Theoretical Investigation of Gas Filling and Leaking in Inertial Confinement Fusion Hohlraum

Abstract

:1. Introduction

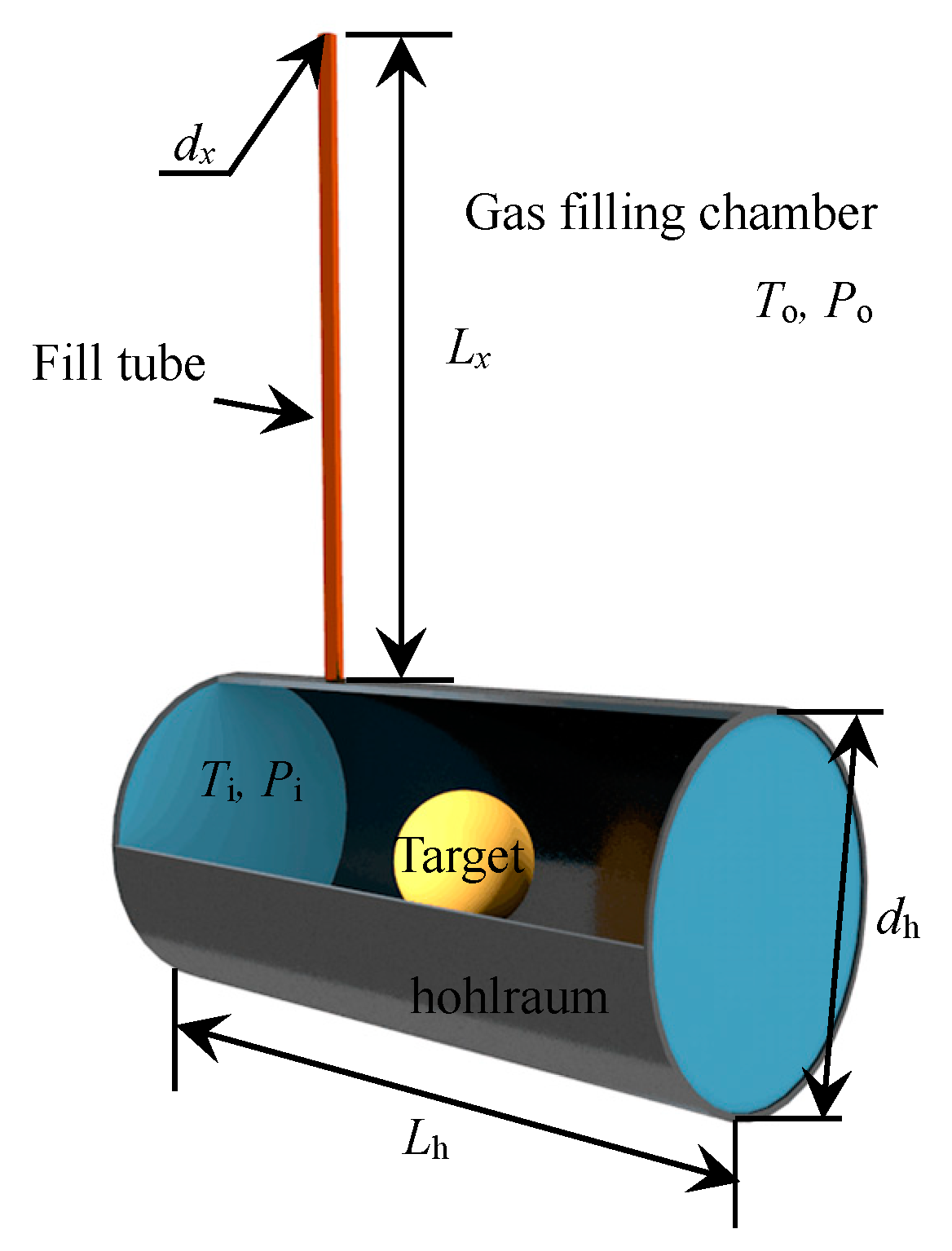

2. Mathematical Model

