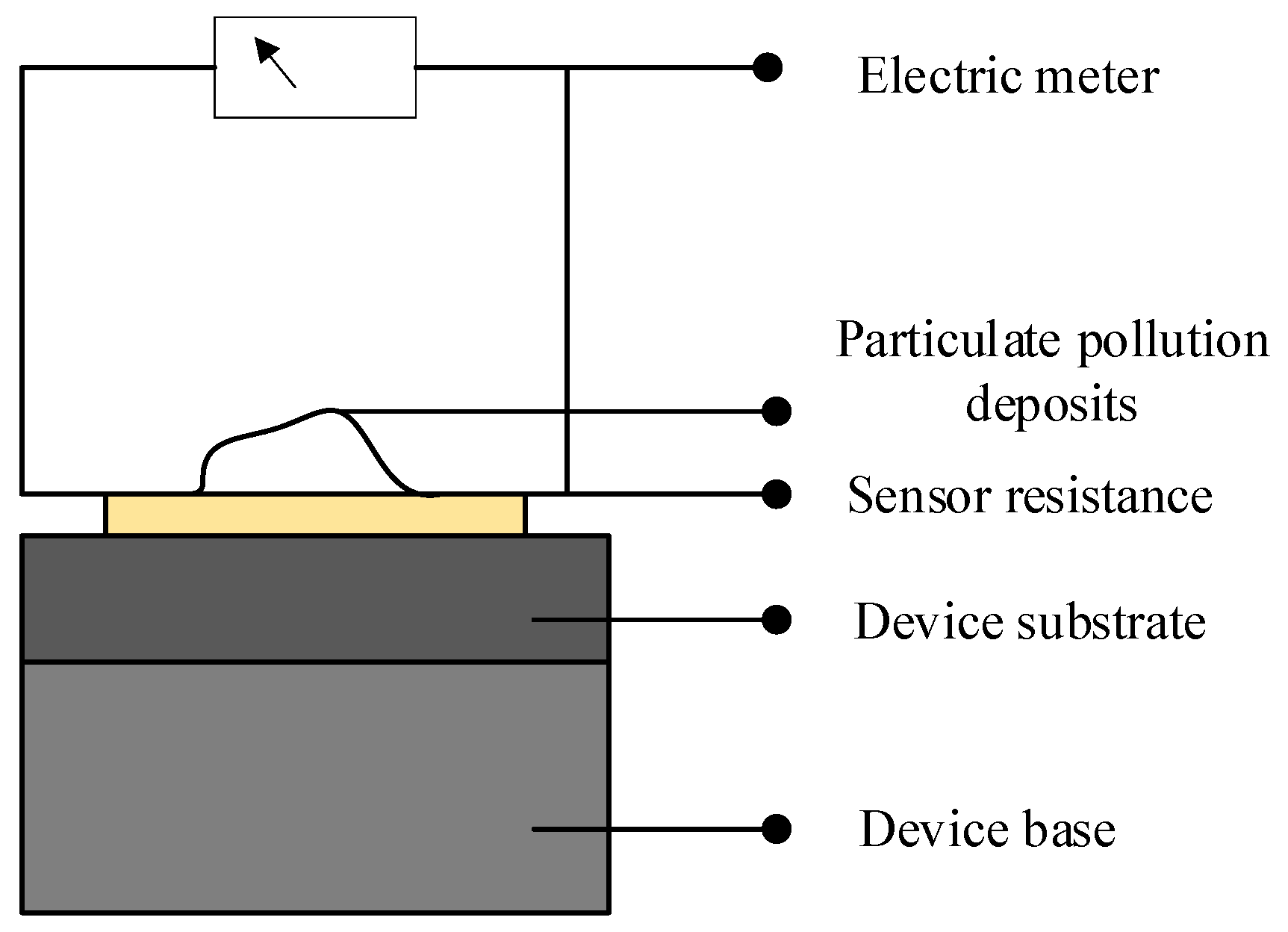

2.2. Principle of Frictional Electrostatic Dissipation

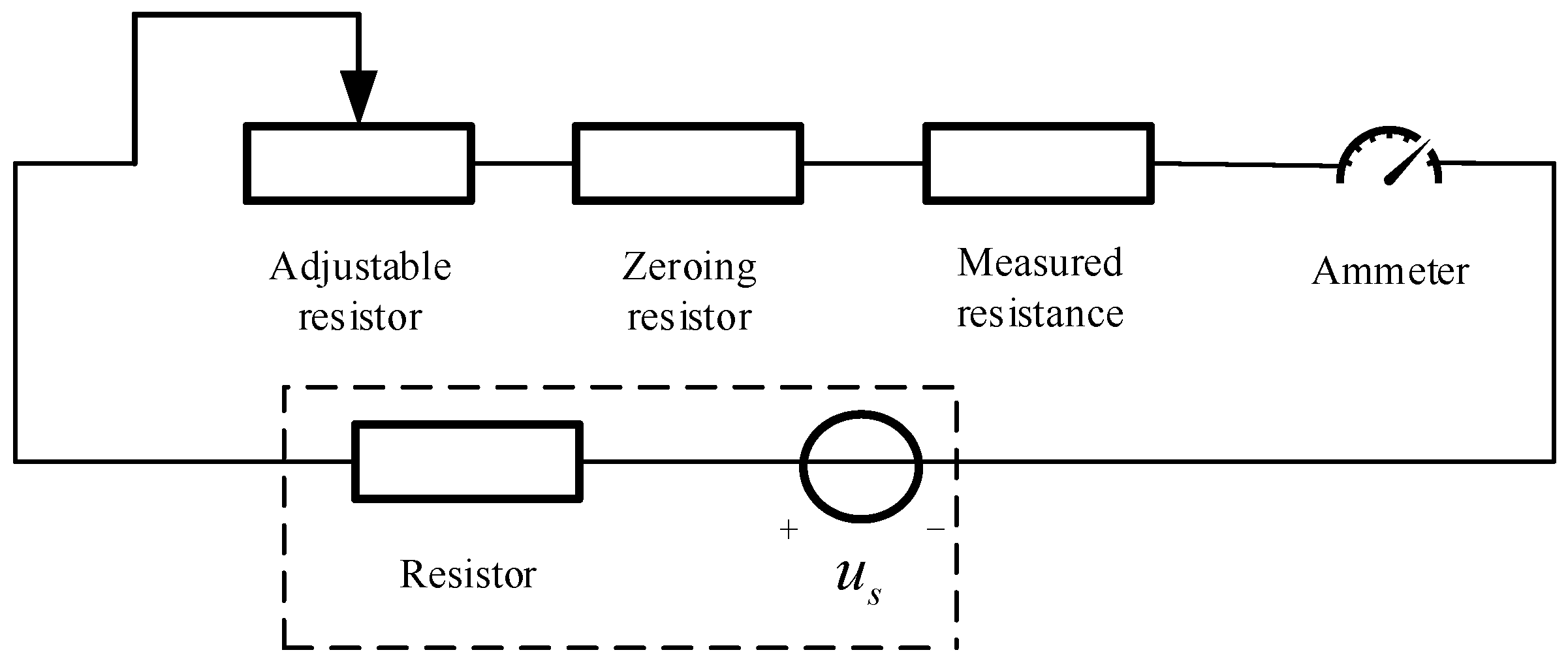

