Experimental Study on Full-Scale Beams Made by Reinforced Alkali Activated Concrete Undergoing Flexure

Abstract

:1. Introduction

2. Materials and Methods

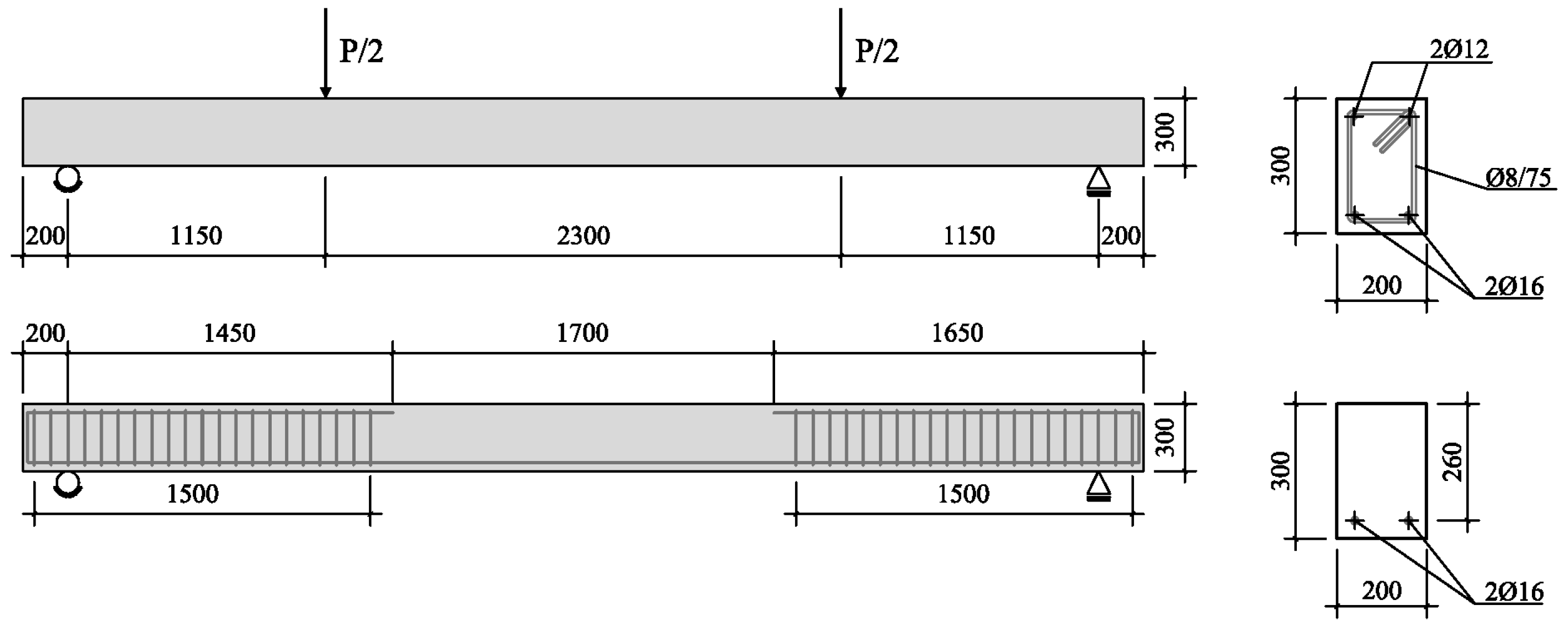

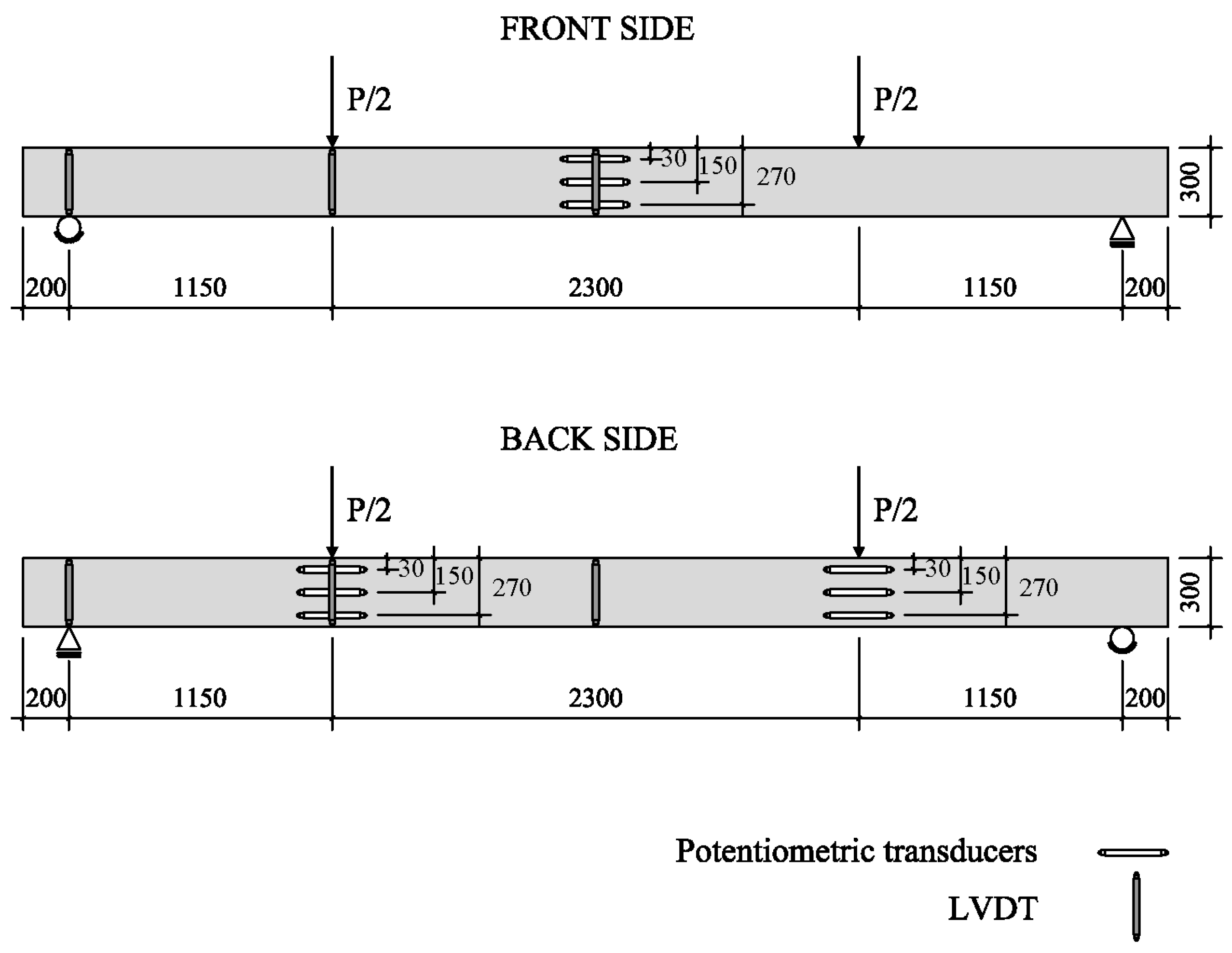

2.1. Specimens Geometry

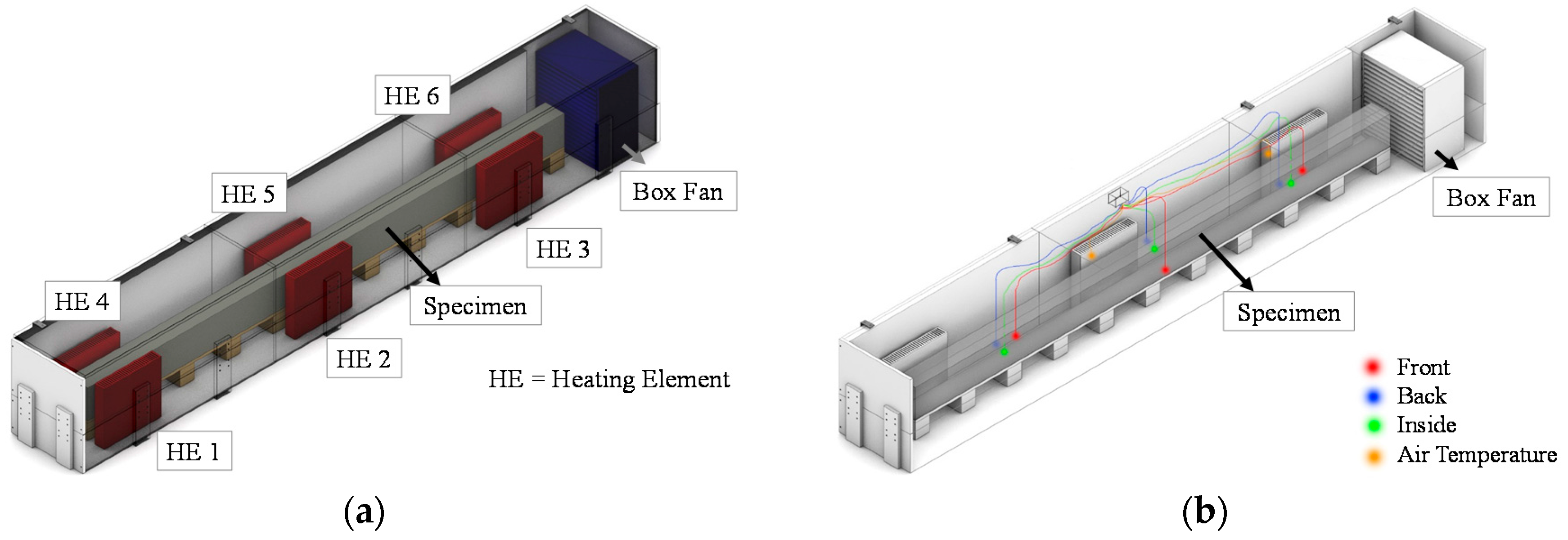

