Social Hotspot Analysis and Trade Policy Implications of the Use of Bioelectrochemical Systems for Resource Recovery from Wastewater

Abstract

:1. Introduction

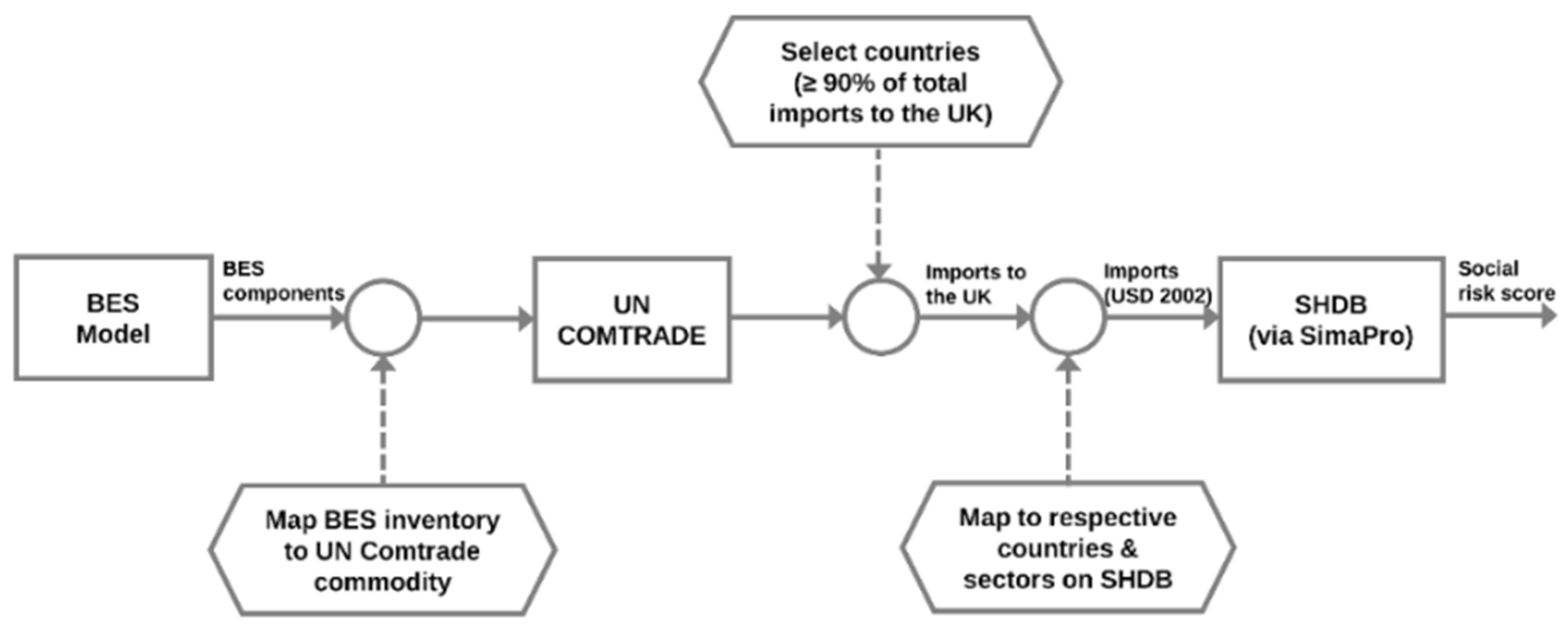

2. Materials and Methods

