An Exploration of Circular Economy Practices and Performance Among Romanian Producers

Abstract

:1. Introduction

2. Literature Review on the Circular Economy

2.1. General Considerations regarding the Circular Economy

2.2. The Macro-Economic Perspective of the Circular Economy

2.3. The Micro-Economic Perspective of the Circular Economy

3. Research Methodology

3.1. Research Variables and Instruments

3.2. Data Collection

4. Results

4.1. The Results of Statistical Analysis

4.2. Producers Clustering according to GSCC Practices Preferences

4.3. Hypotheses Testing

5. Conclusions and Further Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lyle, J.T. Regenerative Design for Sustainable Development; Wiley: New York, NY, USA, 1994; ISBN 978-0-471-17843-9. [Google Scholar]

- Du Plessis, C. Towards a regenerative paradigm for the built environment. Build. Res. Inf. 2012, 40, 7–22. [Google Scholar] [CrossRef] [Green Version]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, L.; Domingues, J.; Pereira, M.; Martins, F.; Zimon, D.; Fonseca, L.M.; Domingues, J.P.; Pereira, M.T.; Martins, F.F.; Zimon, D. Assessment of Circular Economy within Portuguese Organizations. Sustainability 2018, 10, 2521. [Google Scholar] [CrossRef]

- European Commission. Circular Economy—Implementation of the Circular Economy Action Plan; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. European Commission—Press Release—Questions and Answers on the Commission Communication “towards a Circular Economy” and the Waste Targets Review; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Van der Elst, K.; Williams, A. Industry 4.0: The New Production Paradigm and Its Implications for EU Policy; The Global Foresight Group: Geneva, Switzerland, 2017. [Google Scholar]

- Kiørboe, N.; Sramkova, H.; Krarup, M. Moving Towards a Circular Economy: Successful Nordic Business Models; Nordic Council of Ministers: Copenhagen, Denmark, 2015. [Google Scholar]

- Green Report. Este România Pregătită Pentru Economia Circulară? (Is Romania Ready for the Circular Economy?); Green Report: Bucharest, Romania, 2016. [Google Scholar]

- Pelau, C.; Pop, N.A. Implications for the energy policy derived from the relation between the cultural dimensions of Hofstede’s model and the consumption of renewable energies. Energy Policy 2018, 118, 160–168. [Google Scholar] [CrossRef]

- Dodescu, A. Experiences and tendencies of Decentralization at Regional Level in the European Union. Ann. Fac. Econ. 2011, 1, 47–61. [Google Scholar]

- Dodescu, A.; Chirilă, L.F. Regional Innovation Governance in the Context of European Integration and Multi-level Governance Challenges. A Case Study of North-West Region of Romania. Procedia Econ. Financ. 2012, 3, 1177–1184. [Google Scholar] [CrossRef]

- Dodescu, A.; Chirilă, L.F. Multi-level governance and strategic planning for regional development policy. The Case of Romania in the context of European integration. In Proceedings of the Regional Studies Association Global Conference, Beijing, China, 24–27 June 2012; pp. 3–18. [Google Scholar]

- Dodescu, A.; Chirilă, L.F. Industrial Parks in Romania: From Success Stories toEmerging Challenges. Int. J. e-Educ. e-Bus. e-Manag. e-Learn. 2012, 2, 331–335. [Google Scholar] [CrossRef]

- Botezat, E. Creative Entrepreneurial Culture: An Empirical Study. Int. J. e-Educ. e-Bus. e-Manag. e-Learn. 2012, 2, 327–330. [Google Scholar] [CrossRef]

- Botezat, E.; Tomescu, A.-M. Organizational Learning, Quality and Innovation-Evidence from Manufacturing Industry. In Annals of the University of Oradea; Economic Science; University of Oradea: Oradea, Romania, 2017; Volume XXVI, pp. 767–772. [Google Scholar]

- Doranova, A.; Roman, L.; Bahn-Walkowiak, B.; Wilts, H.; O’Brien, M. Policies and Practices for Eco-Innovation Up-Take and Circular Economy Transition; European Commission & Eco-Innovation Observatory (EC&EIO): Brussels, Belgium, 2016; Available online: https://ec.europa.eu/environment/ecoap/sites/ecoap_stayconnected/files/eio_2016_report.pdf (accessed on 22 July 2018).

