Patterning Biological Gels for 3D Cell Culture inside Microfluidic Devices by Local Surface Modification through Laminar Flow Patterning

Abstract

1. Introduction

2. Results and Discussion

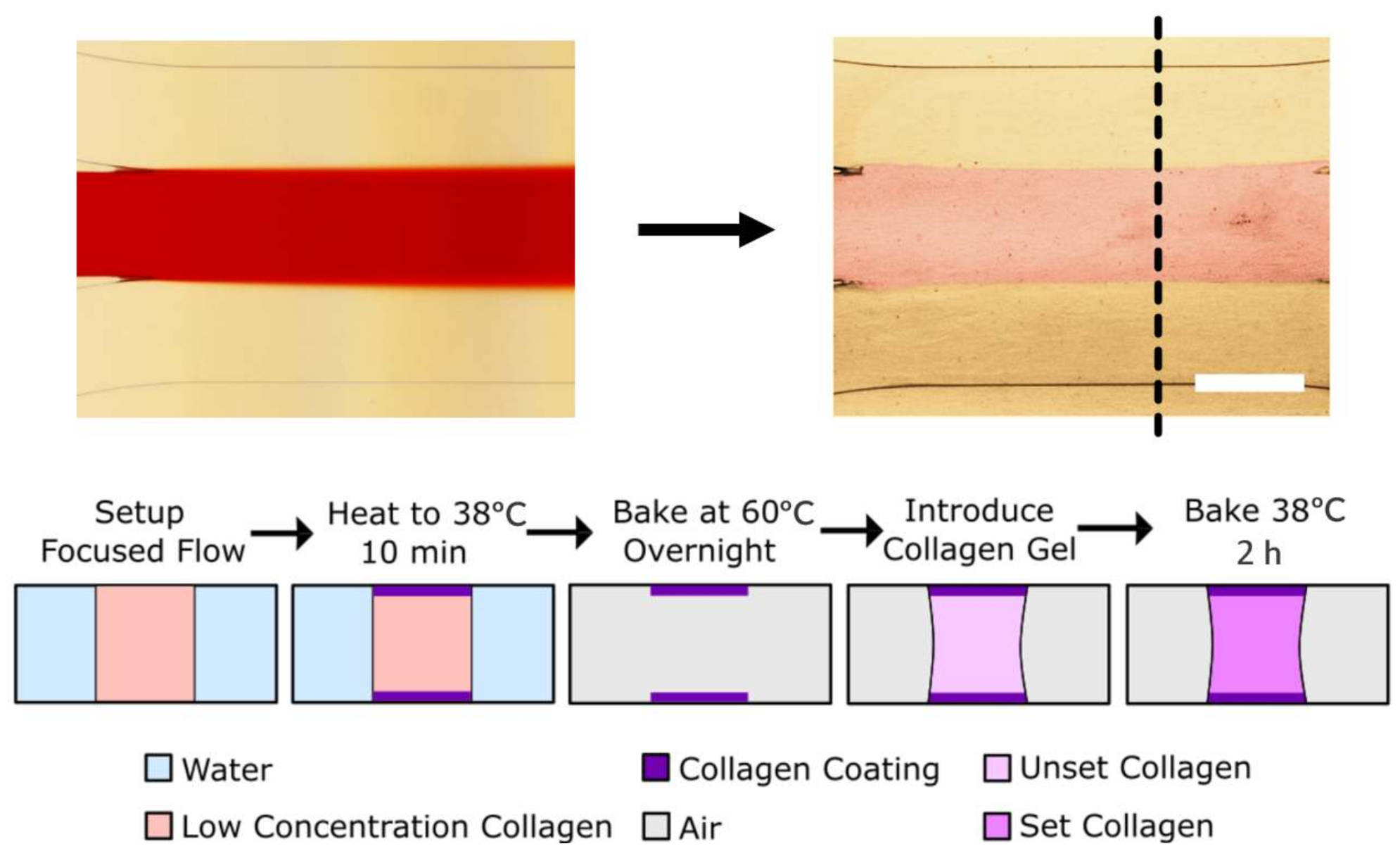

2.1. Laminar Flow Patterning of Surface Hydrophilicity

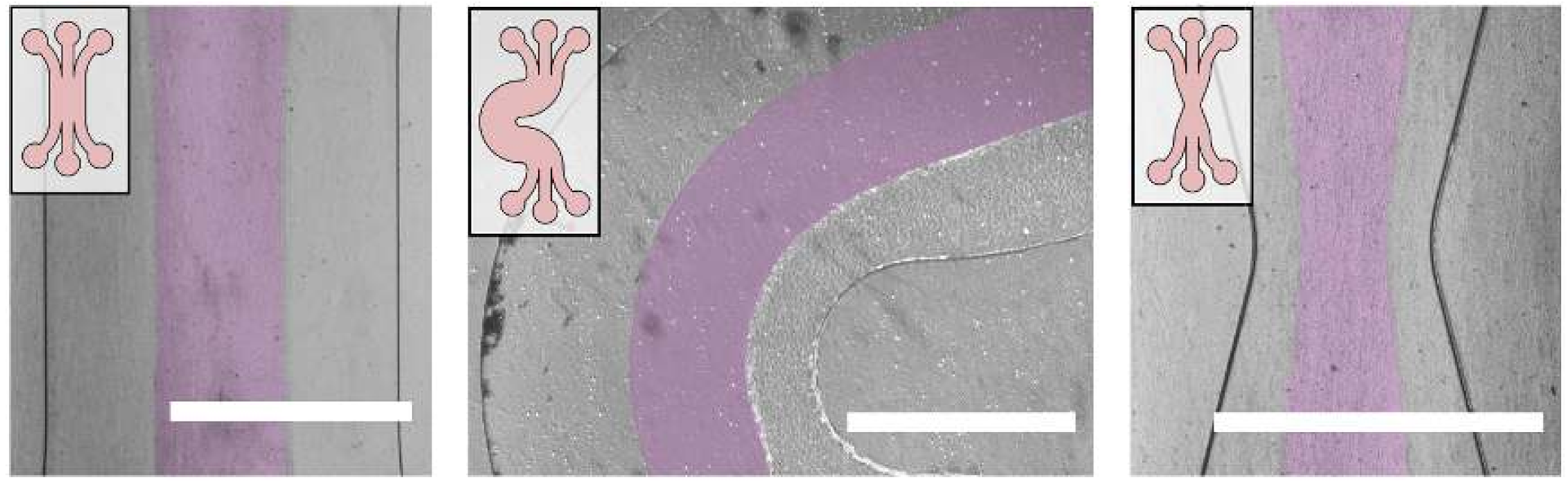

2.2. Gel Geometry Control by Flow and Device Geometry

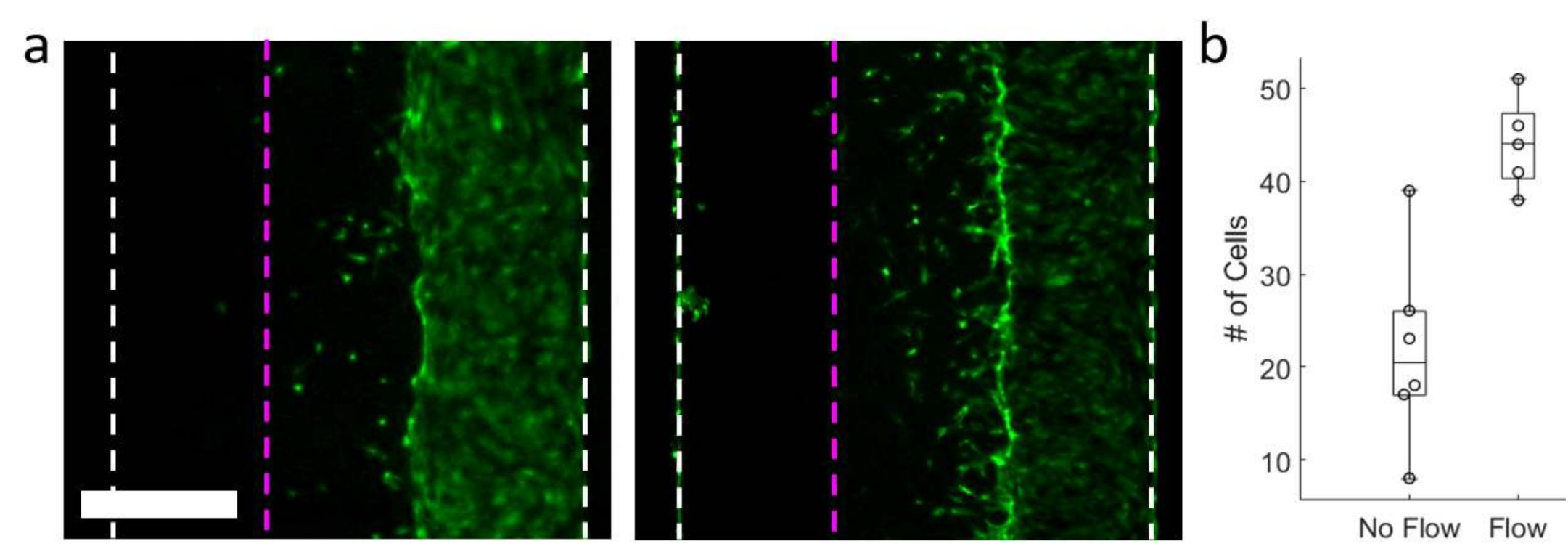

2.3. Cell Culture on Patterned Gels

2.4. Cell Migration through Patterned Gels

3. Conclusions and Outlook

4. Methods

4.1. PDMS Device Fabrication

4.2. Surface Treatment

4.3. Flow Patterning

4.4. Cell Culture

4.5. Device Filling, Cell Seeding, and Culture

4.6. Cell Fixation, Staining, and Imaging

4.7. Interstitial Flow Experiments

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mehling, M.; Tay, S. Microfluidic cell culture. Curr. Opin. Biotechnol. 2014, 25, 95. [Google Scholar] [PubMed]