2.3. Principle of Measuring Electrical Characteristics

3. Emulation

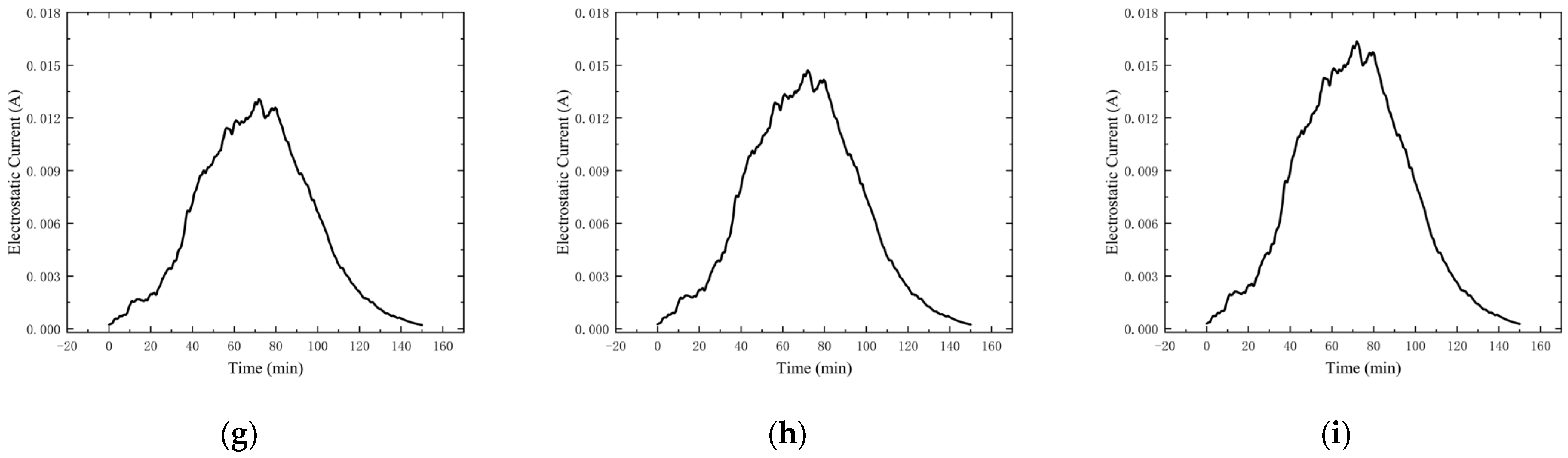

3.1. Principle of Measuring Electrical Characteristics

