Doping Effect of Graphene Nanoplatelets on Electrical Insulation Properties of Polyethylene: From Macroscopic to Molecular Scale

Abstract

:1. Introduction

2. Experimental Works

2.1. Samples Preparation

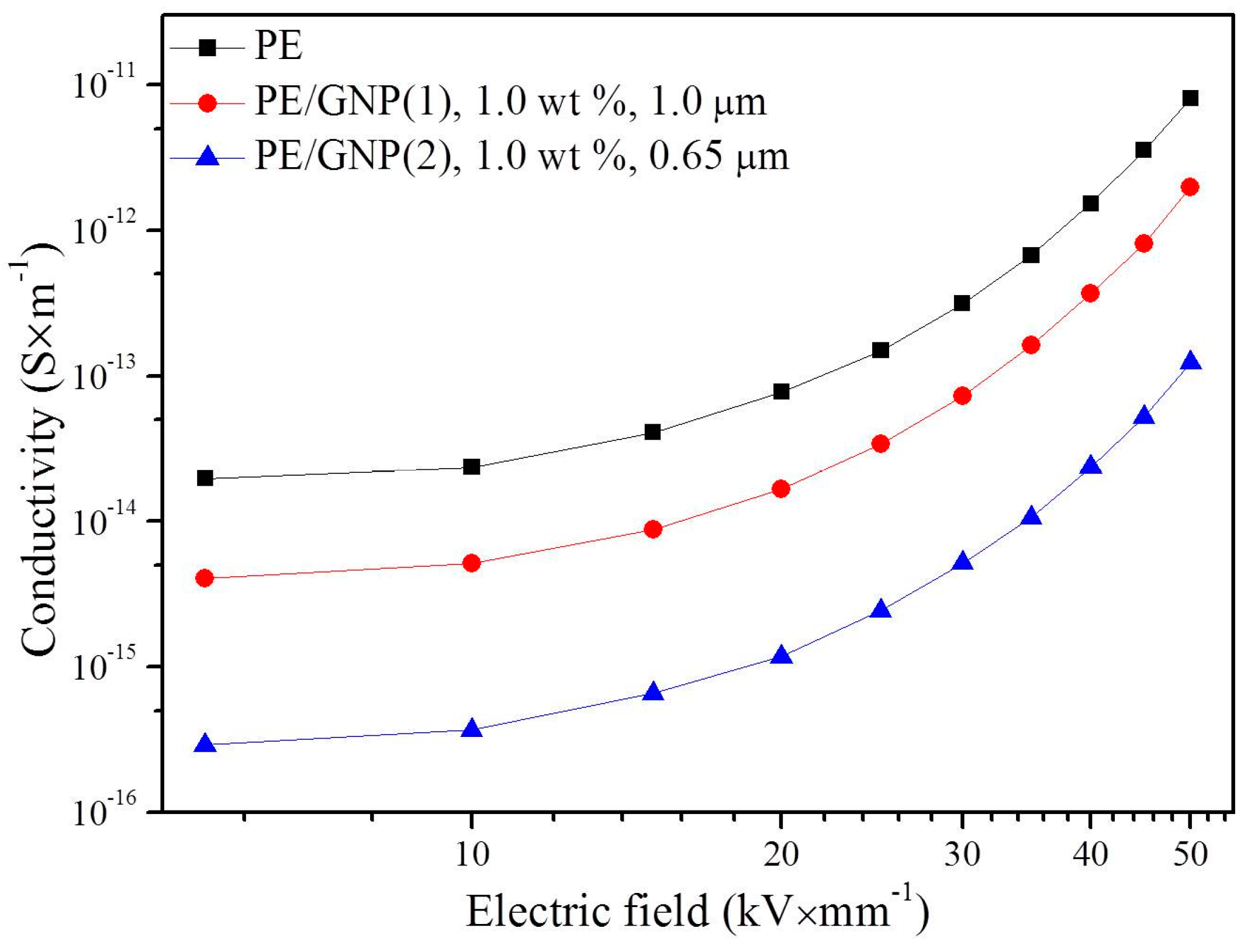

2.2. Conduction Characteristic Test

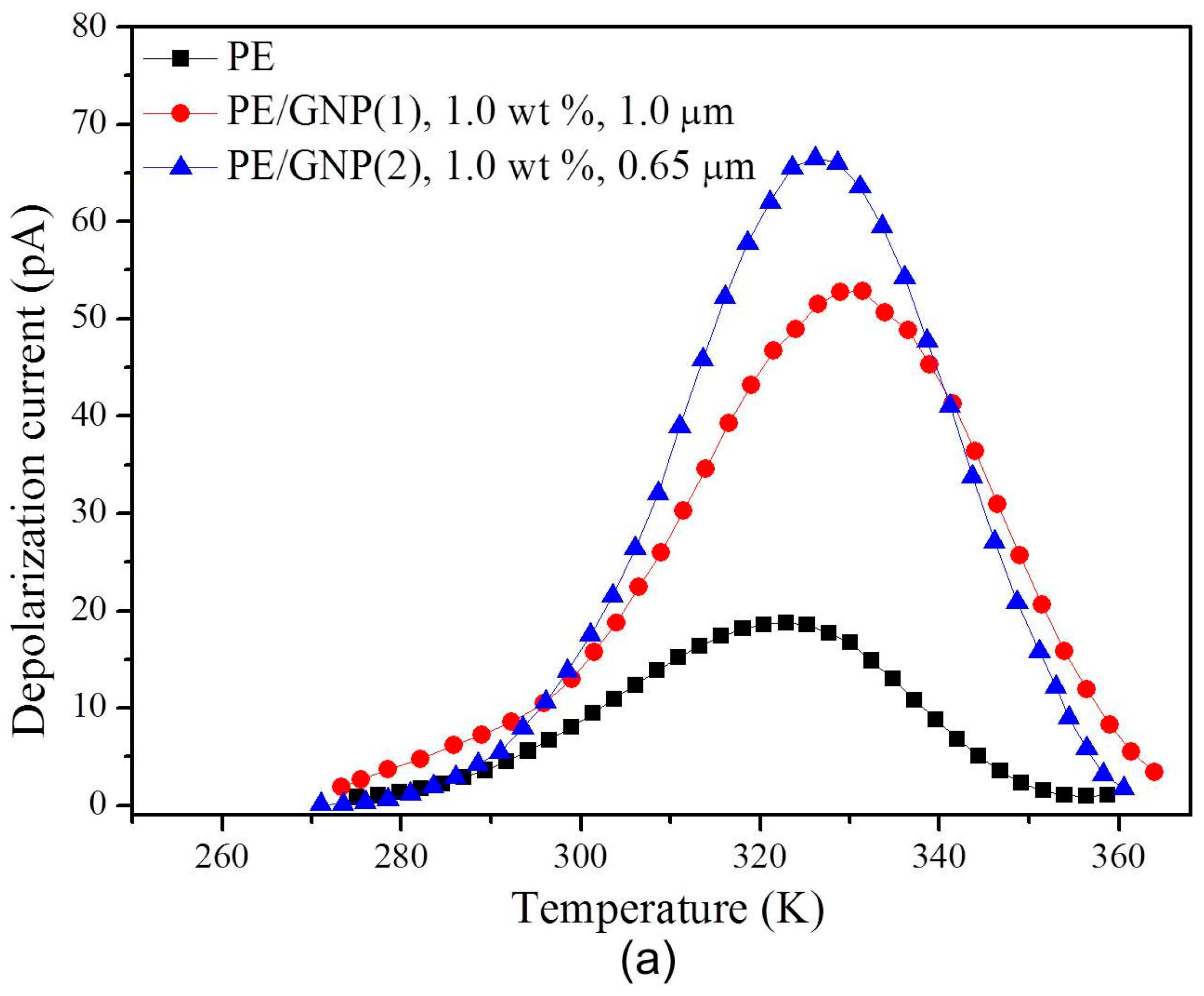

2.3. Electron Trap Characteristic Test

2.4. Results and Discussion

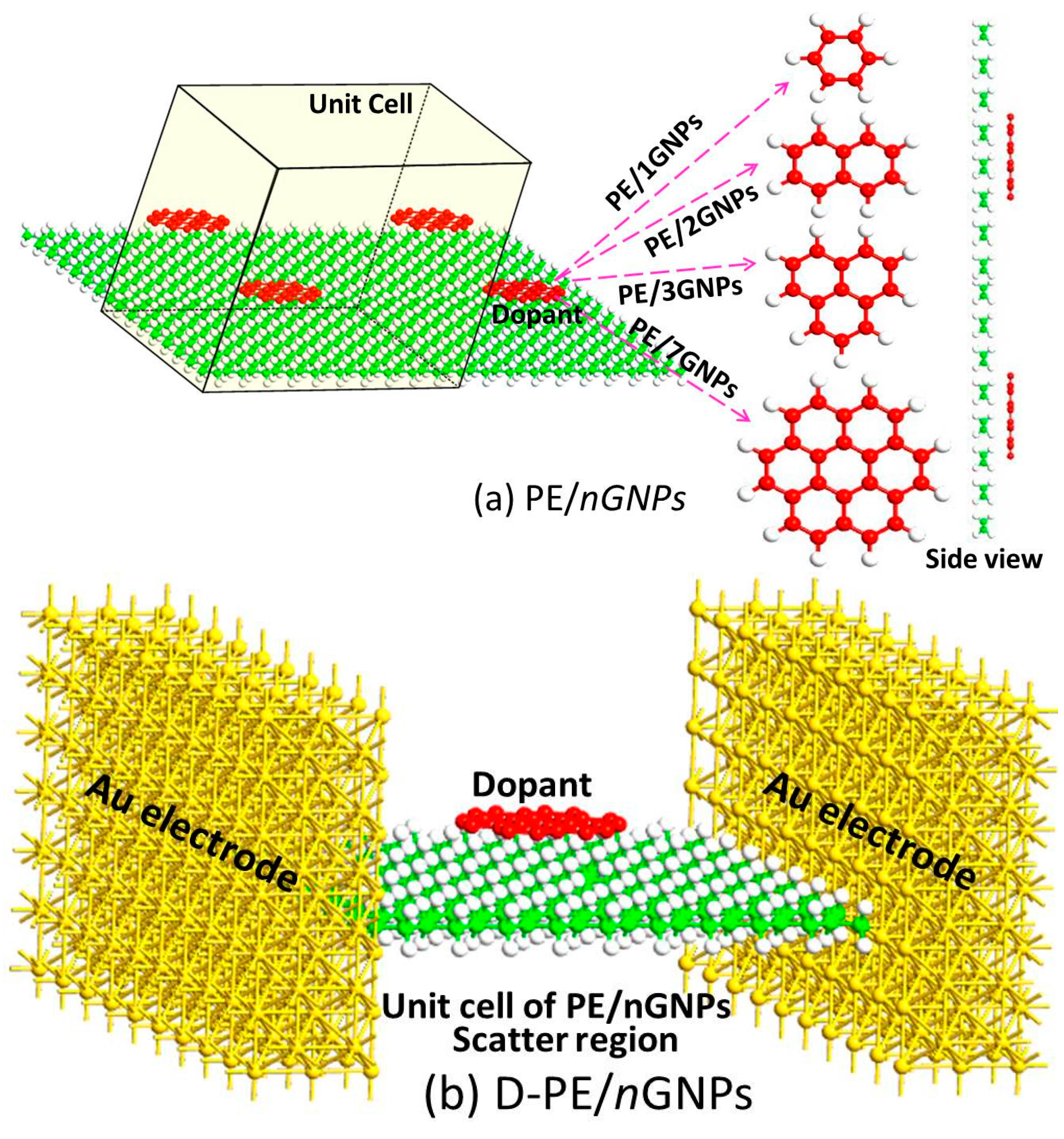

3. Theoretical Works

3.1. Electronic Structure Calculation

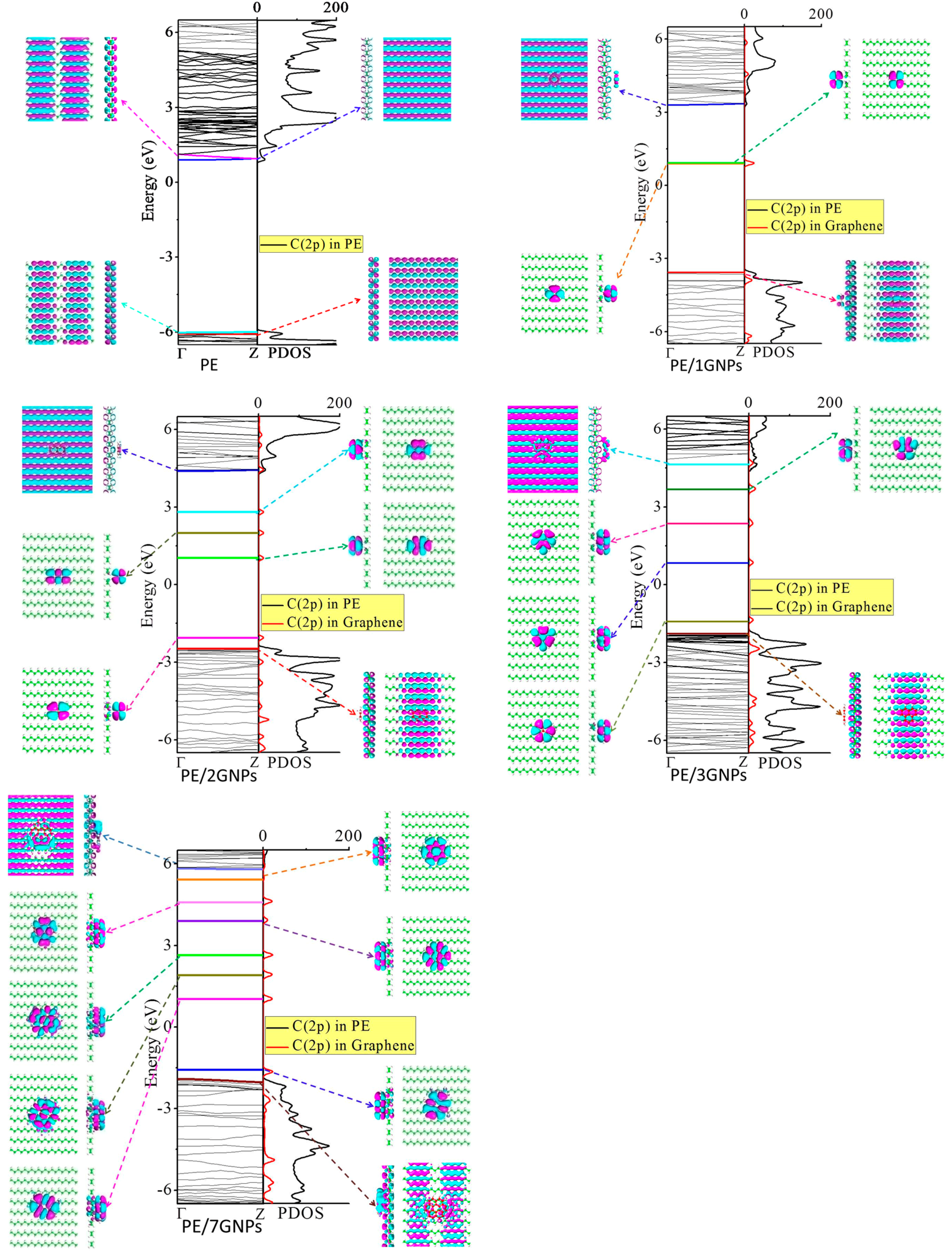

3.2. Electronic Structure

3.3. Transport Property Calculation

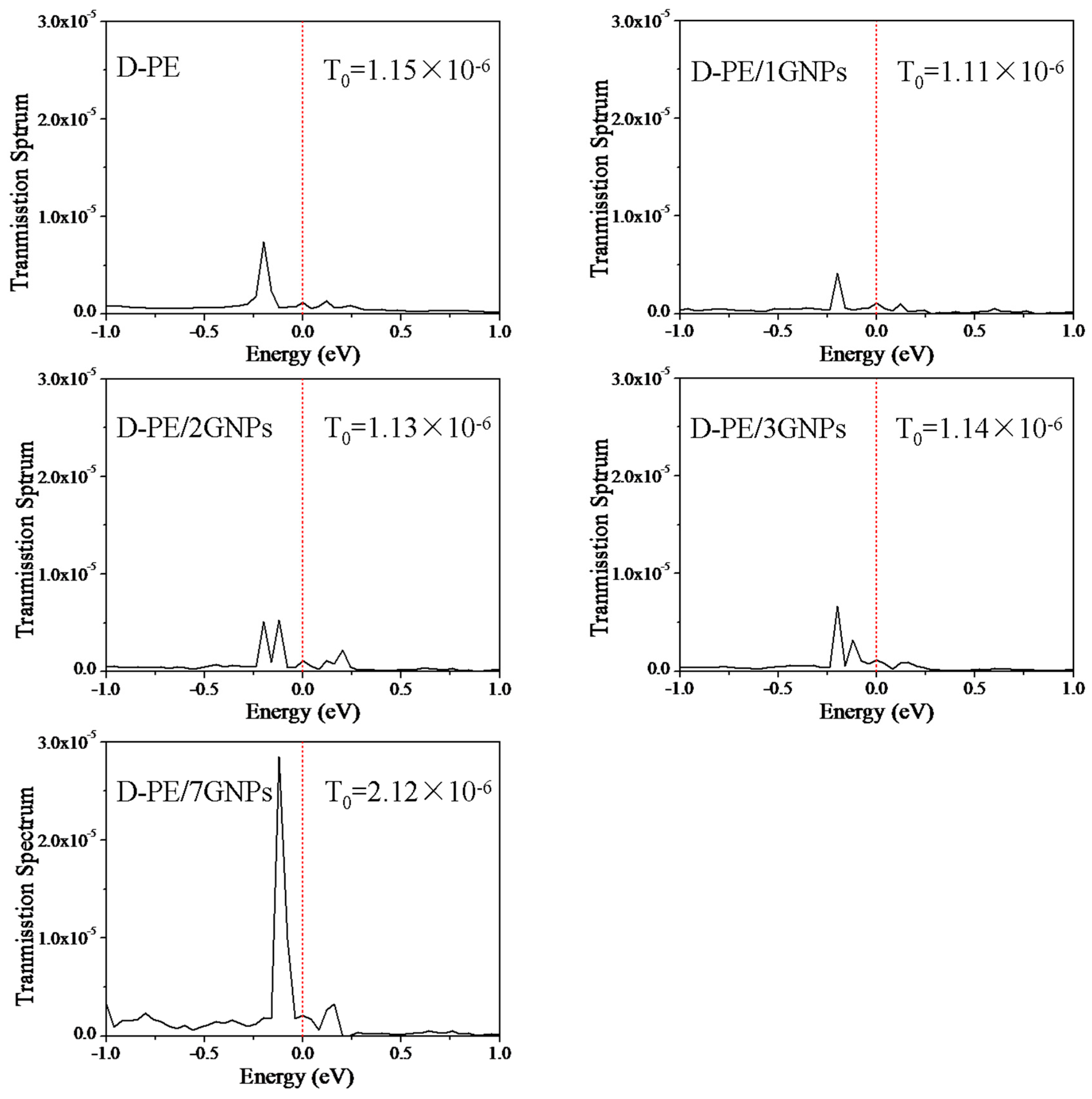

3.4. Transport Property

