Determinants and Differences of Grain Production Efficiency Between Main and Non-Main Producing Area in China

Abstract

:1. Introduction

2. Materials and Methods

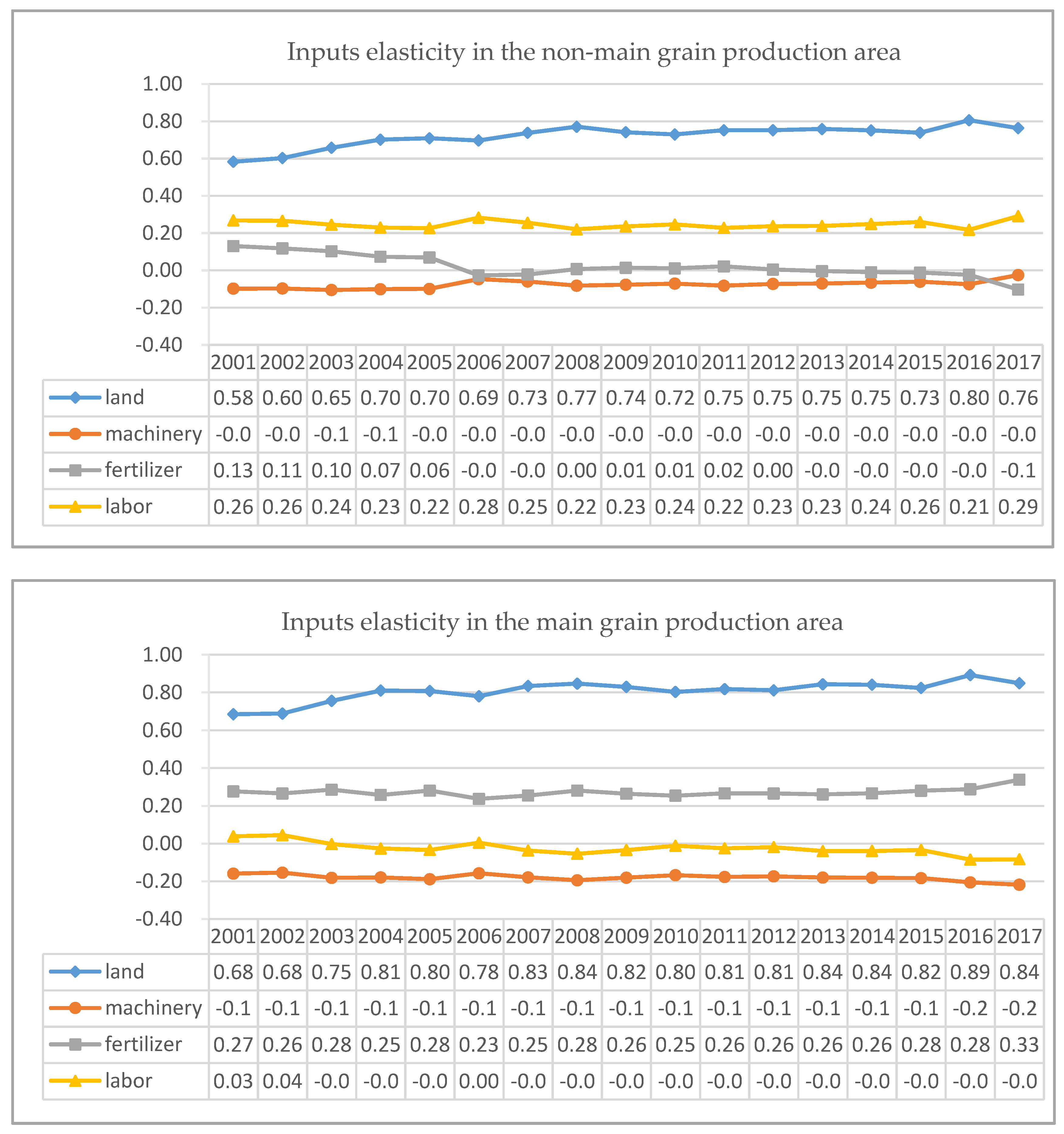

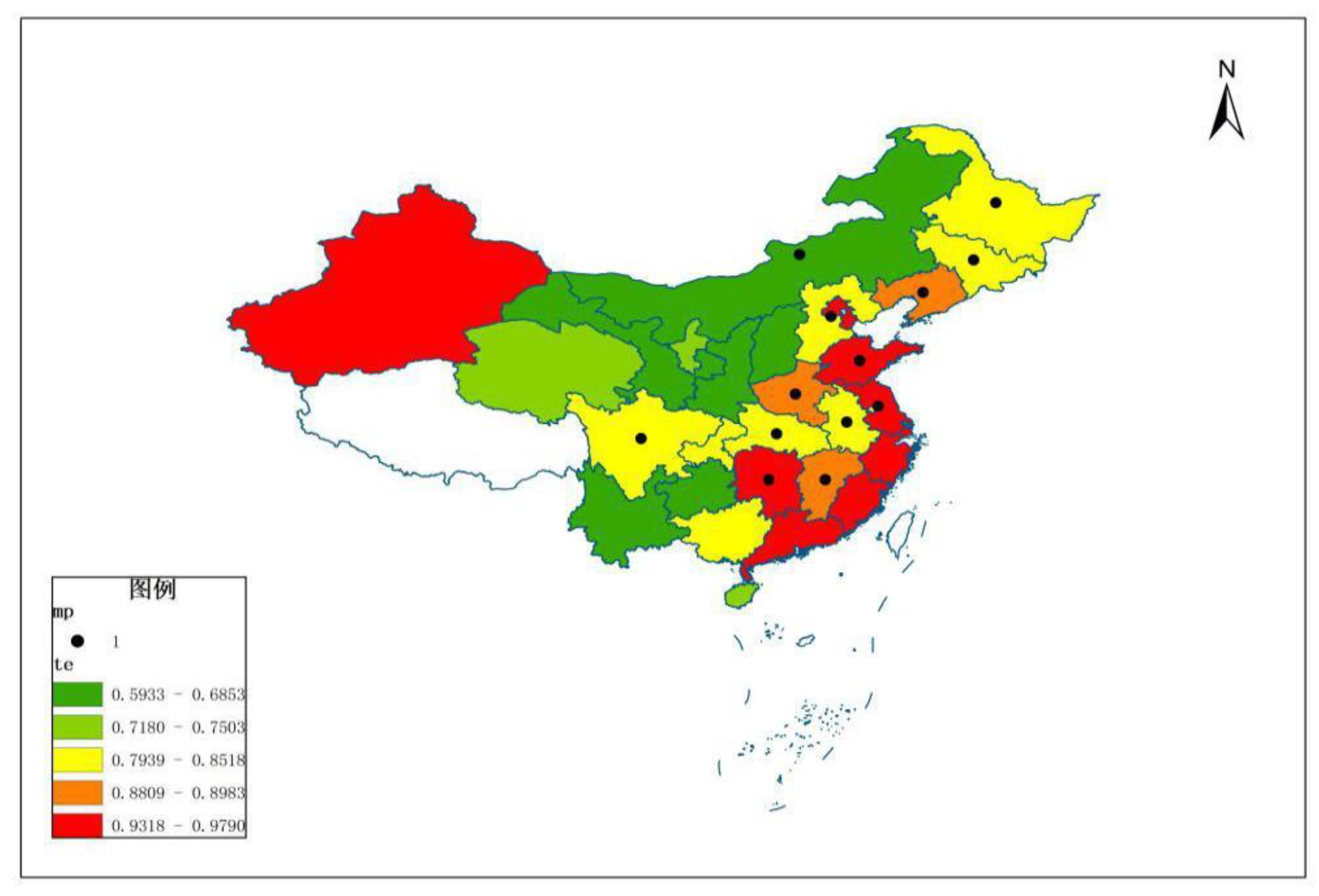

3. Results and Discussion

Determinants and Differences in Technical Efficiency

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tian, W.; Wan, G.H. Technical Efficiency and Its Determinants in China’s Grain Production. J. Product. Anal. 2000, 13, 159–174. [Google Scholar] [CrossRef]