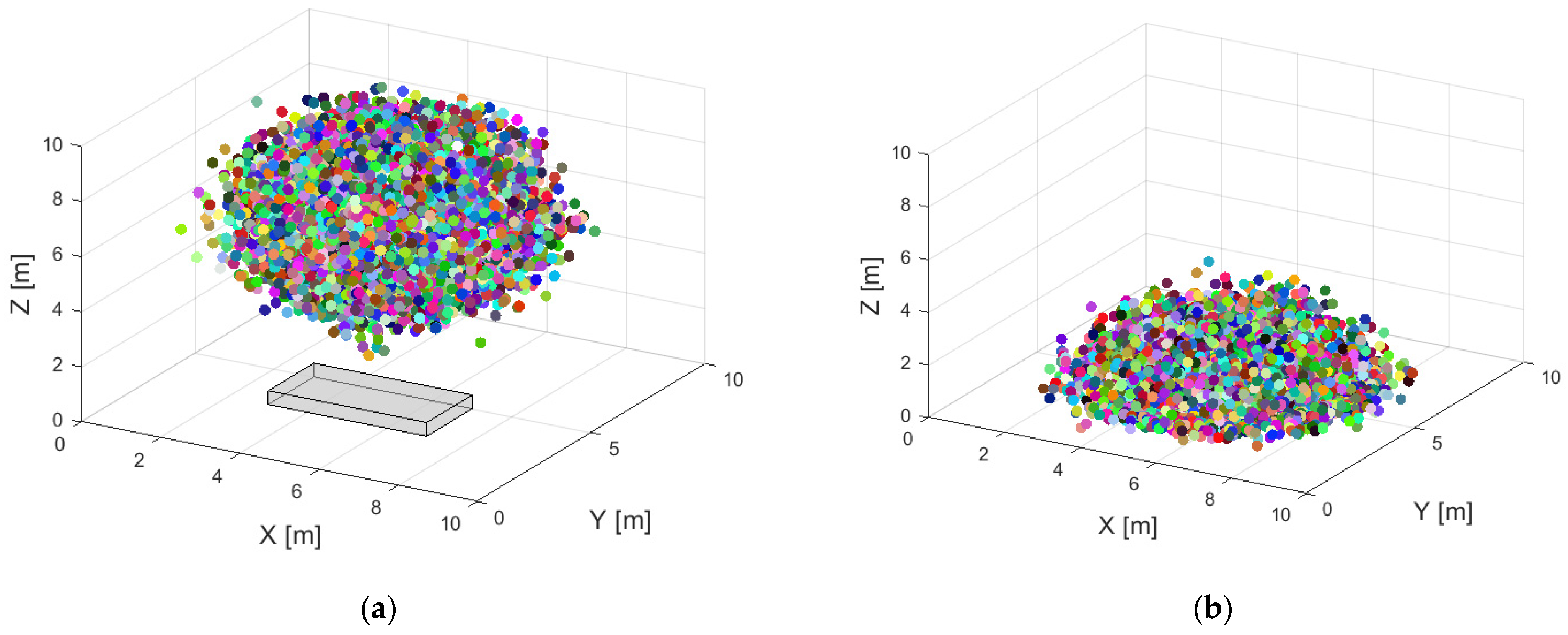

3.2. Sand and Dust Pollution Simulation

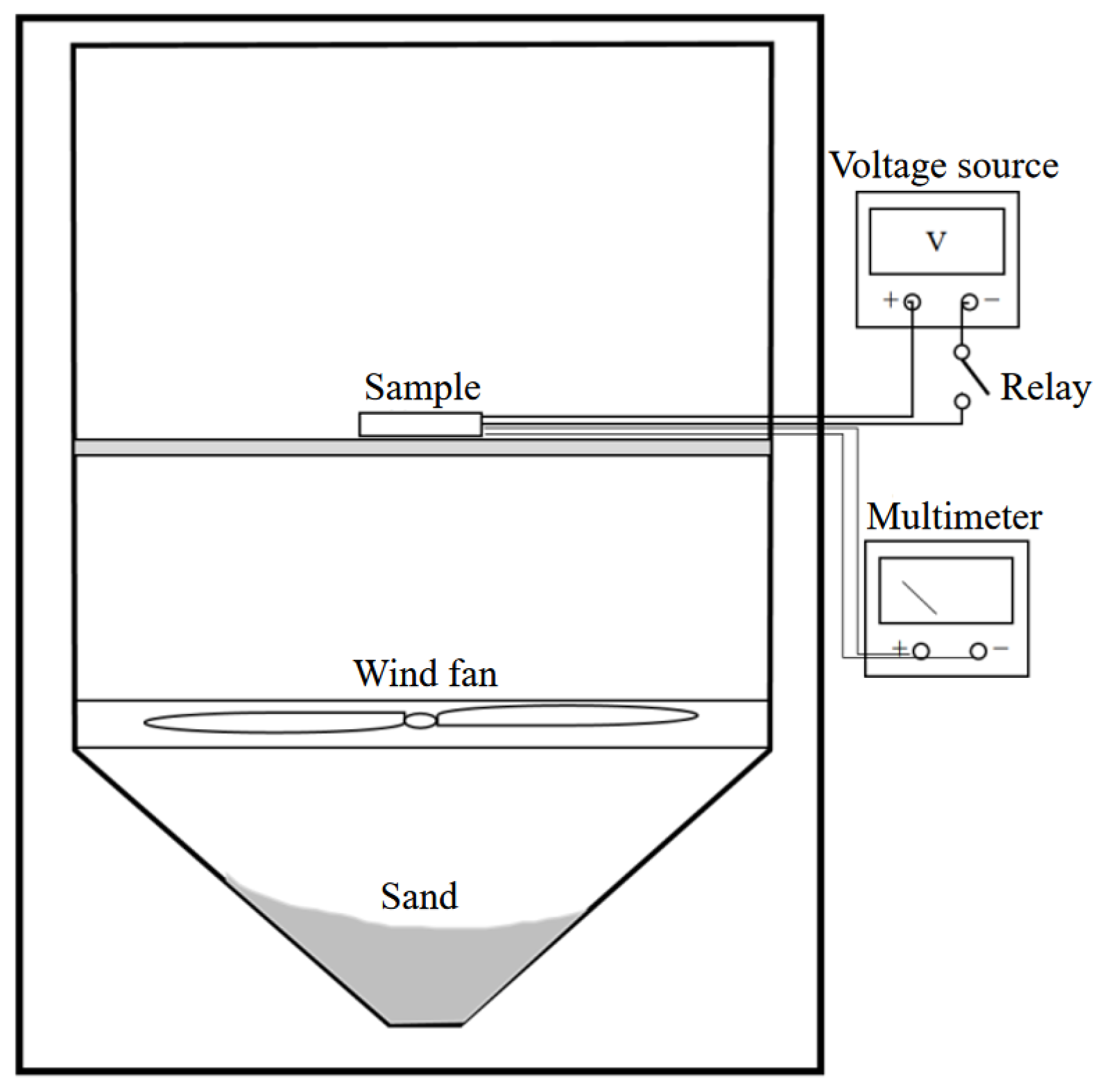

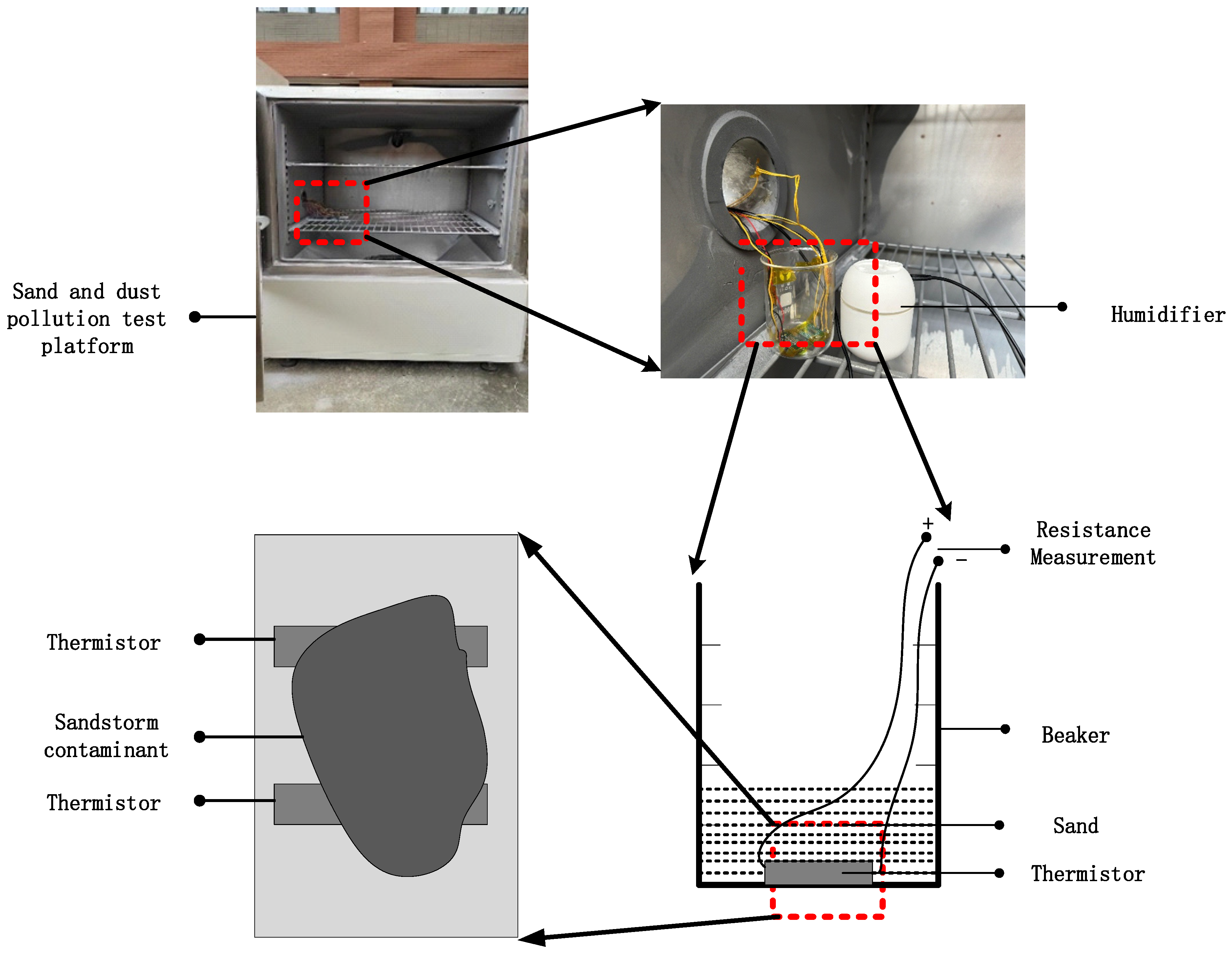