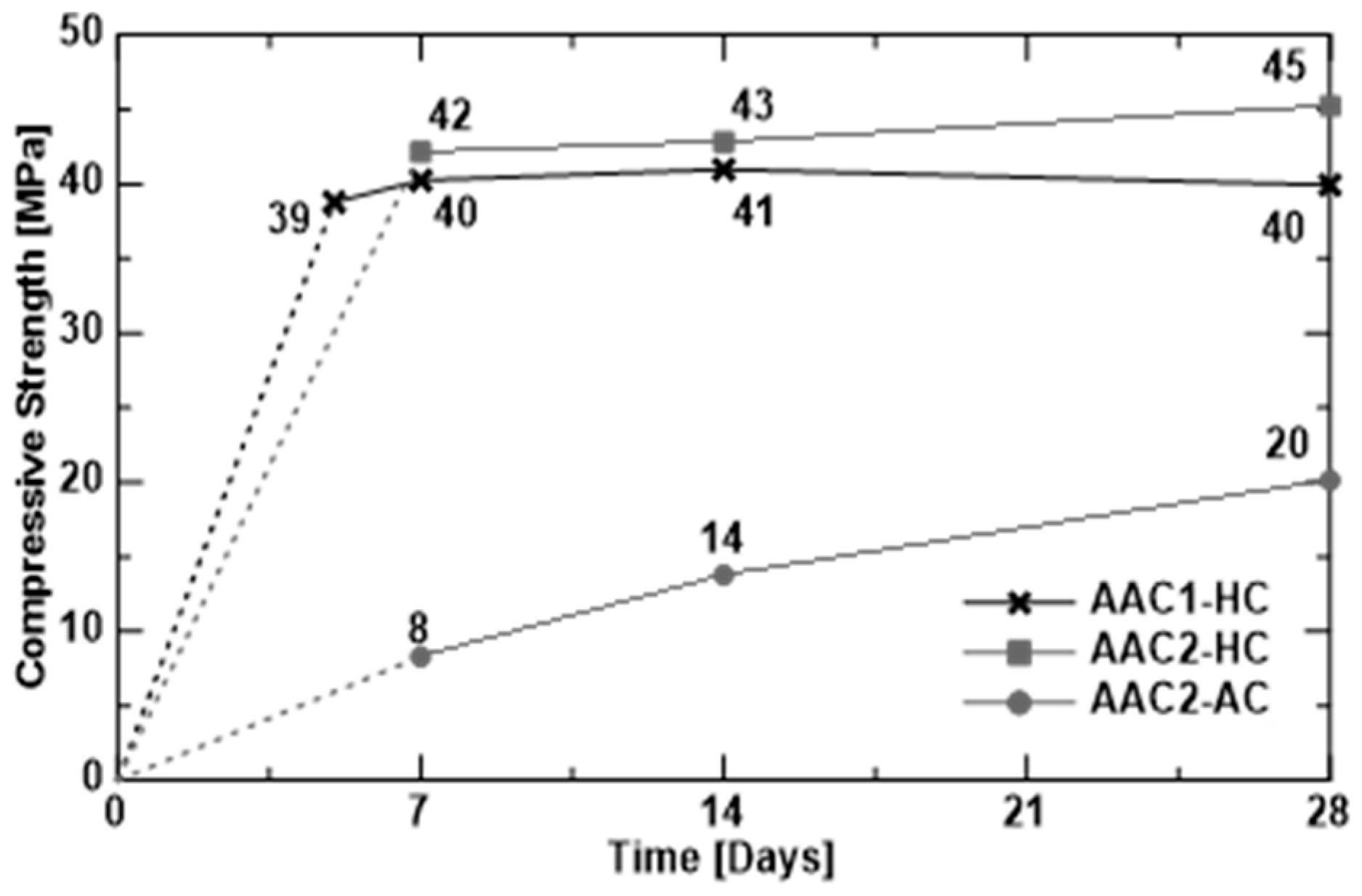

2.2. Material Properties and Curing Conditions

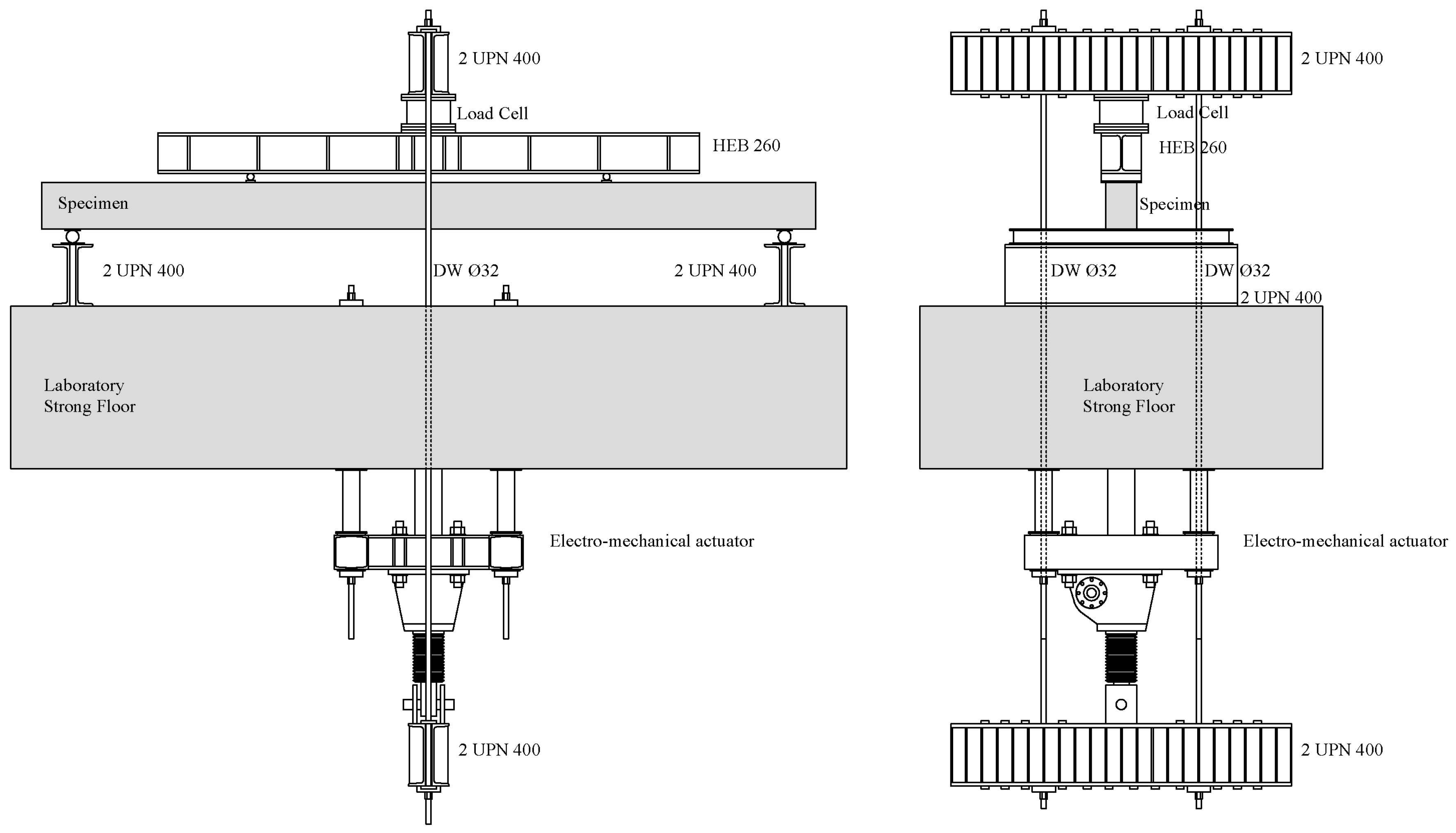

2.3. Test Setup and Investigation

3. Results and Discussion

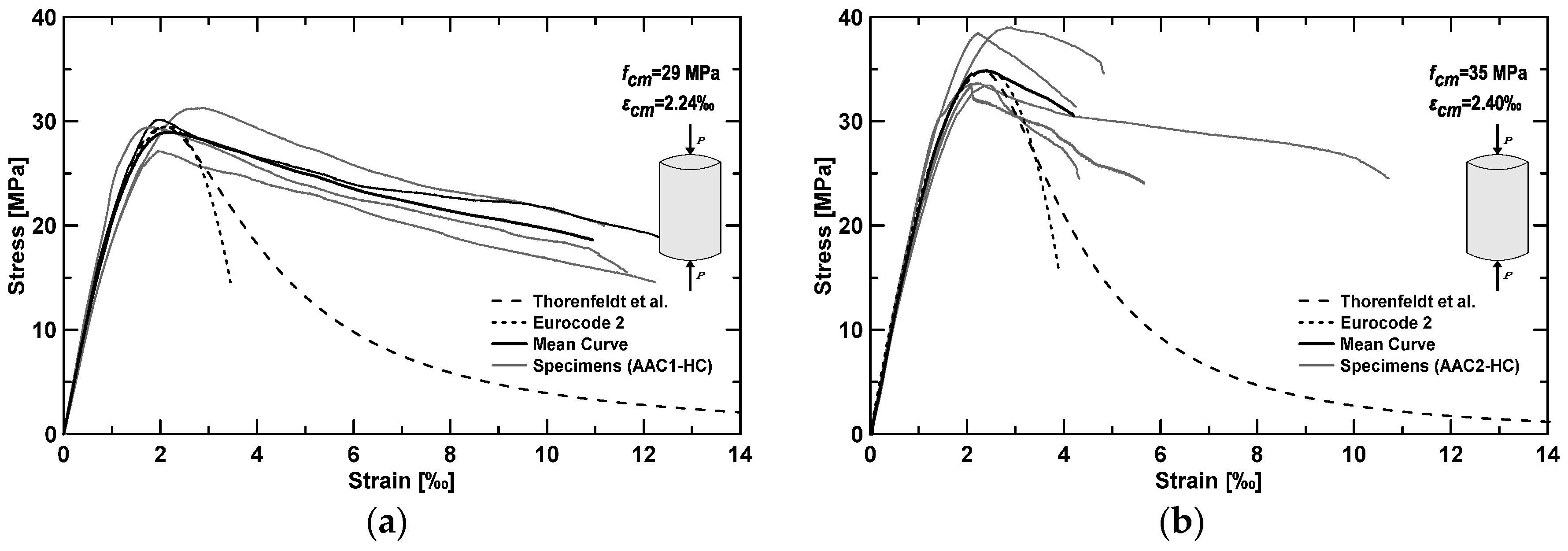

3.1. Modulus of Elasticity and Compression Tests

- fcm = peak stress;

- εcm = strain corresponding at peak stress;

- n = 0.8 + (fcm/17);

- k = 0.67 + (fcm/62), if εc/εcm > 1; and

- k = 1, if εc/εcm ≤ 1;

- fcm = peak stress;

- η = εc/εcm;

- εcm = strain corresponding at peak stress; and

- k = 1.05 Ecm|εcm|/fcm.

