1. Introduction

Ethanol has been recognized as an important renewable and sustainable fuel source for modern industries [

1,

2,

3,

4]. For example, it can be used as a replacement of gasoline for many internal combustion engines, and it can be mixed with gasoline to any concentration. Most existing car engines can run on blends of up to 15% bio-ethanol with petroleum/gasoline, thus it can significantly reduce the dependence on crude oil [

5]. At the same time, food waste, particular fruits and vegetable waste, has become an increasingly alarming issue in North America. It has been estimated that approximately 18.2 billion pounds of fruits and vegetables have been lost every year in America. Therefore if this large amount of food waste can be utilized to produce ethanol, it will lead to significant economic and environmental benefits [

6,

7].

Through a fermentor, the waste vegetables and fruits can be fermented into a liquid wash which contains approximately 15% to 20% ethanol by weight [

8,

9,

10]. To produce usable ethanol, the excess water contents from the liquid wash must be removed through distillation process. The final purity of the ethanol products is limited to 95–96% due to the formation of a low-boiling water-ethanol azeotrope [

11]. Many ethanol distillation approaches have been developed to improve the system efficiencies. Griend

et al. [

12] developed an ethanol production system which includes a fermtator that may produce the beer slurry from the corns. Through a series of arrangement of process units, the system achieved great energy, water and downtime savings. Grethlein

et al. [

13] developed a system which employed a heat pump using a vapor stream from within the distillation system as a heat source and a liquid stream from within the distillation system as a heat sink. However all these improved distilling systems still consume a significant amount of energy to heat the wash and to evaporate the ethanol, which is usually accomplished by burning natural gas in a boiler to produce steam for heating. It is well known that burning any fossil fuel will create more greenhouse gases that are emitted to the atmosphere.

One of the approaches to reduce the amount of burned fuel is to apply a heat recovery system which can capture waste heat from an available system and use it for other applications. In this paper, an ethanol distillation and heat recovery system is introduced, which exploits the thermal energy carried by exhaust gas from the power generation facilities.

2. Ethanol Distillation Process

This ethanol distillation and heat recovery system includes different types of heat exchangers. The simplest design only requires one heat exchanger, which heats the wash up to the boiling point, so that the water and ethanol can be separated through a fractionating column. This single heat exchanger design usually leads to a very low ethanol production rate. In this paper, a three-heat exchanger system has been designed to achieve a higher ethanol production rate with a modest energy recovery efficiency.