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; p. 20. [Google Scholar]

- Kraaijenhagen, C.; van Oppen, C.; Bocken, N. Circular Business: Collaborate and Circulate; Circular Collaboration: Amersfoort/Amsterdam, The Netherlands, 2016; ISBN 978-90-824902-0-6. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Het Groene Brein (The Green Mind) Foundation. Circular Economy; Het Groene Brein Foundation: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Lahti, T.; Wincent, J.; Parida, V. A Definition and Theoretical Review of the Circular Economy, Value Creation, and Sustainable Business Models: Where Are We Now and Where Should Research Move in the Future? Sustainability 2018, 10, 2799. [Google Scholar] [CrossRef]

- Lakatos, E.S.; Cioca, L.-I.; Dan, V.; Ciomos, A.O.; Crisan, O.A.; Barsan, G. Studies and Investigation about the Attitude towards Sustainable Production, Consumption and Waste Generation in Line with Circular Economy in Romania. Sustainability 2018, 10, 865. [Google Scholar] [CrossRef]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.H.; Ometto, A.R. From Linear to Circular Economy: PSS Conducting the Transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Ritzén, S.; Sandström, G.Ö. Barriers to the Circular Economy—Integration of Perspectives and Domains. Procedia CIRP 2017, 64, 7–12. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Núñez-Cacho, P.; Molina-Moreno, V.; Corpas-Iglesias, F.; Cortés-García, F. Family Businesses Transitioning to a Circular Economy Model: The Case of “Mercadona”. Sustainability 2018, 10, 538. [Google Scholar] [CrossRef]

- Domingues, A.R.; Lozano, R.; Ceulemans, K.; Ramos, T.B. Sustainability reporting in public sector organisations: Exploring the relation between the reporting process and organisational change management for sustainability. J. Environ. Manag. 2017, 192, 292–301. [Google Scholar] [CrossRef] [PubMed]

- European Commission European Circular Economy Stakeholder Platform|A Joint Initiative by the European Commission and the European Economic and Social Committee. Available online: https://circulareconomy.europa.eu/platform/ (accessed on 24 June 2018).

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the implementation of the Circular Economy Action Plan; European Commission: Brussels, Belgium, 2017; pp. 1–14. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Closing the loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- European Environment Agency (EEA). Circular Economy in Europe—Developing the Knowledge Base; European Environment Agency (EEA): Copenhaga, Denmark, 2016; pp. 1–42. [Google Scholar]

- European Environment Agency. More from Less—Material Resource Efficiency in EUROPE: 2015 Overview of Policies, Instruments and Targets in 32 Countries; European Environment Agency: Copenhaga, Denmark, 2016; pp. 1–156. [Google Scholar]

- Sarkis, J.; Zhu, Q.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers. J. Environ. Manag. 2007, 85, 179–189. [Google Scholar] [CrossRef] [PubMed]

- Pauliuk, S.; Wang, T.; Müller, D.B. Moving Toward the Circular Economy: The Role of Stocks in the Chinese Steel Cycle. Environ. Sci. Technol. 2012, 46, 148–154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Determining and Applying Sustainable Supplier Key Performance Indicators. Supply Chain Manag. 2014, 19, 275–291. [Google Scholar] [CrossRef]

- Liu, S.; Chang, Y.-T. Manufacturers’ Closed-Loop Orientation for Green Supply Chain Management. Sustainability 2017, 9, 222. [Google Scholar] [CrossRef]

- Geng, Y.; Zhu, Q.; Doberstein, B.; Fujita, T. Implementing China’s circular economy concept at the regional level: A review of progress in Dalian, China. Waste Manag. 2009, 29, 996–1002. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.-M.; Wen, Z.-G. Review and challenges of policies of environmental protection and sustainable development in China. J. Environ. Manag. 2008, 88, 1249–1261. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Geng, Y.; Lai, K. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Sarkis, J.; Wu, Z. Creating integrated business and environmental value within the context of China’s circular economy and ecological modernization. J. Clean. Prod. 2010, 18, 1494–1501. [Google Scholar] [CrossRef]

- Ninlawan, C.; Seksan, P.; Tossapol, K.; Pilada, W. The Implementation of Green Supply Chain Management Practices in Electronics Industry. In Proceedings of the International MultiConference of Engineers and Computer Scientists, Hong Kong, China, 17–19 March 2010; Volume III, ISBN 978-988-18210-5-8. [Google Scholar]