2.1. Governing Equations

2.2. Boundary Conditions and Numerical Solution

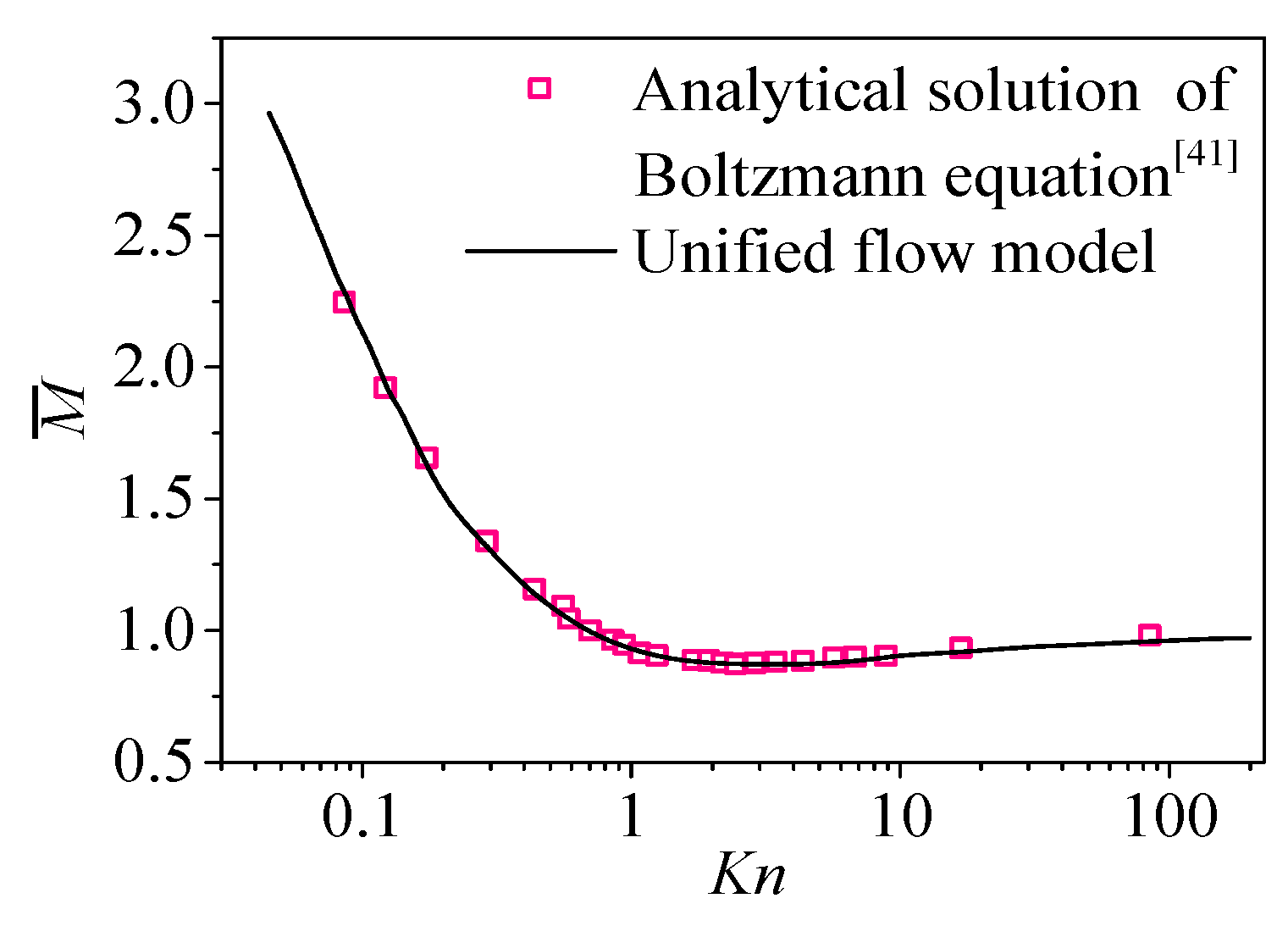

2.3. Case Validation

3. Results and Discussion

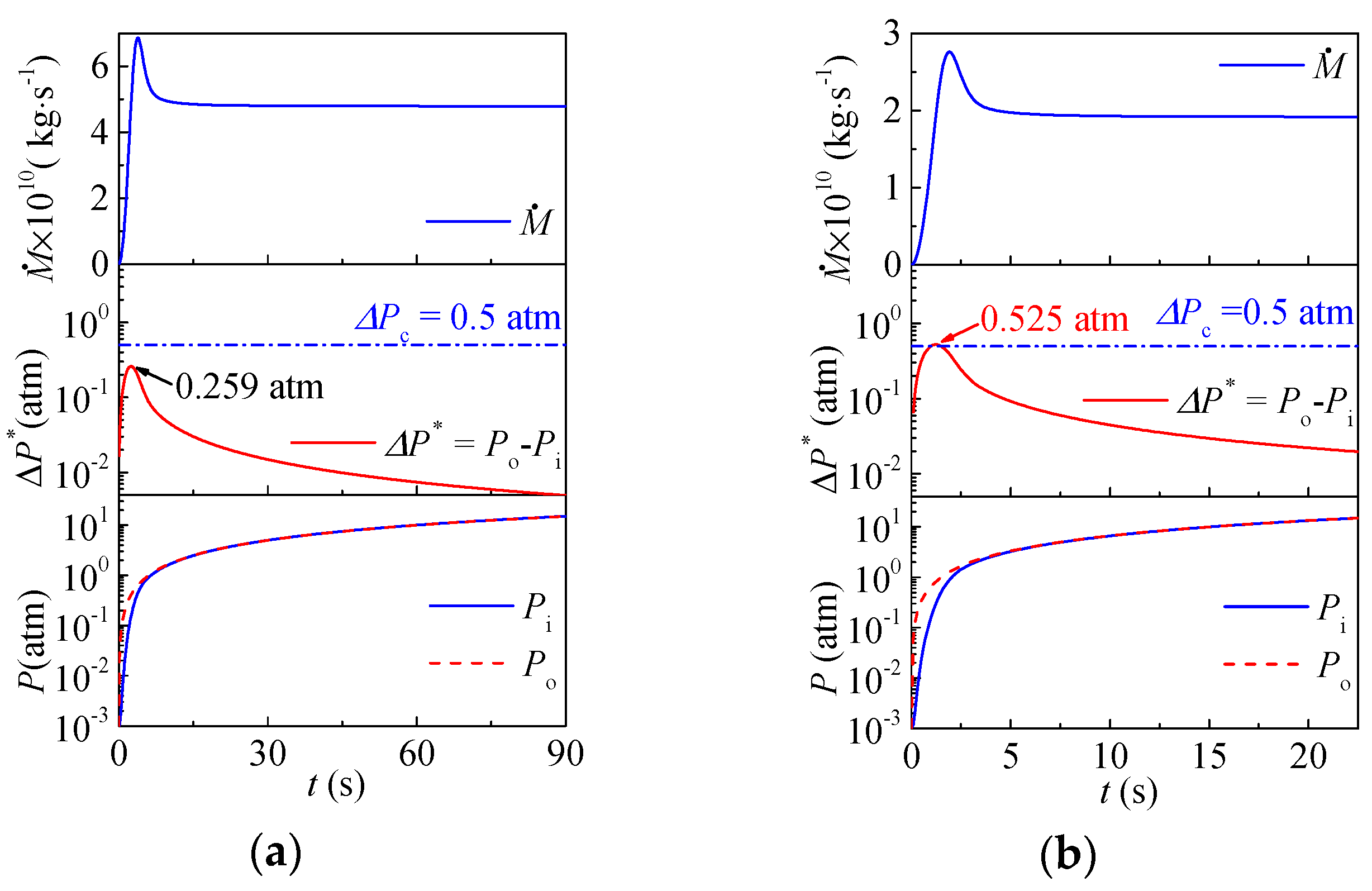