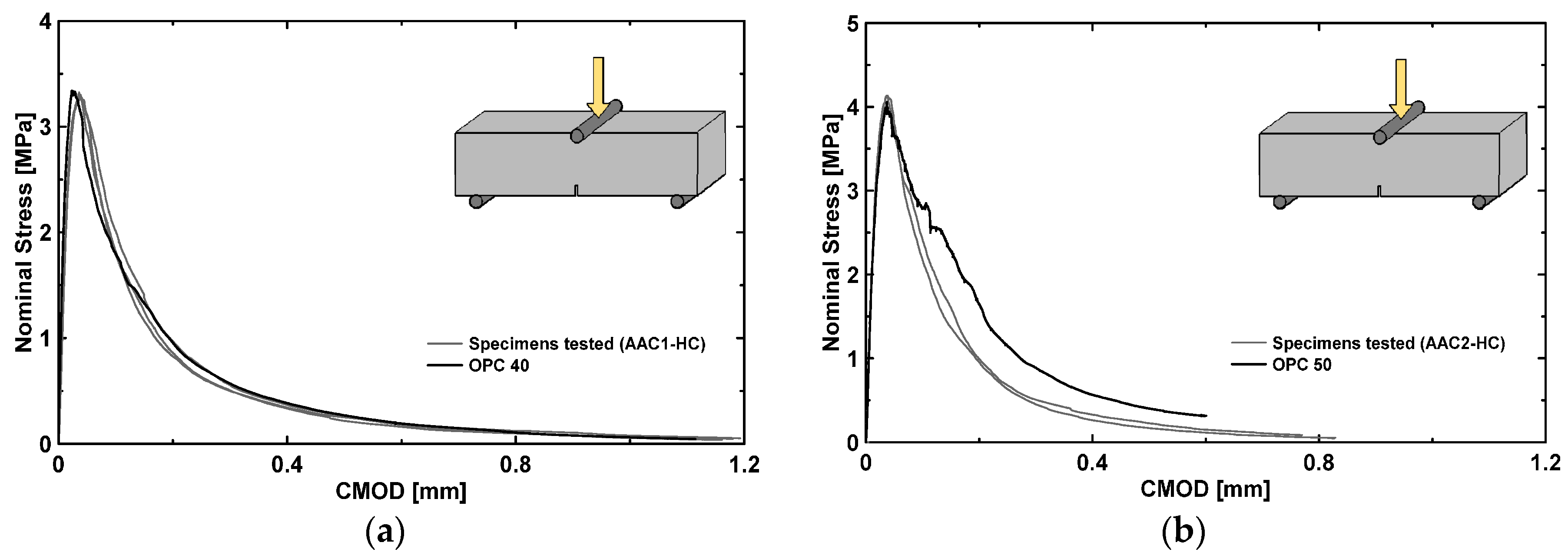

3.2. Material Flexural Behavior (MOR Tests)

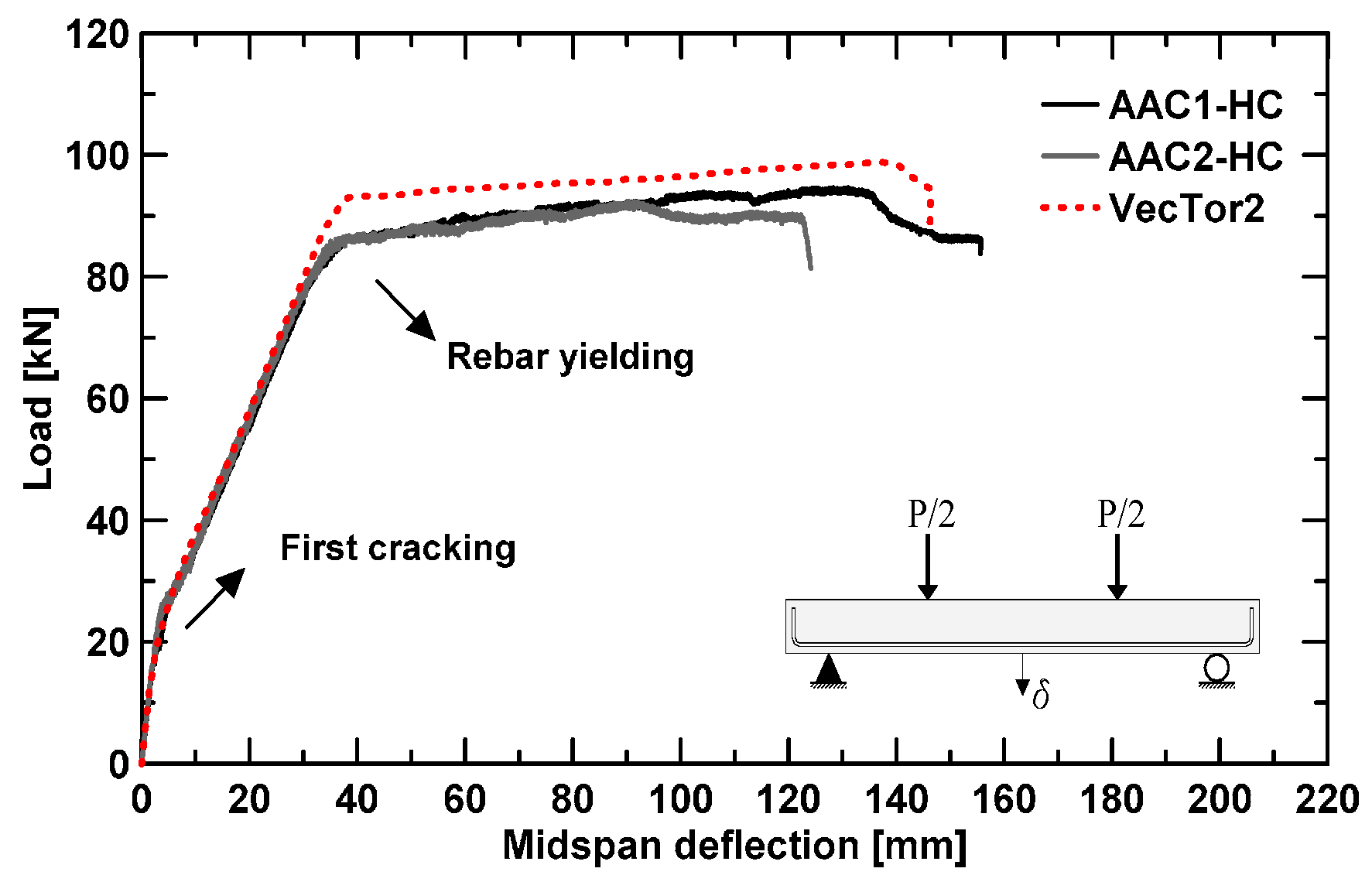

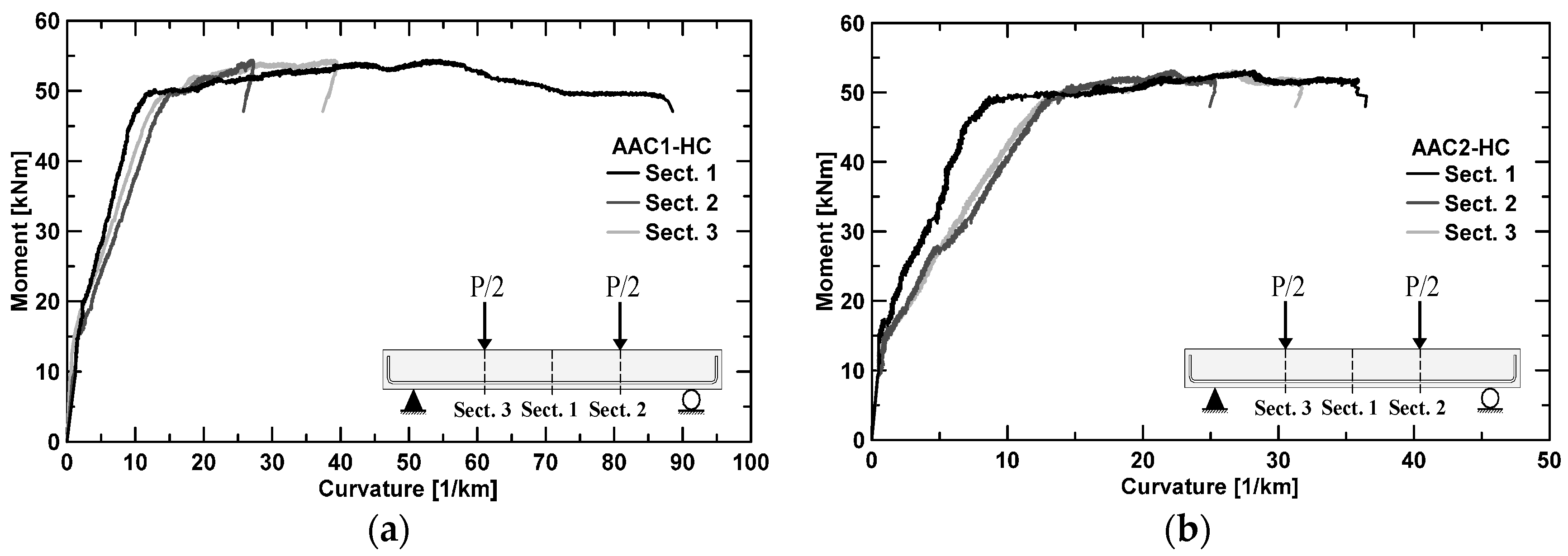

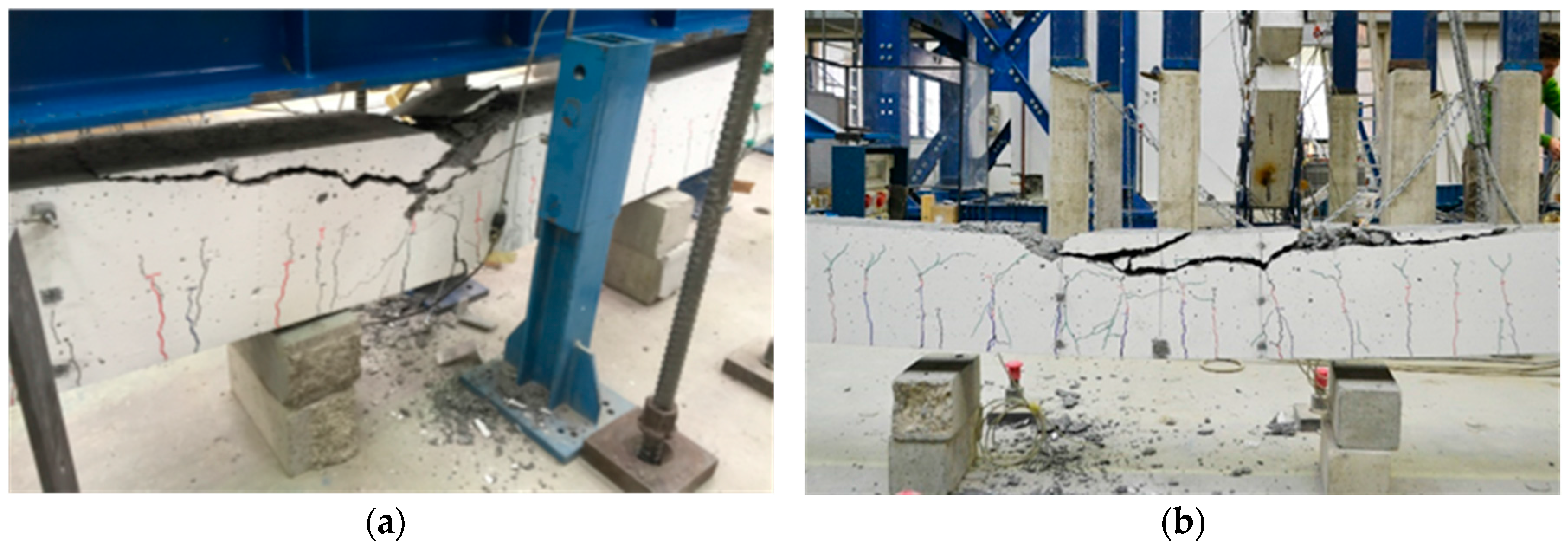

3.3. Structural Response

- d = effective depth (260 mm);

- As = longitudinal reinforcement (402 mm2);

- fy = steel yield strengths (546 MPa); and

- a = shear span (1150 mm).