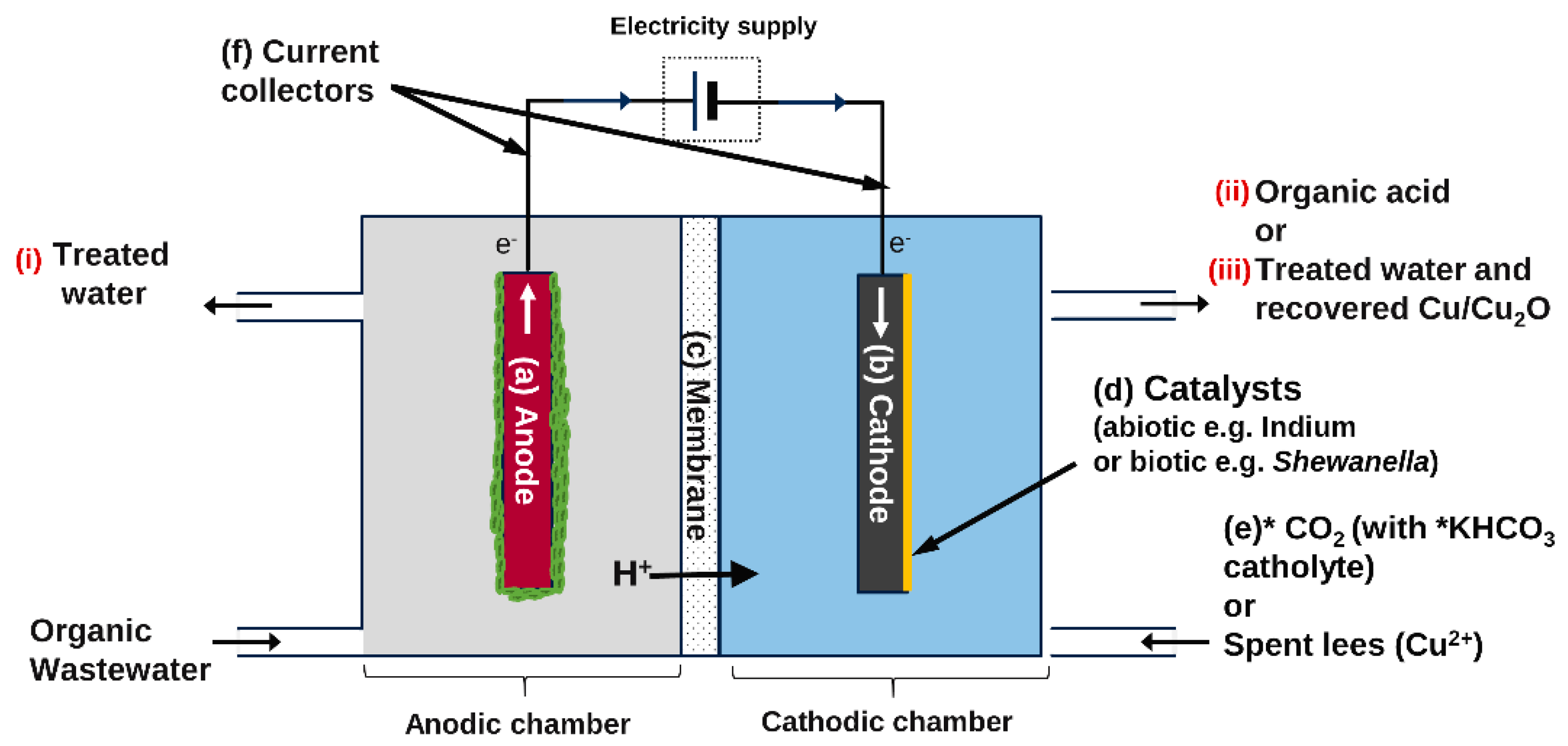

2.1. Goal and Scope of Study

2.2. Inventory Analysis

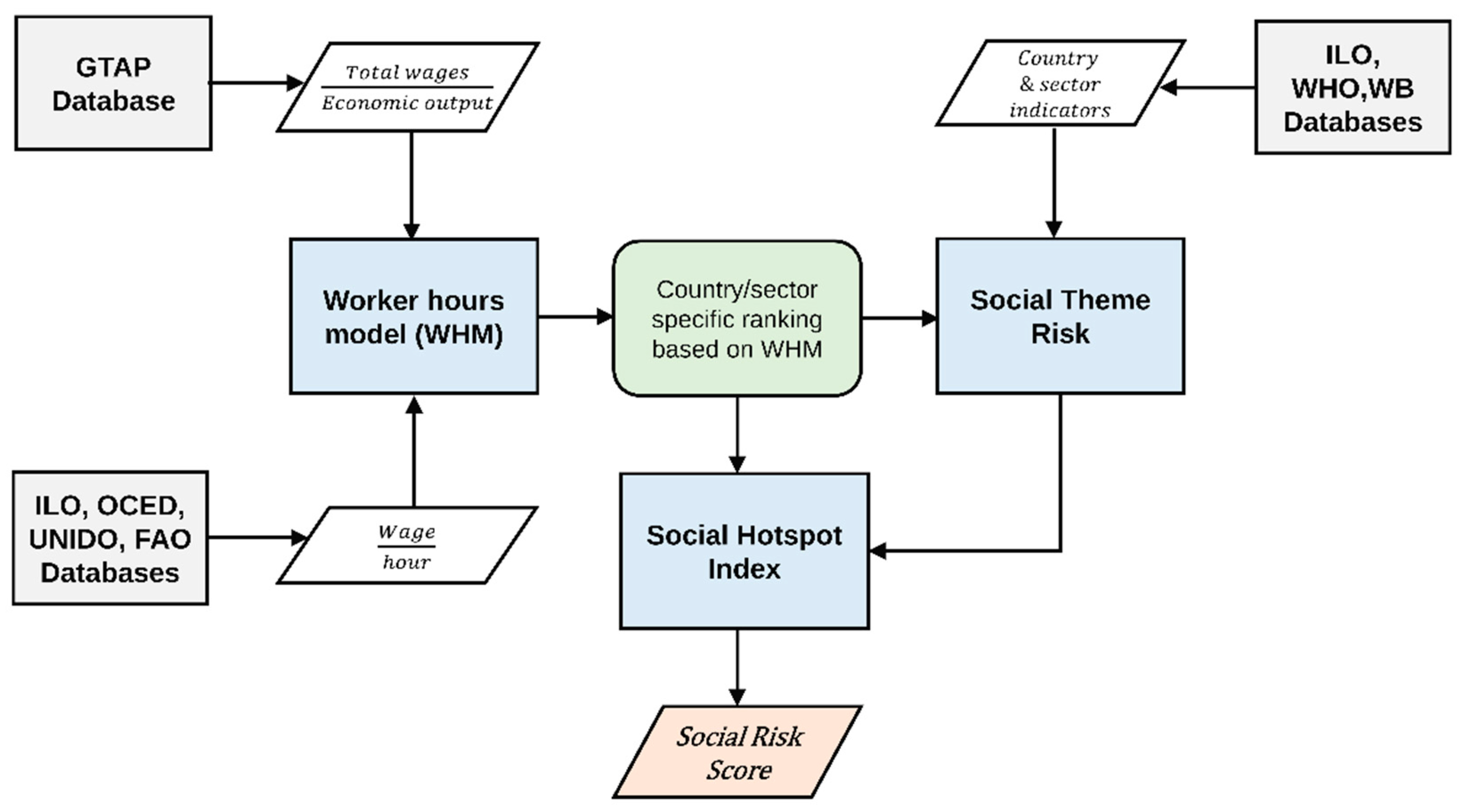

2.3. Impact Assessment

3. Results and Discussion

3.1. Trade Value of BES Components

