Development of a New Gob-Side Entry-Retaining Approach and Its Application

Abstract

:1. Introduction

2. Materials and Methods

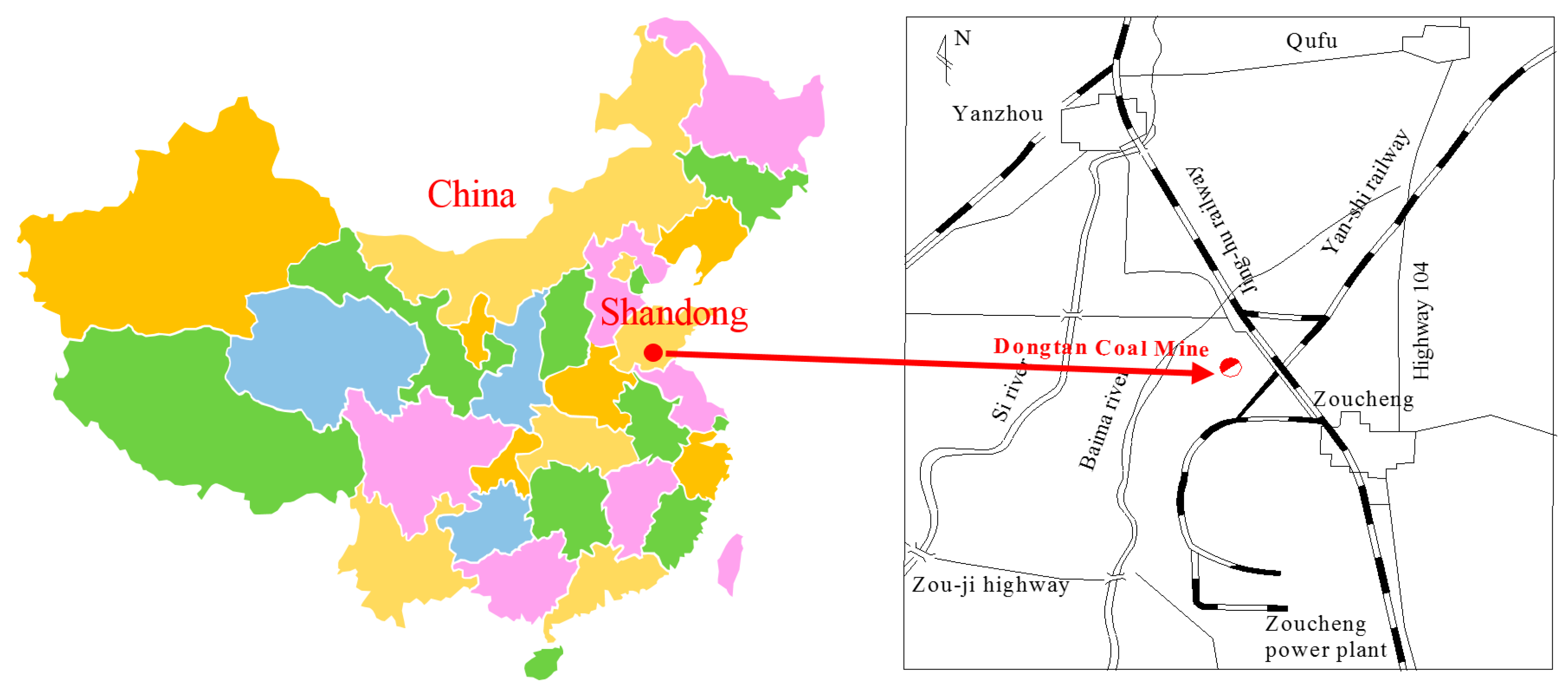

2.1. Engineering Geological Conditions

2.1.1. Working Face Overview