- Tippayawong, K.Y.; Tiwaratreewit, T.; Sopadang, A. Positive Influence of Green Supply Chain Operations on Thai Electronic Firms’ Financial Performance. Procedia Eng. 2015, 118, 683–690. [Google Scholar] [CrossRef]

- Diabat, A.; Khodaverdi, R.; Olfat, L. An exploration of green supply chain practices and performances in an automotive industry. Int. J. Adv. Manuf. Technol. 2013, 68, 949–961. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef] [Green Version]

- Mativenga, P.T.; Agwa-Ejon, J.; Mbohwa, C.; Sultan, A.A.M.; Shuaib, N.A. Circular Economy Ownership Models: A view from South Africa Industry. Procedia Manuf. 2017, 8, 284–291. [Google Scholar] [CrossRef]

- Chiu, J.-Z.; Hsieh, C.-C. The Impact of Restaurants’ Green Supply Chain Practices on Firm Performance. Sustainability 2016, 8, 42. [Google Scholar] [CrossRef]

- Wang, Q.; Gu, G.; Higano, Y. Toward integrated environmental management for challenges in water environmental protection of Lake Taihu basin in China. Environ. Manag. 2006, 37, 579–588. [Google Scholar] [CrossRef] [PubMed]

- Makropoulos, C.; Rozos, E.; Tsoukalas, I.; Plevri, A.; Karakatsanis, G.; Karagiannidis, L.; Makri, E.; Lioumis, C.; Noutsopoulos, C.; Mamais, D.; et al. Sewer-mining: A water reuse option supporting circular economy, public service provision and entrepreneurship. J. Environ. Manag. 2018, 216, 285–298. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, M.A.; Jabbour, C.J.C.; Jabbour, A.B.L.; de Sousa Jabbour, A.B.L. Maturity levels of material cycles and waste management in a context of green supply chain management: An innovative framework and its application to Brazilian cases. J. Mater. Cycles Waste Manag. 2017, 19, 516–525. [Google Scholar] [CrossRef]

- Wagner, M. How to reconcile environmental and economic performance to improve corporate sustainability: Corporate environmental strategies in the European paper industry. J. Environ. Manag. 2005, 76, 105–118. [Google Scholar] [CrossRef] [PubMed]

- Singhal, S.; Kapur, A. Industrial estate planning and management in India—An integrated approach towards industrial ecology. J. Environ. Manag. 2002, 66, 19–29. [Google Scholar] [CrossRef]

- Shang, K.C.; Lu, C.S.; Li, S. A taxonomy of green supply chain management capability among electronics-related manufacturing firms in Taiwan. J. Environ. Manag. 2010, 91, 1218–1226. [Google Scholar] [CrossRef] [PubMed]

- Qi, G.Y.; Zeng, S.X.; Shi, J.J.; Meng, X.H.; Lin, H.; Yang, Q.X. Revisiting the relationship between environmental and financial performance in Chinese industry. J. Environ. Manag. 2014, 145, 349–356. [Google Scholar] [CrossRef] [PubMed]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Chen, F.; Liu, Y.; Hua, G. International Conference on Low-Carbon Transportation and Logistics, and Green Buildings; Springer Science & Business Media: Heidelberg, Germany, 2013; Volume 2, ISBN 978-3-642-34650-7. [Google Scholar]

- Qu, Y.; Zhu, Q.; Sarkis, J.; Geng, Y.; Zhong, Y. A review of developing an e-wastes collection system in Dalian, China. J. Clean. Prod. 2013, 52, 176–184. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z. Green Supply Chain Management, Environmental Collaboration and Sustainability Performance. Procedia CIRP 2015, 26, 695–699. [Google Scholar] [CrossRef]

- Chang-Bong, K.; Sun-Nam, J.; Stephen, E.R. The Impact of Green-Oriented Supply Chain Management Practices and Environmental Management Systems on the Organizational Performance of Korean Manufacturers. J. Korea Trade 2012, 16(4), 27–55. [Google Scholar]

- Jabbour, A.B.L.d.S.; Jabbour, C.J.C.; Freitas, W.R.d.S.; Teixeira, A.A. Lean and green? Empirical evidence from the brazilian automotive industry. Gestão Produção 2013, 20, 653–665. [Google Scholar] [CrossRef]