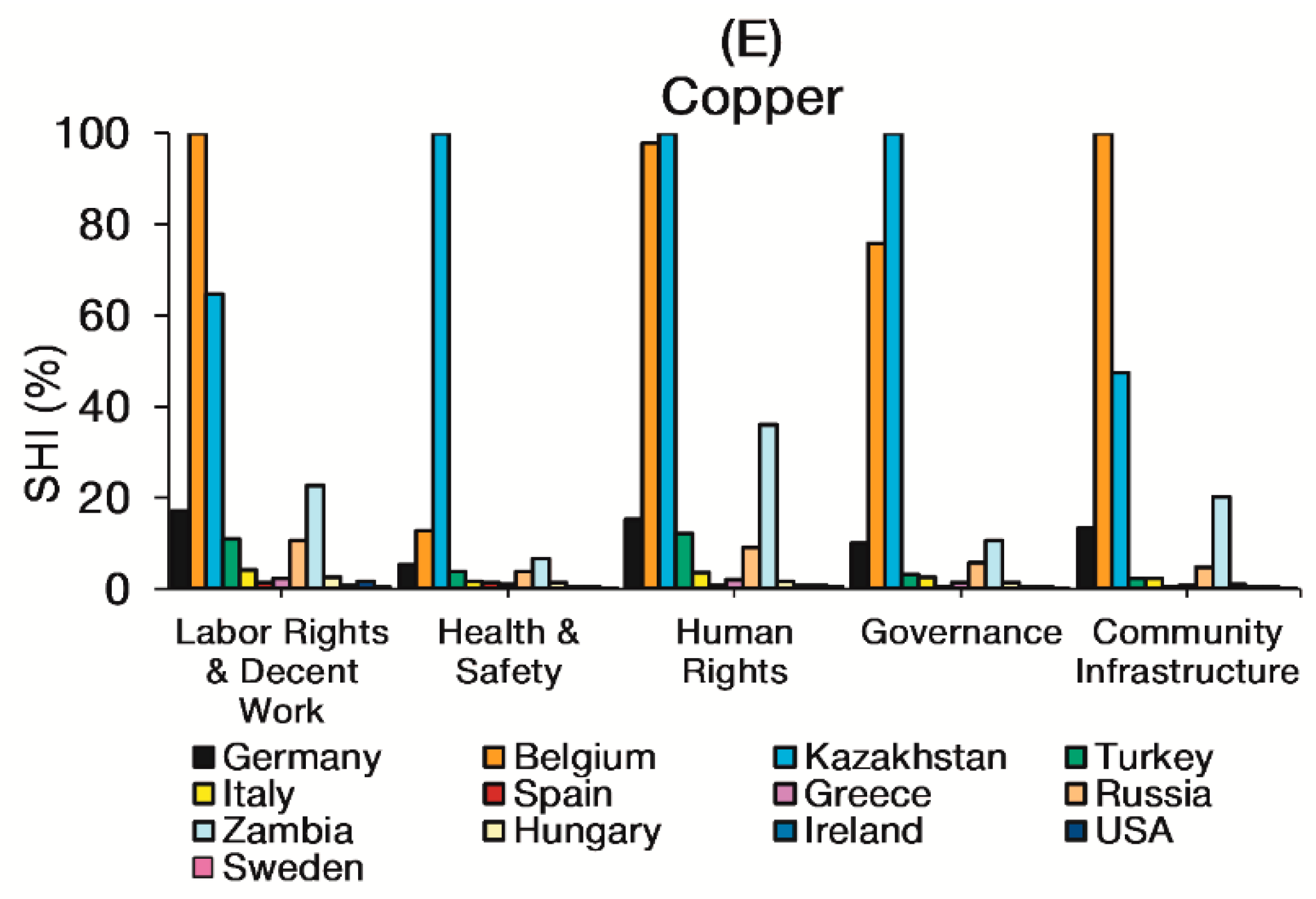

3.2. Social Hotspot Analysis of BES Components

3.3. Limitations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Table of Acronyms and Abbreviations

| BES | Bioelectrochemical System |

| EU | European Union |

| FAO | Food and Agriculture Organisation |

| GTAP | Global Trade Analysis Project |

| ILO | International Labour Organisation |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