- Yao, S.; Liu, Z.; Zhang, Z.Y. Spatial Differences of Grain Production Efficiency in China, 1987–1992. Econ. Plan. 2001, 34, 139–157. [Google Scholar] [CrossRef]

- Chen, A.Z.; Huffman, W.E.; Rozelle, S. Technical Efficiency of Chinese Grain Production: A Stochastic Production Frontier Approach. In Proceedings of the American Agricultural Economics Association Annual Meeting, Montreal, QC, Canada, 27–30 July 2003. [Google Scholar]

- Jiang, M.; Chunjie, Q.I. Measurement and Analysis of Agricultural Production Efficiency in Taiwan of China Based on Three-stage DEA Model. Asian Agric. Res. 2018, 10, 14–19, 22. [Google Scholar]

- Thiam, A.; Bravo-Ureta, B.E.; Rivas, T.E. Technical efficiency in developing country agriculture: A meta-analysis. Agric. Econ. 2001, 25, 235–243. [Google Scholar] [CrossRef]

- Zhou, D.M. Technical Progress, Technical Efficiency, and Productivity Growth of China’s Agriculture. J. Quant. Tech. Econ. 2009, 12, 70–82. [Google Scholar]

- Hervé, G.; Latruffe, L.; Chantal, L.M. Technical efficiency, technical progress and productivity change in French agriculture: Do subsidies and farms’ size matter. In Proceedings of the 96th EAAE Seminar, Tänikon, Switzerland, 10–11 January 2006. [Google Scholar]

- Ataboh, O.E.; Umeh, J.C.; Tsue, P.T. Determinants of Technical Efficiency among Rice Farmers in Kogi State, Nigeria. J. Agric. Sustain. 2014, 6, 39–49. [Google Scholar]

- Sherzod, B.; Kim, K.R.; Lee, S. Agricultural Transition and Technical Efficiency: An Empirical Analysis of Wheat-Cultivating Farms in Samarkand Region, Uzbekistan. Sustainability 2018, 10, 3232. [Google Scholar] [CrossRef]

- Nelson, C.; Neff, D.L.; Garcia, P. Technical efficiency: a comparision of production frontier methods. J. Agric. Econ. 2010, 44, 479–489. [Google Scholar]

- Odeck, J. Measuring technical efficiency and productivity growth: a comparison of SFA and DEA on Norwegian grain production data. Appl. Econ. 2007, 39, 2617–2630. [Google Scholar] [CrossRef]

- Bravo-Ureta, B.E.; Daniel, S.; Víctor, H.; Moreira, L.; José, F.; Maripani, T.A.; Rivas, T. Technical efficiency in farming: a meta-regression analysis. J. Product. Anal. 2007, 27, 57–72. [Google Scholar] [CrossRef]

- Tan, S.H.; Heerink, N.; Fu-Tian, Q.U. Impact of Land Fragmentation on Small Rice Farmers’ Technical Efficiency in Southeast China. Sci. Agric. Sin. 2011, 57, 117–123. [Google Scholar]

- Latruffe, L.; Bravo-Ureta, B.E.; Carpentier, A.; Desjeux, Y.; Moreira, V.H. Subsidies and Technical Efficiency in Agriculture: Evidence from European Dairy Farms. Am. J. Agric. Econ. 2017, 99, 783–799. [Google Scholar] [CrossRef]

- Pei, W.; Deng, X.Z.; Jiang, S.J. Global warming, grain production and its efficiency: Case study of main grain production region. Ecol. Indic. 2019, 105, 563–570. [Google Scholar]