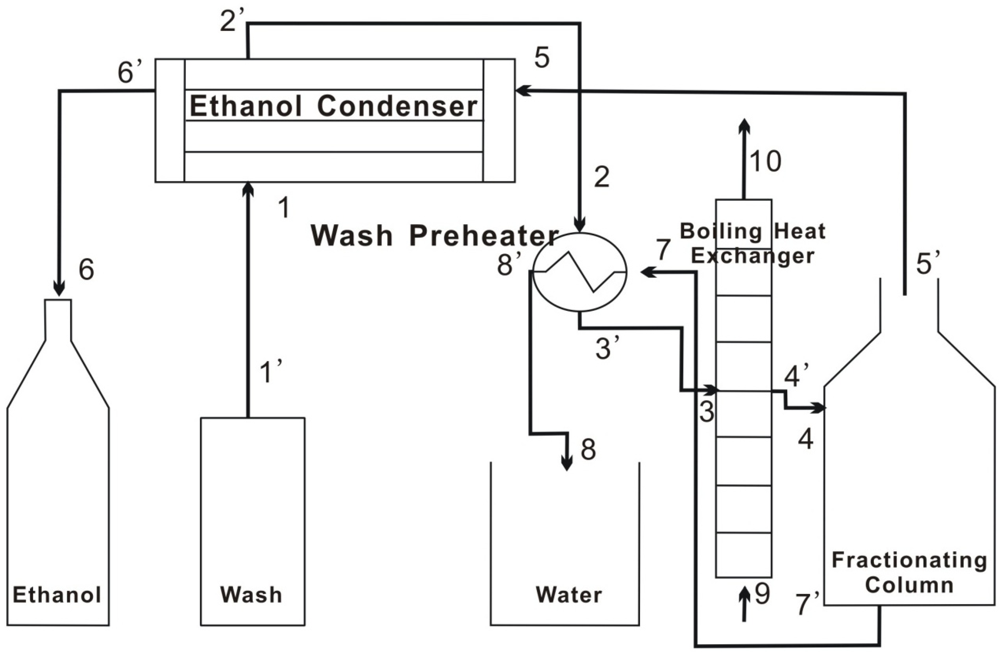

The proposed system is shown in

Figure 1, which includes an ethanol condenser, a wash preheater and a main heat exchanger which exploits the waste heat rejected from the power plant.

Before being pumped into the system, the fermented biomass, or commonly referred to as wash, is filtered to remove solid waste. It is stored in a wash tank shown in

Figure 1. The wash leaves the wash tank at state 1’. Due to the heat and frictional losses within the pipes, when it enters the first heat exchanger, or the ethanol condenser, its state has changed to state 1. This condenser is mainly used to condense the evaporated ethanol from the fractionating column. While the hot ethanol vapor at state 5 flows through this tube and shell heat exchanger and gets condensed, the initial cold wash from the storage tank is heated and then leaves the heat exchanger at state 2’.

Figure 1.

Configuration of the ethanol distillation system.

Figure 1.

Configuration of the ethanol distillation system.

The condenser is used as a preliminary heater which increases the system efficiency, and its energy balance is:

Where

![Sustainability 04 00092 i009]()

and

![Sustainability 04 00092 i010]()

is the mass flow rate of the distilled ethanol and wash, respectively; h

5, and h

6’ are the specific enthalpy of the ethanol at state 5 and 6’ respectively; h

2’ and h

1 are the specific enthalpy of the wash at state 2’ and 1, respectively.

The second heat exchanger can be referred to as an economizer since the wash is being further heated by the hot water from the fractionating column. There is no phase change within this liquid to liquid heat exchanger. The hot water at state 7 flows through the tubes and get cooled down to state 8’, while the wash coming out of the condenser flows outside of the tubes. During this process, the state of wash changes from state 2 to state 3’. The following equation can be obtained:

where

![Sustainability 04 00092 i011]()

is the mass flow rate of the water; h

7 and h

8’ are the specific enthalpy of the water at state 7, and 8’, respectively; h

3’and h

2 are the specific enthalpy of the wash at state 3’ and 2, respectively.

The main heat source for the third heat exchange is from the exhaust gas, which is discarded in the power plants through a stack or chimney. Since the ethanol requires a significant amount of energy to be evaporated, parallel flow design has been adopted in this heat exchanger. Moreover, the principal of risers or rising tubes has been applied when the hot gas are flowing across the outside of the wash tubes. As the ethanol gets evaporated, the bubbles under the hydrodynamic principle rise up without causing any pressure loss. The wash is heated to a temperature which is above the vaporization temperature of the ethanol but below that of water and its state changes from state 3 to state 4’. If state 9 and state 10 represents the state of the exhaust gas at inlet and exit of the heat exchanger, respectively, the energy balance of this heat exchanger will give:

![Sustainability 04 00092 i003]()

where

![Sustainability 04 00092 i012]()

is the mass flow rate of the exhaust gas; h

4’, h

3 is the specific enthalpy of the wash at state 4’, and 3, respectively; h

9, h

10 is the specific enthalpy of the exhaust gas at state 9 and 10, respectively.