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Teyssedre, G.; Laurent, C. Advances in high-field insulating polymeric materials over the past 50 years. IEEE Electr. Insul. Mag. 2013, 29, 26–36. [Google Scholar] [CrossRef]

- Teyssedre, G.; Laurent, C.; Montanari, G.C.; Campus, A.; Nilsson, U.H. From LDPE to XLPE: Investigating the change of electrical properties. Part II. Luminescence. IEEE. Trans. Dielectr. Electr. Insul. 2005, 12, 447–454. [Google Scholar] [CrossRef]

- Iida, K.; Kim, J.S.; Nakamura, S.; Sawa, G. Effects of molecular structure on electrical conduction in low-density polyethylene above its melting point. IEEE Trans. Electr. Insul. 1992, 27, 391–398. [Google Scholar] [CrossRef]

- Suh, K.S.; Lee, C.R.; Noh, J.S.; Tanaka, J.; Damon, D.H. Electrical conduction in polyethylene with semiconductive electrodes. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 224–230. [Google Scholar] [CrossRef]

- Pelissou, S.; St-Onge, H.; Wertheimer, M.R. Electrical conduction of polyethylene below and above its melting point. IEEE Trans. Dielectr. Electr. Insul. 1988, 23, 325–333. [Google Scholar] [CrossRef]

- Hosier, I.L.; Vaughan, A.S.; Swingler, S.G. Structure–property relationships in polyethylene blends: The effect of morphology on electrical breakdown strength. J. Mater. Sci. 1997, 32, 4523–4531. [Google Scholar] [CrossRef]