| LCSA | Life Cycle Sustainability Assessment |

| OECD | Organisation for Economic Co-operation and Development |

| PTFE | Polytetrafluoroethylene |

| SETAC | Society of Environmental Toxicology and Chemistry |

| SHDB | Social Hotspot Database |

| SHI | Social Hotspot Index |

| S-LCA | Social Life Cycle Assessment |

| UN COMTRADE | United Nations Commodity Trade Statistics Database |

| UNEP | United Nations Environment Programme |

| USD | United States Dollar |

| WB | World Bank |

| WHO | World Health Organisation |

References

- UNESCO. New Report Highlights Crucial Role of Water in Development | United Nations Educational, Scientific and Cultural Organization. Available online: http://www.unesco.org/new/en/media-services/single-view/news/new_report_highlights_crucial_role_of_water_in_development/ (accessed on 22 August 2018).

- UNDESA. World Population Prospects: The 2015 Revision, Key Findings and Advance Tables; UNDESA: New York, NY, USA, 2015. [Google Scholar]

- The World Bank Annual Freshwater Withdrawals, Total (Billion Cubic Meters) | Data. Available online: http://data.worldbank.org/indicator/ER.H2O.FWTL.K3 (accessed on 17 September 2016).

- Gude, V.G. Microbial fuel cells for wastewater treatment and energy generation. In Microbial Electrochemical and Fuel Cells-Fundamentals and Applications; Yu, E.H., Scott, K., Eds.; Woodhead Publishing: Boston, MA, USA, 2016; pp. 247–285. [Google Scholar]

- McCarty, P.L.; Bae, J.; Kim, J. Domestic wastewater treatment as a net energy producer—Can this be achieved? Environ. Sci. Technol. 2011, 45, 7100–7106. [Google Scholar] [CrossRef] [PubMed]

- Puyol, D.; Batstone, D.J.; Hülsen, T.; Astals, S.; Peces, M.; Krömer, J.O. Resource recovery from wastewater by biological technologies: Opportunities, challenges, and prospects. Front. Microbiol. 2017, 7, 2106. [Google Scholar] [CrossRef] [PubMed]

- Velenturf, A.P.M.; Purnell, P. Resource recovery from waste: Restoring the balance between resource scarcity and waste overload. Sustainability 2017, 9, 1603. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Lloyd, J.R.; Scott, K.; Premier, G.C.; Yu, E.H.; Curtis, T.; Head, I.M. A critical review of integration analysis of microbial electrosynthesis (MES) systems with waste biorefineries for the production of biofuel and chemical from reuse of CO2. Renew. Sustain. Energy Rev. 2016, 56, 116–132. [Google Scholar] [CrossRef]

- Rabaey, K.; Angenent, L.; Schroder, U.; Keller, J. Bioelectrochemical Systems: From Extracellular Electron Transfer to Biotechnological Application; International Water Association: London, UK, 2009. [Google Scholar]

- Pant, D.; Singh, A.; Van Bogaert, G.; Irving Olsen, S.; Singh Nigam, P.; Diels, L.; Vanbroekhoven, K. Bioelectrochemical systems (BES) for sustainable energy production and product recovery from organic wastes and industrial wastewaters. RSC Adv. 2012, 2, 1248–1263. [Google Scholar] [CrossRef]

- Jain, A.; He, Z. “NEW” resource recovery from wastewater using bioelectrochemical systems: Moving forward with functions. Front. Environ. Sci. Eng. 2018, 12, 1. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our Common Future: Report of the World Commission on Environment and Development. United Nations Comm. 1987, 4, 300. [Google Scholar]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–94. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Ng, K.S.; Hernandez, E.M. Biorefineries and Chemical Processes: Design, Integration and Sustainability Analysis; Wiley: Chichester, UK, 2014. [Google Scholar]

- Clift, R.; Sim, S.; King, H.; Chenoweth, J.L.; Christie, I.; Clavreul, J.; Mueller, C.; Posthuma, L.; Boulay, A.M.; Chaplin-Kramer, R.; et al. The challenges of applying planetary boundaries as a basis for strategic decision-making in companies with global supply chains. Sustainability 2017, 9, 279. [Google Scholar] [CrossRef]