Vaporized ethanol, mixed with liquid water droplets, is introduced into the fractioning column. The fractioning column has two exits, one for ethanol vapor and the other for liquid water, the energy balance leads to:

And from the mass conservation:

Perfect distillation is not expected, due to the chemical restrictions on the process. 95.7% ethanol is assumed to be the upper limit for a single distillation process and thus set the ethanol contents limit for ethanol at state 5’. The mass flow rate of the ethanol is directly related to the flow rate of the wash:

where ϕwash, and ϕethanol vapor represents the ethanol contents of the wash and distilled vapor, respectively.

Figure 2 shows an imaginary prototype of the system. Since the major energy source for this facility is from the exhaust gas from a power plant, the production rate of this system depends on the loading conditions of the power plant. To better explain this system, it is assumed that this distillation system is combined with a power plant with an averaged output of 400 MW, which leads to a full loading exhaust gas mass flow rate of 342.7 kg/s [

14]. The results shown later in this paper are all calculated based on this assumption.

Figure 2.

Proposed ethanol distillation system. 1: Wash Tanks; 2: Liquid Ethanol Tanks; 3: Main Heat Exchanger; 4: Fractionating Column; 5: Preheater; 6: Condenser.

Figure 2.

Proposed ethanol distillation system. 1: Wash Tanks; 2: Liquid Ethanol Tanks; 3: Main Heat Exchanger; 4: Fractionating Column; 5: Preheater; 6: Condenser.

Since the ethanol distillation facility must be operating continually, the rates of heat loss from the pipes to the surroundings vary a lot throughout the entire year. The difference between summer and weather conditions has been illustrated in

Table 1 and

Table 2. It is evident that the production rate is not affected at lower flow rates or lower exhaust gas temperatures, but when the flow rate within the pipes has increased to its maximum level the season effects can be noticed, and will affect performance. At the lowest flow rate, the difference in ethanol production between extreme summer and winter conditions was less than 3000 liters. However at the highest operating exhaust temperature the difference in production was calculated to be approximately 17,000 liters per day. (shown in

Table 2) These variations in production rate are less than 1% of the total output for any given exhaust temperature. Therefore the climate plays a negligible role on the total ethanol production rate. This can be attributed to the insulation covering the pipe network which limits the thermal losses to the environment.

Table 1.

Ethanol production rate variation with load and weather (exhaust gas inlet temperature 112 °C).

Table 1.

Ethanol production rate variation with load and weather (exhaust gas inlet temperature 112 °C).

| Power plant loading |

|---|

| 100% | 95% | 90% | 85% | 80% | 75% | 70% |

|---|

| Ambient weather | Summer (30 °C) | 274,209 L | 259,433 L | 244,720 L | 236,741 L | 221,921 L | 207,140 L | 192,397 L |

| Winter (−40 °C) | 271,365 L | 256,601 L | 241,900 L | 233,855 L | 219,046 L | 204,274 L | 189,541 L |

Table 2.

Ethanol production rate variation with exhaust temperature and weather (power plant loading 100%).

Table 2.

Ethanol production rate variation with exhaust temperature and weather (power plant loading 100%).

| Ambient temperature |

|---|

| −40 °C | −20 °C | 0 °C | 15 °C | 30 °C |

|---|

| Flue gas inlet temperature | 112 °C | 271,365 L | 272,178 L | 272,988 L | 273,601 L | 274,209 L |

| 130 °C | 752,253 L | 754,450 L | 759,145 L | 762,655 L | 766,089 L |

| 160 °C | 1,088,000 L | 1,093,000 L | 1,098,000 L | 1,101,000 L | 1,105,000 L |

The heat exchanger location was crucial to the systems as well. To reduce the heat loss, the pipes containing hot fluid should be short and the main heat exchanger should be close to the fractionating column. The only exception to this was the ethanol pipe exiting the fractionating column. This pipe connects the fractionating column directly to the first heat exchanger. The thermal losses are high for this pipe as it carries fluid with a high initial temperature. If the thermal losses become too high or change over time, pipes should be insulated further to avoid an early condensation or a poor preheating.

