The Influence of Preparation Temperature on the Different Facets of Bulk MgB2 Superconductors

Abstract

:1. Introduction

2. Experimental Section

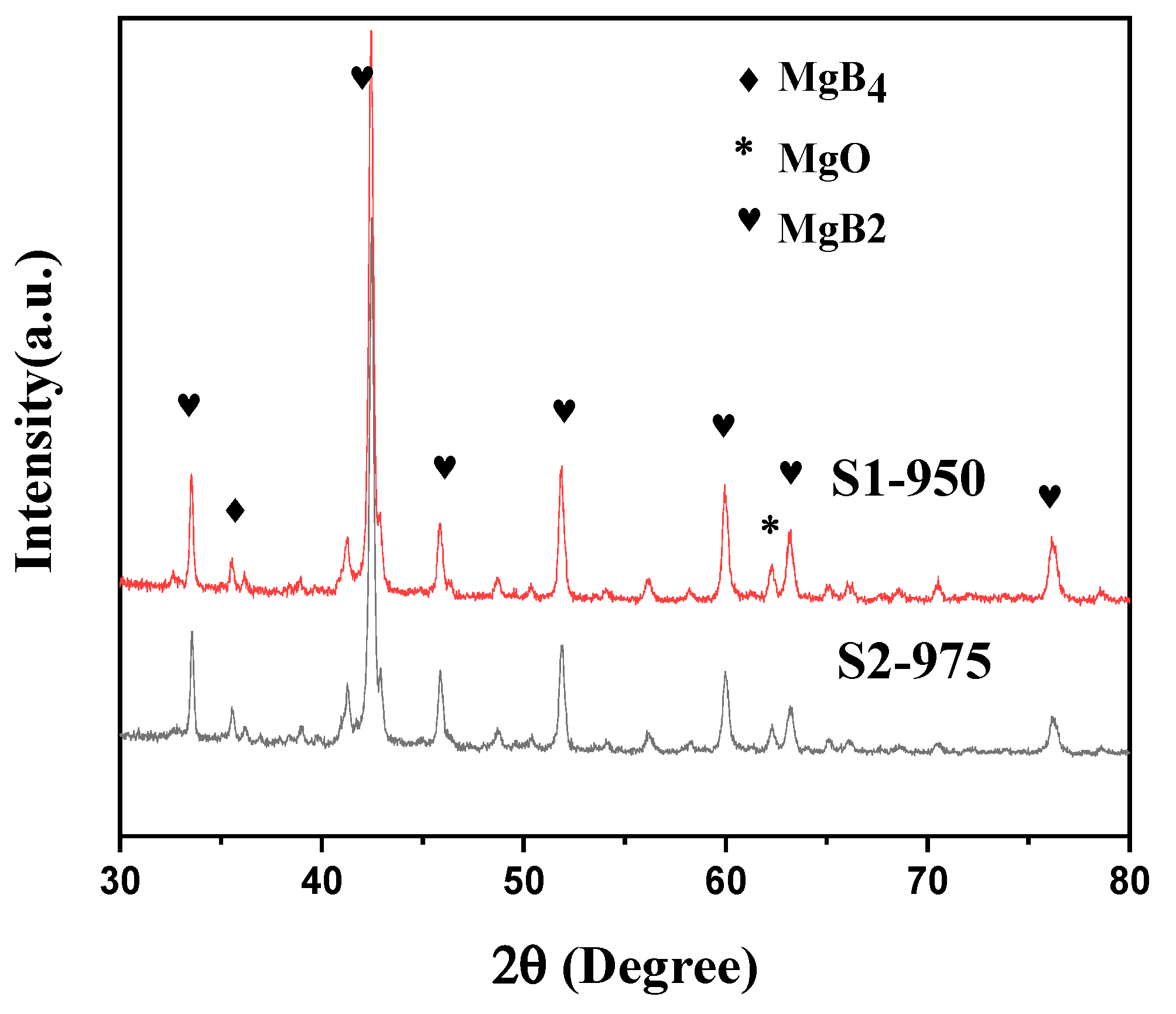

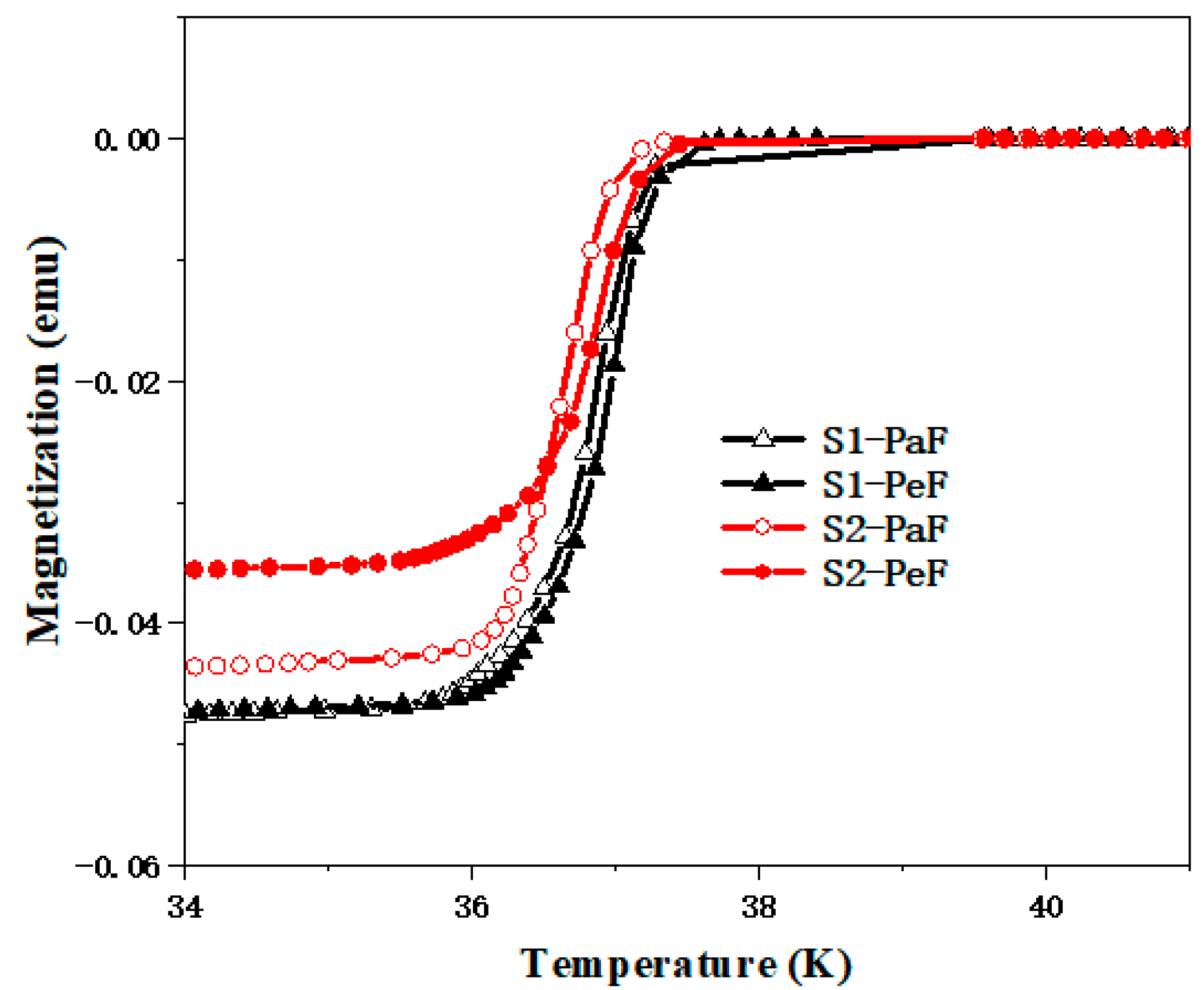

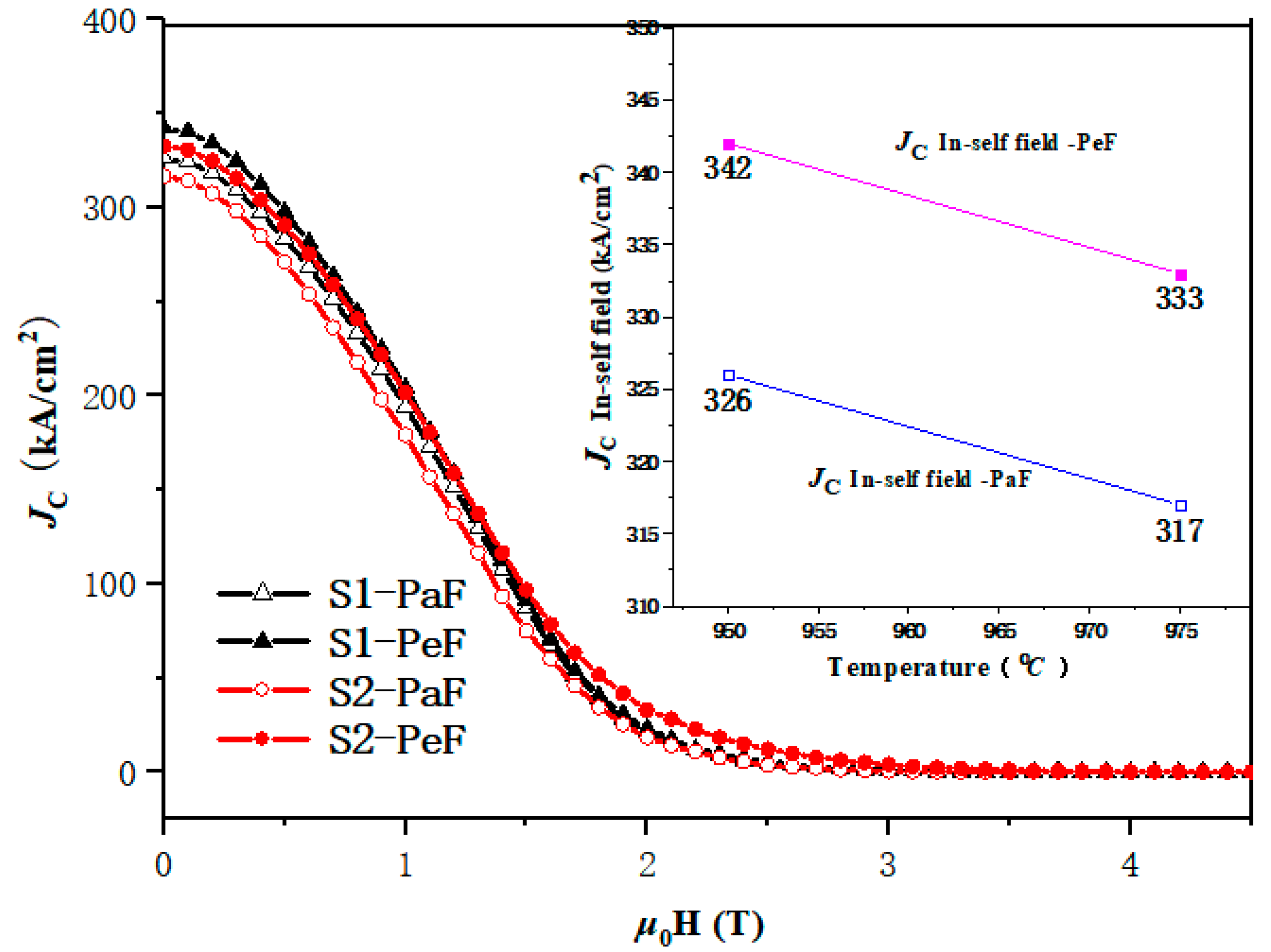

3. Results

3.1. Superconducting Properties of the PeF and PaF of MgB2 Samples at Different Preparation Temperatures (950 °C and 975 °C)

