Laboratory Assessment of the Infiltration Capacity Reduction in Clogged Porous Mixture Surfaces

Abstract

:1. Introduction

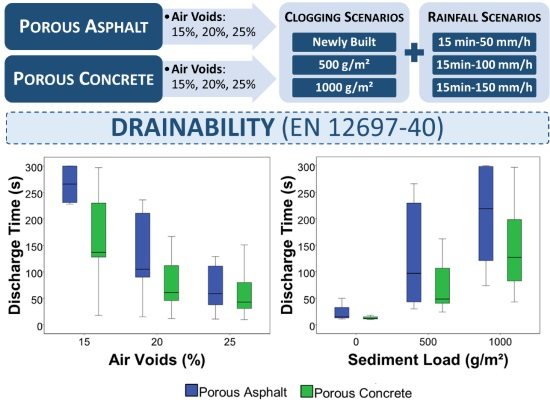

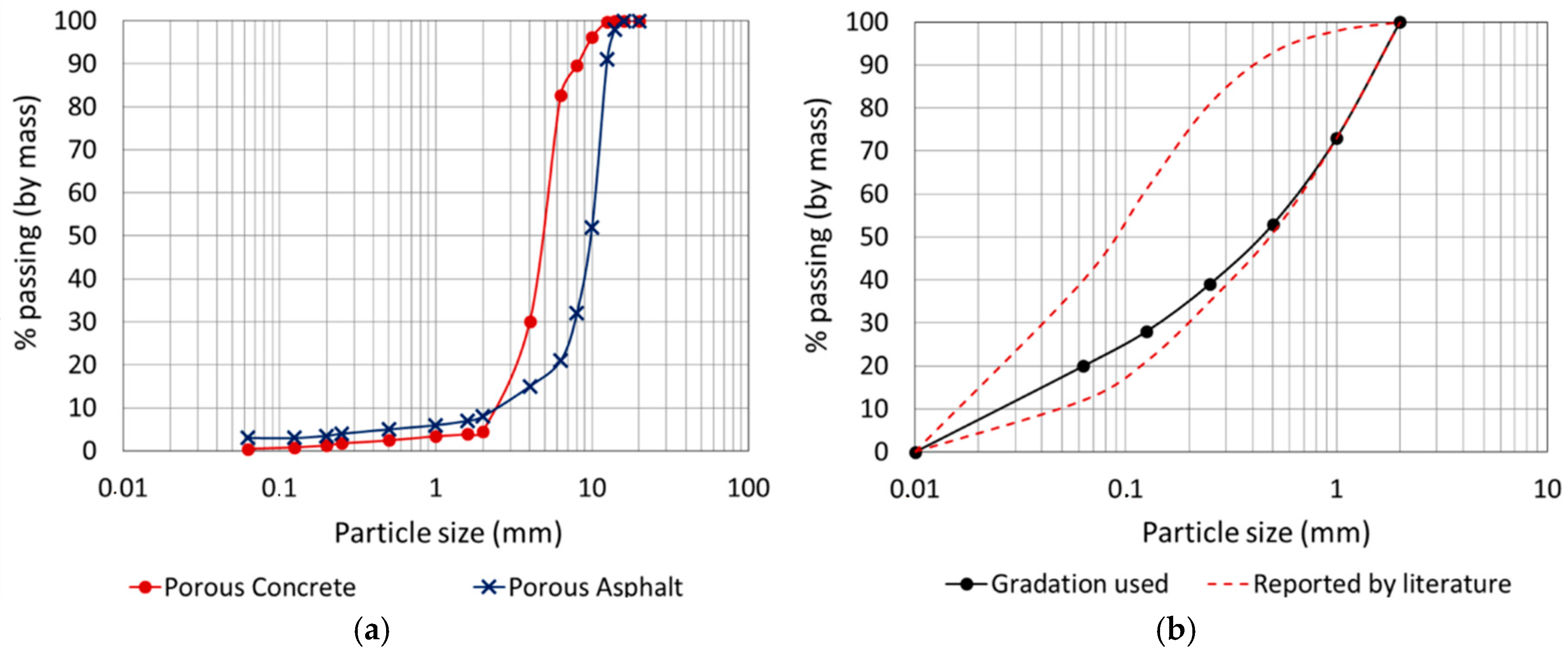