4. Pollution Test

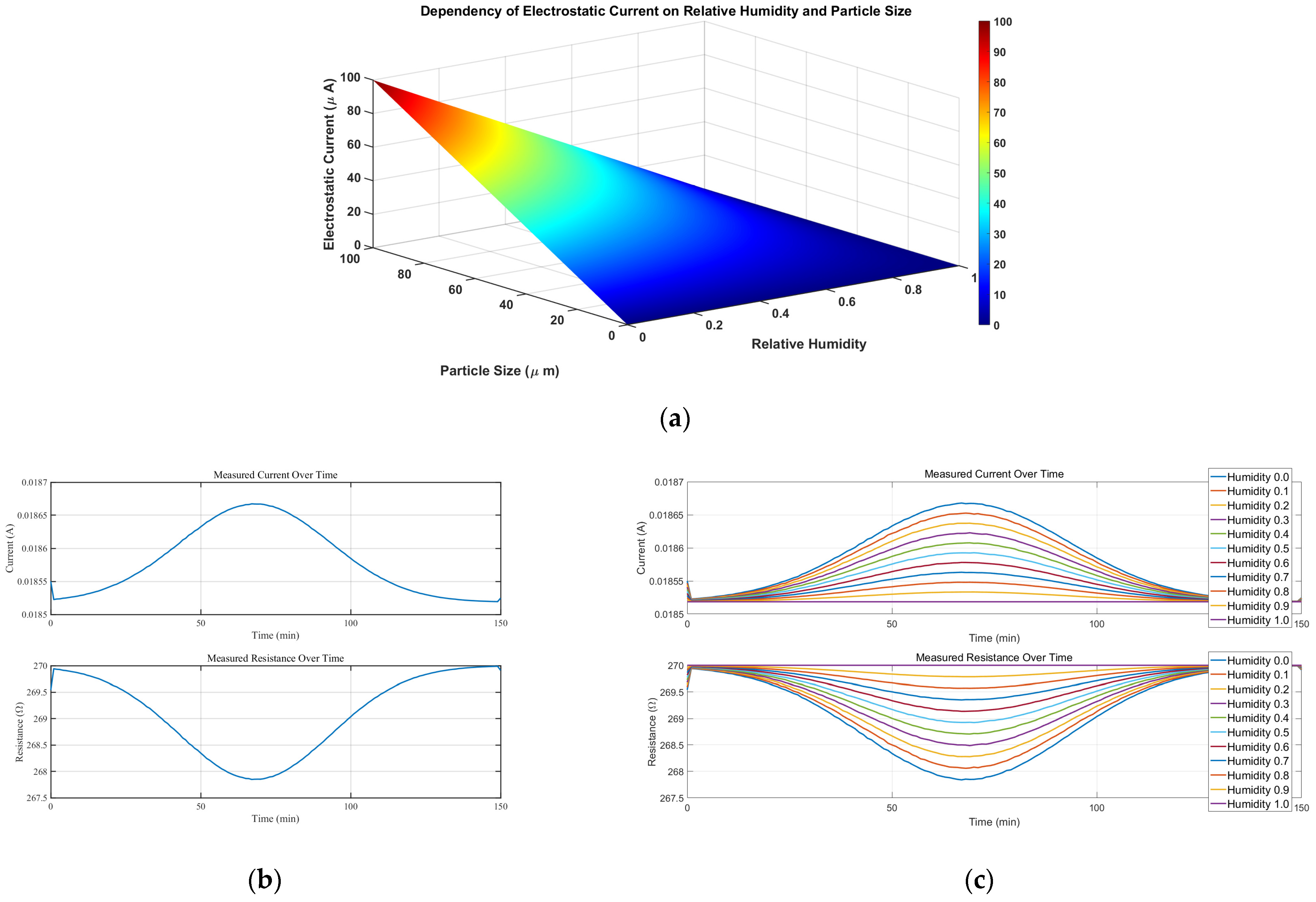

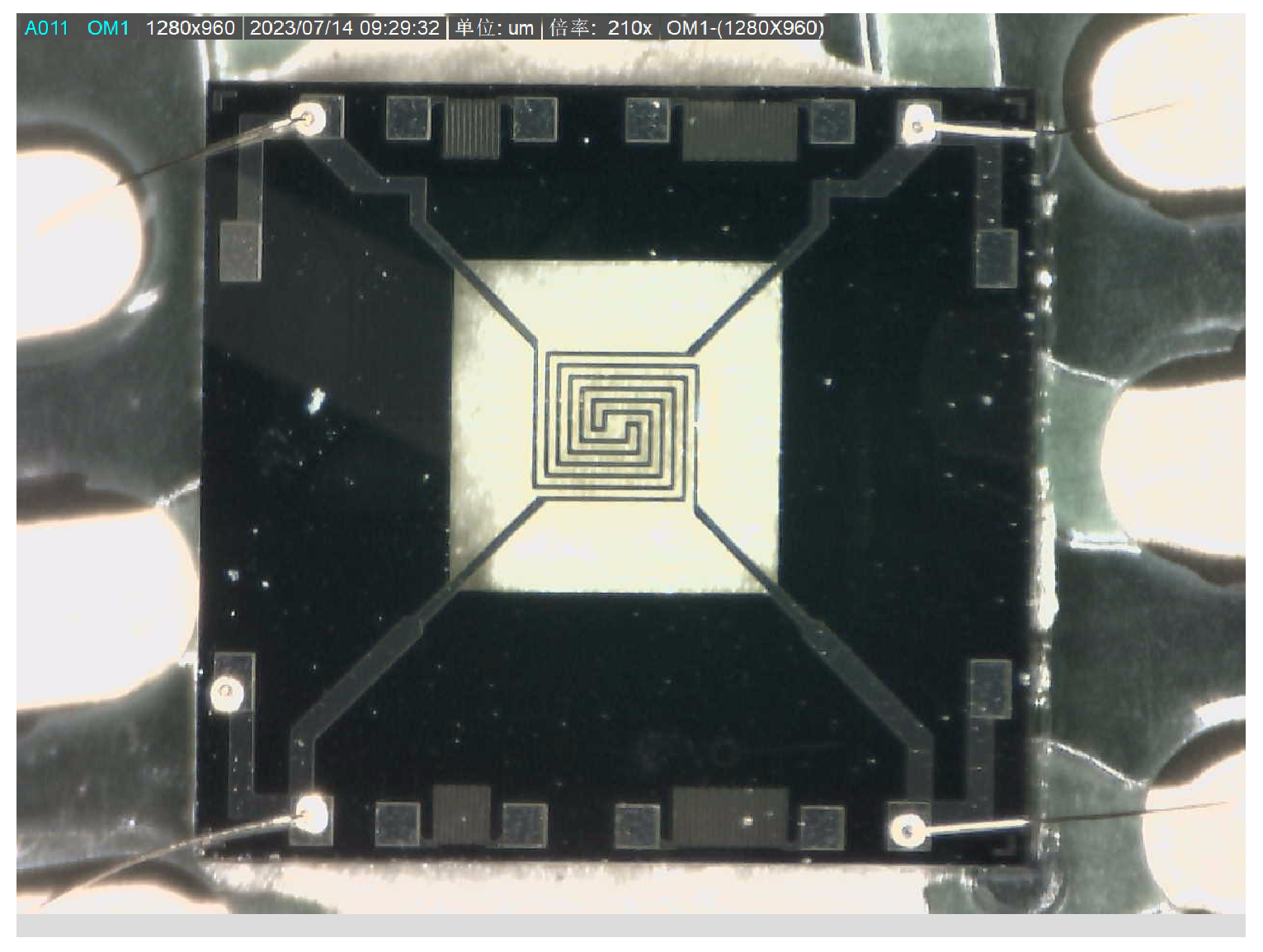

4.1. Samples

4.2. Experimental Methods

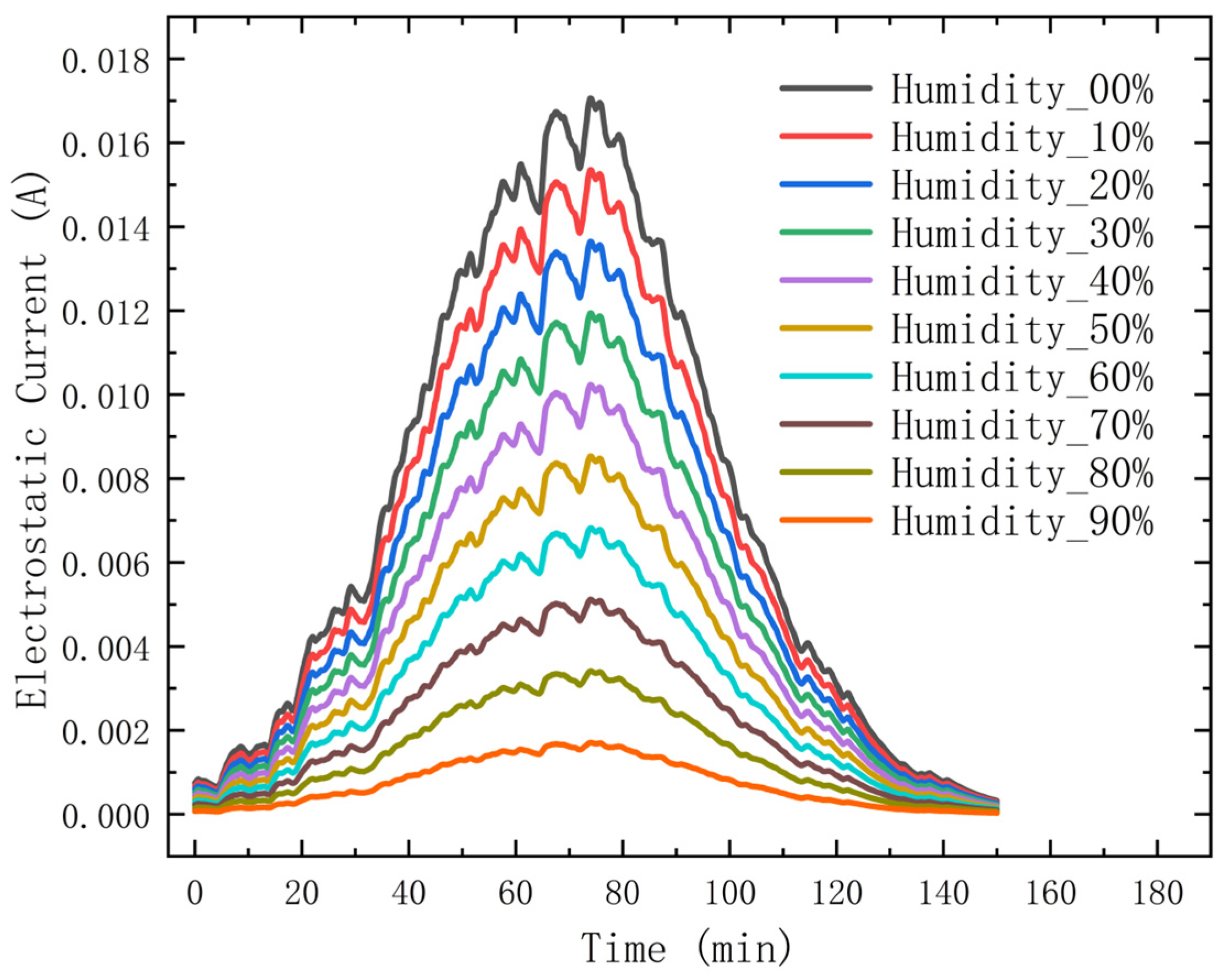