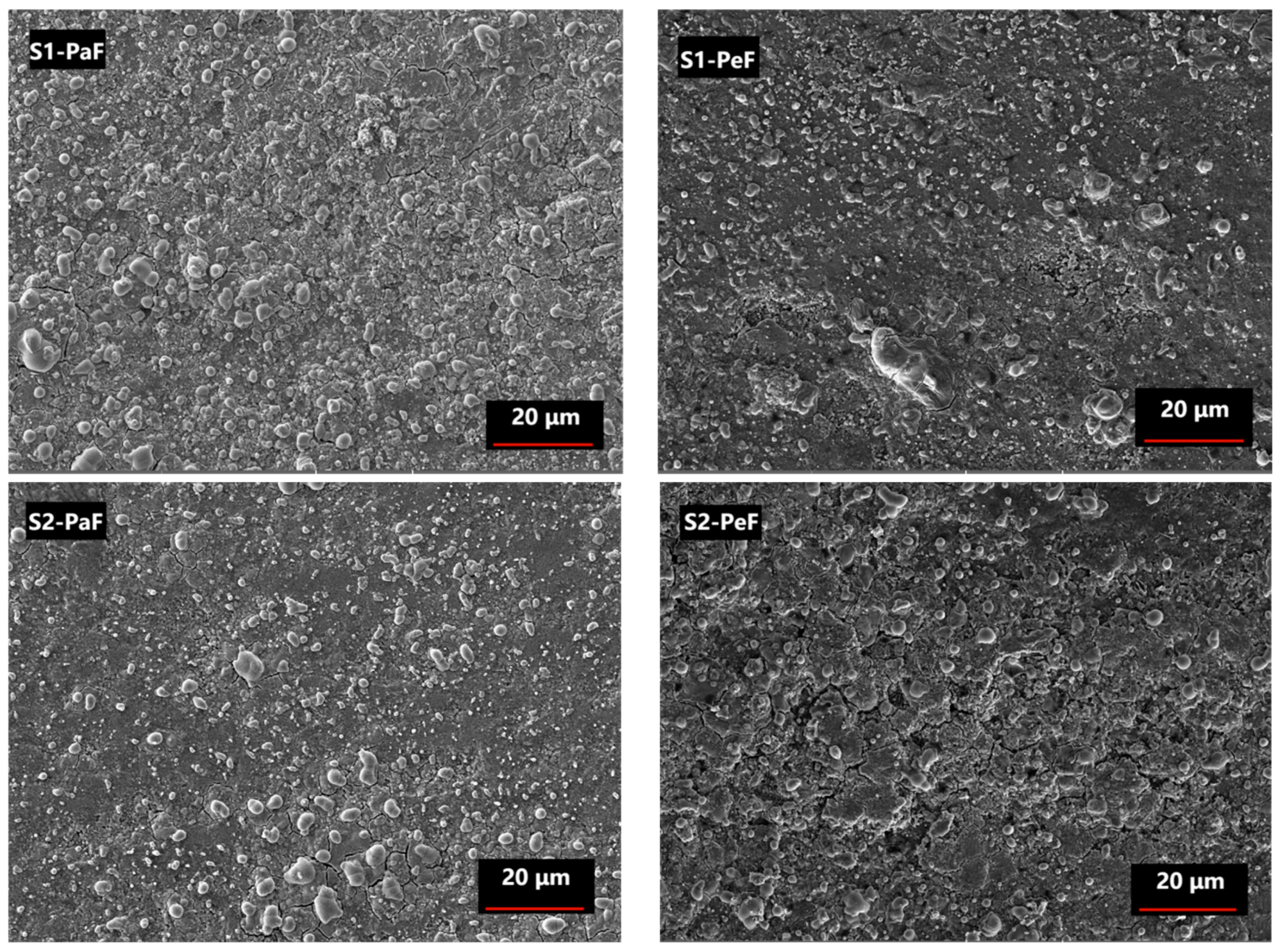

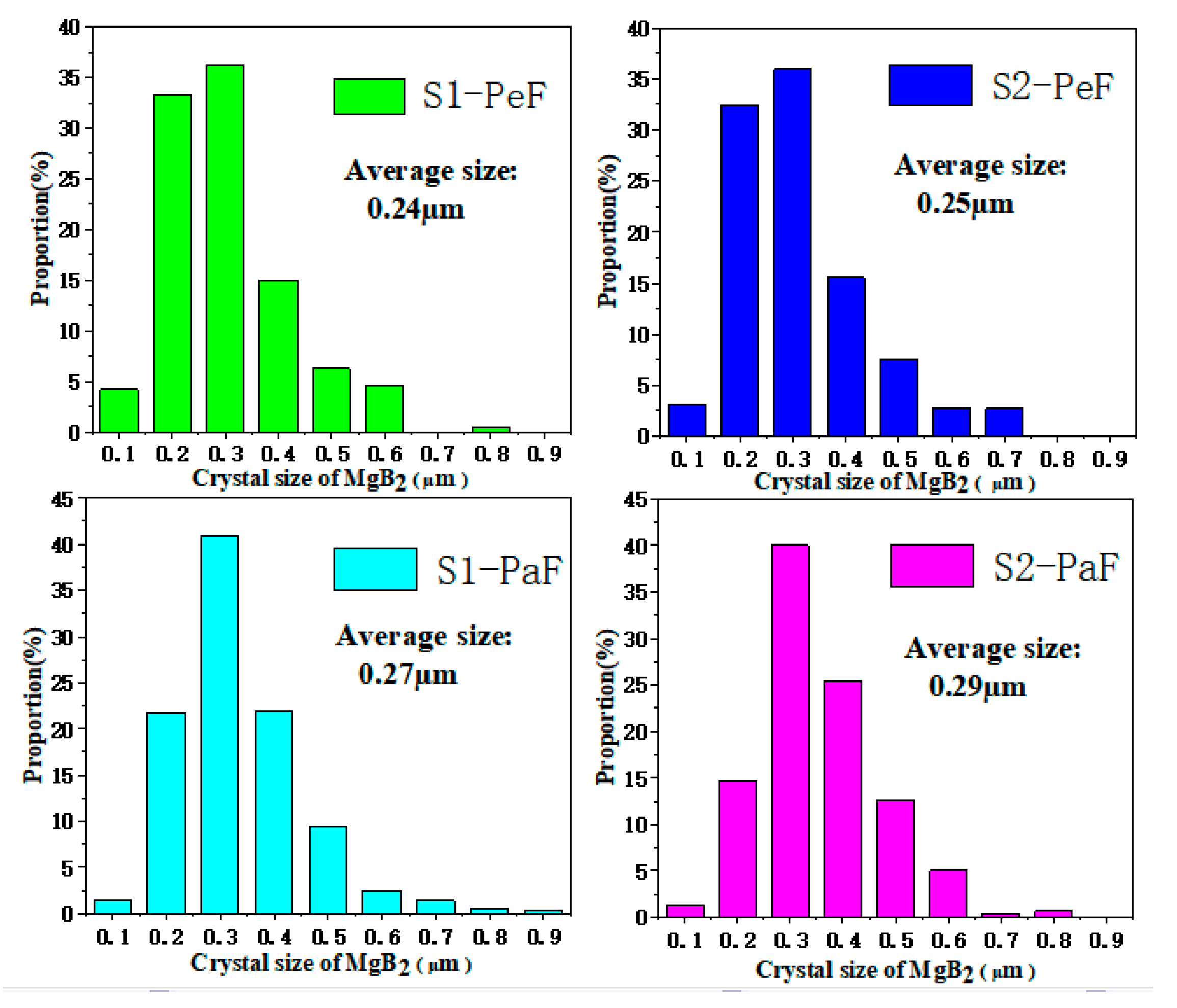

3.2. The Microstructure and Crystal Size of MgB2 Samples at Different Preparation Temperatures (950 °C and 975 °C)

3.3. The Flux-Pinning Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nagamatsu, J.; Nakagawa, N.; Muranaka, T.; Zenitani, Y.; Akimitsu, J. Superconductivity at 39 K in magnesium diboride. Nature 2001, 410, 63. [Google Scholar] [CrossRef]