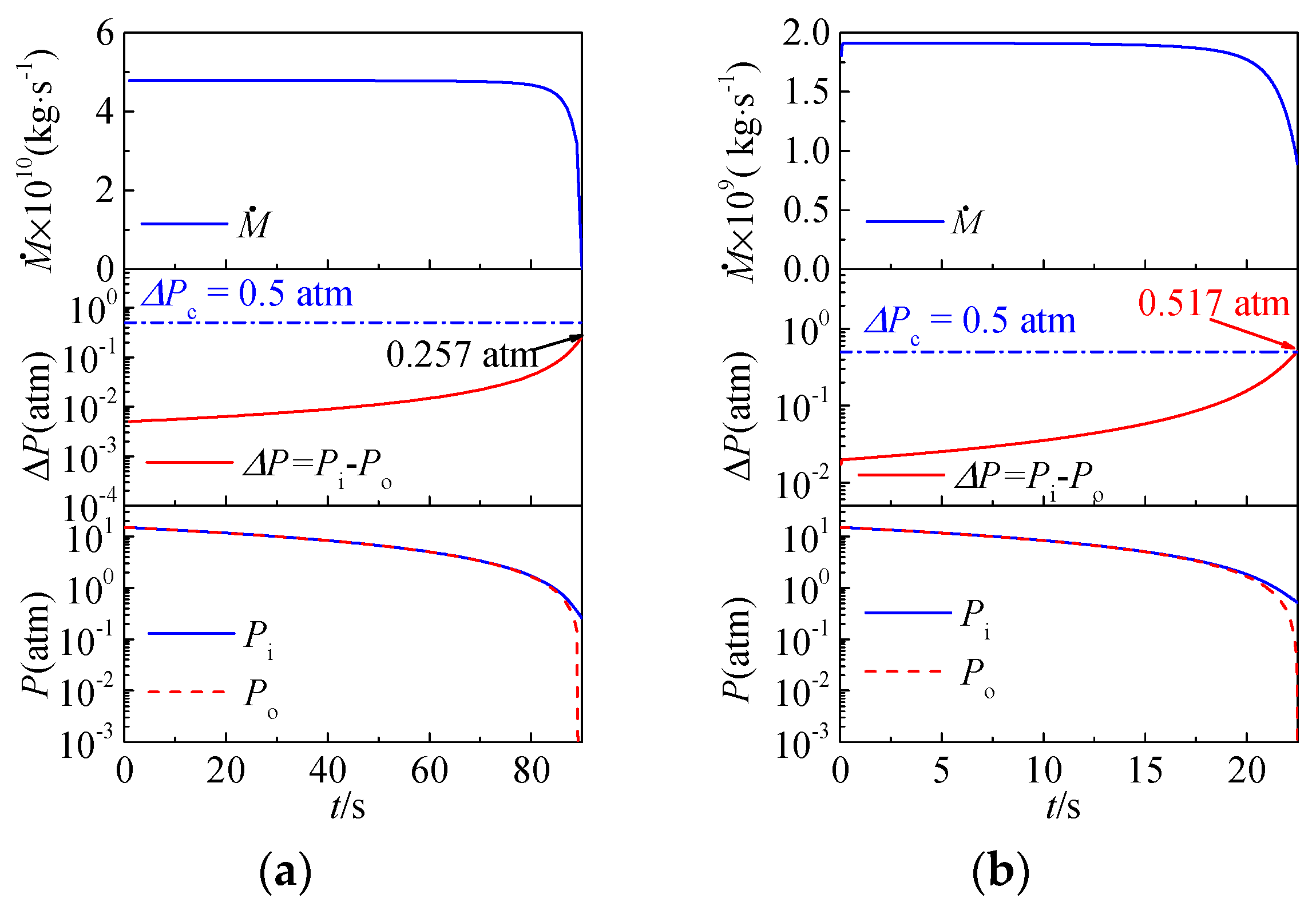

3.1. Gas Filling and Leaking Processes

3.2. Influence Factor Analysis

4. Conclusions

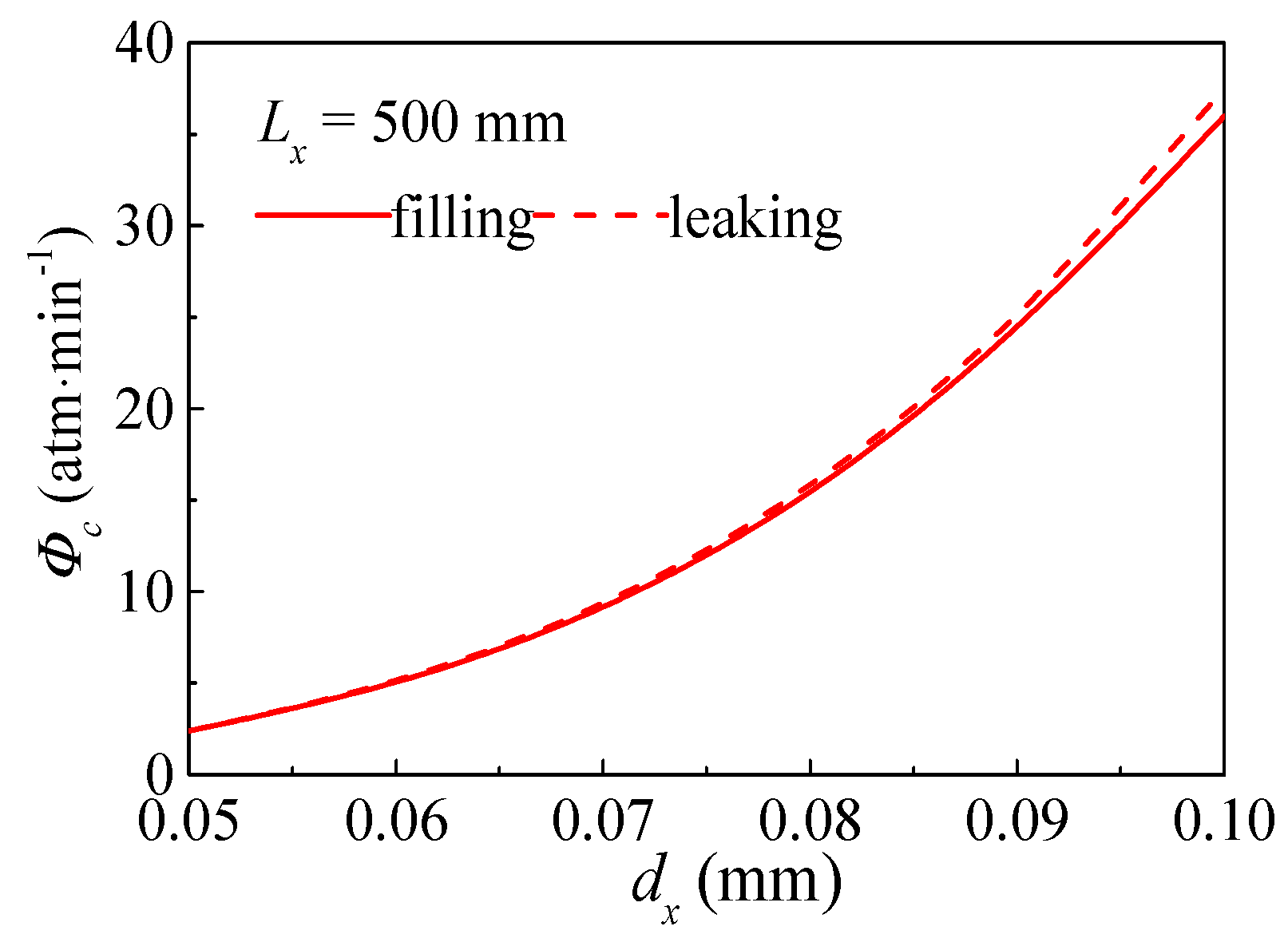