- Valdivia, S.; Ugaya, C.; Sonnemann, G.; Hildenbrand, J. (Eds.) Towards a Life Cycle Sustainability Assessment: Making Informed Choices on Products; UNEP/SETAC Life Cycle Initiative: Paris, France, 2011. [Google Scholar]

- Benoît, C.; Norris, G.A.; Valdivia, S.; Ciroth, A.; Moberg, A.; Bos, U.; Prakash, S.; Ugaya, C.; Beck, T. The guidelines for social life cycle assessment of products: Just in time! Int. J. Life Cycle Assess. 2010, 15, 156–163. [Google Scholar] [CrossRef]

- Foley, J.; Rozendal, R.A.; Hertle, C.K.; Lant, P.A.; Rabaey, K. Life cycle assessment of high-rate anaerobic treatment, microbial fuel cells, and microbial electrolysis cells. Environ. Sci. Technol. 2010, 44, 3629–3637. [Google Scholar] [CrossRef] [PubMed]

- Christodoulou, X.; Velasquez-Orta, S.B. Microbial electrosynthesis and anaerobic fermentation: An economic evaluation for acetic acid production from CO2 and CO. Environ. Sci. Technol. 2016, 50, 11234–11242. [Google Scholar] [CrossRef] [PubMed]

- Pant, D.; Singh, A.; Van Bogaert, G.; Gallego, Y.A.; Diels, L.; Vanbroekhoven, K. An introduction to the life cycle assessment (LCA) of bioelectrochemical systems (BES) for sustainable energy and product generation: Relevance and key aspects. Renew. Sustain. Energy Rev. 2011, 15, 1305–1313. [Google Scholar] [CrossRef]

- Shemfe, M.; Gadkari, S.; Yu, E.; Rasul, S.; Scott, K.; Head, I.M.; Gu, S.; Sadhukhan, J. Life cycle, techno-economic and dynamic simulation assessment of bioelectrochemical systems: A case of formic acid synthesis. Bioresour. Technol. 2018, 255, 39–49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benoît, C.; Mazijn, B. (Eds.) Guidelines for Social Life Cycle Assessment of Products. Available online: http://www.unep.fr/shared/publications/pdf/DTIx1164xPA-guidelines_sLCA.pdf (accessed on 8 July 2018).

- Ng, K.S.; Head, I.; Premier, G.C.; Scott, K.; Yu, E.; Lloyd, J.; Sadhukhan, J. A multilevel sustainability analysis of zinc recovery from wastes. Resour. Conserv. Recycl. 2016, 113, 88–105. [Google Scholar] [CrossRef]

- Shemfe, M.; Sadhukhan, J.; Ng, K.S. Bioelectrochemical Systems for biofuel (electricity, hydrogen, and methane) and valuable chemical production. In Green Chemistry for Sustainable Biofuel Production; Gnaneswar, V., Ed.; Apple Academic Press: New York, NY, USA, 2018. [Google Scholar]

- Norris, C.B.; Norris, C.B.; Norris, G.A. Chapter 8: The Social Hotspots Database Context of the SHDB. Sustain. Pract. Guid. Soc. Anal. Assess. 2015, 200, 52–73. [Google Scholar]

- Benoît Norris, C. Data for social LCA. Int. J. Life Cycle Assess. 2014, 19, 261–265. [Google Scholar] [CrossRef]

- Benoit-norris, C.; Cavan, D.A.; Norris, G. Identifying Social Impacts in Product Supply Chains: Overview and Application of the Social Hotspot Database. Sustainability 2012, 4, 1946–1965. [Google Scholar] [CrossRef]