- Zhu, Q.; Qu, Y.; Geng, Y.; Fujita, T. A Comparison of Regulatory Awareness and Green Supply Chain Management Practices Among Chinese and Japanese Manufacturers. Bus. Strategy Environ. 2017, 26, 18–30. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K. Environmental Supply Chain Cooperation and Its Effect on the Circular Economy Practice-Performance Relationship Among Chinese Manufacturers. J. Ind. Ecol. 2011, 15, 405–419. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Green supply chain management implications for “closing the loop”. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 1–18. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Sarkis, J.; Lai, K. Evaluating green supply chain management among Chinese manufacturers from the ecological modernization perspective. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 808–821. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, K.; Xu, Z.; Liao, P.; Zhang, X.; Liu, L.; Wei, K.; Liu, D.; Li, Y.-F.; Sunkar, R.; et al. Small RNA profiles from Panax notoginseng roots differing in sizes reveal correlation between miR156 abundances and root biomass levels. Sci. Rep. 2017, 7, 9418. [Google Scholar] [CrossRef] [PubMed]

- Noya, I.; Aldea, X.; González-García, S.; Gasol, C.M.; Moreira, M.T.; Amores, M.J.; Marín, D.; Boschmonart-Rives, J. Environmental assessment of the entire pork value chain in Catalonia—A strategy to work towards Circular Economy. Sci. Total Environ. 2017, 589, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Șeitan, O. Perfomanța lanțului logistic: Armonizarea strategică (The performance of the supply chain: Strategical harmonization). Amfiteatru Econ. 2008, X, 224–235. [Google Scholar]

- Constăngioară, A. Măsurarea performanţelor în managementul lanţurilor de aprovizionare-livrare. Evidenţe empirice din România (Performance Metrics in Supply Chain Management. Evidence from Romanian Economy). Amfiteatru Econ. 2013, XIV, 130–140. [Google Scholar]

- Van Berkel, R.; Willems, E.; Lafleur, M. The Relationship between Cleaner Production and Industrial Ecology. J. Ind. Ecol. 1997, 1, 51–66. [Google Scholar] [CrossRef]

- Ramani, K.; Ramanujan, D.; Bernstein, W.Z.; Zhao, F.; Sutherland, J.; Handwerker, C.; Choi, J.K.; Kim, H.; Thurston, D. Integrated sustainable life cycle design: A Review. J. Mech. Des. Trans. ASME 2010, 132, 910041–9100415. [Google Scholar] [CrossRef]

- Winkler, H. Closed-loop production systems—A sustainable supply chain approach. CIRP J. Manuf. Sci. Technol. 2011, 4, 243–246. [Google Scholar] [CrossRef]

- Prendeville, D.S.; Sanders, C.; Sherry, J.; Costa, F. Circular Economy: Is It Enough; Ecodesign Centre (EDC): Cardiff, UK, 2014; pp. 1–18. [Google Scholar]

- Aoe, T. Eco-efficiency and ecodesign in electrical and electronic products. J. Clean. Prod. 2007, 15, 1406–1414. [Google Scholar] [CrossRef]

- Schnitzer, H.; Ulgiati, S. Less bad is not good enough: Approaching zero emissions techniques and systems. J. Clean. Prod. 2007, 15, 1185–1189. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Almeida, C.M.V.B.; Giannetti, B.F.; Huisingh, D. The roles of cleaner production in the sustainable development of modern societies: An introduction to this special issue. J. Clean. Prod. 2010, 18, 1–5. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, S.; Bi, J. Enterprises’ willingness to adopt/develop cleaner production technologies: An empirical study in Changshu, China. J. Clean. Prod. 2013, 40, 62–70. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, Y. An exploration of firms’ awareness and behavior of developing circular economy: An empirical research in China. Resour. Conserv. Recycl. 2014, 87, 145–152. [Google Scholar] [CrossRef]

- Fischer, A.; Pascucci, S. Institutional incentives in circular economy transition: The case of material use in the Dutch textile industry. J. Clean. Prod. 2017, 17–32. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular Economy Rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Oncioiu, I.; Căpuşneanu, S.; Türkeș, M.C.; Topor, D.I.; Constantin, D.-M.O.; Marin-Pantelescu, A.; Ștefan Hint, M. The Sustainability of Romanian SMEs and Their Involvement in the Circular Economy. Sustainability 2018, 10, 2761. [Google Scholar] [CrossRef]

- Ghenta, M.; Matei, A. SMEs and the Circular Economy: From Policy to Difficulties Encountered During Implementation. Amfiteatru Econ. 2018, 20, 294–309. [Google Scholar]