2.1.2. Coal Seam and Strata

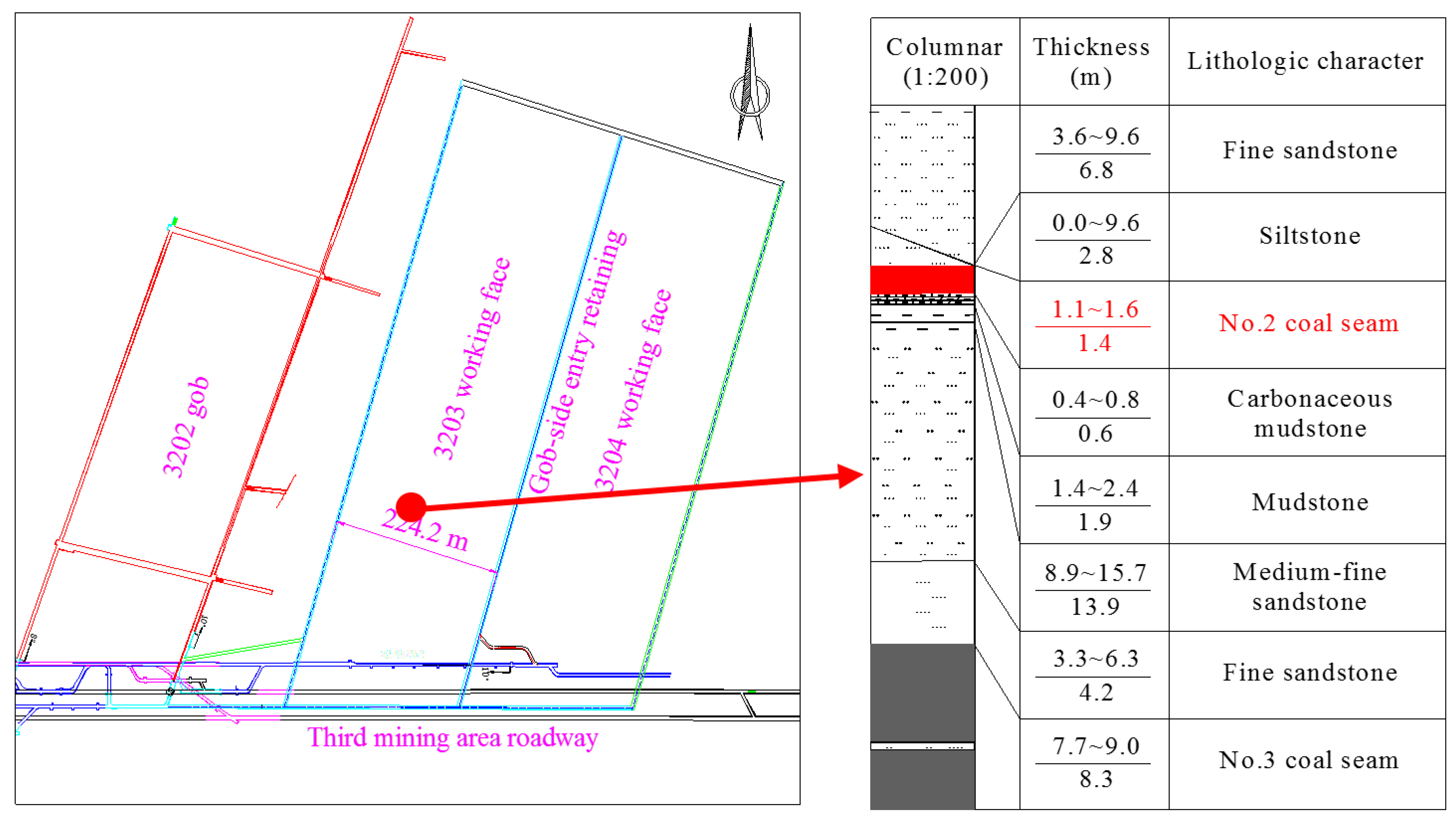

2.2. Development of a Lightweight and High-Strength Foam Concrete

2.2.1. Experiment Materials and Methods

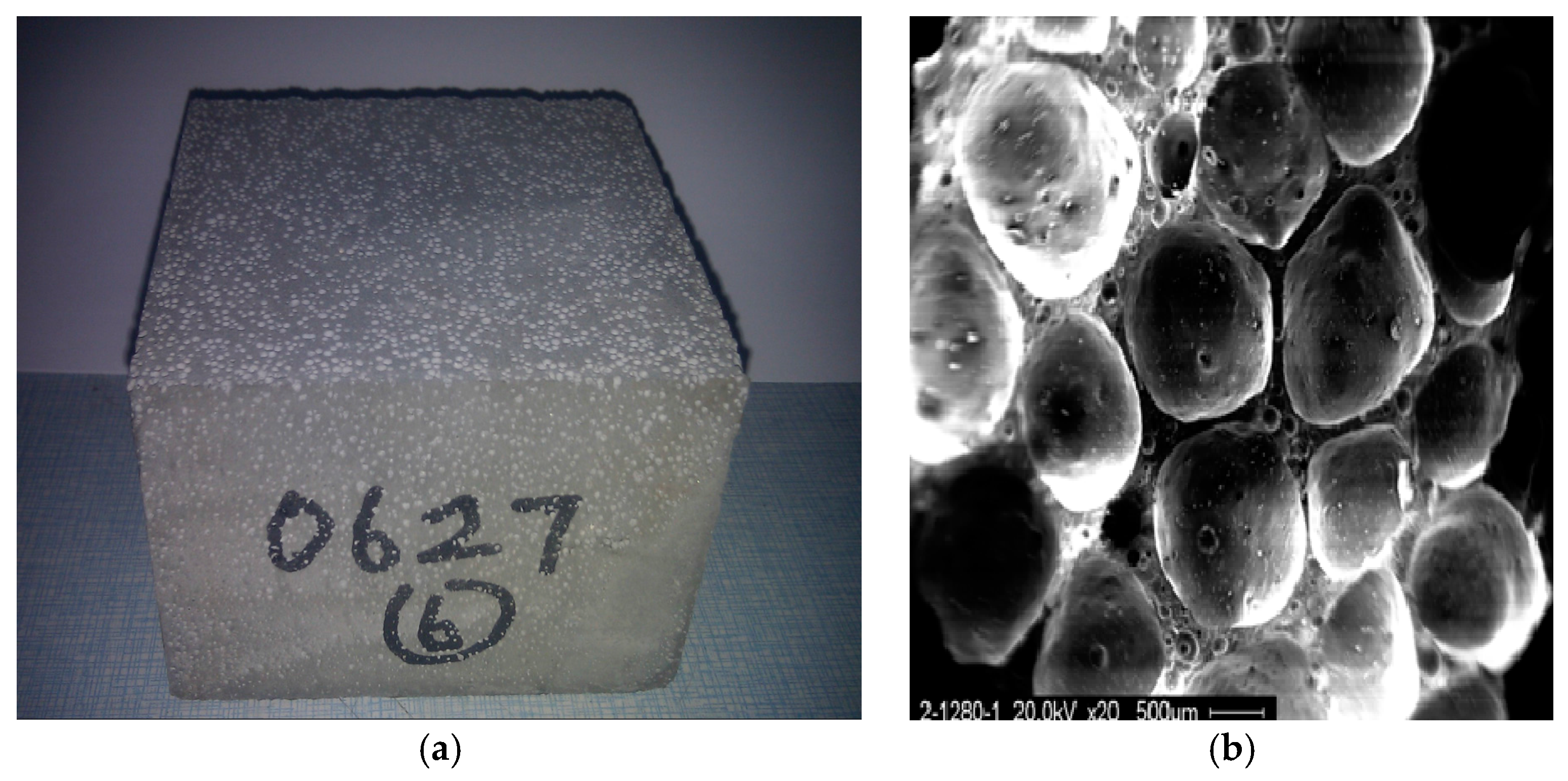