3. Discussion

3.1. Operating Temperatures of Working Fluids

One of the most important techniques to make this system successful is temperature control. The temperature of the wash entering the fractionating column must be within the range between azeotrope point and boiling point of pure water. If wash temperature is too low, the ethanol will not be evaporated. If its temperature is too high, the wash will be overheated and the distillation will fail as well.

The temperatures of working fluids are shown in

Table 3, these temperatures are calculated based on the energy and mass balance Equations (1)–(6), as well as the 70% loading of the power plant It can be seen that wash temperature is lifted steadily through the heat exchangers. Temperature jumps significantly through the first heat exchanger due to the massive energy release of the ethanol vapor during the condensation.

The preheating process utilizes a fair amount of heat from the water leaving the fractioning column. As shown in

Table 3, wash is preheated and its temperature is further lifted from 59.1 °C to 75.0 °C, while water temperature decreases from 92.1 °C to 70.8 °C.

The third heat exchanger vaporizes the ethanol contents of the wash. The exhaust gas temperature leaving the stack can vary a lot, depending on the operating conditions within the plant. When a power plant is increasing its output, its fuel rate is increased as well as the thermal utilization of the air or steam, and the exhaust gas temperature is usually decreased. But if a plant is rapidly decelerating, the extremely hot exhaust gases can be produced and it will significantly affect the ethanol production rate. In

Table 3, it can be found that when the power plant operates at 70% of its full capacity, and the exhaust gas temperature is around 112 °C, the temperature gradient of the exhaust gas across the main heat exchanger is about 11.9 °C.

Table 3.

Working fluids temperature.

Table 3.

Working fluids temperature.

| Parameters | Amount |

|---|

| Power Plant Loading (%) | 70.0 |

| Gas Inlet Temperature (°C) | 112.0 |

| Gas Exit Temperature (°C) | 100.1 |

| Wash Temperature at Wash Tank (°C) | 26.9 |

| Wash Temperature at the Exit of Condenser (°C) | 59.1 |

| Wash Temperature at the Exit of Preheater (°C) | 75.0 |

| Wash Temperature at the Exit of Main Heat Exchanger (°C) | 95.0 |

| Water Temperature at the Exit of Fraction Column (°C) | 92.1 |

| Water Temperature at the Exit of Preheater (°C) | 70.8 |

| Ethanol Vapor Temperature at the Exit of Fraction Column (°C) | 92.1 |

| Ethanol Liquid Temperature at the Exit of Condenser (°C) | 68.5 |

The liquid water exiting the fractioning column will contain trace amounts of ethanol due to the nature of distillation, and it can be recycled and thus maximize the ethanol recovered from the wash. However, in this design, only one distillation process is considered and the liquid water will be used to preheat the wash. The temperatures of the water and ethanol vapor are lower than that of the fluid entering the fractioning column due to heat losses through the column and the pipes.

The ethanol flowing into the storage tank will be at a reasonably high temperature (shown in

Table 3), given a relatively high ethanol vapor temperature from the fraction column. The sensible energy stored in the liquid ethanol can be released into the atmosphere through natural convection. Alternatively the energy could be used for district heating or hot water production.

The temperature of wash at the entrance of the fractioning column must be controlled within the range between the azeotrope point of wash and boiling point of pure water. Temperature of the heated wash can be controlled with the mass flow rates of the exhaust gas and wash. If the temperature at the entrance of the fractioning column approaches the upper limit of the range, the mass flow rate of the supplied exhaust gas should be reduced or the mass flow rate of the wash should be increased. If the temperature approaches the lower limits, the opposite operations should be conducted. The mass flow rates of the wash and exhaust gas can be controlled with pumps and fans.

3.2. Heat Exchangers

The heat exchanger effectiveness is a measurement used for determining how well the heat exchanger utilizes the available energy [

15], which is given by:

where

where

hh,in and

hc,in represents the specific enthalpy of the hot fluid and cold fluid at the inlets of the heat exchanger, respectively.