- Tantau, A.D.; Maassen, M.A.; Fratila, L. Models for Analyzing the Dependencies between Indicators for a Circular Economy in the European Union. Sustainability 2018, 10, 2141. [Google Scholar] [CrossRef]

- Ceptureanu, S.-I.; Ceptureanu, E.-G.; Murswieck, R.G.D. Perceptions of Circular Business Models in SMEs. Amfiteatru Econ. 2018, 20, 310–324. [Google Scholar]

- Ionascu, I.; Ionascu, M. Business Models for Circular Economy and Sustainable Development: The Case of Lease Transactions. Amfiteatru Econ. 2018, 20, 356–372. [Google Scholar]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 1st ed.; Routledge: Hillsdale, NJ, USA, 1977; ISBN 978-0-8058-0283-2. [Google Scholar]

- Nunnally, J.C. Psychometric Theory; McGraw-Hill: New York, NY, USA, 1978; ISBN 978-0-07-047465-9. [Google Scholar]

- Litwin, M.S. How to Measure Survey Reliability and Validity; SAGE Publications: Thousand Oaks, CA, USA, 1995; ISBN 978-1-5063-1981-0. [Google Scholar]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.; Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What Gets Measured, Gets Done: Development of a Circular Economy Measurement Scale for Building Industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef]

| Type of Business | Number | Percent |

|---|---|---|

| Groups of producers | ||

| Metallurgy, metallic and non-metallic constructions | 15 | 15.31% |

| Woodworking, furniture manufacturing | 7 | 7.14% |

| Electrical, electronic, printing | 18 | 18.37% |

| Agriculture and food industry | 13 | 13.27% |

| Textiles, leather | 11 | 11.22% |

| Chemicals, pharmaceuticals, rubber, plastics, paper | 17 | 17.35% |

| Motor vehicle, machinery and equipment | 17 | 17.35% |

| Total | 98 | 100.00% |

| Ownership structure | ||

| Private-owned | 93 | 94.90% |

| State-owned | 5 | 5.10% |

| Total | 98 | 100.00% |

| Number of employees | ||

| Under 249 | 66 | 67.35% |

| Over 249 | 32 | 32.65% |

| Total | 98 | 100.00% |

| Green Purcha-Sing | Customer Cooperation | Eco Design | Internal Environ-Mental | Investment Recovery | Environ-Mental Perfor-Mance | Economic Perfor-Mance | ||

|---|---|---|---|---|---|---|---|---|

| Green Purchasing | Pearson Correlation | |||||||

| Sig. (2-tailed) | ||||||||

| Customer cooperation | Pearson Correlation | 0.631 ** | ||||||

| Sig. (2-tailed) | 0.000 | |||||||

| Eco Design | Pearson Correlation | 0.443 ** | 0.584 ** | |||||

| Sig. (2-tailed) | 0.000 | 0.000 | ||||||

| Internal Environmental | Pearson Correlation | 0.568 ** | 0.451 ** | 0.425 ** | ||||

| Sig. (2-tailed) | 0.000 | 0.000 | 0.000 | |||||

| Investment Recovery | Pearson Correlation | 0.295 ** | 0.341 ** | 0.394 ** | 0.368 ** | |||

| Sig. (2-tailed) | 0.003 | 0.001 | 0.000 | 0.000 | ||||

| Environmental Performance | Pearson Correlation | 0.420 ** | 0.528 ** | 0.588 ** | 0.387 ** | 0.267 ** | ||

| Sig. (2-tailed) | 0.000 | 0.000 | 0.000 | 0.000 | 0.008 | |||

| Economic performance | Pearson Correlation | 0.456 ** | 0.476 ** | 0.443 ** | 0.338 ** | 0.202 * | 0.659 ** | |

| Sig. (2-tailed) | 0.000 | 0.000 | 0.000 | 0.001 | 0.047 | 0.000 | ||

| Factor | Scale | Alpha Cronbach | Total Item Correlation Interval | Model Fit Indices | ||||