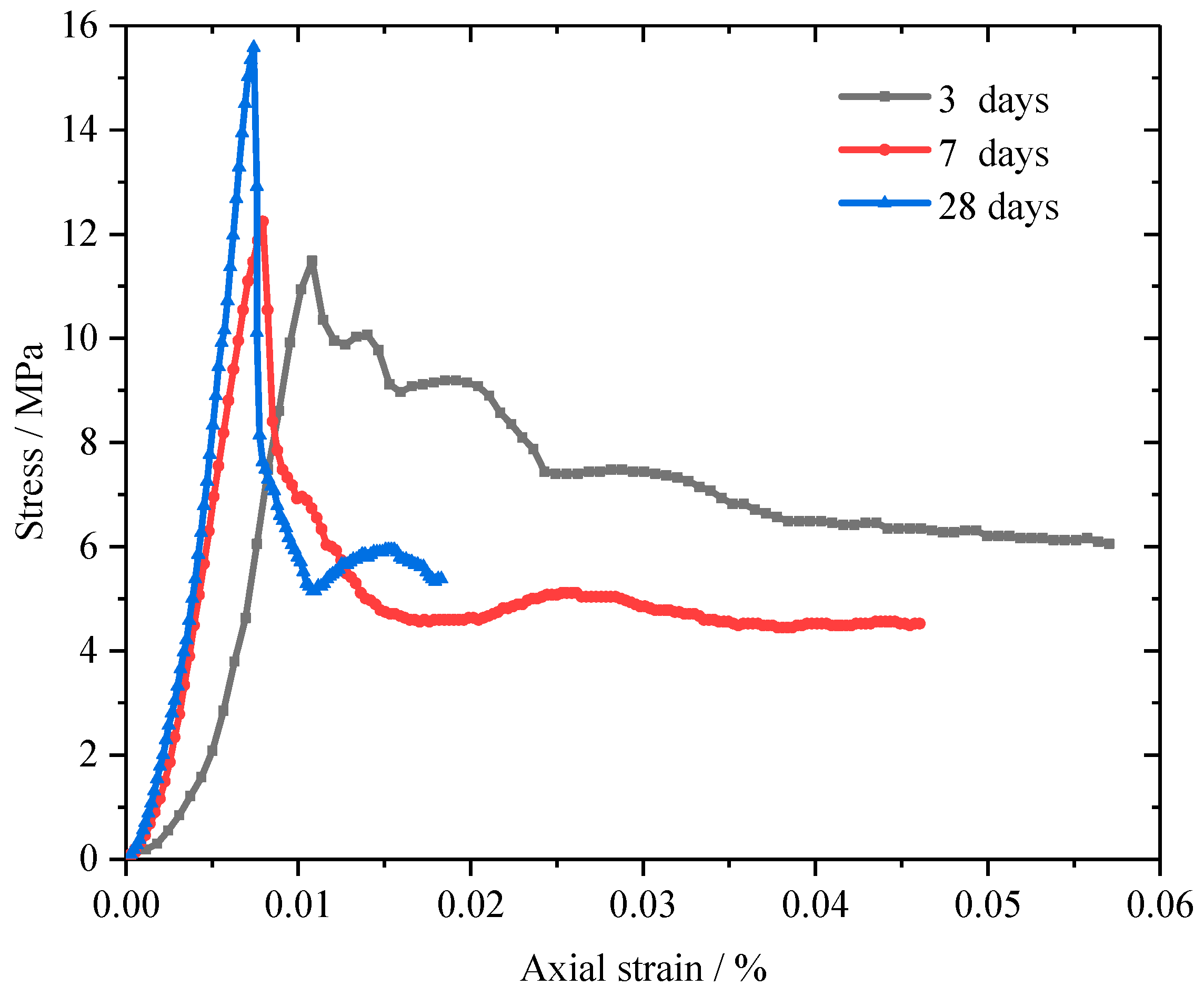

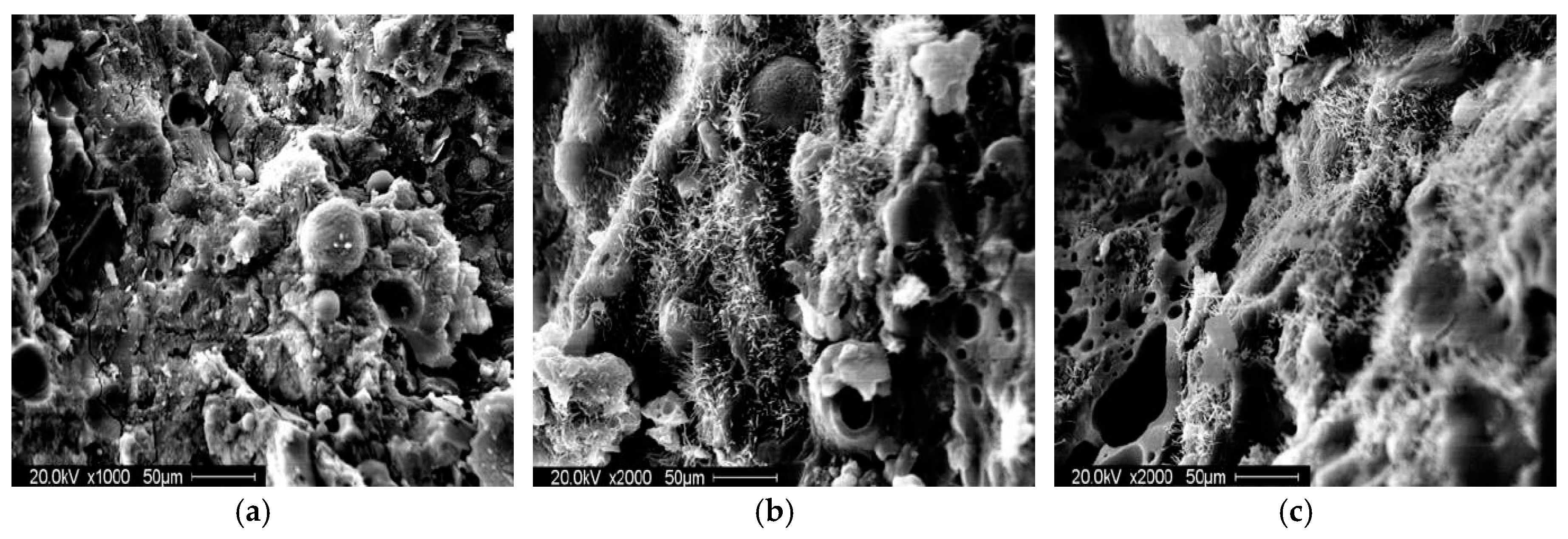

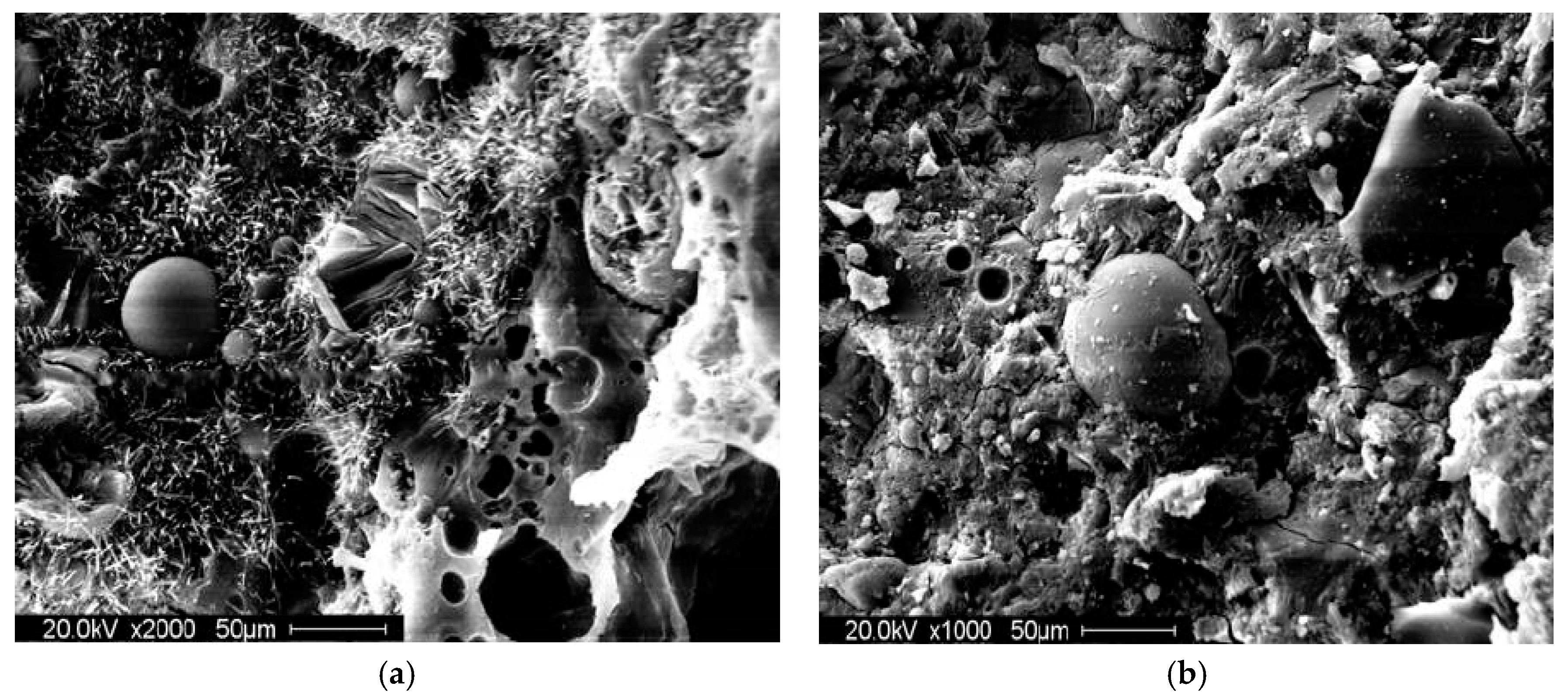

2.2.2. Strength and Deformation Characteristics

2.2.3. Comparative Analysis

2.2.4. Main Conclusions

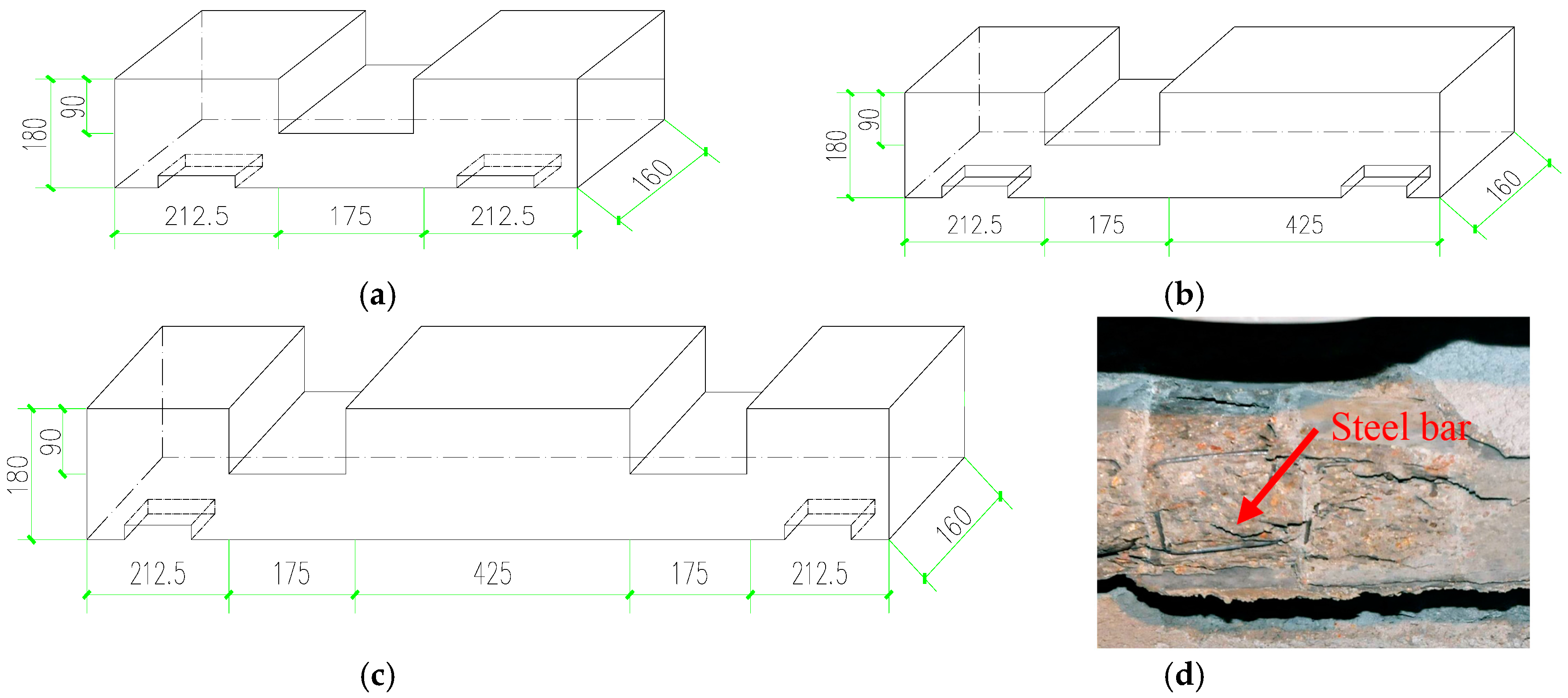