- Pakapon, S.; Isriya, B.; Prapinwadee, S.; Itthipong, M. The impact of age structure on technical efficiency in Thai agriculture. Kasetsart J. Soc. Sci. 2018. [Google Scholar] [CrossRef]

- Aigner, D.; Lovell, C.A.K.; Schmidt, P. Formulation and estimation of stochastic frontier production function models. J. Econ. 1977, 6, 21–37. [Google Scholar] [CrossRef]

- Meeusen, W.; Julien, V.D.B. Efficiency Estimation from Cobb-Douglas Production Functions with Composed Error. Int. Econ. Rev. 1977, 18, 435. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empir. Econ. 1995, 20, 325–332. [Google Scholar] [CrossRef] [Green Version]

- Yao, S.; Liu, Z. Determinants of Grain Production and Technical Efficiency in China. J. Agric. Econ. 2010, 49, 171–184. [Google Scholar] [CrossRef]

- Coelli, T.J. A computer program for frontier production function estimation: Frontier version 2.0. Econ. Lett. 1992, 39, 29–32. [Google Scholar] [CrossRef]

- Zeng, S.Y.; Zhu, F.W.; Chen, F.; Yu, M.; Zhang, S.L.; Yang, Y.J. Assessing the Impacts of Land Consolidation on Agricultural Technical Efficiency of Producers: A Survey from Jiangsu Province, China. Sustainability 2018, 10, 2490. [Google Scholar] [CrossRef]

- Jiao, X.Q.; He, G.; Cui, Z.L.; Shen, J.B.; Zhang, F.S.; Xin, X. Agri-environment policy for grain production in china: towards sustainable intensification. China Agric. Econ. Rev. 2017, 10, 78–92. [Google Scholar] [CrossRef]

- Zeng, Y.T.; Li, B.; Lu, Y.R. Regional differences of grain production technical efficiency and its influencing factors in China: A method of stochastic frontier analysis on trans-logarithmic production function. J. Hunan Agric. Univ. (Soc. Sci.) 2018, 19, 13–21. [Google Scholar]

| Year | Area | Grain Output (10 kt) | Sown Area (000 ha) | Machinery Input (10 kW) | Fertilizer Use (10 kt) | Labor Input (10 kn) |