|---|---|---|---|---|---|---|---|---|

| χ2 | DF | p | RMSEA | PCLOSE | ||||

| ESCC practices | 40.73 | 32 | 0.138 | 0.53 | 0.429 | |||

| Green Purchasing | 0.830 (5 items) | 0.61–0.75 | ||||||

| Customer Cooperation | 0.727 (5 items) | 0.46–0.65 | ||||||

| CE practices | 39.30 | 29 | 0.096 | 0.061 | 0.335 | |||

| Eco-design | 0.838 (5 items) | 0.60–0.86 | ||||||

| Internal environmental management | 0.870 (5 items) | 0.68–0.89 | ||||||

| Investment recovery | 0.860 (5 items) | 0.49–0.88 | ||||||

| CE targeted performance | 28.27 | 22 | 0.164 | 0.055 | 0.412 | |||

| Environmental performance | 0.882 (5 items) | 0.66–0.87 | ||||||

| Economic performance | 0.835 (4 items) * | 0.63–0.90 | ||||||

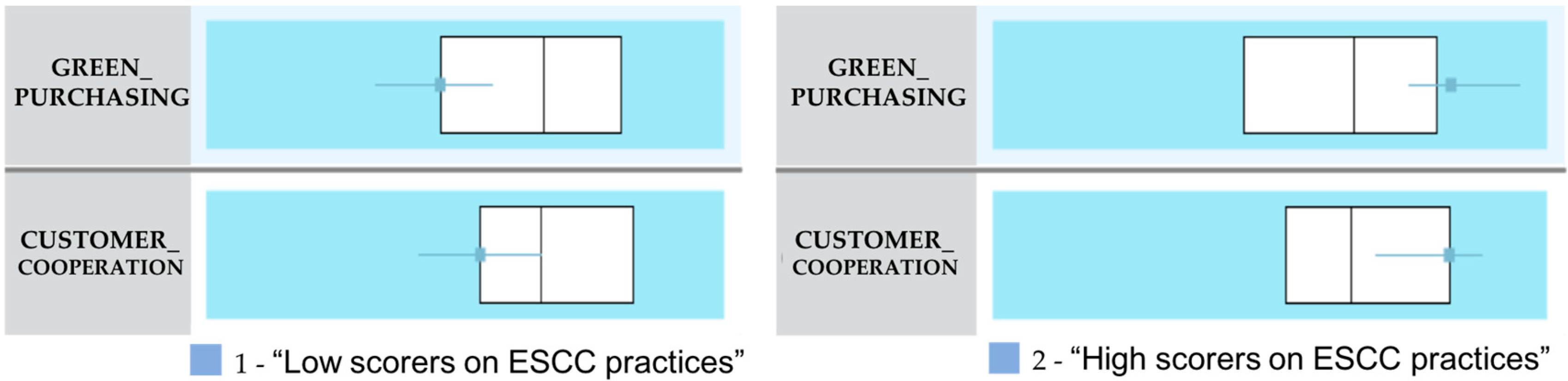

| Variable | M & SD | t & p Value | |

|---|---|---|---|

| Low scorers on GSCC practices (CLUSTER 1) | High scorers on GSCC practices (CLUSTER 2) | t = −5.347, p = 0.000 | |

| CE practices | |||

| Eco design | M = 19.76, SD = 3.31 | M = 22.97, SD = 2.58 | t = −5.347, p = 0.000 |

| Internal environment | M = 16.70, SD = 6.03 | M = 21.83, SD = 3.43 | t = −5.199, p = 0.000 |

| Investment recovery | M = 19.22, SD = 4.50 | M = 20.79, SD = 4.77 | t = −1.676, p = 0.097 |

| CE targeted performance | |||

| Environmental performance | M = 19.10, SD = 3.58 | M = 22.35, SD = 2.86 | t = −4.956, p = 0.000 |

| Economic performance | M = 14.00, SD = 3.08 | M = 17.54, SD = 2.79 | t = −5.954, p = 0.000 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botezat, E.A.; Dodescu, A.O.; Văduva, S.; Fotea, S.L. An Exploration of Circular Economy Practices and Performance Among Romanian Producers. Sustainability 2018, 10, 3191. https://doi.org/10.3390/su10093191

Botezat EA, Dodescu AO, Văduva S, Fotea SL. An Exploration of Circular Economy Practices and Performance Among Romanian Producers. Sustainability. 2018; 10(9):3191. https://doi.org/10.3390/su10093191

Chicago/Turabian StyleBotezat, Elena Aurelia, Anca Otilia Dodescu, Sebastian Văduva, and Silvia Liana Fotea. 2018. "An Exploration of Circular Economy Practices and Performance Among Romanian Producers" Sustainability 10, no. 9: 3191. https://doi.org/10.3390/su10093191