- van der Helm, M.W.; van der Meer, A.D.; Eijkel, J.C.T.; van den Berg, A.; Segerink, L.I. Microfluidic organ-on-chip technology for blood-brain barrier research. Taylor Fracis 2016, 4, 2168. [Google Scholar]

- Caballero, D.; Kaushik, S.; Correlo, V.M.; Oliveira, J.M.; Reis, R.L.; Kundu, S.C. Organ-on-chip models of cancer metastasis for future personalized medicine: From chip to the patient. Biomaterials 2017, 149, 98. [Google Scholar] [PubMed]

- van Duiden, V.; Trietsch, S.J.; Joore, J.; Vulto, P.; Hankemeier, T. Microfluidic 3D cell culture: From tools to tissue models. Curr. Opin. Biotechnol. 2015, 35, 118. [Google Scholar]

- Kashaninejad, N.; Nikmaneshi, M.R.; Moghadas, H.; Oskouei, A.K.; Rismanian, M.; Barisam, M.; Saidi, M.; Firoozabadi, B. Organ-Tumor-on-a-Chip for Chemosensitivity Assay: A Critical Review. Micromachines 2016, 7, 130. [Google Scholar]

- Hasan, A.; Paul, A.; Vrana, N.E.; Zhao, X.; Memic, A.; Hwang, Y.; Khademhosseini, M.R.D.A. Microfluidic techniques for development of 3D vascularized tissue. Biomaterials 2014, 35, 7308. [Google Scholar]

- Polacheck, W.J.; Charest, J.L.; Kamm, R.D. Interstitial flow influences direction of tumor cell migration through competing mechanisms. Proc. Natl. Acad. Sci. USA 2011, 108, 11115. [Google Scholar]

- Shirure, V.S.; Lezia, A.; Tao, A.; Alonzo, L.; George, S.C. Low levels of physiological interstitial flow eliminate morphogen gradients and guide angiogenesis. Angiogenisis 2017, 20, 493. [Google Scholar]

- Sudo, R.; Chung, S.; Zervontonakis, I.K.; Vikerman, V.; Toshimitsu, Y.; Griffith, L.G.; Kamm, R.D. Transport-mediated angiogenesis in 3D epithelial coculture. FASEB J. 2009, 23, 2155. [Google Scholar]