4.3. Data Analysis

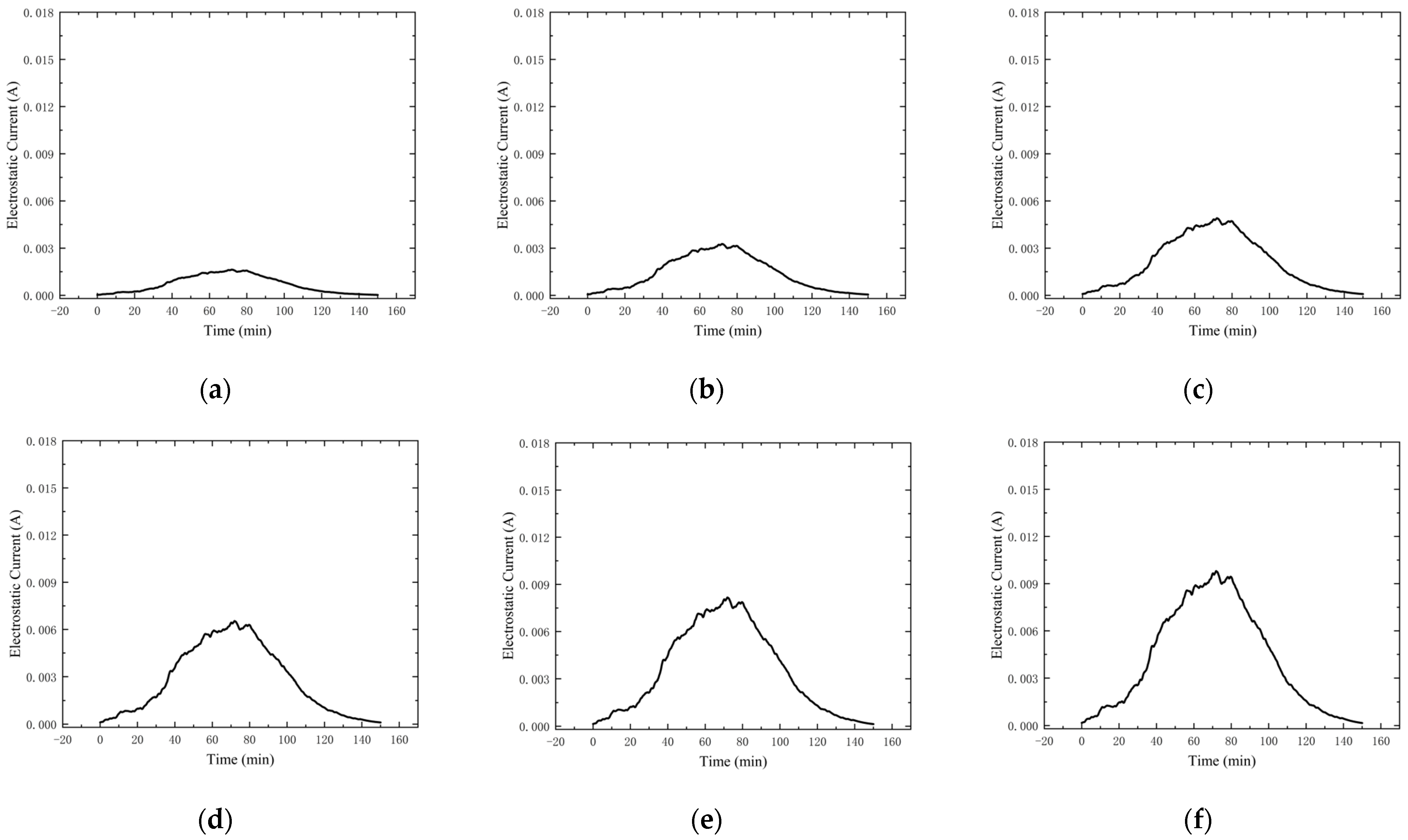

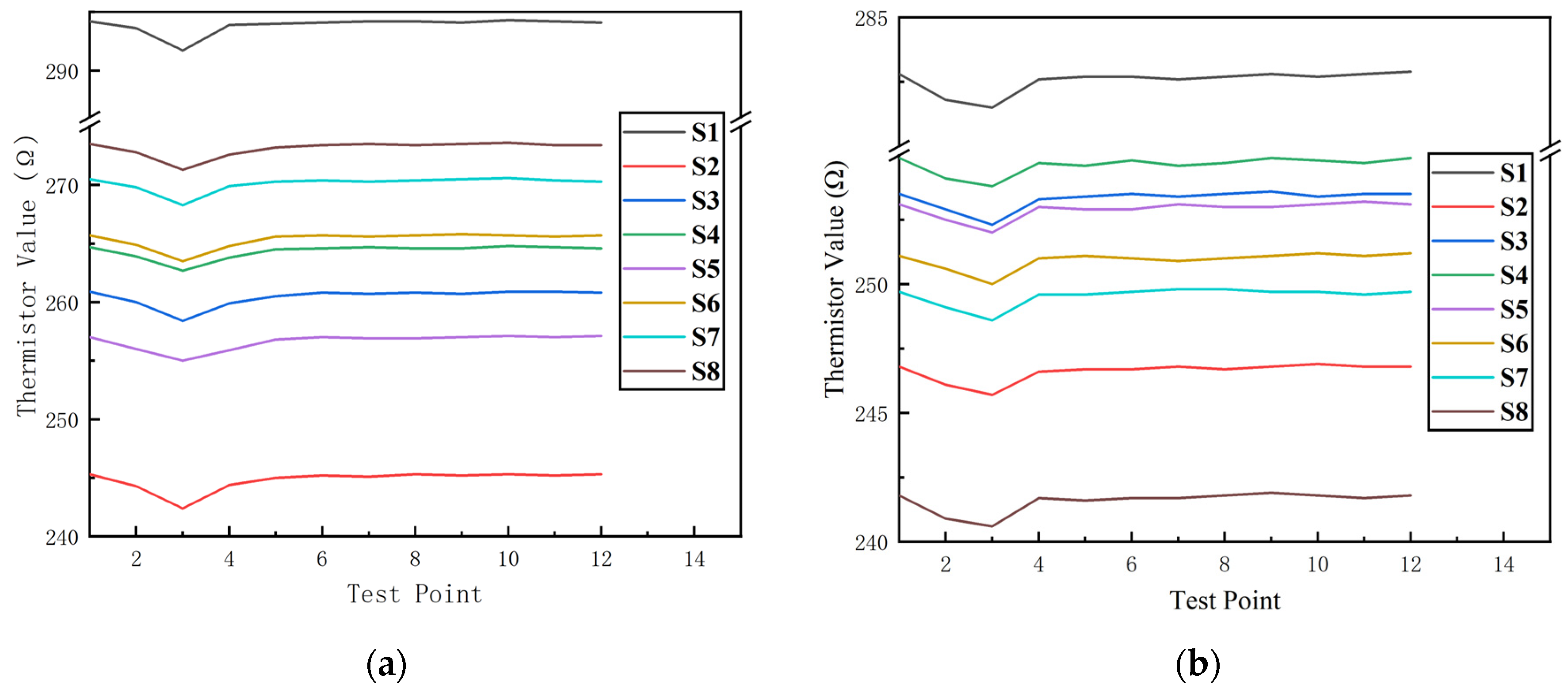

4.3.1. Experimental Data