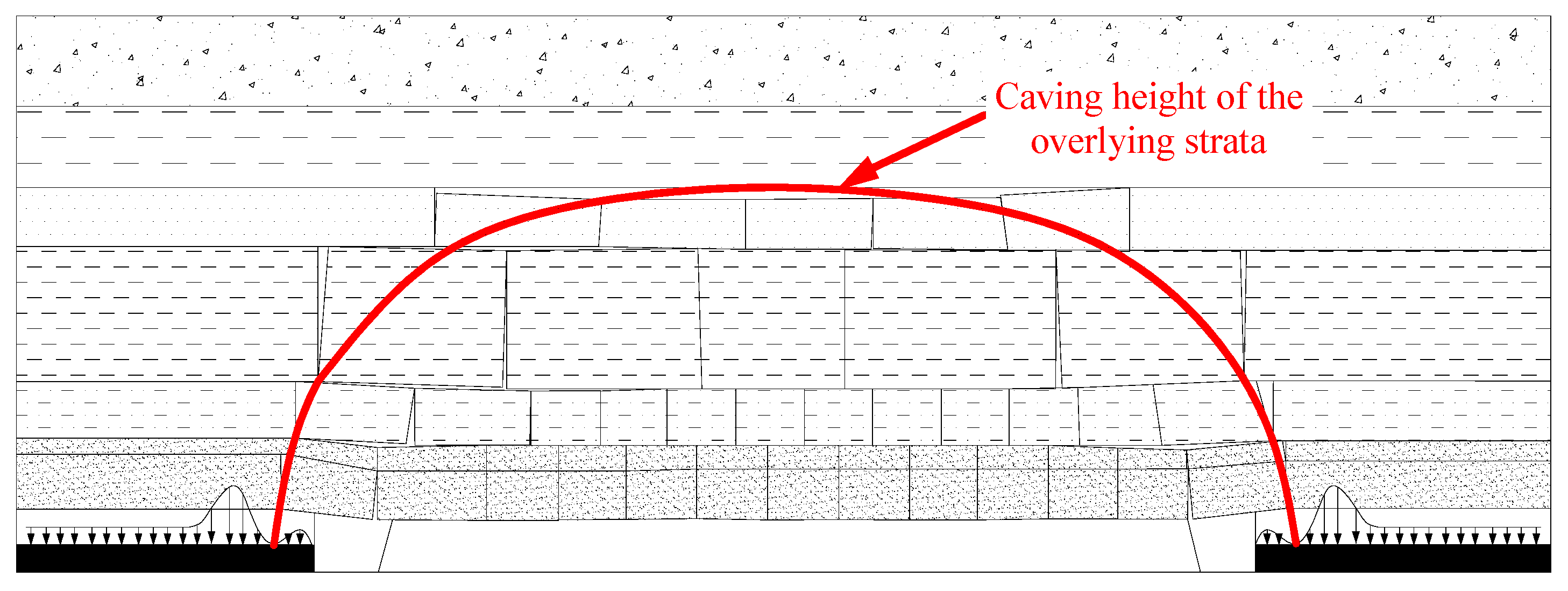

2.3. Design of the Wall Structure of Gob-Side Entry Retaining

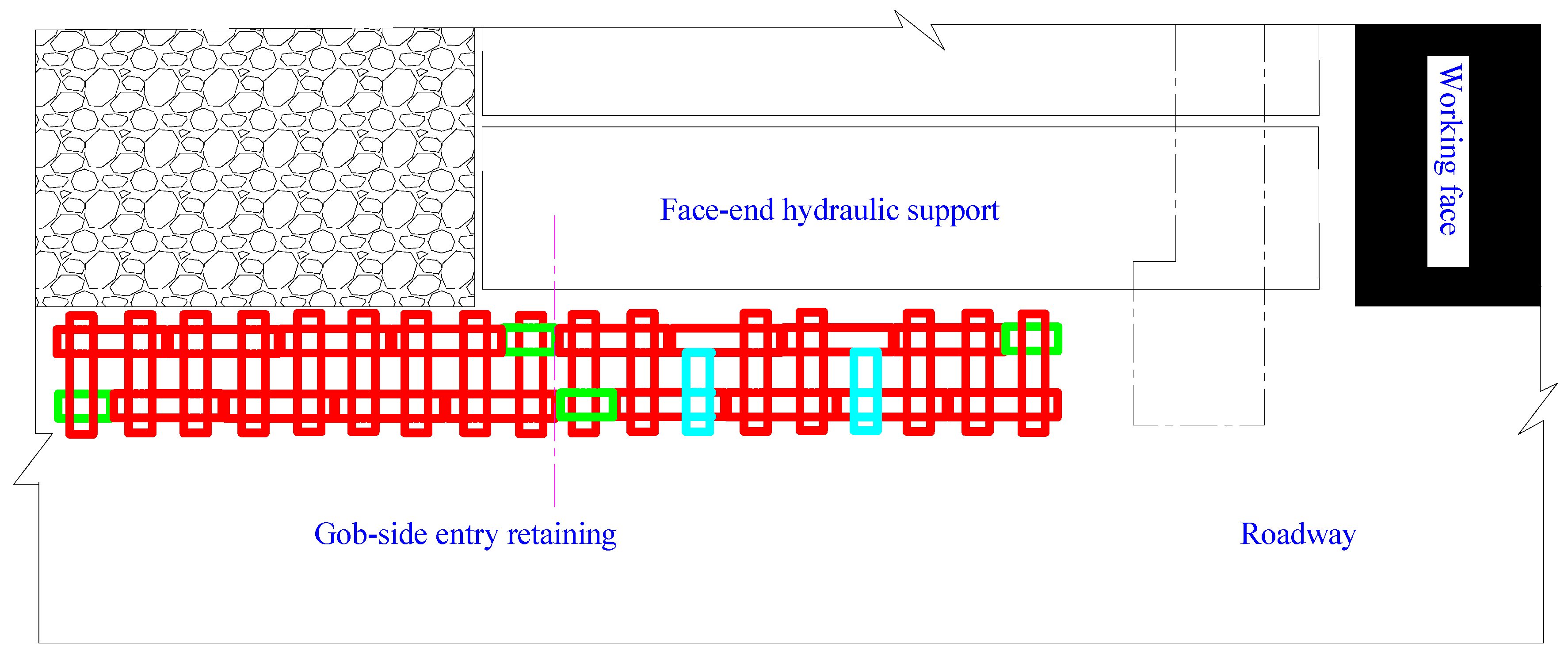

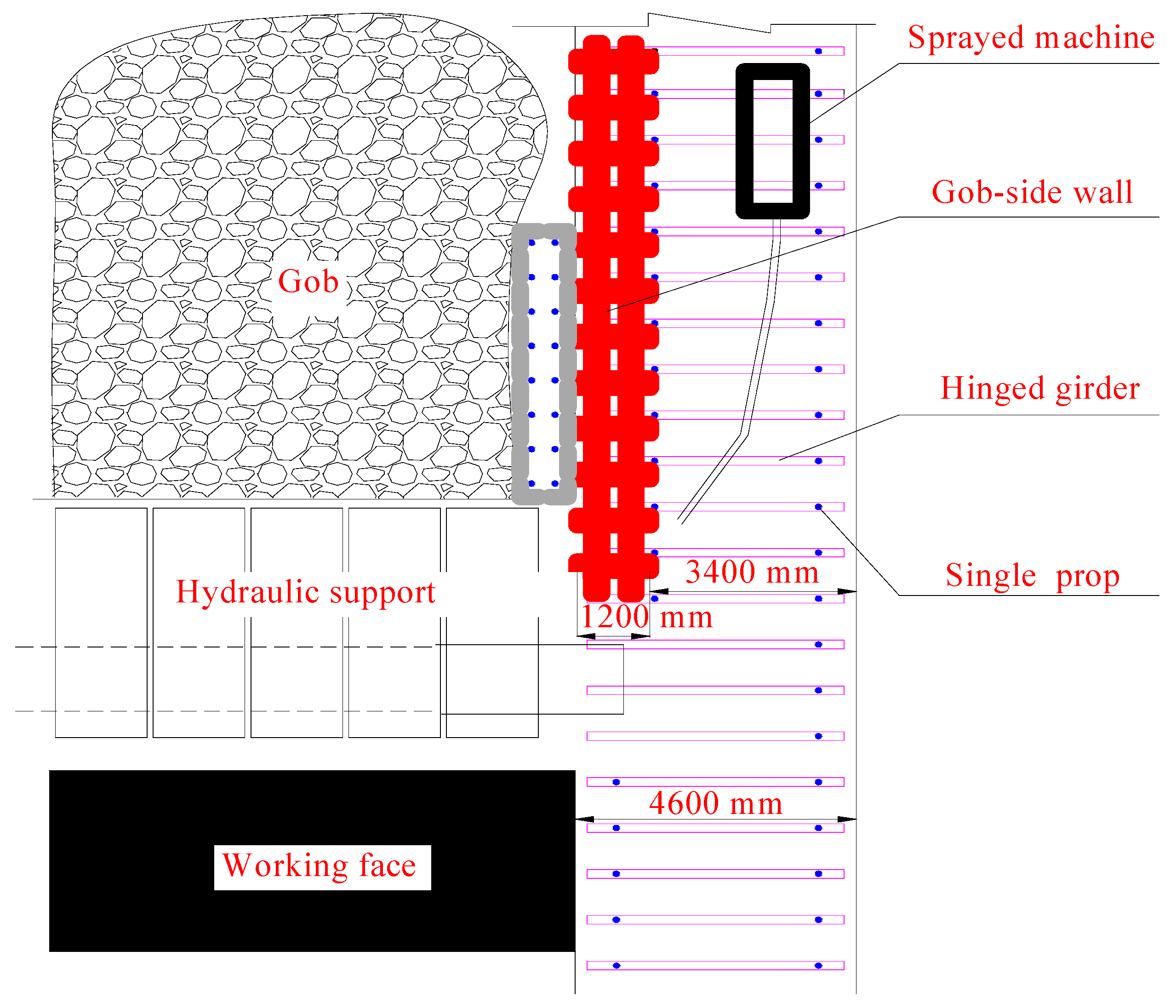

2.3.1. New Wall Structure