- Bersini, S.; Jeon, J.S.; Dubini, D.; Arrigoni, C.; Chung, S.; Charest, J.L.; Moretti, M.; Kamm, R.D. A microfluidic 3D in vitro model for specificity of breast cancer metastasis to bone. Biomaterials 2014, 35, 2454. [Google Scholar]

- Jeong, G.S.; Han, S.; Shin, Y.; Kwon, G.H.; Kamm, R.D.; Lee, S.; Chung, S. Sprouting Angiogenesis under a Chemical Gradient Regulated by Interactions with an Endothelial Monolayer in a Microfluidic Platform. Anal. Chem. 2011, 83, 8454. [Google Scholar] [CrossRef]

- Kim, C.; Kasuya, J.; Jeon, J.; Chung, S.; Kamm, R.D. A quantitative microfluidic angiogenesis screen for studying anti-angiogenic therapeutic drugs. Lab Chip 2015, 15, 501. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lee, H.; Chung, M.; Jeon, N.L. Engineering of functional, perfusable 3D microvascular networks on a chip. Lab Chip 2013, 13, 1489. [Google Scholar] [CrossRef]

- Trietsch, S.J.; Israels, G.D.; Joore, J.; Hankemeier, T.; Vulto, P. Microfluidic titer plate for stratified 3D cell culture. Lab Chip 2013, 13, 3548. [Google Scholar] [CrossRef] [PubMed]

- Swartz, M.A.; Fleury, M.E. Interstitial Flow and Its Effects in Soft Tissues. Annu. Rev. Biomed. Eng. 2007, 9, 229. [Google Scholar] [CrossRef]

- Loessberg-Zahl, J.; van der Meer, A.D.; van den Berg, A.; Eijkel, J.C.T. Flow focusing through gels as a tool to generate 3D concentration profiles in hydrogel-filled microfluidic chips. Lab Chip 2019, 19, 206. [Google Scholar] [CrossRef]

- Vulto, P.; Podszun, S.; Meyer, P.; Hermann, C.; Manz, A.; Urban, G.A. Phaseguides: A paradigm shift in microfluidic priming and emptying. Lab Chip 2010, 11, 1561. [Google Scholar] [CrossRef] [PubMed]

- Lampin, M.; Warocquier-Clerout, R.; Legris, C.; Degrange, M.; Sigot-Luizard, M.F. Correlation between substratum roughness and wettability, cell adhesion, and cell migration. J. Med. Mater. Res. 1998, 36, 99. [Google Scholar] [CrossRef]

- Pathak, A.; Kumar, S. Independent regulation of tumor cell migration by matrix stiffness and confinement. Proc. Natl. Acad. Sci. USA 2011, 109, 10334. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Moore, J.S.; Beebe, D.J. Surface-directed liquid flow inside microchannels. Sci. Rep. 2001, 291, 1023. [Google Scholar] [CrossRef]

- Aota, A.; Nonaka, M.; Hibara, A.; Kitamori, T. Pressure Balance at the Liquid−Liquid Interface of Micro Countercurrent Flows in Microchips. Angew. Chem. Int. Ed. 2007, 46, 878. [Google Scholar] [CrossRef] [PubMed]

- Hibara, A.; Iwayama, S.; Matsuoka, S.; Ueno, M.; Kikutani, Y.; Tokeshi, M.; Kitamori, T. Surface Modification Method of Microchannels for Gas−Liquid Two-Phase Flow in Microchips. Anal. Chem. 2005, 77, 943. [Google Scholar] [CrossRef] [PubMed]

- Qin, M.; Hou, S.; Wang, L.; Feng, X.; Wang, R.; Yang, Y.; Wang, C.; Yu, L.; Shao, B.; Qiao, M. Two methods for glass surface modification and their application in protein immobilization. Colloids Surf. B 2007, 60, 243. [Google Scholar] [CrossRef] [PubMed]

- Klasen, E.A.; Rigutti, A.; Bos, A.; Bernini, L.F. Development of a screening system for detection of somatic mutations. II. The use of peptides and insoluble protein fragments in a non-competitive solid-phase enzyme immunoassay. J. Immunol. Methods 1983, 59, 181. [Google Scholar] [CrossRef]