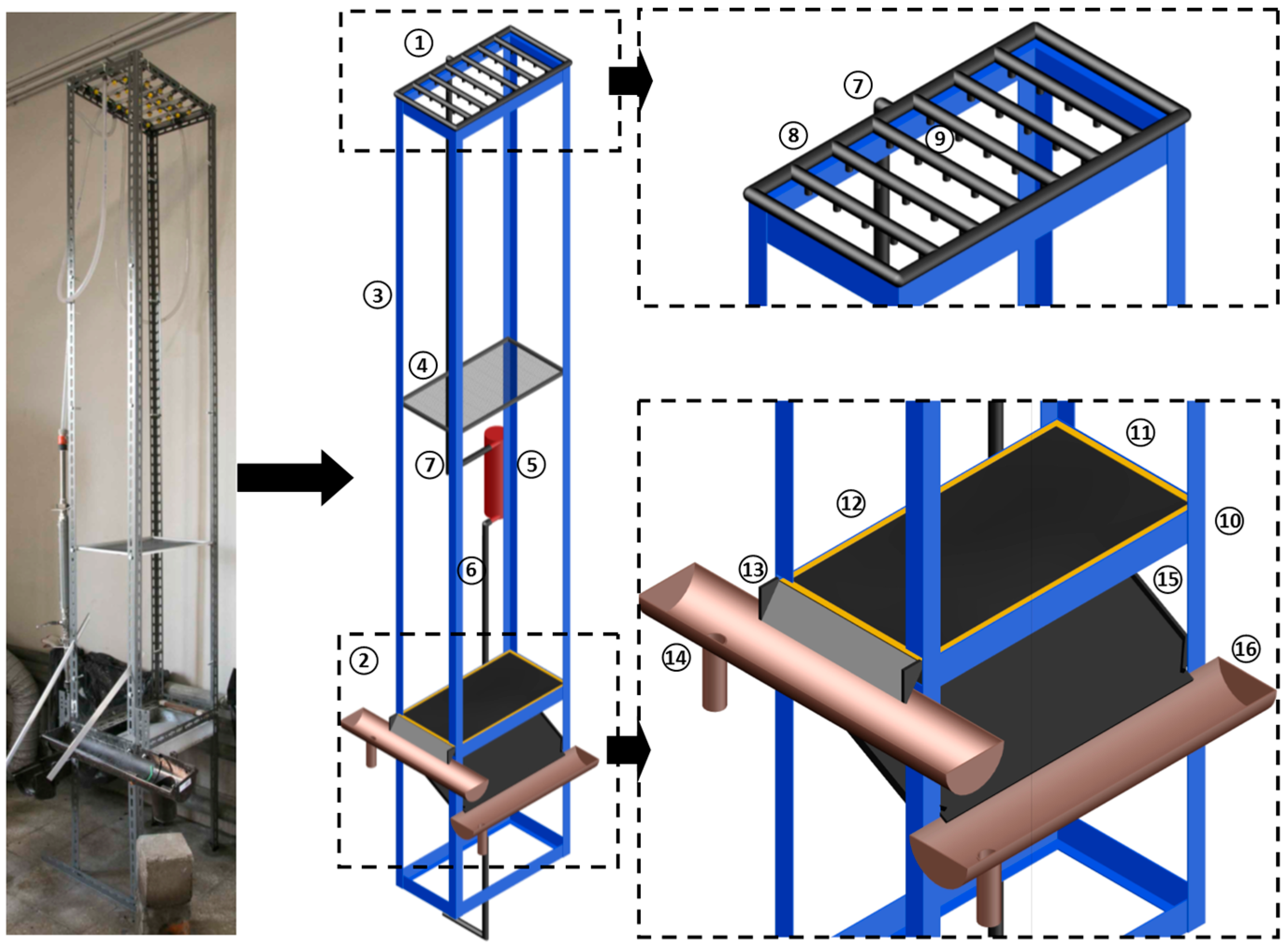

2. Materials and Methods

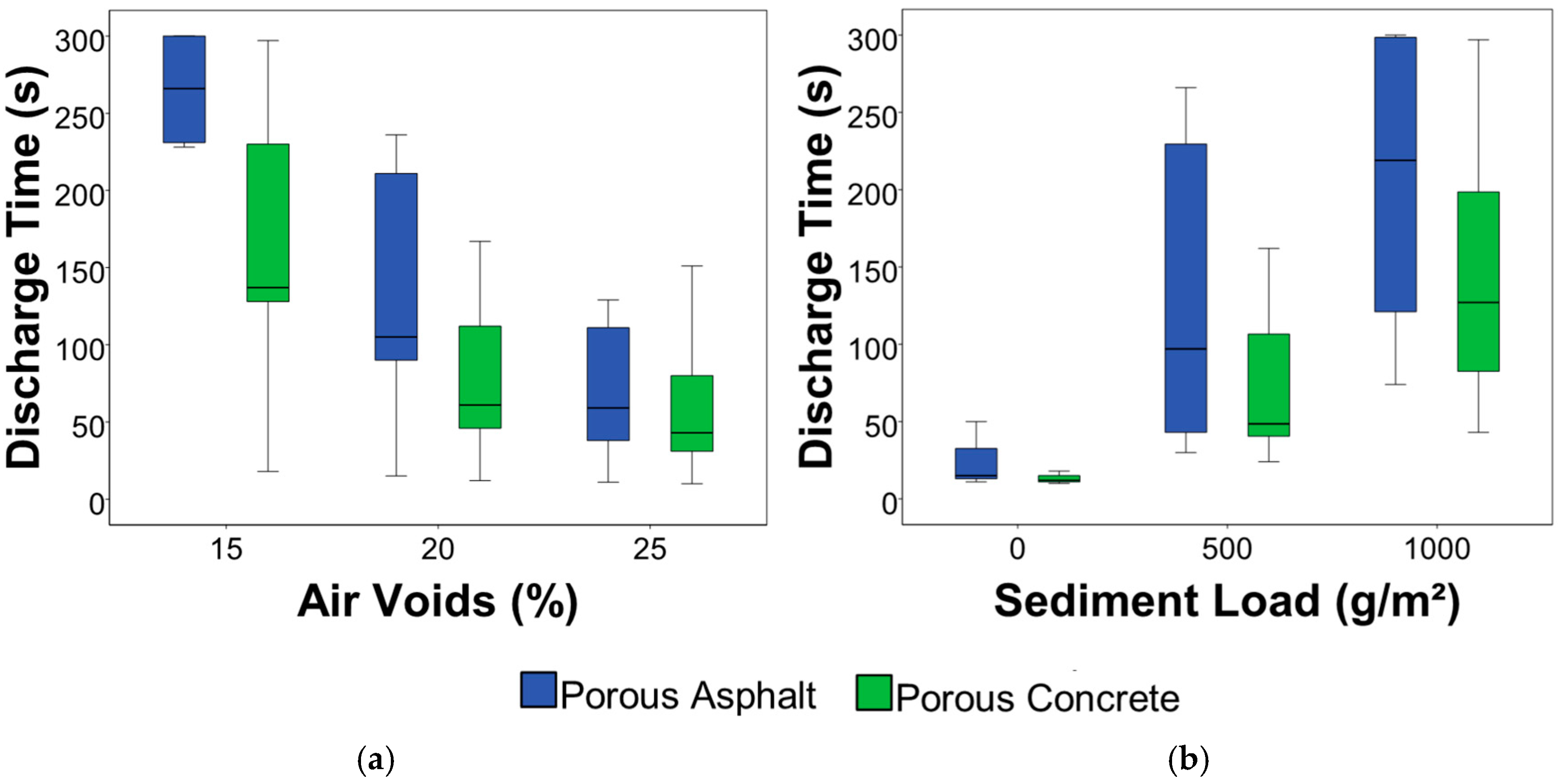

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rodriguez-Hernandez, J.; Andrés-Valeri, V.C.; Ascorbe-Salcedo, A.; Castro-Fresno, D. Laboratory study on the stormwater retention and runoff attenuation capacity of four permeable pavements. J. Environ. Eng. 2016, 142. [Google Scholar] [CrossRef]