2.3.2. Wall Construction

3. Field-Application Effect and Analysis

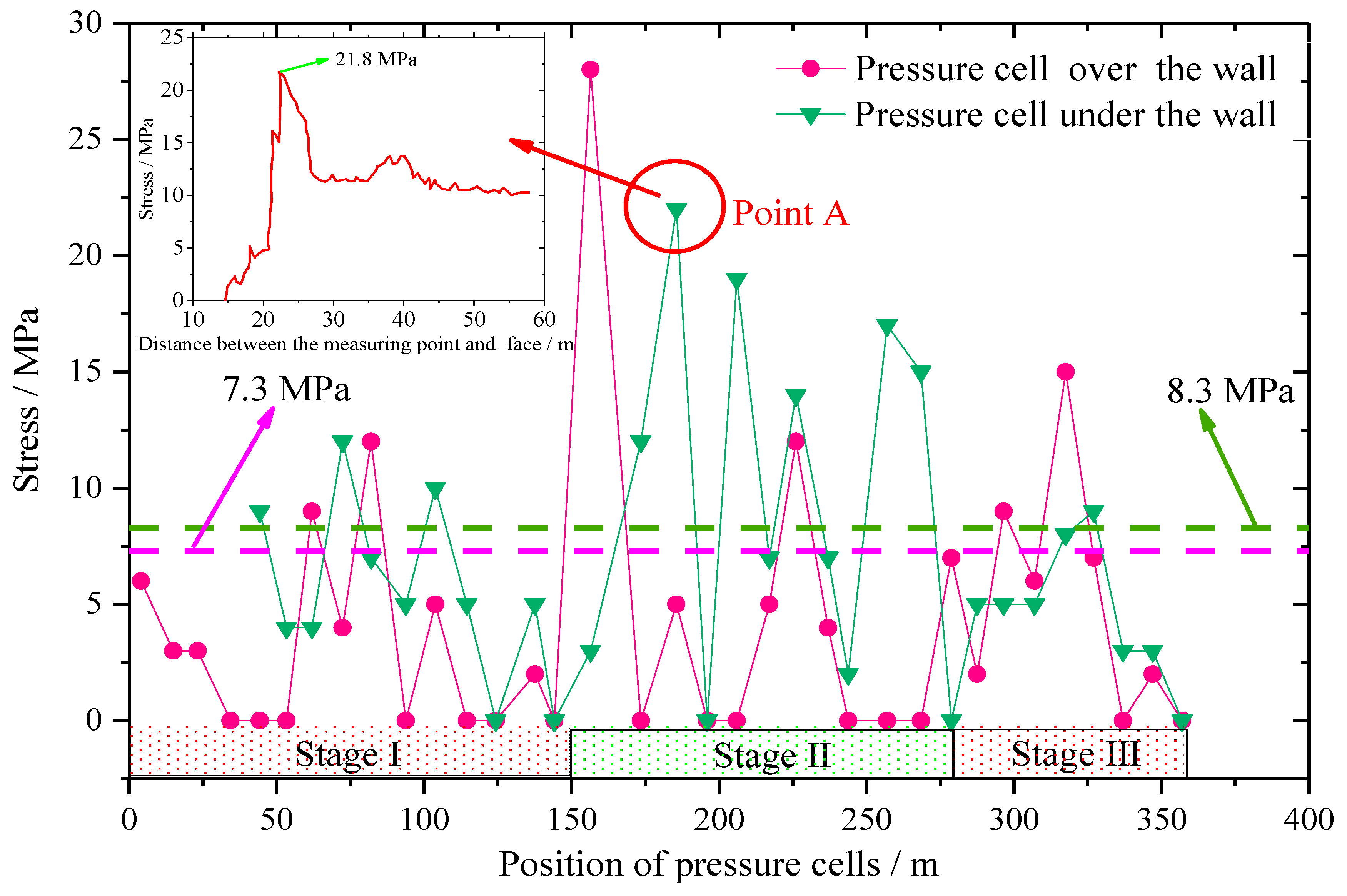

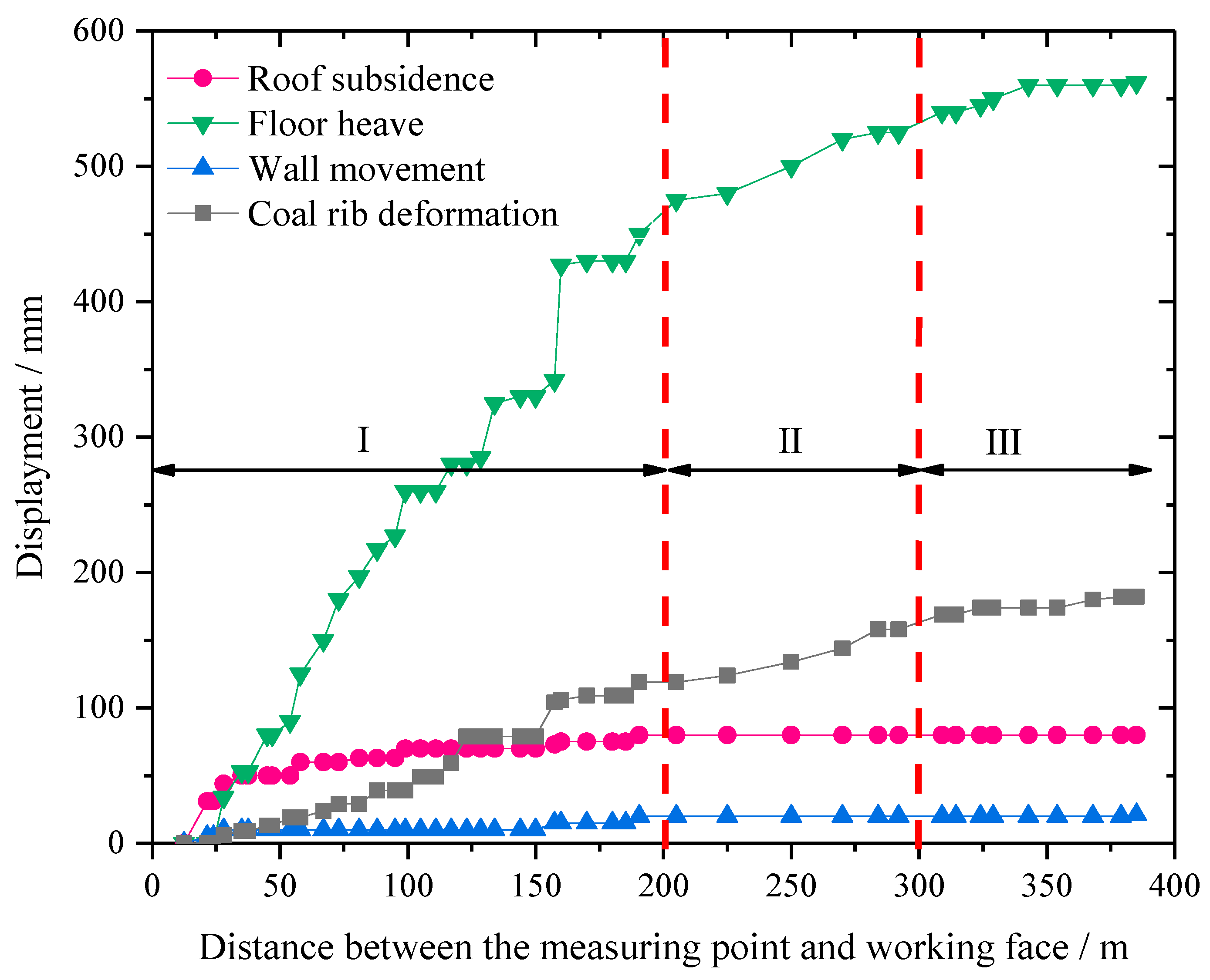

3.1. Application Effect

3.2. Analysis and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vakili, A.; Hebblewhite, B.K. A new cavability assessment criterion for Longwall Top Coal Caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 1317–1329. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int. J. Rock Mech. Min. Sci. 2012, 51, 24–34. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, D.; Zhang, X.; He, M. Analysis and Optimization of Entry Stability in Underground Longwall Mining. Sustainability 2017, 9, 2079. [Google Scholar] [CrossRef]