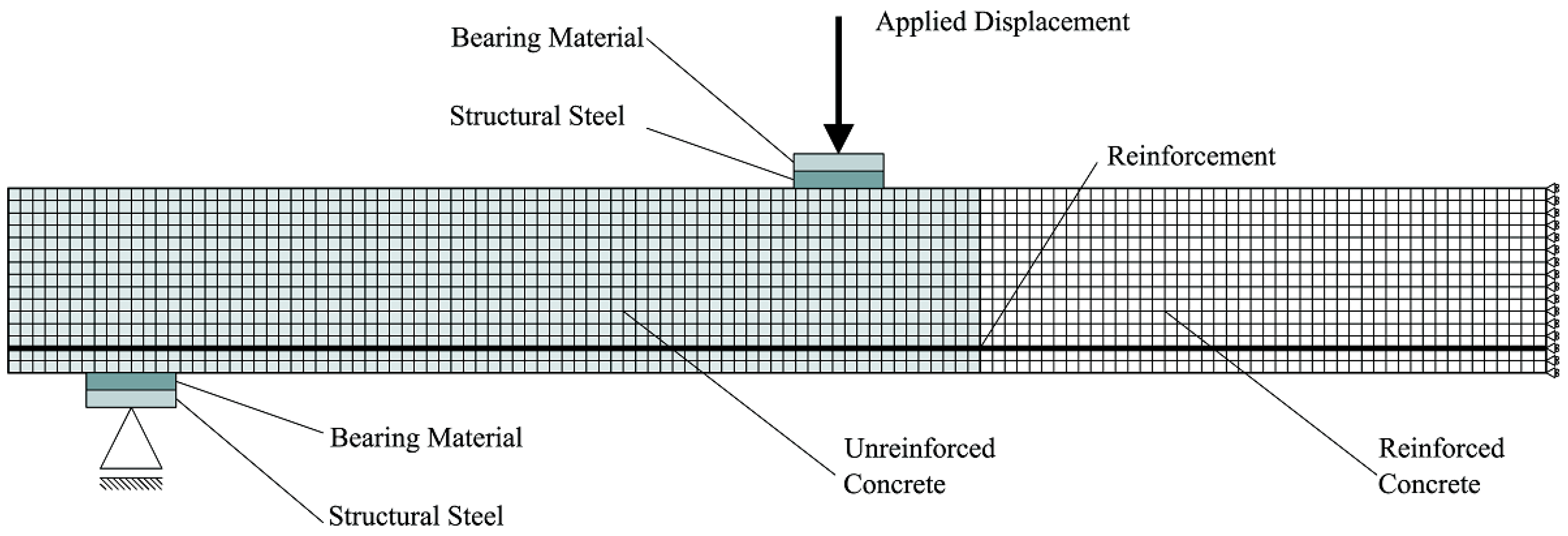

3.4. Numerical Analyses

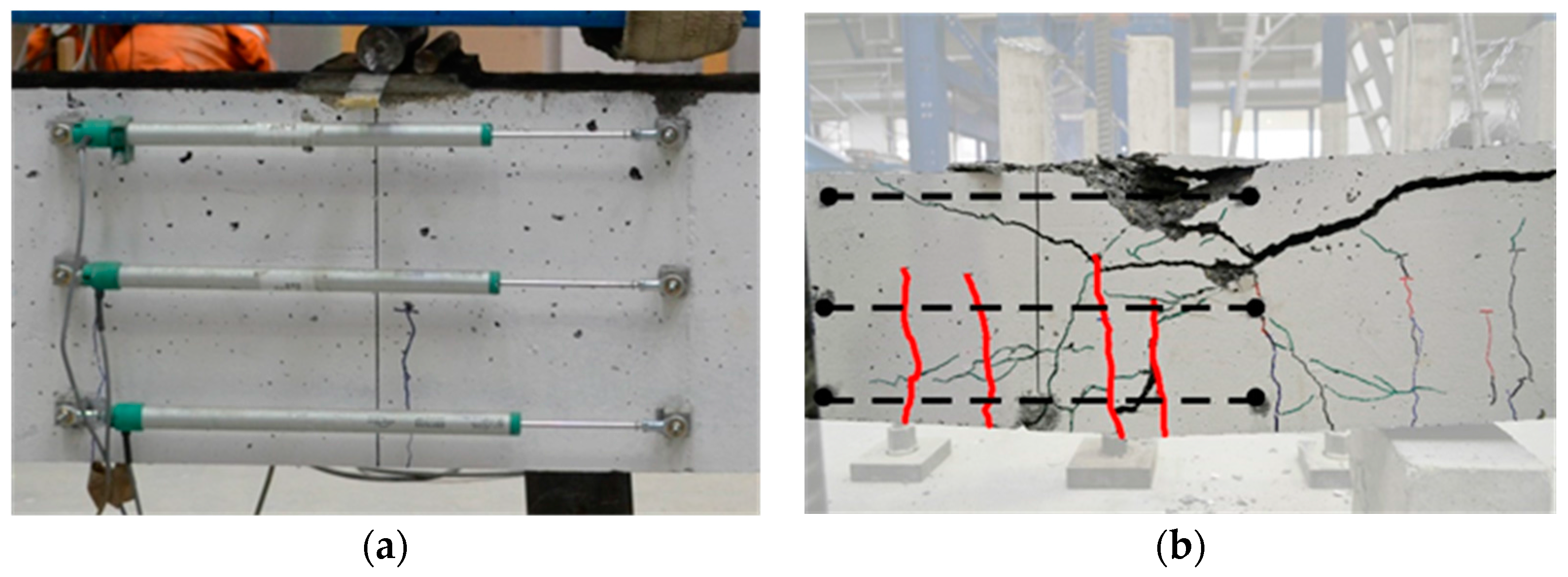

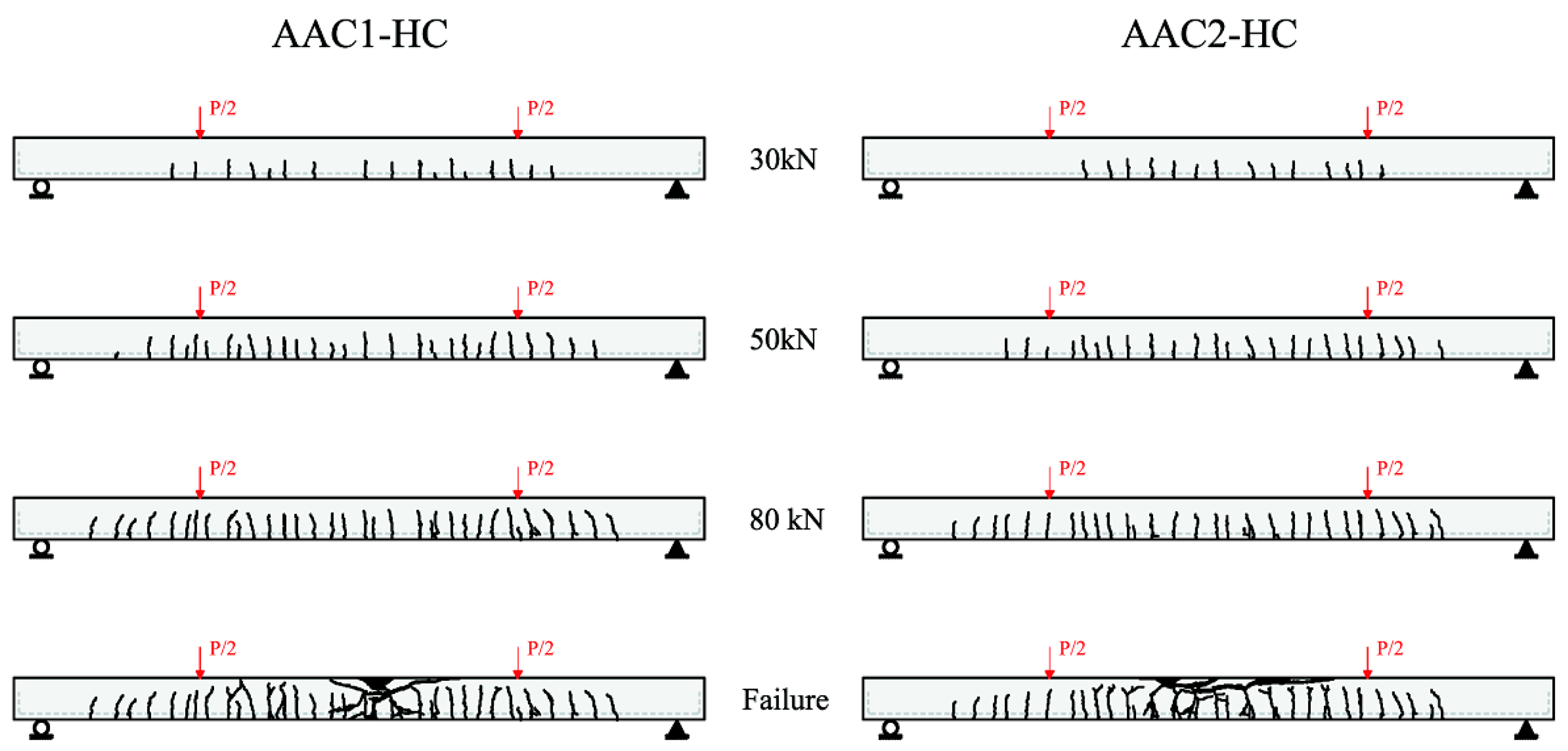

3.5. Crack Pattern

- c = concrete clear cover;

- s = distance between longitudinal reinforcement bars;

- k1 = coefficient regarding bond between bars and concrete (k1 = 0.4)

- k2 = coefficient regarding stress distribution in the cross section (k2 = 0.125);

- Ф = longitudinal reinforcement bars diameter; and

- ρeff = effective reinforcement ratio.

4. Conclusions

- (1)

- Due to heat process, no increase in compressive strength over time (between 7 and 28 days) was noticed.

- (2)

- MOR tests, besides the peak strength, pointed out a rather brittle behavior in tension of the AAC herein considered, coincident to OPC.

- (3)

- Experimental Young’s modulus resulted around 20% lower than OPC concrete, which might be due to the use of a 10 mm maximum aggregate size in the mix design.

- (4)

- Constitutive law in compression was found to have a trend similar to analytical formulas proposed for OPC only in the pre-peak response. On the contrary, in the post-peak response, AAC presented rather higher ductility, in contrast with other authors.

- (5)

- Despite a difference in testing time, flexural behavior of full-scale beams did not show significant differences in terms of the overall response, uncracked and cracked-elastic parameters, yielding and ultimate load.

- (6)

- The overall behavior under flexure (cracking formation and development included) was seen to be similar to an ordinary reinforced beam made of OPC concrete, showing failure due to concrete crushing after rebar yielding.

- (7)

- The preliminary nonlinear finite element analyses performed, using a set of equations describing the linear and nonlinear phenomena of classical OPC reinforced concrete elements, gave a rather good modeling of the AAC tested beams, promoting the utilization of these already available tools for further analyses able to improve the structural understanding of ACC members.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- The Cement Sustainable Initiative. Report from WBCSD: Business Solution for a Sustainable World. Available online: http://www.wbcsd.org/Pages/EDocument/EDocumentDetails.aspx?ID=11133&NoSearchContextKey=true (accessed on 23 August 2016).

- Malhotra, V.M. Introduction: Sustainable Development and Concrete Technology. ACI Concr. J. 2002, 24, 1147–1165. [Google Scholar]

- Mahasenan, N.; Smith, S.; Humphreys, K. The cement industry and global climate change: Current and potential future cement industry CO2 emissions. In Proceedings of the 6th International Conference on Greenhouse Gas Control Technologies, Kyoto, Japan, 1–4 October 2002; Gale, J., Kaya, Y., Eds.; Volume II, pp. 995–1000.

- Purdon, A.O. The action of alkalis on blast furnace slag. J. Soc. Chem. Ind. 1940, 59, 191–202. [Google Scholar]

- Glukhovsky, V.D. Gruntosilikaty (Soil Silicates); Gosstroyizdat: Kiev, Ukraine, 1959. [Google Scholar]