- Castro-Fresno, D.; Andrés-Valeri, V.C.A.; Sañudo-Fontaneda, L.A.; Rodríguez-Hernández, J. Sustainable Drainage Practices in Spain, Specifically Focused on Pervious Pavements. Water 2013, 5, 67–93. [Google Scholar] [CrossRef]

- Rodriguez-Hernandez, J.; Andrés-Valeri, V.C.; Calzada-Pérez, M.A.; Vega-Zamanillo, A.; Castro-Fresno, D. Study of the raveling resistance of porous asphalt pavements used in sustainable drainage systems affected by hydrocarbon spills. Sustainability 2015, 7, 16226–16236. [Google Scholar] [CrossRef]

- Andrés-Valeri, V.C.A.; Castro-Fresno, D.; Sañudo-Fontaneda, L.Á.; Rodríguez-Hernández, J.; Ballester-Muñoz, F.; Canteras-Jordana, J.C. Rehabilitación hidrológica urbana. In Proceedings of the RHEABEND 2014 World Congress, Santander, Spain, 1–4 April 2014. (In Spanish)

- Willems, P.; Arnbjerg-Nielsen, K.; Olsson, J.; Nguyen, V.T.V. Climate change impact assessment on urban rainfall extremes and urban drainage: Methods and shortcomings. Atmos. Res. 2012, 103, 106–118. [Google Scholar] [CrossRef]

- Kuang, X.; Fu, Y. Coupled infiltration and filtration behaviours of concrete porous pavement and stormwater management. Hydrol. Process. 2012, 27, 532–540. [Google Scholar] [CrossRef]

- Rodriguez-Hernandez, J.; Castro-Fresno, D.; Fernández-Barrera, A.H.; Vega-Zamanillo, Á. Characterization of Infiltration Capacity of Permeable Pavements with Porous Asphalt Surface Using Cantabrian Fixed Infiltrometer. J. Hydrol. Eng. 2012, 17, 597–603. [Google Scholar] [CrossRef]

- Sansalone, J.; Kuang, X.; Ying, G.; Ranieri, V. Filtration and clogging of permeable pavement loaded by urban drainage. Water Res. 2012, 46, 6763–6774. [Google Scholar] [CrossRef] [PubMed]

- Sañudo-Fontaneda, L.A.; Rodriguez-Hernandez, J.; Calzada-Pérez, M.A.; Castro-Fresno, D. Infiltration behaviour of polymer-modified porous concrete and porous asphalt surfaces used in SuDS techniques. Clean Soil Air Water 2014, 42, 139–145. [Google Scholar] [CrossRef]

- Alvarez, A.E.; Martin, A.E.; Estakhri, C. A review of mix design and evaluation research for permeable friction course mixtures. Constr. Build. Mater. 2011, 25, 1159–1166. [Google Scholar] [CrossRef]

- Liu, Q.; Cao, D. Research on material composition and performance of porous asphalt pavement. J. Mater. Civ. Eng. 2009, 21, 135–140. [Google Scholar] [CrossRef]

- Dougherty, M.; Hein, M.; Martina, B.A.; Ferguson, B.K. Quick surface infiltration test to assess maintenance needs on small pervious concrete sites. J. Irrig. Drain. Eng. 2011, 137, 553–563. [Google Scholar] [CrossRef]