![Sustainability 04 00092 i013]()

and

![Sustainability 04 00092 i014]()

are the actual heat transfer rate and maximum heat transfer rate of the system, respectively.

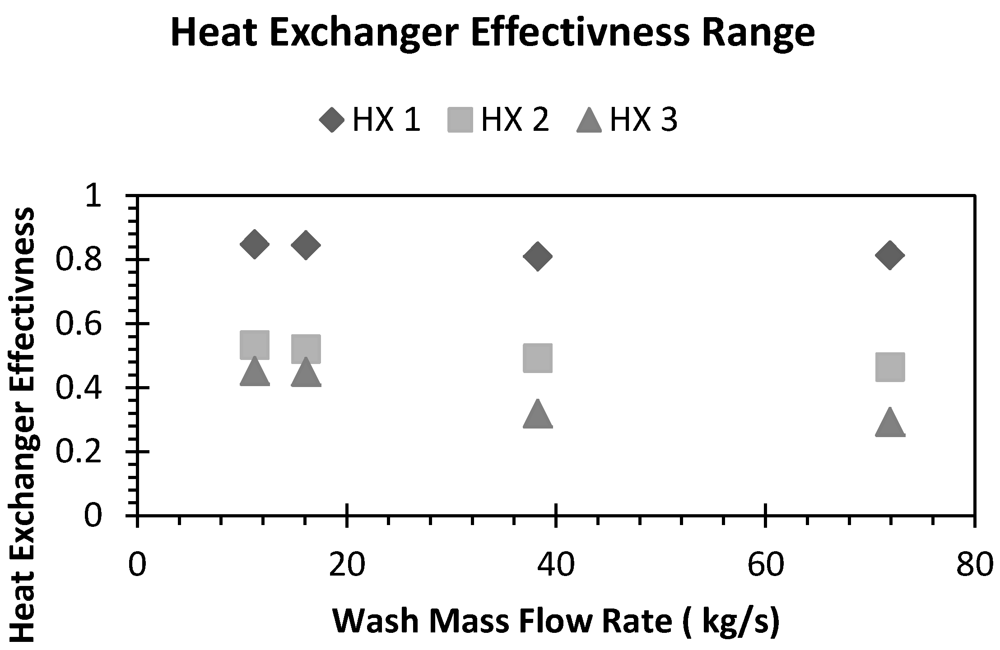

The effectiveness of the three major heat exchangers is shown in

Table 4, with the operating conditions as following: 112 °C exhaust gas temperature, an ambient temperature of −40 °C and a power plant loading level of 70%. It can be seen that the condenser is the most effective heat exchanger, and the liquid to liquid preheater is the second most efficient, while the main heat exchanger is the least efficient. The relatively low effectiveness of the main heat exchanger is due to its relatively low overall heat transfer rate, which can be explained by a relatively low convection heat transfer coefficient at its gas side, compared with the other two heat exchangers. To enhance the convection effects at the gas side, one possible option is to increase the velocity of the exhaust gas, but that will lead to higher exhaust fan work consumptions.

Table 4.

Comparisons of heat exchanger effectiveness.

The effectiveness of these heat exchangers with different wash flow rates is shown in

Figure 3. It can be seen that the lower wash mass flow rate is, the higher effectiveness can be achieved. This can be explained by the fact a lower mass flow rate will lead to a higher wash exit temperature. To achieve a high ethanol production rate, a high wash mass flow rate is desired, although it may lead to lower effectiveness of the heat exchanger.

Figure 3.

Effectiveness of heat exchangers with different wash flow rates.

Figure 3.

Effectiveness of heat exchangers with different wash flow rates.