- Guo, C.; Wang, H.Z.; Cai, X.W.; Luo, W.H.; Huang, Z.G.; Zhang, Y.; Feng, Q.R.; Gan, Z.Z. High performance superconducting joint for MgB2 films. Phys. C 2021, 584, 1353863. [Google Scholar] [CrossRef]

- Jin, S.; Mavoori, H.; Bower, C.; Van Dover, R.B. High critical currents in iron-clad superconducting MgB2 wires. Nature 2001, 411, 563. [Google Scholar] [CrossRef]

- Eom, C.B.; Lee, M.K.; Choi, J.H. High critical current density and enhanced irreversibility field in superconducting MgB2 thin films. Nature 2001, 411, 558. [Google Scholar] [CrossRef] [PubMed]

- Dadiel, J.L.; Naik, S.P.K.; Pęczkowski, P.; Sugiyama, J.; Ogino, H.; Sakai, N.; Kazuya, Y.; Warski, T.; Wojcik, A.; Oka, T.; et al. Synthesis of Dense MgB2 Superconductor via In-Situ and Ex-Situ Spark Plasma Sintering Method. Materials 2021, 14, 7395. [Google Scholar] [CrossRef]

- Takahashi, Y.; Naito, T.; Fujishiro, H. Trapped Field Properties of MgB2 Bulks Prepared Via an in-situ Infiltration-Reaction Process Using Refined Boron Powders. IEEE Trans. Appl. Supercond. 2022, 32, 6801005. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Zhang, Y.F.; Lou, Z.W.; Zhang, P.H.; Li, C.Y.; Yuan, J.W.; Peng, L.; Ma, Y.X.; Noudem, J.G.; Izumi, M. The discrepancies in different facets of MgB2 bulk superconductors prepared under various sintering durations by spark plasma sintering. Supercond. Sci. Technol. 2021, 34, 045011. [Google Scholar] [CrossRef]

- Xing, Y.; Bernstein, P.; Miryala, M.; Noudem, J.G. High Critical Current Density of Nanostructured MgB2 Bulk Superconductor Densified by Spark Plasma Sintering. Nanomaterials 2022, 12, 2583. [Google Scholar] [CrossRef] [PubMed]

- Buzea, C.; Yamashita, T. Review of superconducting properties of MgB2. Supercond. Sci. Technol. 2001, 14, R115–R146. [Google Scholar] [CrossRef]

- Noudem, J.G.; Dupont, L.; Gozzelino, L.; Bernstein, P. Superconducting Properties of MgB2 Bulk Shaped by Spark Plasma Sintering. Mater. Today-Process. 2016, 3, 545–549. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Lou, Z.W.; Zhang, P.H.; Li, C.Y.; Zhang, J.Y.; Zhang, X.J. Flux Pinning Properties of Single-Grain Bulk GdBCO Superconductors Processed by Different Thicknesses of Y123 Liquid Source. Micromachines 2022, 13, 701. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.H.; Zmorayová, K.; He, J.Y.; Zhang, Y.X.; Diko, P.; Zhou, D.F.; Yao, X. An in situ self-assembly strategy for exact-(110)-plane-controlled crystallization of high-performance YBa2Cu3O7−δ single. Ceram. Int. 2022, 48, 22196–22205. [Google Scholar] [CrossRef]

- Mishima, F.; Terada, T.; Akiyama, Y.; Nishijima, S. High gradient superconducting magnetic separation for iron removal from the glass polishing waste. IEEE Trans. Appl. Supercond. 2011, 21, 2059–2062. [Google Scholar] [CrossRef]

- Moseley, D.A.; Wilkinson, D.P.; Mousavi, T.; Dennis, A.R.; Speller, S.; Durrell, J.H. A new MgB2 bulk ring fabrication technique for use in magnetic shielding or bench-top NMR system. Supercond. Sci. Technol. 2022, 35, 085003. [Google Scholar] [CrossRef]