- Li, H.; Kayhanian, M.; Harvey, J.T. Comparative field permeability measurement of permeable pavements using ASTM C1701 and NCAT permeameter methods. J. Environ. Manag. 2013, 118, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Ranieri, V.; Colonna, P.; Sansalone, J.J.; Sciddurlo, A. Measurement of hydraulic conductivity in porous mixes. J. Transp. Res. Board 2012, 2295, 1–10. [Google Scholar] [CrossRef]

- Fernández-Barrera, A.H.; Castro-Fresno, D.; Rodríguez-Hernández, J.; Calzada-Pérez, M.A. Infiltration capacity assessment of urban pavements using the LCS permeameter and the CP infiltrometer. J. Irrig. Drain. Eng. 2008, 134, 659–665. [Google Scholar] [CrossRef]

- Nichols, P.W.B.; Lucke, T.; Dierkes, C. Comparing two methods of determining infiltration rates of permeable interlocking concrete pavers. Water 2014, 6, 2353–2366. [Google Scholar] [CrossRef]

- Sansalone, J.; Kuang, X.; Ranieri, V. Permeable pavement as a hydraulic and filtration interface for urban drainage. J. Irrig. Drain. Eng. 2008, 134, 666–674. [Google Scholar] [CrossRef]

- Coughlin, J.P.; Campbell, C.D.; Mays, D.C. Infiltration and Clogging by Sand and Clay in a Pervious Concrete Pavement System. J. Hydrol. Eng. 2011, 17, 68–73. [Google Scholar] [CrossRef]

- Lucke, T.; Beecham, S. Field investigation of clogging in a permeable pavement system. Build. Res. Inf. 2011, 39, 603–615. [Google Scholar] [CrossRef]

- Sañudo-Fontaneda, L.A.; Andrés-Valeri, V.C.A.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Field study of infiltration capacity reduction of porous mixture surfaces. Water 2014, 6, 661–669. [Google Scholar] [CrossRef]

- Balades, J.-D.; Legret, M.; Madiec, H. Permeable pavements: Pollution management tools. Water Sci. Technol. 1995, 32, 49–56. [Google Scholar] [CrossRef]

- Al-Rubaei, A.M.; Stenglein, A.L.; Viklander, M.; Blecken, G.T. Long-Term hydraulic performance of porous asphalt pavements in Northern Sweden. J. Irrig. Drain. Eng. 2013, 139, 499–505. [Google Scholar] [CrossRef]

- Martin, W.D.; Kaye, N.B.; Putman, B.J. Impact of vertical porosity distribution on the permeability of pervious concrete. Constr. Build. Mater. 2014, 59, 78–84. [Google Scholar] [CrossRef]

- Kayhanian, M.; Anderson, D.; Harvey, J.T.; Jones, D.; Muhunthan, B. Permeability measurement and scan imaging to assess clogging of pervious concrete pavements in parking lots. J. Environ. Manag. 2012, 95, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Hernandez, J.; Fernández-Barrera, A.H.; Andrés-Valeri, V.C.A.; Vega-Zamanillo, A.; Castro-Fresno, D. Relationship between urban runoff pollutant and catchment characteristics. J. Irrig. Drain. Eng. 2013, 139, 833–840. [Google Scholar] [CrossRef]

- Yong, C.F.; McCarthy, D.T.; Deletic, A. Predicting physical clogging of porous and permeable pavements. J. Hydrol. 2013, 481, 48–55. [Google Scholar] [CrossRef]

- Bonicelli, A.; Giustozzi, F.; Crispino, M.; Borsa, M. Evaluating the effect of reinforcing fibres on pervious concrete volumetric and mechanical properties according to different compaction energies. Eur. J. Environ. Civ. Eng. 2013, 19, 184–198. [Google Scholar] [CrossRef]

- Bonicelli, A.; Giustozzi, F.; Crispino, M. Experimental study on the effects of fine sand addition on differentially compacted pervious concrete. Constr. Build. Mater. 2015, 91, 102–110. [Google Scholar] [CrossRef]