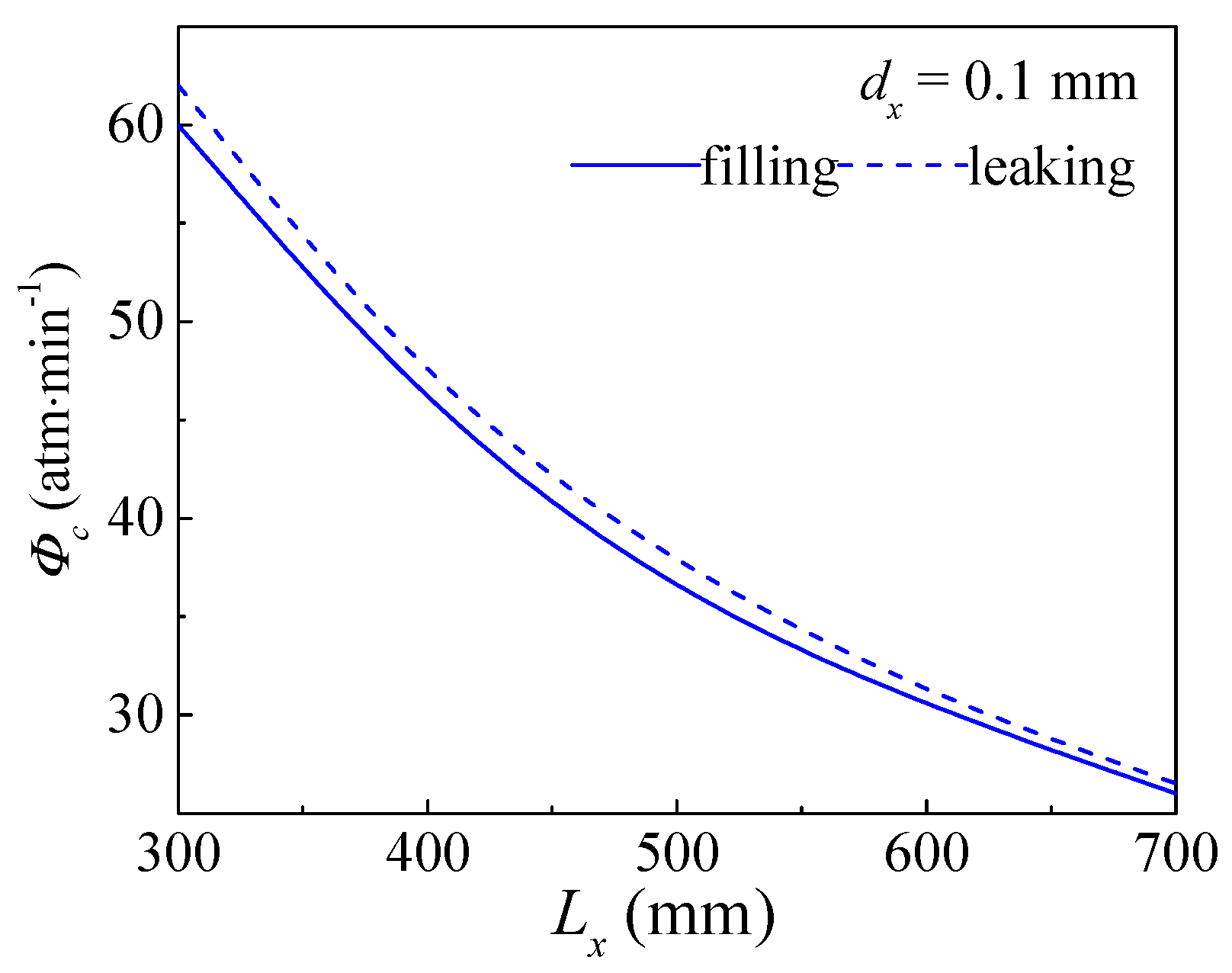

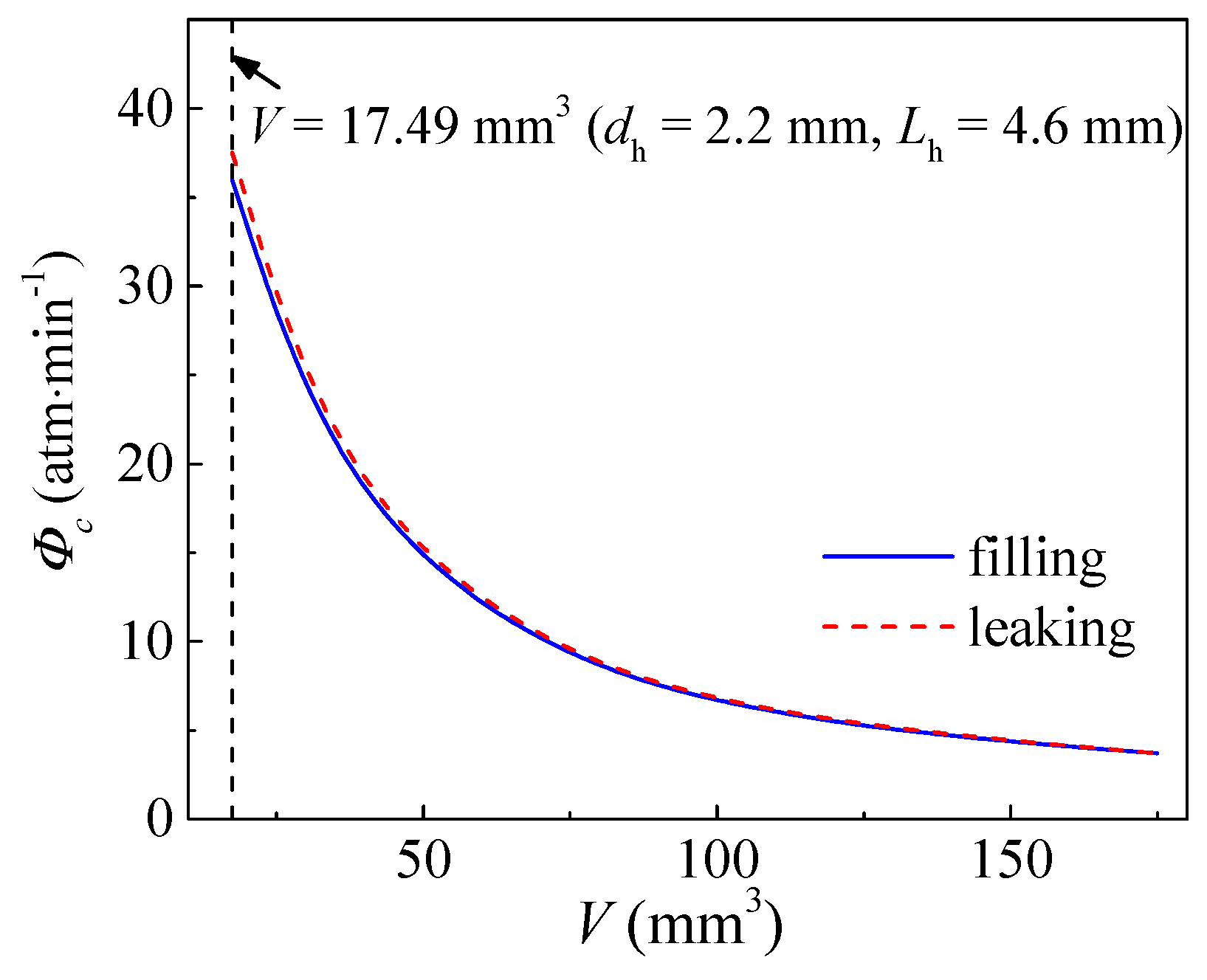

- An increase in the variation rate of the filling/leaking pressure leads to a larger maximum pressure difference between the inside and outside of the ICF hohlraum during the filling/leaking process, and the critical pressure difference of the gas filling process is nearly equal to that of the gas leaking process.