- Duchin, F.; Levine, S.H. The rectangular sector-by-technology model: Not every economy produces every product and some products may rely on several technologies simultaneously. J. Econ. Struct. 2012, 1, 3. [Google Scholar] [CrossRef] [Green Version]

- Duchin, F.; Levine, S.H. Choosing among alternative technologies: Conditions for assuring the feasibility of an input–output database or scenario. Econ. Syst. Res. 2017, 29, 541–556. [Google Scholar] [CrossRef]

| Social Impact Categories | Social Themes | Stakeholder |

|---|---|---|

| Labour Rights and Decent Work | Child labour | Workers |

| Forced labour | ||

| Excessive working time | ||

| Poverty | ||

| Wage assessment | ||

| Migrant labour | ||

| Collective bargaining | ||

| Inadequate social benefits | ||

| Health and Safety | Injuries and fatalities | Workers and society |

| Toxics and hazards | ||

| Human Rights | Indigenous rights | Society and local community |

| Gender equity | ||

| High conflict | ||

| Governance | Legal system | Society and value chain actors |

| Corruption | ||

| Community Infrastructure | Drinking water | Society and local community |

| Improved sanitation | ||

| Hospital beds |

| Weighting Factors | Risk Levels |

|---|---|

| 10 | Very high |

| 5 | High |

| 1 | Medium |

| 0.1 | Low |

| Inventory | Country | Region | Trade Value | SHDB Sector |

|---|---|---|---|---|

| Polytetrafluoroethylene (PTFE) | Germany | Europe | 8160 | Chemicals, rubber and plastic products |

| Italy | Europe | 2992 | ||

| Belgium | Europe | 2863 | ||

| USA | N. America | 2723 | ||

| India | Asia | 2023 | ||

| Polyacrylonitrile | Spain | Europe | 818 | Chemicals, rubber and plastic products |

| Belgium | Europe | 729 | ||

| Rep. of Korea | Asia | 654 | ||

| Italy | Europe | 484 | ||

| USA | N. America | 155 | ||

| Potassium bicarbonate | Germany | Europe | 4329 | Chemicals, rubber and plastic products |

| Rep. of Korea | Asia | 728 | ||

| USA | N. America | 605 | ||

| Italy | Europe | 391 | ||

| Ireland | Europe | 227 | ||

| Indium | Germany | Europe | 11,456 | Metals nec. |

| USA | N. America | 10,918 | ||

| Belgium | Europe | 1532 | ||

| Estonia | Europe | 847 | ||

| Canada | N. America | 681 | ||

| Copper | Germany | Europe | 580,054 | Metals nec. |

| Belgium | Europe | 347,562 | ||

| Kazakhstan | Asia | 279,130 | ||

| Turkey | Europe | 90,356 | ||

| Italy | Europe | 89,889 | ||

| Spain | Europe | 85,112 | ||

| Greece | Europe | 68,710 | ||

| Russia * | Europe | 66,159 | ||

| Zambia | Africa | 60,966 | ||

| Hungary | Hungary | 47,512 | ||

| Ireland | Europe | 44,317 | ||

| USA | America | 41,624 | ||

| Sweden | Europe | 39,942 |

| Countries | Labour Rights and Decent Work | Health and Safety | Human Rights | Governance | Community Infrastructure | |