|---|---|---|---|---|---|---|

| 2001 | Non-main | 752.17 | 1969.13 | 609.86 | 50.39 | 295.00 |

| Main | 2490.66 | 5569.68 | 2066.84 | 152.22 | 631.75 | |

| Total | 1505.52 | 3529.36 | 1241.22 | 94.51 | 440.93 | |

| 2006 | Non-main | 754.78 | 1721.53 | 730.24 | 55.20 | 248.64 |

| Main | 2832.63 | 5809.24 | 2843.58 | 182.80 | 543.56 | |

| Total | 1655.18 | 3492.87 | 1646.02 | 110.49 | 376.44 | |

| 2011 | Non-main | 800.34 | 1841.11 | 963.46 | 64.51 | 216.75 |

| Main | 3340.12 | 6084.93 | 3820.98 | 208.25 | 484.02 | |

| Total | 1900.91 | 3680.10 | 2201.72 | 126.80 | 332.57 | |

| 2016 | Non-main | 867.47 | 1843.48 | 917.25 | 67.62 | 203.61 |

| Main | 3598.19 | 6270.18 | 3845.68 | 218.82 | 451.77 | |

| Total | 2050.78 | 3761.72 | 2186.24 | 133.14 | 311.15 | |

| 2017 | Non-main | 818.58 | 1709.89 | 913.73 | 65.75 | 204.28 |

| Main | 4010.62 | 6825.79 | 4153.60 | 226.40 | 481.58 | |

| Total | 2201.80 | 3926.78 | 2317.68 | 135.36 | 324.44 | |

| The growth rate between 2001 and 2017 | ||||||

| 2001–2017 | 0 | 8.83 | −13.16 | 49.83 | 30.49 | −30.75 |

| 1 | 61.03 | 22.55 | 100.96 | 48.73 | −23.77 | |

| Total | 46.25 | 11.26 | 86.73 | 43.22 | −26.42 | |

| Main Grain Production Area | Non-main Grain Production Area | ||||

|---|---|---|---|---|---|

| Province | Abbreviation | Province | Abbreviation | Province | Abbreviation |

| Hebei | HEB | Beijing | BJ | Chongqin | CQ |

| Inner Mongolia | IM | Tianjing | TJ | Guizhou | GZ |

| Liaoning | LN | Shanxi | SX1 | Yunnan | YN |

| Jilin | JL | Shanghai | SH | Shaanxi | SX2 |

| Heilongjiang | HLJ | Zhejiang | ZJ | Gansu | GS |

| Jiangsu | JS | Fujian | FJ | Qinghai | QH |

| Anhui | AH | Guangdong | GD | Ningxia | NX |

| Jiangxi | JX | Guangxi | GX | Xinjiang | XJ |

| Shandong | SD | Hainan | HN | ||

| Henan | HEN | ||||

| Hubei | HUB | ||||

| Hunan | HUN | ||||

| Sichuan | SC | ||||

| Variables | Estimated Coefficients | Standard-Error | T-Values |

|---|---|---|---|

| Production Function | |||

| Constant | −6.204 *** | 0.527 | −11.765 |

| Ln(A) | 3.124 *** | 0.253 | 12.370 |

| Ln(M) | 1.191 *** | 0.190 | 6.256 |

| Ln(F) | −4.056 *** | 0.319 | −12.724 |

| Ln(L) | 0.964 *** | 0.230 | 4.200 |

| T | 0.009 *** | 0.001 | 6.304 |

| Ln(A) * Ln(M) | −0.559 *** | 0.070 | −8.018 |

| Ln(A) * Ln(F) | 1.145 *** | 0.087 | 13.221 |

| Ln(A) * Ln(L) | −0.585 *** | 0.089 | −6.566 |

| Ln(M) * Ln(F) | 0.147 *** | 0.052 | 2.823 |

| Ln(M) * Ln(L) | 0.338 *** | 0.046 | 7.431 |

| Ln(F) * Ln(L) | −0.373 *** | 0.050 | −7.434 |

| 0.5 * Ln(A) * Ln(A) | −0.028 | 0.110 | −0.257 |

| 0.5 * Ln(M) * Ln(M) | 0.080 | 0.057 | 1.411 |

| 0.5 * Ln(F) * Ln(F) | −0.860 *** | 0.086 | −9.945 |

| 0.5 * Ln(L) * Ln(L) | 0.543 *** | 0.084 | 6.477 |

| MP | 0.201 *** | 0.021 | 9.594 |

| sigma-squared | 0.011 *** | 0.001 | 10.369 |

| gamma | 0.747 *** | 0.060 | 12.517 |

| Inefficiency Function | |||

| Constant | 0.126 * | 0.071 | 1.777 |

| Per_AP | −0.093 *** | 0.020 | −4.745 |

| Out_L | 0.512 *** | 0.110 | 4.657 |

| AFE | 0.514 * | 0.264 | 1.946 |

| Per_GDP | 0.015 ** | 0.006 | 2.543 |

| IRR | −0.395 *** | 0.064 | −6.204 |

| DI | 0.625 *** | 0.078 | 7.983 |

| MCI | −0.031 | 0.032 | −0.941 |

| Diagnosis Statistics | Null Hypothesis | LR | Degree of Freedom | χ-Value | Decision |

|---|---|---|---|---|---|

| Testing the applicability of SFA | H0: γ = 0 | 397.25 * | 9 | 16.919 | Reject |