- Increase in fill tube diameter and decrease in its length both lead to a lower probability of the rupture of polymeric films at two ends of the ICF hohlraum, and thus increases the security of the hohlraum.

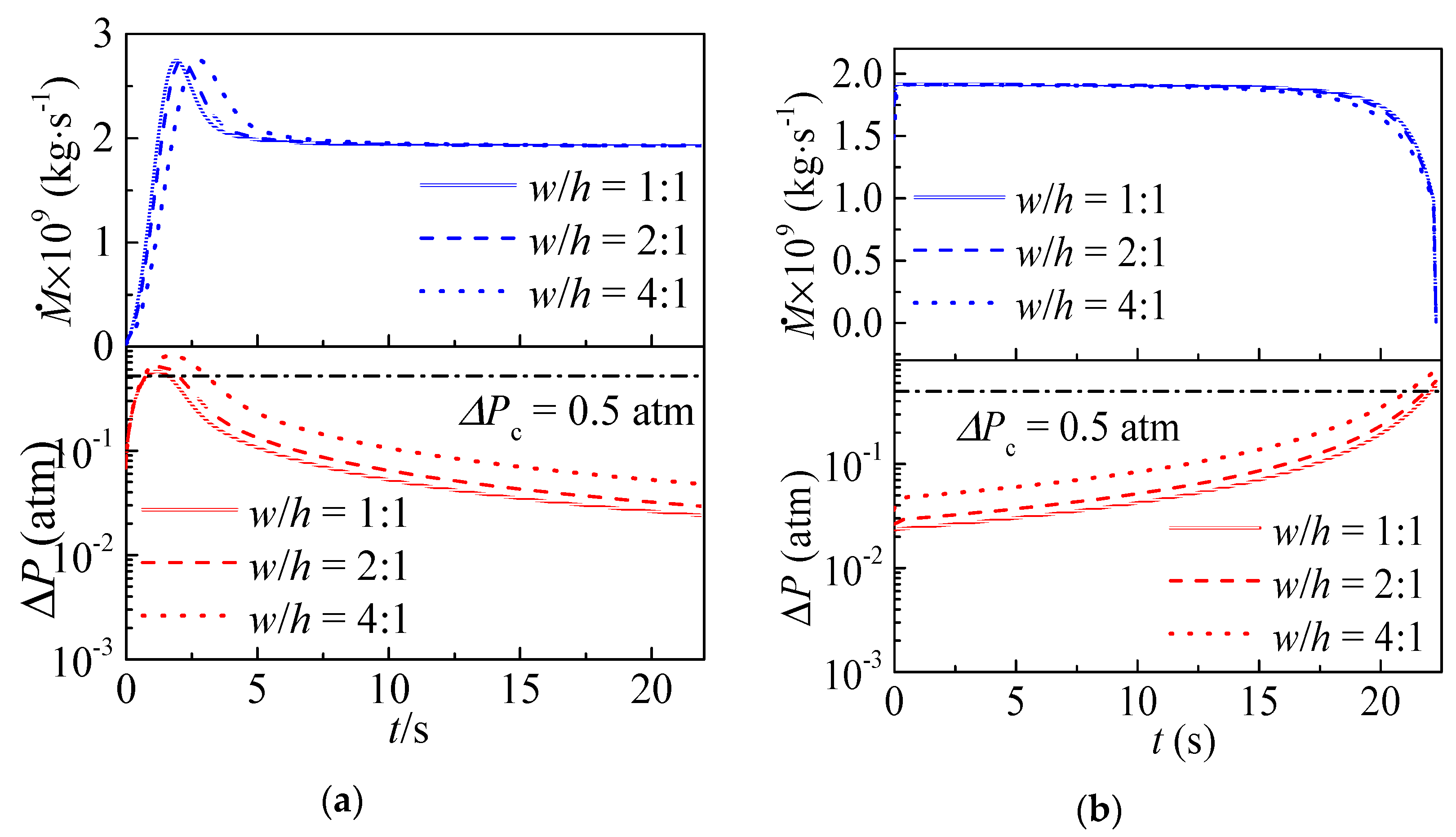

- A departure in cross sectional shape of fill tube from circle to rectangle triggers an increase in pressure difference between the inside and outside of the ICF hohlraum, which raises the risk of polymeric films rupture and decreases the security of the hohlraum structure.

Author Contributions

Funding

Conflicts of Interest

References

- Nuckolls, J.; Wood, L.; Thiessen, A.; Zimmerman, G. Laser compression of matter to super-high densities: Thermonuclear (CTR) applications. Nature 1972, 239, 139–142. [Google Scholar] [CrossRef]

- Lindl, J. Development of the indirect-drive approach to inertial confinement fusion and the target physics basis for ignition and gain. Phys. Plasmas 1995, 2, 3933–4024. [Google Scholar] [CrossRef]

- Lan, K.; Liu, J.; Li, Z.; Xie, X.; Huo, W.; Chen, Y.; Ren, G.; Zheng, C.; Yang, D.; Li, S.; et al. Progress in octahedral spherical hohlraum study. Matter Radiat. Extremes 2016, 1, 8–27. [Google Scholar] [CrossRef]