- Cominsky, R.J.; Huber, G.A.; Kennedy, T.W.; Anderson, M. The Superpave 279 Mix Design Manual for New Construction and Overlays; SHRP A-407 Report; U.S. National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Deletic, A.; Orr, D.W. Pollution buildup on road surfaces. J. Environ. Eng. 2005, 131, 49–59. [Google Scholar] [CrossRef]

- Zanders, J.M. Road sediment: Characterization and implications for the performance of vegetated strips for treating road run-off. Sci. Total Environ. 2005, 339, 41–47. [Google Scholar] [CrossRef] [PubMed]

- Zafra, C.A.; Temprano, J.; Tejero, I. Particle size distribution of accumulated sediments on an urban road in rainy weather. Environ. Technol. 2008, 29, 571–582. [Google Scholar] [CrossRef] [PubMed]

- Bian, B.; Zhu, W. Particle size distribution and pollutants in road-deposited sediments in different areas of Zhenjiang, China. Environ. Geochem. Health 2009, 31, 511–520. [Google Scholar] [CrossRef] [PubMed]

- EN 12697-40. Bituminous Mixtures—Test Methods for Hot Mix Asphalt Part 40: In Situ Drainability; CEN (European Committee for Standarization): Bruxelles, Belgium, 2012. [Google Scholar]

- Hudson, N.W. The Flour Pellet Method for Measuring the Size of Raindrops; Department of Conservation and Extension: Salisbury, Rhodesia, 1964.

- Kathiravelu, G.; Lucke, T.; Nichols, P. Rain Drop Measurement Techniques: A Review. Water 2016, 8, 29. [Google Scholar] [CrossRef]

- Asseline, J.; Valentin, C. Construction et mise au point d’un infiltromètre à aspersion. Cah. ORSTOM Sér. Hydrol. 1978, 15, 321–349. (In French) [Google Scholar]

- Nnadi, E.O.; Coupe, S.J.; Sañudo-Fontaneda, L.A.; Rodriguez-Hernandez, J. An evaluation of enhanced geotextile layer in permeable pavement to improve stormwater infiltration and attenuation. Int. J. Pavement Eng. 2014, 15, 925–932. [Google Scholar] [CrossRef]

- Shirke, N.A.; Shuler, S. Cleaning porous pavements using a reverse flush process. J. Transp. Eng. 2009, 135, 832–838. [Google Scholar] [CrossRef]

- Mann, H.B.; Whitney, D.R. On a test of whether one or more random variables is stochastically larger than in the other. Ann. Math. Stat. 1947, 18, 52–54. [Google Scholar] [CrossRef]

- Alvarez, A.E.; Martin, A.E.; Estakhri, C. Internal structure of compacted permeable friction course mixtures. Constr. Build. Mater. 2010, 24, 1027–1035. [Google Scholar] [CrossRef]

- Mansour, T.N.; Putman, B.J. Influence of aggregate gradation on the performance properties of porous asphalt mixtures. J. Mater. Civ. Eng. 2013, 25, 281–288. [Google Scholar] [CrossRef]

- Martin, W.D.; Putman, B.J.; Neptune, A.I. Influence of aggregate gradation on clogging characteristics of porous asphalt mixtures. J. Mater. Civ. Eng. 2014, 26, 04014026. [Google Scholar] [CrossRef]

| Material | Air Voids (%) | Discharge Time (s) | ||

|---|---|---|---|---|

| Newly Built | After Testing a Sediment Load of 500 g/m2 | After Testing a Sediment Load of 1000 g/m2 | ||