- Kajikawa, K.; Nakamura, T.; Kobayashi, H.; Wakuda, T.; Tanaka, K. Development of Stator Windings for Fully Superconducting Motor with MgB2 Wires. IEEE Trans. Appl. Supercond. 2013, 23, 2240033. [Google Scholar] [CrossRef]

- Bean, C.P. Magnetization of hard superconductors. Phys. Rev. Lett. 1962, 8, 250–253. [Google Scholar] [CrossRef]

- Hassler, W.; Scheiter, J.; Hadrich, P.; Kauffmann-Weiss, S.; HolzaPaFel, B.; Oomen, M.; Nielsch, K. Properties of ex-situ MgB2 bulk samples prepared by uniaxial hot pressing and spark plasma sintering. Phys. C Supercond. Appl. 2018, 551, 48–54. [Google Scholar] [CrossRef]

- Erdem, O.; Yanmaz, E. Effect of laser irradiation on activation energy, irreversibility field and upper critical magnetic field of bulk MgB2 superconductor. J. Mater. Sci. 2016, 27, 6502–6510. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A.; Miryala, M.; Murakami, M. Magnetic Characterization of Bulk C-Added MgB2. J. IEEE Trans. Appl. Supercond. 2019, 29, 6800104. [Google Scholar] [CrossRef]

- Erdem, O.; Guner, S.; Celik, S.; Kucukomeroglu, T. Superconducting and levitation force characterisation of pyrene added MgB2 bulk superconductors. Cryogenics 2020, 112, 103205. [Google Scholar] [CrossRef]

- Badica, P.; Burdusel, M.; Popa, S.; Pasuk, I.; Ivan, I.; Borodianska, H.; Vasylkiv, O.; Kuncser, A.; Ionescu, A.M.; Miu, L.; et al. Reactive spark plasma sintering of MgB2 in nitrogen atmosphere for the enhancement of the high-field critical current density. Supercond. Sci. Tech. 2016, 29, 105020. [Google Scholar] [CrossRef]

- Aldica, G.; Batalu, D.; Popa, S.; Ivan, I.; Nita, P.; Sakka, Y.; Vasylkiv, O.; Miu, L.; Pasuk, I.; Badica, P. Spark plasma sintering of MgB2 in the two-temperature route. Phys. C Supercond. Appl. 2012, 477, 43–50. [Google Scholar] [CrossRef]

- Jirsa, M.; Rames, M.; Koblischka, M.R.; Koblischka-Veneva, A.; Berger, K.; Douine, B. Douine. Relaxation and pinning in spark-plasma sintered MgB2 superconductor. Supercond. Sci. Technol. 2016, 29, 1. [Google Scholar] [CrossRef]

- Noudem, J.G.; Bernstein, P.; Dupont, L.; Martin, F.G.R.; Sotelo, G.G.; Dias, D.H.N.; de Andrade, R.; Muralidhar, M.; Murakami, M. Spark plasma sintering of bulk MgB2 and levitation force measurements. Supercond. Sci. Technol. 2020, 33, 024001. [Google Scholar] [CrossRef]

- Sandu, V.; Ivan, I. On the scaling of pinning force in ceramic MgB2. Int. Conf. Low Temp. Phys. 2012, 400, 22102–22105. [Google Scholar] [CrossRef]

- Chen, D.X.; Goldfarb, R.B. Kim model for magnetization of type-II superconductors. J. Appl. Phys. 1989, 66, 2489–2500. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, W.; Yang, D.; Yao, R.-L. Decomposition and oxidation of magnesium diboride. J. Am. Ceram. Soc. 2012, 95, 754–759. [Google Scholar] [CrossRef]

- Kim, S.; Stone, D.S.; Cho, J.-I.; Jeong, C.-Y.; Kang, C.-S.; Bae, J.-C. Phase stability determination of the Mg-B binary system using the CALPHAD method and ab initio calculations. J. Alloy. Compd. 2009, 470, 85–89. [Google Scholar] [CrossRef]