- Kirkwood, R.K.; Moody, J.D.; Kline, J.; Dewald, E.; Glenzer, S.; Divol, L.; Michel, P.; Hinkel, D.; Berger, R.; Williams, E.; et al. A review of laser–plasma interaction physics of indirect-drive fusion. Plasma Phys Control. Fusion 2013, 55, 103001. [Google Scholar] [CrossRef]

- Itoh, Y.; Fujii-E, Y. Constricted liquid metal curtain for inertial confinement fusion reactors. J. Nucl. Sci. Technol. 1981, 18, 241–248. [Google Scholar] [CrossRef]

- Bardi, U. Extracting minerals from seawater: An energy analysis. Sustainability 2010, 2, 980–992. [Google Scholar] [CrossRef]

- Gabbar, H.; Stoute, C.A.B.; Bondarenko, D.; Tarsitano, N.; Abdel Rihem, A.; Sirakov, S.; Jani, S.; Menashi, S. X-pinch plasma generation testing for neutron source development and nuclear fusion. Energies 2018, 11, 988–1005. [Google Scholar] [CrossRef]

- Wang, J.; Gao, W.; Zhang, H.; Zou, M.; Chen, Y.; Zhao, Y. Programmable wettability on photocontrolled graphene film. Sci. Adv. 2018, 4, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Liu, X.; Shi, M. Hydrodynamics of double emulsion droplet in shear flow. Appl. Phys. Lett. 2013, 102, 051609. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, W.; Zhang, C.; Zhao, Y. Three-dimensional splitting microfluidics. Lab Chip 2016, 16, 1332–1339. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Liu, X.; Zhang, C.; Zhao, Y. Enhancing and suppressing effects of an inner droplet on deformation of a double emulsion droplet under shear. Lab Chip 2015, 15, 1255–1261. [Google Scholar] [CrossRef] [PubMed]

- Campbell, E.M.; Goncharov, V.N.; Sangster, T.C.; Regan, S.P.; Radha, P.B.; Betti, R.; Myatt, J.F.; Froula, D.H.; Rosenberg, M.J.; Igumenshchev, I.V.; et al. Laser-direct-drive program: Promise, challenge, and path forward. Matter Radiat. Extremes 2017, 2, 37–54. [Google Scholar] [CrossRef]

- Murakami, M.; Nishi, D. Optimization of laser illumination configuration for directly driven inertial confinement fusion. Matter Radiat. Extremes 2017, 2, 55–68. [Google Scholar] [CrossRef]

- Craxton, R.S.; Anderson, K.S.; Boehly, T.R.; Goncharov, V.N.; Harding, D.R.; Knauer, J.P.; McCrory, R.L.; McKenty, P.W.; Meyerhofer, D.D.; Myatt, J.F.; et al. Direct-drive inertial confinement fusion: A review. Phys. Plasmas 2015, 22, 110501–110654. [Google Scholar] [CrossRef]

- Li, F.; Zhang, Z.; Li, J.; Pan, D.; Feng, J.; Shi, R.; Li, B. Study on the strength of titanium doped hollow glass microspheres. J. Non-Cryst. Solids 2017, 459, 18–25. [Google Scholar] [CrossRef]

- Wang, T.; Du, K.; He, Z.B.; He, X.S. Development of target fabrication for laser-driven inertial confinement fusion at research center of laser fusion. High Power Laser Sci. Eng. 2017, 5, 1–9. [Google Scholar] [CrossRef]

- Kauffman, R.L.; Powers, L.V.; Dixit, S.N.; Glendinning, S.G.; Glenzer, S.H.; Kirkwood, R.K.; Landen, O.L.; MacGowan, B.J.; Moody, J.D.; Orzechowski, T.J.; et al. Improved gas-filled hohlraum performance on nova with beam smoothing. Phys. Plasmas 1998, 5, 1927–1934. [Google Scholar] [CrossRef]

- Liu, M.; Zheng, Y.; Li, J.; Chen, S.; Liu, Y.; Li, J.; Li, B.; Zhang, Z. Effects of molecular weight of pva on formation, stability and deformation of compound droplets for icf polymer shells. Nucl. Fusion 2017, 57, 016018. [Google Scholar] [CrossRef]

- Vu, H.X.; Wallace, J.M.; Bezzerides, B. An analytical and numerical investigation of ion acoustic waves in a two-ion plasma. Phys. Plasmas 1994, 1, 3542–3556. [Google Scholar] [CrossRef]

- Tanaka, K.A.; Yamanaka, T.; Nishihara, K.; Norimatsu, T.; Miyanaga, N.; Shiraga, H.; Nakai, M.; Kitagawa, Y.; Kodama, R.; Kanabe, T.; et al. Cryogenic deuterium target experiments with the gekko xii, green laser system. Phys. Plasmas 1995, 2, 2495–2503. [Google Scholar] [CrossRef] [Green Version]

- Williams, E.A.; Berger, R.L.; Drake, R.P.; Rubenchik, A.M.; Bauer, B.S.; Meyerhofer, D.D.; Gaeris, A.C.; Johnston, T.W. The frequency and damping of ion acoustic waves in hydrocarbon (ch) and two-ion-species plasmas. Phys. Plasmas 1995, 2, 129–138. [Google Scholar] [CrossRef]

- Fernández, J.C.; Goldman, S.R.; Kline, J.L.; Dodd, E.S.; Gautier, C.; Grim, G.P.; Hegelich, B.M.; Montgomery, D.S.; Lanier, N.E.; Rose, H.; et al. Gas-filled hohlraum experiments at the national ignition facility. Phys. Plasmas 2006, 13, 056319. [Google Scholar] [CrossRef]