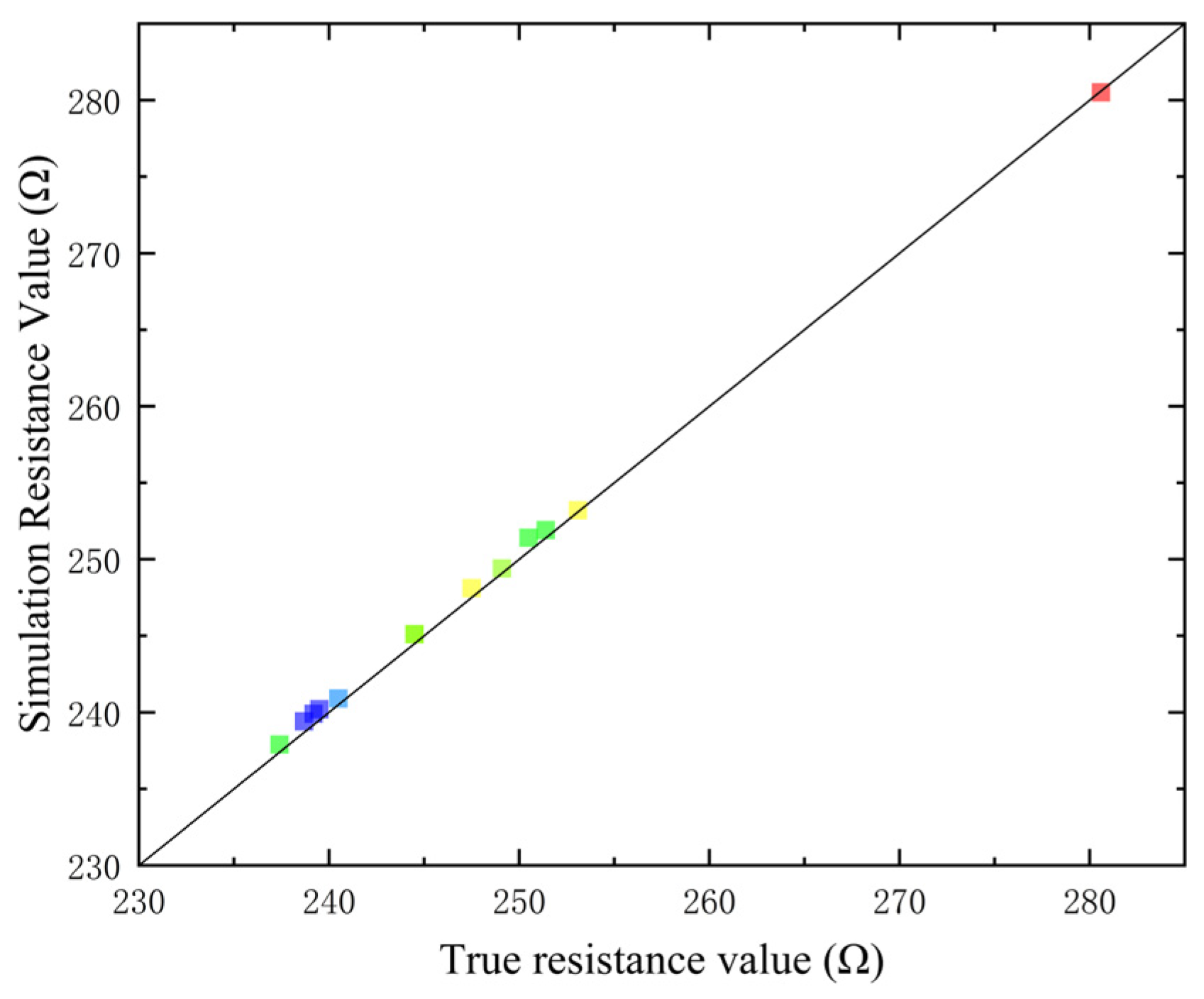

4.3.2. Comparison of Data Fitting

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, Y.; Wang, J.; Hu, Z.; Sun, M.; Liu, J.; Du, T.; Sun, P.; Xu, M. Advances in Triboelectric Flow Sensor Advanced Materials Technologies. Adv. Mater. Technol. 2023, 8, 2300316. [Google Scholar] [CrossRef]