- Davidovits, J. Solid-Phase Synthesis of a Mineral Blockpolymer by Low Temperature Polycondensation of Alumino-Silicate Polymers: Na-poly(sialate) or Na-PS and Characteristics. In Proceedings of the IUPAC Symposium on Long-Term Properties of Polymers and Polymeric Materials, Stockholm, Sweden, 30 August–1 September 1976.

- Vora, P.R.; Dave, U.V. Parametric studies on compressive strength of geopolymer concrete. Procedia Eng. 2013, 51, 210–219. [Google Scholar] [CrossRef]

- Rangan, B.V. Geopolymer concrete for environmental protection. Indian Concr. J. 2014, 88, 41–58. [Google Scholar]

- Hardjito, D.; Rangan, B.V. Development and Properties of Low-Calcium Fly Ash Based Geopolymer Concrete; Research Report GC-1; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2005. [Google Scholar]

- Fernandez-Jimenez, A.M.; Palomo, A.; Lopez-Hombrados, C. Engineering properties of alkali-activated fly ash concrete. ACI Mater. J. 2006, 103, 106–112. [Google Scholar]

- Sofi, M.; Van Deventer, J.S.J.; Mendis, P.A.; Lukey, G.C. Engineering properties of inorganic polymer concretes (IPCs). Cem. Concr. Res. 2007, 37, 251–257. [Google Scholar] [CrossRef]

- Yost, J.R.; Radlinska, A.; Ernst, S.; Salera, M. Structural behavior of alkali activated fly ash concrete. Part 1: Mixture design, material properties and sample fabrication. Mater. Struct. 2013, 46, 435–447. [Google Scholar] [CrossRef]

- Sarker, P.K. Analysis of geopolymer concrete columns. Mater. Struct. 2009, 42, 715–724. [Google Scholar] [CrossRef]

- Popovics, S. A numerical approach to the complete stress–strain curve of concrete. Cem. Concr. Res. 1979, 3, 583–599. [Google Scholar] [CrossRef]

- Sarker, P.K. Bond strength of reinforcing steel embedded in fly ash-based geopolymer concrete. Mater. Struct. 2011, 44, 1021–1030. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On the development of fly ash-based geopolymer concrete. ACI Mater. J. Am. Concr. Inst. 2004, 101, 467–472. [Google Scholar]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Puertas, F.; Palomo, A.; Fernández-Jiménez, A.; Izquierdo, J.; Granizo, M. Effect of superplasticisers on the behaviour and properties of alkaline cements. Adv. Cem. Res. 2003, 15, 23–28. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J. Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Mater. Des. 2014, 57, 667–672. [Google Scholar] [CrossRef]

- Yost, J.R.; Radlinska, A.; Ernst, S.; Salera, M. Structural behavior of alkali activated fly ash concrete. Part 2: Structural testing and experimental findings. Mater. Struct. 2013, 46, 449–462. [Google Scholar] [CrossRef]

- Sumajouw, D.M.J.; Rangan, B.V. Low Calcium Fly Ash Based Geopolymer Concrete: Reinforced Beams and Columns; Research Report GC-3; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2006. [Google Scholar]

- Sumajouw, D.M.J.; Hardjito, D.; Wallah, S.; Rangan, B.V. Behavior of Geopolymer Concrete Columns under Equal Load Eccentricities; American Concrete Institute: Farmington Hills, MI, USA, 2005; pp. 577–594. [Google Scholar]