- Khnouf, R.; Karasneh, D.; Albiss, B.A. Protein immobilization on the surface of polydimethylsiloxane and polymethyl methacrylate microfluidic devices. Electrophoresis 2015, 37, 529. [Google Scholar] [CrossRef] [PubMed]

- Kenis, P.J.A.; Ismagilov, R.F.; Whitesides, G.M. Microfabrication Inside Capillaries Using Multiphase Laminar Flow Patterning. Science 1999, 285, 88. [Google Scholar] [CrossRef] [PubMed]

- Autebert, J.; Kashyap, A.; Lovchik, R.D.; Delamarche, E.; Kaigala, G.V. Hierarchical Hydrodynamic Flow Confinement: Efficient Use and Retrieval of Chemicals for Microscale Chemistry on Surfaces. Langmuir 2014, 30, 3640. [Google Scholar] [CrossRef]

- Juncker, D.; Schmid, H.; Bernard, A.; Caelen, I.; Michel, B.; de Rooij, N.; Delamarche, E. Soft and rigid two-level microfluidic networks for patterning surfaces. J. Micromech. Microeng. 2001, 11, 532. [Google Scholar] [CrossRef]

- Bernard, A.; Renault, J.P.; Michel, B.; Bosshard, H.R.; Delamarche, E. Microcontact Printing of Proteins. Adv. Mater. 2000, 12, 1067. [Google Scholar] [CrossRef]

- Gunda, N.S.G.; Singh, M.; Norman, L.; Kaur, K.; Mitra, S.K. Optimization and characterization of biomolecule immobilization on silicon substrates using (3-aminopropyl)triethoxysilane (APTES) and glutaraldehyde linker. Appl. Surf. Sci. 2014, 305, 522. [Google Scholar] [CrossRef]

- Baker, B.M.; Trappmann, B.; Stapleton, S.C.; Toro, E.; Chen, C.S. Microfluidics embedded within extracellular matrix to define vascular architectures and pattern diffusive gradients. Lab Chip 2013, 13, 3240. [Google Scholar] [CrossRef] [PubMed]

- Ismagilov, R.F.; Stroock, A.D.; Kenis, P.J.A.; Whitesides, G.; Stone, H.A. Experimental and theoretical scaling laws for transverse diffusive broadening in two-phase laminar flows in microchannels. Appl. Phys. Lett. 1999, 76, 2376. [Google Scholar] [CrossRef]

- Chandran, P.L.; Barocas, V.H. Microstructural Mechanics of Collagen Gels in Confined Compression: Poroelasticity, Viscoelasticity, and Collapse. J. Biomech. Eng. 2004, 126, 152. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loessberg-Zahl, J.; Beumer, J.; van den Berg, A.; Eijkel, J.C.T.; van der Meer, A.D. Patterning Biological Gels for 3D Cell Culture inside Microfluidic Devices by Local Surface Modification through Laminar Flow Patterning. Micromachines 2020, 11, 1112. https://doi.org/10.3390/mi11121112

Loessberg-Zahl J, Beumer J, van den Berg A, Eijkel JCT, van der Meer AD. Patterning Biological Gels for 3D Cell Culture inside Microfluidic Devices by Local Surface Modification through Laminar Flow Patterning. Micromachines. 2020; 11(12):1112. https://doi.org/10.3390/mi11121112

Chicago/Turabian StyleLoessberg-Zahl, Joshua, Jelle Beumer, Albert van den Berg, Jan C. T. Eijkel, and Andries D. van der Meer. 2020. "Patterning Biological Gels for 3D Cell Culture inside Microfluidic Devices by Local Surface Modification through Laminar Flow Patterning" Micromachines 11, no. 12: 1112. https://doi.org/10.3390/mi11121112

APA StyleLoessberg-Zahl, J., Beumer, J., van den Berg, A., Eijkel, J. C. T., & van der Meer, A. D. (2020). Patterning Biological Gels for 3D Cell Culture inside Microfluidic Devices by Local Surface Modification through Laminar Flow Patterning. Micromachines, 11(12), 1112. https://doi.org/10.3390/mi11121112