|---|---|---|---|---|---|---|

| PTFE | Germany | 2,577,174 | 2,119,651 | 584,900 | 561,975 | 703,444 |

| Italy | 1,501,217 | 1,354,188 | 379,546 | 544,078 | 215,612 | |

| Belgium | 3,325,478 | 1,507,194 | 806,299 | 1,046,476 | 876,013 | |

| USA | 2,962,025 | 701,936 | 370,338 | 470,814 | 238,298 | |

| India | 73,356,715 | 35,550,940 | 27,155,486 | 20,484,899 | 8,263,333 | |

| Polyacrylonitrile | Spain | 591,383 | 544,917 | 97,013 | 142,918 | 71,735 |

| Belgium | 1,151,553 | 521,914 | 279,207 | 362,376 | 303,347 | |

| Korea | 1,332,786 | 608,275 | 276,474 | 342,838 | 257,752 | |

| Italy | 330,649 | 298,265 | 83,596 | 119,835 | 47,489 | |

| USA | 229,958 | 54,495 | 28,751 | 36,552 | 18,500 | |

| KHCO3 | Germany | 1,860,387 | 1,530,115 | 422,223 | 405,673 | 507,796 |

| Korea | 1,485,032 | 677,760 | 308,056 | 382,001 | 287,195 | |

| USA | 895,877 | 212,304 | 112,010 | 142,400 | 72,074 | |

| Italy | 266,690 | 240,570 | 67,426 | 96,655 | 38,303 | |

| Ireland | 208,743 | 109,119 | 49,415 | 32,086 | 28,300 | |

| Indium | Germany | 12,410,936 | 5,482,484 | 2,974,947 | 4,726,056 | 4,700,009 |

| USA | 14,726,434 | 3,516,719 | 1,599,988 | 1,821,052 | 982,496 | |

| Belgium | 16,339,111 | 2,933,776 | 4,237,613 | 8,003,899 | 7,792,364 | |

| Estonia | 2,002,089 | 1,106,674 | 349,829 | 570,115 | 400,539 | |

| Canada | 511,532 | 263,102 | 93,228 | 106,059 | 59,416 | |

| Copper | Germany | 628,404,804 | 277,595,465 | 150,630,942 | 239,295,108 | 237,976,295 |

| Belgium | 3,705,652,779 | 665,370,095 | 961,075,645 | 1,815,256,117 | 1,767,280,628 | |

| Kazakhstan | 2,404,645,460 | 5,179,686,690 | 981,873,381 | 2,388,544,991 | 841,536,953 | |

| Turkey | 399,437,194 | 204,898,945 | 118,076,683 | 76,136,845 | 37,831,224 | |

| Italy | 151,446,222 | 90,742,861 | 35,797,251 | 64,360,424 | 40,504,452 | |

| Spain | 52,804,710 | 65,842,137 | 6,664,583 | 11,133,944 | 5,445,993 | |

| Greece | 87,859,737 | 51,152,200 | 20,149,236 | 34,057,486 | 12,301,866 | |

| Russia | 392,250,069 | 189,972,359 | 88,226,634 | 135,381,628 | 82,321,925 | |

| Zambia | 839,948,514 | 346,915,625 | 355,717,051 | 253,052,828 | 355,099,991 | |

| Hungary | 93,568,774 | 68,144,917 | 15,269,800 | 35,691,960 | 20,276,281 | |

| Ireland | 32,321,689 | 18,454,612 | 7,416,720 | 6,915,875 | 6,301,878 | |

| USA | 56,141,443 | 13,406,755 | 6,099,618 | 6,942,381 | 3,745,559 | |

| Sweden | 18,594,240 | 16,602,542 | 4,164,349 | 5,043,023 | 3,944,785 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shemfe, M.B.; Gadkari, S.; Sadhukhan, J. Social Hotspot Analysis and Trade Policy Implications of the Use of Bioelectrochemical Systems for Resource Recovery from Wastewater. Sustainability 2018, 10, 3193. https://doi.org/10.3390/su10093193

Shemfe MB, Gadkari S, Sadhukhan J. Social Hotspot Analysis and Trade Policy Implications of the Use of Bioelectrochemical Systems for Resource Recovery from Wastewater. Sustainability. 2018; 10(9):3193. https://doi.org/10.3390/su10093193

Chicago/Turabian StyleShemfe, Mobolaji B., Siddharth Gadkari, and Jhuma Sadhukhan. 2018. "Social Hotspot Analysis and Trade Policy Implications of the Use of Bioelectrochemical Systems for Resource Recovery from Wastewater" Sustainability 10, no. 9: 3193. https://doi.org/10.3390/su10093193