| Testing translog vs. C-D | H0: βaa = βmm = βff = βll = βam = βaf = βal = βmf = βml = βfl = 0 | 262.34 * | 9 | 16.919 | Reject |

| Testing technical change | H0: βt = 0 | 140.80 * | 9 | 16.919 | Reject |

| Total | Land | Machinery | Fertilizer | Labor |

|---|---|---|---|---|

| 2001 | 0.627 | −0.125 | 0.194 | 0.169 |

| 2002 | 0.639 | −0.122 | 0.182 | 0.170 |

| 2003 | 0.700 | −0.138 | 0.182 | 0.138 |

| 2004 | 0.749 | −0.135 | 0.153 | 0.119 |

| 2005 | 0.752 | −0.138 | 0.161 | 0.114 |

| 2006 | 0.733 | −0.095 | 0.087 | 0.162 |

| 2007 | 0.780 | −0.111 | 0.098 | 0.129 |

| 2008 | 0.804 | −0.131 | 0.126 | 0.101 |

| 2009 | 0.779 | −0.122 | 0.123 | 0.119 |

| 2010 | 0.761 | −0.113 | 0.116 | 0.135 |

| 2011 | 0.781 | −0.123 | 0.128 | 0.118 |

| 2012 | 0.778 | −0.117 | 0.118 | 0.126 |

| 2013 | 0.795 | −0.118 | 0.111 | 0.118 |

| 2014 | 0.790 | −0.116 | 0.110 | 0.124 |

| 2015 | 0.776 | −0.114 | 0.115 | 0.133 |

| 2016 | 0.843 | −0.131 | 0.111 | 0.086 |

| 2017 | 0.800 | −0.109 | 0.088 | 0.128 |

| average | 0.758 | −0.121 | 0.130 | 0.129 |

| Year | Non-Main Grain-Producing Area | Main Grain-Producing Area | Nation | Gap of Technical Efficiency |

|---|---|---|---|---|

| 2001 | 0.746 | 0.769 | 0.756 | 0.023 |

| 2002 | 0.753 | 0.796 | 0.771 | 0.043 |

| 2003 | 0.772 | 0.766 | 0.770 | −0.006 |

| 2004 | 0.791 | 0.828 | 0.807 | 0.037 |

| 2005 | 0.786 | 0.838 | 0.808 | 0.053 |

| 2006 | 0.799 | 0.838 | 0.816 | 0.039 |

| 2007 | 0.801 | 0.829 | 0.813 | 0.028 |

| 2008 | 0.814 | 0.872 | 0.839 | 0.058 |

| 2009 | 0.816 | 0.836 | 0.824 | 0.020 |

| 2010 | 0.809 | 0.860 | 0.831 | 0.052 |

| 2011 | 0.827 | 0.900 | 0.858 | 0.073 |

| 2012 | 0.844 | 0.911 | 0.873 | 0.067 |

| 2013 | 0.843 | 0.914 | 0.874 | 0.071 |

| 2014 | 0.847 | 0.901 | 0.870 | 0.053 |

| 2015 | 0.852 | 0.919 | 0.881 | 0.067 |

| 2016 | 0.852 | 0.902 | 0.874 | 0.051 |

| 2017 | 0.858 | 0.916 | 0.883 | 0.058 |

| Average | 0.812 | 0.858 | 0.832 | 0.046 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Zhao, Y. Determinants and Differences of Grain Production Efficiency Between Main and Non-Main Producing Area in China. Sustainability 2019, 11, 5225. https://doi.org/10.3390/su11195225

Chen F, Zhao Y. Determinants and Differences of Grain Production Efficiency Between Main and Non-Main Producing Area in China. Sustainability. 2019; 11(19):5225. https://doi.org/10.3390/su11195225

Chicago/Turabian StyleChen, Furong, and Yifu Zhao. 2019. "Determinants and Differences of Grain Production Efficiency Between Main and Non-Main Producing Area in China" Sustainability 11, no. 19: 5225. https://doi.org/10.3390/su11195225