- Sumajouw, D.M.J.; Hardjito, D.; Wallah, S.; Rangan, B.V. Fly ash-based geopolymer concrete: Study of slender reinforced columns. J. Mater. Sci. 2007, 42, 3124–3130. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). ACI 318-02; Building Code Requirements for Structural Concrete; ACI Committee: Farmington Hills, MI, USA, 2002; p. 318. [Google Scholar]

- Standards Association of Australia. AS3600; Concrete Structures Code; Standards Association of Australia: Sydney, Australia, 2001. [Google Scholar]

- Ng, T.S.; Amin, A.; Foster, S.J. The behaviour of steel-fibre-reinforced geopolymer concrete beams in shear. Mag. Concr. Res. 2013, 65, 308–318. [Google Scholar] [CrossRef]

- UNI 6556-1976. Tests on Concrete: Determination of the Secant Modulus of Elasticity in Compression; UNI-Ente Nazionale Italiano di Unificazion: Milano, Italy, 1976. [Google Scholar]

- EN 14651-5. Precast Concrete Products—Test Method for Metallic Fibre Concrete-Measuring the Flexural Tensile Strength; CEN-European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Davidovits, J. Geopolymer: Chemistry and Applications, 3rd ed.; Geopolymer Institute: Saint Quentin, France, 2011; p. 612. [Google Scholar]

- Davidovits, J.; Izquierdo, M.; Querol, X.; Antennuci, D.; Nugteren, H.; Butselaar-Orthlieb, V.; Fernández-Pereira, C.; Luna, Y. The European Research Project GEOASH: Geopolymer Cement Based On European Coal Fly Ashes. Available online: https://www.geopolymer.org/fichiers_pdf/GEOASH.pdf (accessed on 29 August 2016).

- EN 15630-1. Steel for the Reinforcement and Prestressing of Concrete—Part I: Test Methods; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- Wallah, S.E.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Long-Term Properties; Research Report GC-2; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2006. [Google Scholar]

- NTC2008. Norme Tecniche per le Costruzioni. Decreto Ministeriale 14 Gennaio 2008. Available online: http://www.ingegneriasoft.com/NTC2008_Norme_tecniche_per_le_costruzioni.htm (accessed on 23 August 2016).

- EUROCODE 2. Design of Concrete Structures; EN-1992-1-1; CEN-European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Thorenfeldt, E.; Tomaszewicz, A.; Jensen, J.J. Mechanical properties of high strength concrete and application in design. In Proceedings of the Symposium Utilization of High Strength Concrete, Stravanger, Norway, 15–18 June 1987; Trondheim, T., Ed.; pp. 149–159.

- Wong, P.S.; Vecchio, F.J. VecTor2 and FormWorks User’s Manual; Technical Report of the Department of Civil Engineering; University of Toronto: Toronto, ON, Canada, 2002. [Google Scholar]

- Vecchio, F.J.; Collins, M.P. The Modified Compression Field Theory for Reinforced Concrete Elements Subjected to Shear. ACI J. 1986, 83, 219–231. [Google Scholar]

- Comité Euro-Internationale du Béton. CEB-FIP Model Code-Design Code; Comité Euro-International du Béton, CEB Bulletin d’ Information; Thomas Telford: London, UK, 1978; pp. 124–125. [Google Scholar]

| Component | Al2O3 | SiO2 * | CaO | Fe2O3 | MgO | K2O | Na2O | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | (%) | (%) | (%) | (%) | |

| Percent Composition | 28 | 56 | 2 | 5.5 | 0.2 ÷ 3 | 0.2 ÷ 2 | 0.1 ÷ 0.6 | 0.1 ÷ 1.7 | 0.2 ÷ 2 |

| Parameter Investigated | Best Value |

|---|---|

| Extra water content, kg/m3 | 25–35 |

| Total mixing time, min | 8–10 |

| Rest period, h | 48 |

| Curing time at 60 °C, h | 24 |

| Results Investigated | AAC1-HC | AAC2-HC | VT2 | Comparison AAC1-HC-VT2 (%) | Comparison AAC2-HC-VT2 (%) |

|---|---|---|---|---|---|

| Maximum Load, kN | 95 | 92 | 99 | 4.0 | 7.1 |

| Displacement at maximum load, mm | 131 | 90 | 136 | 3.7 | 33.8 |

| Ultimate displacement, mm | 156 | 123 | 146 | −6.8 | 15.8 |

| Ultimate load, kN | 86 | 88 | 94 | 8.5 | 6.4 |

| Ultimate displacement/span length | 1/29 | 1/37 | 1/32 | −10.3 | 13.5 |

| Yielding displacement, mm | 37 | 38 | 38 | 2.6 | 0.0 |

| Yielding load, kN | 85 | 86 | 93 | 8.6 | 7.5 |

| Ductility | 4.22 | 3.24 | 3.84 | −9.7 | 15.8 |

| Mean crack spacing, mm | 102 | 113 | - | - | - |

| Unreinforced Concrete Parameters | |

| Cylinder compressive Strength f’c | 32 MPa |

| Elastic modulus E | 24.6 GPa |

| Maximum aggregate size | 10 mm |

| Reinforced Concrete Parameters | |

| Cylinder compressive strength f’c | 32 MPa |

| Elastic modulus E | 24.6 GPa |

| Maximum aggregate size | 10 mm |

| Reinforcement direction | 90 deg |

| Reinforcement ratio | 0.67% |

| Transverse reinforcement yield strength fy | 545 MPa |

| Transverse reinforcement ultimate strength fu | 649 MPa |

| Transverse reinforcement elastic modulus Es | 206 GPa |

| Transverse reinforcement strain hardening εsh | 7 millistrain |

| Transverse reinforcement ultimate strain εu | 100 millistrain |

| Longitudinal Steel Reinforcement Parameters | |

| Yield Strength fy | 545 MPa |

| Ultimate Strength fu | 649 MPa |

| Elastic Modulus Es | 206 GPa |

| Strain Hardening εsh | 7 millistrain |

| Ultimate Strain εu | 100 millistrain |

| Bearing Material Parameters | |

| Direction | 90° to the horizontal |

| Structural Steel Parameters | |

| Yield Strength fy | 500 MPa |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monfardini, L.; Minelli, F. Experimental Study on Full-Scale Beams Made by Reinforced Alkali Activated Concrete Undergoing Flexure. Materials 2016, 9, 739. https://doi.org/10.3390/ma9090739

Monfardini L, Minelli F. Experimental Study on Full-Scale Beams Made by Reinforced Alkali Activated Concrete Undergoing Flexure. Materials. 2016; 9(9):739. https://doi.org/10.3390/ma9090739

Chicago/Turabian StyleMonfardini, Linda, and Fausto Minelli. 2016. "Experimental Study on Full-Scale Beams Made by Reinforced Alkali Activated Concrete Undergoing Flexure" Materials 9, no. 9: 739. https://doi.org/10.3390/ma9090739