- Deng, Y.; Wang, S. Feasibility analysis of gob-side entry retaining on a working face in a steep coal seam. Int. J. Min. Sci. Technol. 2014, 24, 499–503. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Bu, T.; Hu, S.; Liu, X. An Innovative Support Structure for Gob-Side Entry Retention in Steep Coal Seam Mining. Minerals 2017, 7, 75. [Google Scholar] [CrossRef]

- Zhang, Z.; Shimada, H.; Sasaoka, T.; Hamanaka, A. Stability Control of Retained Goaf-Side Gateroad under Different Roof Conditions in Deep Underground Y Type Longwall Mining. Sustainability 2017, 9, 1671. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, L.; Jiang, J.; Zheng, P.; Li, W. Strata Behaviors and Rock Burst–Inducing Mechanism under the Coupling Effect of a Hard, Thick Stratum and a Normal Fault. Int. J. Geomech. 2017, 18, 04017135. [Google Scholar] [CrossRef]

- Tan, Y.L.; Yu, F.H.; Ning, J.G.; Zhao, T.B. Design and construction of entry retaining wall along a gob side under hard roof stratum. Int. J. Rock Mech. Min. Sci. 2015, 77, 115–121. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Hideki, S.; Qian, D.Y.; Takashi, S. Application of the retained gob-side gateroad in a deep underground coalmine. Int. J. Min. Reclam. Environ. 2016, 30, 371–389. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, D.; Liu, L.; Guo, W.; Fan, G.; Song, K.; Wang, X. Stabilization of Gob-Side Entry with an Artificial Side for Sustaining Mining Work. Sustainability 2016, 8, 627. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Li, Y.; Sun, C.; Guo, P. Soft Roof Failure Mechanism and Supporting Method for Gob-Side Entry Retaining. Minerals 2015, 5, 707–722. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Wang, S.; Fan, Y.; Wang, S.; Chen, X. Adaptation assessment of gob-side entry retaining based on geological factors. Eng. Geol. 2016, 209, 143–151. [Google Scholar] [CrossRef]

- Han, C.; Zhang, N.; Li, B.; Si, G.; Zheng, X. Pressure relief and structure stability mechanism of hard roof for gob-side entry retaining. J. Cent. South Univ. 2015, 22, 4445–4455. [Google Scholar] [CrossRef]

- Zhang, Z.; Bai, J.; Chen, Y.; Yan, S. An innovative approach for gob-side entry retaining in highly gassy fully-mechanized longwall top-coal caving. Int. J. Rock Mech. Min. Sci. 2015, 80, 1–11. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, J.; Xiao, D.; Sun, L.; Zhang, W. Spontaneous caving and gob-side entry retaining of thin seam with large inclined angle. Int. J. Min. Sci. Technol. 2014, 24, 441–445. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, N. Position-optimization on retained entry and backfilling wall in gob-side entry retaining techniques. Int. J. Coal Sci. Technol. 2015, 2, 186–195. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Deo, R.C.; Hilal, A.; Abd, A.M.; Bueno, L.C.; Salcedo-Sanz, S.; Nehdi, M.L. Predicting compressive strength of lightweight foamed concrete using extreme learning machine model. Adv. Eng. Softw. 2018, 115, 112–125. [Google Scholar] [CrossRef]

- Prabha, P.; Palani, G.S.; Lakshmanan, N.; Senthil, R. Behaviour of steel-foam concrete composite panel under in-plane lateral load. J. Constr. Steel Res. 2017, 139, 437–448. [Google Scholar]

- Nguyen, L.H.; Beaucour, A.L.; Ortola, S.; Noumowé, A. Experimental study on the thermal properties of lightweight aggregate concretes at different moisture contents and ambient temperatures. Constr. Build. Mater. 2017, 151, 720–731. [Google Scholar] [CrossRef]

- Xu, D.; Peng, S.; Xiang, S.; He, Y. A Novel Caving Model of Overburden Strata Movement Induced by Coal Mining. Energies 2017, 10, 476. [Google Scholar] [CrossRef]

| Specimen Number | Cement/g | Admixture/g | Sand/g | Foaming Agent/g | Polypropylene Fibre/g | Superplasticizer/g | Curing Agent/g | Activator/g |

|---|---|---|---|---|---|---|---|---|

| 1# | 960 | 0 | 240 | 45 | 5 | 1.6 | 20 | 6 |

| 2# | 840 | 120 (silica fume) | 240 | 45 | 5 | 1.6 | 20 | 6 |

| 3# | 840 | 120 (slag) | 240 | 45 | 5 | 1.6 | 20 | 6 |

| 4# | 840 | 120 (fly ash) | 240 | 45 | 5 | 1.6 | 20 | 6 |

| 5# | 840 | 60 (slag) + 60 (fly ash) | 240 | 45 | 5 | 1.6 | 20 | 6 |

| 6# | 840 | 60 (silica fume) + 60 (fly ash) | 240 | 45 | 5 | 1.6 | 20 | 6 |

| 7# | 840 | 60 (silica fume) + 60 (slag) | 240 | 45 | 5 | 1.6 | 20 | 6 |

| Specimen Number | Uniaxial Compressive Strength/MPa | ||

|---|---|---|---|

| 3 Days | 7 Days | 28 Days | |

| 1# | 8.52 | 10.51 | 12.27 |

| 2# | 9.89 | 12.83 | 14.72 |

| 3# | 9.64 | 13.32 | 14.38 |

| 4# | 7.20 | 10.68 | 13.26 |

| 5# | 11.04 | 13.96 | 14.75 |

| 6# | 10.80 | 12.40 | 15.02 |

| 7# | 11.40 | 12.20 | 15.55 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, H.; Jiang, Y.; Lin, H.; Li, G. Development of a New Gob-Side Entry-Retaining Approach and Its Application. Sustainability 2018, 10, 470. https://doi.org/10.3390/su10020470

Luan H, Jiang Y, Lin H, Li G. Development of a New Gob-Side Entry-Retaining Approach and Its Application. Sustainability. 2018; 10(2):470. https://doi.org/10.3390/su10020470

Chicago/Turabian StyleLuan, Hengjie, Yujing Jiang, Huili Lin, and Guofeng Li. 2018. "Development of a New Gob-Side Entry-Retaining Approach and Its Application" Sustainability 10, no. 2: 470. https://doi.org/10.3390/su10020470