3.3. Ethanol Production Rates

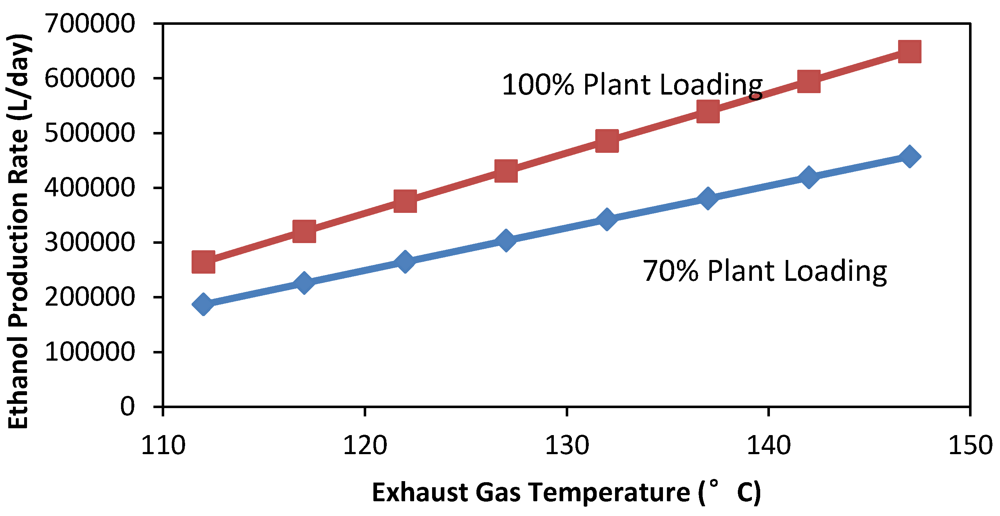

As mentioned earlier, this ethanol facility is a passive system which relies on the energy in the exhaust gas to evaporate the ethanol, thus the ethanol production rate depends on the temperature and mass flow rate of the exhaust gas.

Figure 4 shows that with a 70% power plant loading and a 112 °C exhaust gas temperature, the average daily ethanol production rate is about 187,000 L, while with full power plant loading and an exhaust gas temperature of 147 °C, the average daily ethanol production rate can reach 649,000 L. This can be well explained by the fact that with a higher exhaust temperature and mass flow rate, more energy can be used to distill the ethanol.

Figure 4.

Relationships between the ethanol flow rate and exhaust gas temperature.

Figure 4.

Relationships between the ethanol flow rate and exhaust gas temperature.