- Yi, S.; Zhang, Z.; Huang, Q.; Zhang, Z.; Wang, Z.; Wei, L.; Liu, D.; Cao, L.; Gu, Y. Note: Tandem kirkpatrick–baez microscope with sixteen channels for high-resolution laser-plasma diagnostics. Rev. Sci. Instrum. 2018, 89, 036105. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.P.; Deng, Z.L. Hydrodynamics of a droplet passing through a microfluidic t-junction. J. Fluid Mech. 2017, 819, 401–434. [Google Scholar] [CrossRef]

- Zhang, C.B.; Chen, Y.P.; Deng, Z.L.; Shi, M.H. Role of rough surface topography on gas slip flow in microchannels. Phys. Rev. E 2012, 86, 016319. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wu, L.; Zhang, C. Emulsion droplet formation in coflowing liquid streams. Phys. Rev. E 2013, 87, 013002. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.B.; Deng, Z.L.; Chen, Y.P. Temperature jump at rough gas-solid interface in couette flow with a rough surface described by cantor fractal. Int. J. Heat Mass Transf. 2014, 70, 322–329. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Zhang, C.; Huang, Y.; Chen, Y. Melting behaviors of pcm in porous metal foam characterized by fractal geometry. Int. J. Heat Mass Transfer 2017, 113, 1031–1042. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Li, B.; Tang, Y.J.; Wang, C.Y.; Chen, S.F.; Lin, B.; Chu, X.M.; Huang, Y.H.; Huang, L.Z.; Zhou, L.; et al. Fabrication of the hohlraum gas-filled target connected with gas source. High Power Laser and Part. Beams 2005, 17, 209–212. [Google Scholar]

- Zhang, Z.; Huang, Y.; Liu, Y.; Li, B.; Qi, X.; Chen, S. Fabrication of gas-filled targets without gas source. High Power Laser Part. Beams 2009, 21, 79–82. [Google Scholar]

- Kline, J.L.; Hager, J.D. Aluminum x-ray mass-ablation rate measurements. Matter Radiat. Extremes 2017, 2, 16–21. [Google Scholar] [CrossRef]

- Lindl, J.D.; Amendt, P.; Berger, R.L.; Glendinning, S.G.; Glenzer, S.H.; Haan, S.W.; Kauffman, R.L.; Landen, O.L.; Suter, L.J. The physics basis for ignition using indirect-drive targets on the national ignition facility. Phys. Plasmas 2004, 11, 339–491. [Google Scholar] [CrossRef]

- Deng, Z.L.; Chen, Y.P.; Shao, C.X. Gas flow through rough microchannels in the transition flow regime. Phys. Rev. E 2016, 93, 013128. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.P.; Zhang, C.B.; Shi, M.H.; Peterson, G.P. Slip boundary for fluid flow at rough solid surfaces. Appl. Phys. Lett. 2012, 100, 1–4. [Google Scholar] [CrossRef]

- Chen, Y.P.; Zhang, C.B.; Shi, M.H.; Wu, J.F. Three-dimensional numerical simulation of heat and fluid flow in noncircular microchannel heat sinks. Int. Commun. Heat Mass Transf. 2009, 36, 917–920. [Google Scholar] [CrossRef]

- Wu, J.F.; Shi, M.H.; Chen, Y.P.; Li, X. Visualization study of steam condensation in wide rectangular silicon microchannels. Int. J. Therm. Sci. 2010, 49, 922–930. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Shi, M. Dynamic performance analysis on start-up of closed-loop pulsating heat pipes (CLPHPS). Int. J. Therm. Sci. 2013, 65, 224–233. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C.; Shi, M.; Yang, Y. Thermal and hydrodynamic characteristics of constructal tree-shaped minichannel heat sink. AIChE J. 2010, 56, 2018–2029. [Google Scholar] [CrossRef]

- Karniadakis, G.E.; Beskok, A.; Aluru, N. Microflows and Nanoflows: Fundamentals and Simulation; Springer: New York, NY, USA, 2005. [Google Scholar]

- Tison, S.A. Experimental data and theoretical modeling of gas flows through metal capillary leaks. Vacuum 1993, 44, 1171–1175. [Google Scholar] [CrossRef]

- Loyalka, S.K.; Hamoodi, S.A. Poiseuille flow of a rarefied gas in a cylindrical tube: Solution of linearized boltzmann equation. Phys. Fluids A 1990, 2, 2061–2065. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, Y.; Liu, Y.; Li, B.; Tang, Y.; Chen, S. Application of polyimide in innertial confinement fusion targets. J. Funct. Mater. 2007, 38, 1678–1682. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, C.; Wu, S.; Yang, W. Theoretical Investigation of Gas Filling and Leaking in Inertial Confinement Fusion Hohlraum. Sustainability 2018, 10, 3763. https://doi.org/10.3390/su10103763

Yu C, Wu S, Yang W. Theoretical Investigation of Gas Filling and Leaking in Inertial Confinement Fusion Hohlraum. Sustainability. 2018; 10(10):3763. https://doi.org/10.3390/su10103763

Chicago/Turabian StyleYu, Cheng, Suchen Wu, and Weibo Yang. 2018. "Theoretical Investigation of Gas Filling and Leaking in Inertial Confinement Fusion Hohlraum" Sustainability 10, no. 10: 3763. https://doi.org/10.3390/su10103763