- Aldica, G.; Burdusel, M.; Popa, S.; Enculescu, M.; Pasuk, I.; Badica, P. The influence of heating rate on superconducting characteristics of MgB2 obtained by spark plasma sintering technique. Phys. C Supercond. Appl. 2015, 519, 184–189. [Google Scholar] [CrossRef]

- Badica, P.; Burdusel, M.; Popa, S.; Hayasaka, Y.; Ionescu, M.A.; Aldica, G. Addition of Sb2O5 into MgB2 Superconductor Obtained by Spark Plasma Sintering. Supercond. Novel Magn. 2017, 30, 2073–2080. [Google Scholar] [CrossRef]

- Shimada, Y.; Hata, S.; Ikeda, K.-I.; Nakashima, H.; Matsumura, S.; Tanaka, H.; Yamamoto, A.; Shimoyama, J.-I.; Kishio, K. Microstructural Characteristics of Ball-Milled Self-Sintered Ex Situ MgB2 Bulks. IEEE Trans. Appl. Supercond. 2015, 25, 1–5. [Google Scholar] [CrossRef]

- Shah, M.S.; Shahabuddin, M.; Parakkandy, J.M.; Qaid, S.; Alzayed, N.S. Enhanced critical current density in undoped MgB2 prepared by in situ/ex situ combination technique. Solid State Commun. 2015, 218, 31–34. [Google Scholar] [CrossRef]

- Dew-Hughes, D. Flux pinning mechanisms in type II superconductors. Philos. Mag. 1974, 30, 293305. [Google Scholar] [CrossRef]

- Eisterer, M. Calculation of the volume pinning force in MgB2 superconductors. Phys. Rev. B 2008, 77, 144524. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, Y.; Han, Y.; Zhao, Q.; Gao, Z. Variation of the enhancement mechanism in the critical current density of Cu-doped MgB2 samples sintered at different temperatures(Article). J. Appl. Phys. 2008, 104, 063917. [Google Scholar] [CrossRef]

- Batalu, D.; Aldica, G.; Popa, S.; Kuncser, A.; Mihalache, V.; Badica, P. GeO2-added MgB2 superconductor obtained by Spark Plasma Sintering. Solid State Sci. 2015, 48, 23–30. [Google Scholar] [CrossRef]

- Aldica, G.; Popa, S.; Enculescu, M.; Pasuk, I.; Ionescu, A.M.; Badica, P. Dwell time influence on spark plasma-sintered MgB2. J. Supercond. Novel Magn. 2018, 31, 317–325. [Google Scholar] [CrossRef]

| Sample | Lattice Parameters (Å) | Average Particle Size (µm) |

|---|---|---|

| a/c | PaF/PeF | |

| S1 (950 °C) | 3.0847/3.5232 | 0.27/0.24 |

| S2 (975 °C) | 3.0811/3.5223 | 0.29/0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Zhang, Y.; Li, C.; Zhang, Y.; Shen, S.; Ruan, G.; Zhang, J.; Noudem, J.G. The Influence of Preparation Temperature on the Different Facets of Bulk MgB2 Superconductors. Micromachines 2023, 14, 988. https://doi.org/10.3390/mi14050988

Zhang P, Zhang Y, Li C, Zhang Y, Shen S, Ruan G, Zhang J, Noudem JG. The Influence of Preparation Temperature on the Different Facets of Bulk MgB2 Superconductors. Micromachines. 2023; 14(5):988. https://doi.org/10.3390/mi14050988

Chicago/Turabian StyleZhang, Penghe, Yufeng Zhang, Chunyan Li, Yan Zhang, Shuangyuan Shen, Guanjie Ruan, Jiaying Zhang, and Jacques Guillaume Noudem. 2023. "The Influence of Preparation Temperature on the Different Facets of Bulk MgB2 Superconductors" Micromachines 14, no. 5: 988. https://doi.org/10.3390/mi14050988