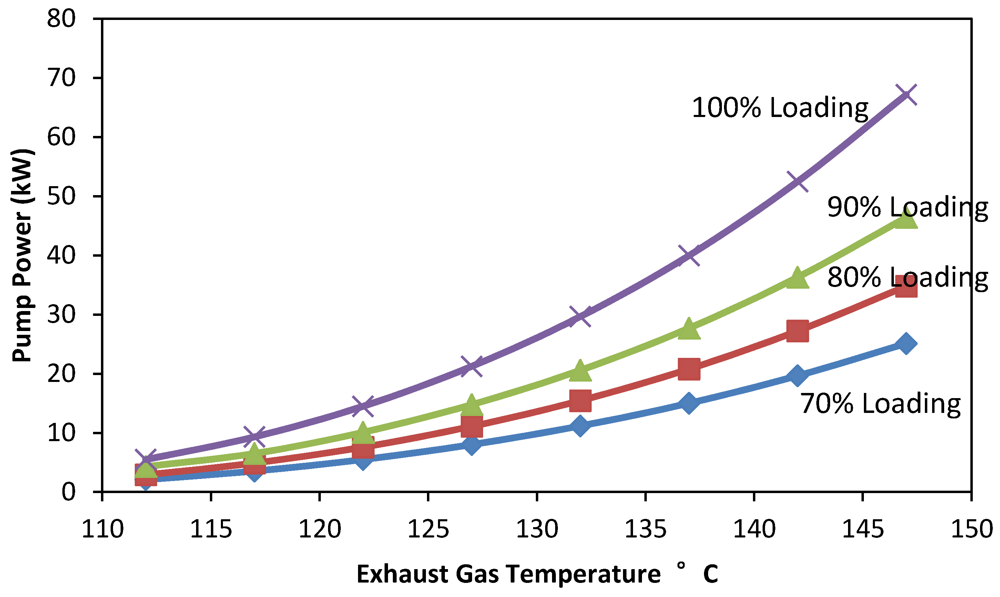

3.4. Pump Work and Exhaust Fan Capacity

The exhaust gas is known to be pressurized as it is pumped out of the stack. The desired exhaust gas velocity should be determined when designing the heat exchanger as it will affect the convection heat transfer. The higher the gas exhaust velocity is, the better convection can be achieved. Therefore fans are required to propel the exhaust gas. Total power consumption of the fan depends on two major factors. The first factor is the plant loading, which is directly related to the mass flow rate of the exhaust gas.

Figure 5 shows that for an exhaust gas temperature of 160 °C, with a full power plant loading, the required fan power consumptions is about 7.6 MW; while with a 70% power plant loading, the required fan power consumption is 2.1 MW. Power plants are notorious for operating at different ranges of capacity as the demand for energy fluctuates through a given day, month, and even year. Therefore the ethanol production facility must be able to accommodate changes in exhaust flow rate. As the power plant’s operating level rises so does the exhaust flow rate, this requires a great deal of energy from the fans.

The second factor affecting fan power is the temperature of the exhaust gas. Since with a higher temperature, its density decreases, leading to a larger volumetric flow rate and a higher frictional loss.

The fan configuration design may largely depend on the operating characteristics of the power plant. If the power generation system is prone to fluctuations it would be advantageous to choose a dual fan design capable of operating efficiently over a wide range of operating conditions. However with a steady operating plant it could be reasonable to pick a single fan due to its lower initial cost.

Pumps are used to propel the wash, the hot water as well as the purified ethanol product. It is related to many factors such as production flow rate, wash flow rate, the pipe characteristics,

etc.

Figure 6 shows the pump work required to propel the wash through the heat exchanger network, with different plant loadings and exhaust gas temperatures. The pump operates at a value of 4 kW for the majority of the operating cycle if a 70% plant loading and 112 °C exhaust temperature is applied. However in the event of a decreased power demand the exhaust temperature will spike, resulting in a much higher exhaust gas temperature. To avoid overheating the wash, the mass flow rate of the wash must be increased, so is the required pump work. Based on these conditions, a dual pump design will be the most effective.

Figure 6.

Relationship between pump work and exhaust gas temperature.

Figure 6.

Relationship between pump work and exhaust gas temperature.

3.5. Capacity of Storage Tanks

There are three kinds of storage tanks needed in this system: wash tank, wash storage tank and ethanol storage tank. The tank construction is not important to the process performance but is a substantial cost in the construction of the facility and the layout of the pipe network.

3.5.1. Wash Tank Storage Capacity

The ethanol storage tanks require a special design to enable quick fluid extraction as well as easy filling. The most common tank suitable for this purpose has a conical bottom with a release valve located at the vertex. The bottom valve would be used to distribute the ethanol to an appropriate transportation vessel. A shallow dish shaped base is required for the mash filtration in the tank. According to the standard fermentation process [

10], the yeast requires up to 2 weeks to produce a wash solution of 15% ethanol concentration. Therefore the wash tanks must be able to accommodate the median volumetric consumption rate for a period of 15–20 days, depending on the operational conditions of the facility. The water tanks will be constructed with an almost flat base, with a sediment basin to collect any lingering particulates which remained after the mash filtration.

Based on an average ethanol production rate presented in

Section 3.3, to safely allow for overflow and delay error, 4–8 wash tanks need to be constructed, and each tank with a storage capacity of 5 million liters.