| PC | 15 | 18 | 16 | 16 |

| 20 | 17 | 12 | 13 | |

| 25 | 11 | 11 | 12 | |

| PA | 15 | 66 | 57 | 55 |

| 20 | 16 | 16 | 17 | |

| 25 | 14 | 16 | 19 | |

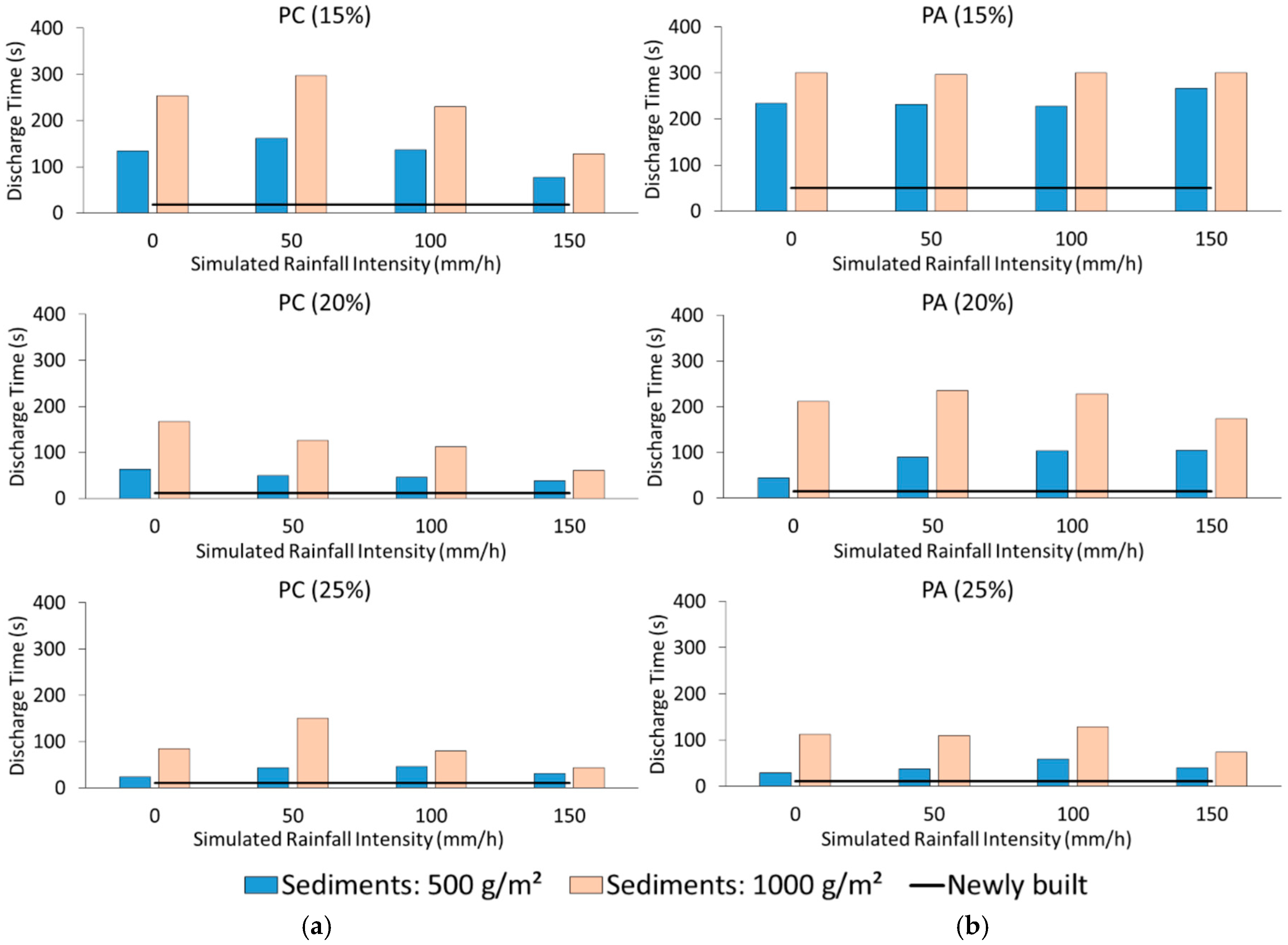

| Air Void Content (%) | Sediment Load (g/m2) | Simulated Rainfall Intensity (mm/h) | Discharge Time (s) | Runoff (% of Rainfall) | ||||