- Wu, K.; Chai, H.; Xu, K.; Debliquy, M.; Zhang, C. Effect of {010} crystal facets of Bi2MoO6 and 1D/2D heterostructures for conductometric room temperature NH3 gas sensors. Sens. Actuators B. Chem. 2023, 376, 132983. [Google Scholar] [CrossRef]

- Chuai, R.; Zhang, B.; Hao, S.; Yang, Y.; Zhang, H. Characteristic analysis of a capacitive pressure-sensitive structure with linkage film. J. Comput. Electron. 2021, 20, 658–667. [Google Scholar] [CrossRef]

- Guzman-Gonzalez, J.; Fitzgerald, R.M.; Karle, N.N.; Sakai, R.K.; Stockwell, W.R. Particulate Matter in the American Southwest: Detection and Analysis of Dust Storms Using Surface Measurements and Ground-Based LIDAR. Atmosphere 2024, 15, 110. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. Degrees of Protection Provide by Enclosure (IP Code): IEC 60529-2013; International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- Standardization Administration of PRC (SAC). Degrees of Protection Provide by Enclosure (IP Code): GB/T 4208-2017; China Standard Publishing House: Guangzhou, China, 2018. [Google Scholar]

- Standardization Administration of PRC (SAC). Environmental Test for Electrical and Electronic Products Part 2: Test Methods Test L: Sand and Dust Test: GB/T 2423.37-2006; China Standard Publishing House: Guangzhou, China, 2007. [Google Scholar]

- General Armaments Department of the Chinese People’s Liberation Army (PLA). Laboratory Environmental Test Methods for Military Materiel Part 12: Sand and Dust Test: GJB 150.12A-2009; China Standard Publishing House: Guangzhou, China, 2009. [Google Scholar]

- Zhang, W.-M.; Meng, G.; Chen, D. Stability, Nonlinearity and Reliability of Electrostatically Actuated MEMS Devices. Sensors 2007, 7, 760–796. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.W.; Du, C.H.; Hong, W.P. Gas flow influences on bubbling and flow characteristics of fluidized bed with immersed tube under electrostatic effects. Adv. Powder Technol. 2022, 33, 103575. [Google Scholar] [CrossRef]

- Samotaev, N.; Podlepetsky, B.; Mashinin, M.; Ivanov, I.; Obraztsov, I.; Oblov, K.; Dzhumaev, P. Thermal Conductivity Gas Sensors for High-Temperature Applications. Micromachines 2024, 15, 138. [Google Scholar] [CrossRef]

- Yuan, C.; Sun, Z.; Li, X. Simulation analysis of foreign matter contamination flow field of hot film gas flow sensor. Mech. Manuf. Autom. 2017, 46, 89–91. [Google Scholar]

- Wei, Y. Performance Degradation Analysis and Reliability Evaluation of MEMS Flow Sensor Based on Physics of Failure. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2022. [Google Scholar]

- Bai, X. Research on the Mechanism of Micro Friction Charge and Charge Dissipation on Silicon Dioxide Surface Based on AFM. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2021. [Google Scholar]

- Khan Mughal, M.U.; Waheed, K.; Sadiq, M.I.; Molla, A.H.; Harun, Z.; Etminan, A. Water Flow Boiling in Micro/Mini Channels Using Volume of Fluid Model. Appl. Sci. 2024, 14, 759. [Google Scholar] [CrossRef]

- Talic, A.; Cerimovic, S.; Beigelbeck, R.; Kohl, F.; Sauter, T.; Keplinger, F. MEMS Flow Sensors Based on Self-Heated aGe-Thermistors in a Wheatstone Bridge. Sensors 2015, 15, 10004–10025. [Google Scholar] [CrossRef]

- Fan, F.G.; Ahmadi, G. A sublayer model for turbulent deposition of particles in vertical ducts with smooth and rough surfaces. J. Aerosol Sci. 1993, 24, 45–64. [Google Scholar] [CrossRef]

- Borges, J.E.; Puelles, S.C.P.; Demicoli, M.; Padilla, E.L.M. Application of the Euler–Lagrange Approach and Immersed Boundary Method to Investigate the Behavior of Rigid Particles in a Confined Flow. Axioms 2023, 12, 1121. [Google Scholar] [CrossRef]

- Lee, G.; Sim, J.-H.; Oh, G.; Won, M.; Mantry, S.P.; Kim, D.-S. Electrostatic Spray Deposition of Al-Doped ZnO Thin Films for Acetone Gas Detection. Processes 2023, 11, 3390. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion; Oxford University Press: London, UK, 1956; pp. 1–61. [Google Scholar]

- Sambathkumar, S.; Arunagirinathan, R.S. A Simple Technique for the Precise Establishment of the Working Gap in an Electrochemical Discharge Machining Process and Some Experimental Results Thereof. Micromachines 2022, 13, 1367. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Xu, Z.; Han, Z. A particle deposition model considering particle size distribution based on the Eulerian approach. Powder Technol. 2023, 427, 118759. [Google Scholar] [CrossRef]

- Xu, Z.; Li, J.; Han, Z.; Yang, X. Investigation of deposition characteristics on tube-bundle heat exchanger with an improved ash particle model. Powder Technol. 2023, 413, 118027. [Google Scholar] [CrossRef]

- Feng, C.; Tang, Z.; Yu, J.; Sun, C. A MEMS Device Capable of Measuring Near-Field Thermal Radiation between Membranes. Sensors 2013, 13, 1998–2010. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wen, X.; Huang, Q.; Ren, W.; Liu, R.; He, C. Characterization of Sand and Dust Pollution Degradation Based on Sensitive Structure of Microelectromechanical System Flow Sensor. Micromachines 2024, 15, 574. https://doi.org/10.3390/mi15050574

Chen J, Wen X, Huang Q, Ren W, Liu R, He C. Characterization of Sand and Dust Pollution Degradation Based on Sensitive Structure of Microelectromechanical System Flow Sensor. Micromachines. 2024; 15(5):574. https://doi.org/10.3390/mi15050574

Chicago/Turabian StyleChen, Jinchuan, Xiao Wen, Qinwen Huang, Wanchun Ren, Ruiwen Liu, and Chunhua He. 2024. "Characterization of Sand and Dust Pollution Degradation Based on Sensitive Structure of Microelectromechanical System Flow Sensor" Micromachines 15, no. 5: 574. https://doi.org/10.3390/mi15050574