3.5.2. Water Storage Tank Capacity

The water storage tanks should be able to accommodate 2 days operation at average capacity. This works out to about 5.0 million L of water storage in total, which can easily be accommodated by 2 tanks with a capacity of 3.14 million liters. The water tank is similar in design to the wash tanks to reduce the design cost and improve construction speed. Only 2 days operating capacity is required because the water can be recycled. The water tanks can be directly connected to the wash tanks to allow for on-the-fly water tank emptying and wash tank filling.

3.5.3. Ethanol Storage Tank Capacity

The ethanol storage tanks need to accommodate the average daily ethanol production between shipments. Assuming a steady shipping process, with a modest reserve leads to determining to support a 2-week storage capacity. It was good practice to use the expected operating capacity, of full power plant loading and 112 °C exhaust temperatures for the storage requirements. With a daily production rate of ethanol of 260,000 liters, if the capacity of a single tank is 1 million liters, 5 storage tanks will meet the design requirement.

3.6. Economical Analysis

With minimal upgrades required to the original power plant, this ethanol distillation facility can be constructed on site for the purpose of bio-fuel production. The facility has an extremely low energy demand compared to traditional distillation cycles and the fuel required for heating can be eliminated. The system was not expensive to construct with an expected cost of $25 million [

14], resulting in a feasible design which is both economical and sustainable.

Based on an average daily ethanol production of 260,000 liters and an average fan and pump power consumption of 6 MW, one kWh of electricity can generate 1.81 liters of ethanol.

Table 5 shows the breakdown of the financial analysis of the operations of this facility. The yearly revenue is calculated based on a conservative estimate with an ethanol price of 0.5 $/liter [

16]. The wash is generated from the discarded fruits and vegetables, considering its transportation, collection and fermentation costs, it has a unit price of less than 0.05$/liter [

14]. The financial cost is calculated based on 25 million dollars, 10-year loan with an annual interest rate of 8%. It can be seen that the facility can generate a profit of 6.46 million dollars per year. From

Table 5 it can be found that the highest cost comes from the wash. The cost of wash will significantly affect the profitability of the facility. Other risk factors include the ethanol price, inflation, and labor costs.

Table 5.

Financial analysis of the distillation facility (in thousand dollars).

Table 5.

Financial analysis of the distillation facility (in thousand dollars).

| Total revenue | 47,450 |

|---|

| Cost of materials (wash) | 26,889 |

| Cost of fan and pump work | 5256 |

| Financial cost | 2844 |

| Labor | 2000 |

| Maintenance | 4000 |

| Estimated profit | 6461 |

and

and  is the mass flow rate of the distilled ethanol and wash, respectively; h5, and h6’ are the specific enthalpy of the ethanol at state 5 and 6’ respectively; h2’ and h1 are the specific enthalpy of the wash at state 2’ and 1, respectively.

is the mass flow rate of the distilled ethanol and wash, respectively; h5, and h6’ are the specific enthalpy of the ethanol at state 5 and 6’ respectively; h2’ and h1 are the specific enthalpy of the wash at state 2’ and 1, respectively.

is the mass flow rate of the water; h7 and h8’ are the specific enthalpy of the water at state 7, and 8’, respectively; h3’and h2 are the specific enthalpy of the wash at state 3’ and 2, respectively.

is the mass flow rate of the water; h7 and h8’ are the specific enthalpy of the water at state 7, and 8’, respectively; h3’and h2 are the specific enthalpy of the wash at state 3’ and 2, respectively.

is the mass flow rate of the exhaust gas; h4’, h3 is the specific enthalpy of the wash at state 4’, and 3, respectively; h9, h10 is the specific enthalpy of the exhaust gas at state 9 and 10, respectively.

is the mass flow rate of the exhaust gas; h4’, h3 is the specific enthalpy of the wash at state 4’, and 3, respectively; h9, h10 is the specific enthalpy of the exhaust gas at state 9 and 10, respectively.

and

and  are the actual heat transfer rate and maximum heat transfer rate of the system, respectively.

are the actual heat transfer rate and maximum heat transfer rate of the system, respectively.