|---|---|---|---|---|---|---|---|---|

| PA Mixtures | PC Mixtures | PA Mixtures | PC Mixtures | |||||

| Mean | Std. Dev. | Mean | Std. Dev. | |||||

| 15 | 500 | 0 | 235 | 58 | 135 | 69 | - | - |

| 20 | 500 | 0 | 45 | 18 | 63 | 48 | - | - |

| 25 | 500 | 0 | 30 | 18 | 24 | 14 | - | - |

| 15 | 1000 | 0 | 300 | 1 | 254 | 41 | - | - |

| 20 | 1000 | 0 | 211 | 14 | 167 | 87 | - | - |

| 25 | 1000 | 0 | 113 | 53 | 85 | 84 | - | - |

| 15 | 500 | 50 | 231 | 20 | 162 | 5 | 2.0% | 0.0% |

| 20 | 500 | 50 | 90 | 50 | 50 | 6 | 2.5% | 0.5% |

| 25 | 500 | 50 | 38 | 6 | 43 | 20 | 0.0% | 0.0% |

| 15 | 1000 | 50 | 297 | 5 | 297 | 6 | 0.5% | 0.0% |

| 20 | 1000 | 50 | 236 | 89 | 126 | 56 | 0.5% | 0.0% |

| 25 | 1000 | 50 | 111 | 29 | 151 | 110 | 0.5% | 0.0% |

| 15 | 500 | 100 | 228 | 65 | 137 | 43 | 1% | 0.5% |

| 20 | 500 | 100 | 104 | 41 | 46 | 17 | 1.5% | 0.5% |

| 25 | 500 | 100 | 59 | 23 | 47 | 28 | 1.5% | 0.5% |

| 15 | 1000 | 100 | 300 | 1 | 230 | 24 | 1% | 0.5% |

| 20 | 1000 | 100 | 227 | 67 | 112 | 39 | 1.5% | 0.5% |

| 25 | 1000 | 100 | 129 | 10 | 80 | 28 | 1.5% | 0.5% |

| 15 | 500 | 150 | 266 | 29 | 78 | 21 | 0.5% | 0.0% |

| 20 | 500 | 150 | 105 | 42 | 38 | 11 | 0.5% | 0.0% |

| 25 | 500 | 150 | 41 | 7 | 31 | 14 | 0.0% | 0.0% |

| 15 | 1000 | 150 | 300 | 1 | 128 | 40 | 0.0% | 0.0% |

| 20 | 1000 | 150 | 174 | 1 | 61 | 16 | 0.0% | 0.0% |

| 25 | 1000 | 150 | 74 | 32 | 43 | 19 | 0.0% | 0.0% |

| 15 | 0 | 50/100/150 (*) | 50 | 15 | 18 | 2 | 0.0% | 0.0% |

| 20 | 0 | 50/100/150 (*) | 15 | 1 | 12 | 2 | 0.0% | 0.0% |

| 25 | 0 | 50/100/150 (*) | 11 | 2 | 10 | 3 | 0.0% | 0.0% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrés-Valeri, V.C.; Marchioni, M.; Sañudo-Fontaneda, L.A.; Giustozzi, F.; Becciu, G. Laboratory Assessment of the Infiltration Capacity Reduction in Clogged Porous Mixture Surfaces. Sustainability 2016, 8, 751. https://doi.org/10.3390/su8080751

Andrés-Valeri VC, Marchioni M, Sañudo-Fontaneda LA, Giustozzi F, Becciu G. Laboratory Assessment of the Infiltration Capacity Reduction in Clogged Porous Mixture Surfaces. Sustainability. 2016; 8(8):751. https://doi.org/10.3390/su8080751

Chicago/Turabian StyleAndrés-Valeri, Valerio C., Mariana Marchioni, Luis Angel Sañudo-Fontaneda, Filippo Giustozzi, and Gianfranco Becciu. 2016. "Laboratory Assessment of the Infiltration Capacity Reduction in Clogged Porous Mixture Surfaces" Sustainability 8, no. 8: 751. https://doi.org/10.3390/su8080751