- Perlman, M.; Kumar, A.; Coelho, R.; Aladenize, B. Steady-state conduction in linear low-density polyethylene with Poole-lowered trap depth. IEEE Trans. Electr. Insul. 1990, 25, 419–425. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, G.; Liao, R.; Xu, Z. Charge trapping and detrapping in polymeric materials: Trapping parameters. J. Appl. Phys. 2011, 110, 3626468. [Google Scholar] [CrossRef]

- Wang, S.J.; Zha, J.W.; Li, W.K.; Dang, Z.M. Distinctive electrical properties in sandwich-structured Al2O3/low density polyethylene nanocomposites. Appl. Phys. Lett. 2016, 108, 031605. [Google Scholar] [CrossRef]

- Tian, F.; Lei, Q.; Wang, X.; Wang, Y. Investigation of electrical properties of LDPE/ZnO nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 763–769. [Google Scholar] [CrossRef]

- Chen, J.; Yin, Y.; Li, Z.; Xiao, D.M. Electrical prestressing of high-electric-field conduction in composite of low-density polyethylene/nano-SiOx. Jpn. J. Appl. Phys. 2005, 44, 940–947. [Google Scholar] [CrossRef]

- Chodak, I.; Krupa, I. “Percolation effect” and mechanical behavior of carbon black filled polyethylene. J. Mater. Sci. Lett. 1999, 18, 1457–1459. [Google Scholar] [CrossRef]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. A Route for Polymer Nanocomposites with Engineered Electrical Conductivity and Percolation Threshold. Materials 2010, 3, 1089–1103. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, P.; Xie, L. Ferroelectric polymer/silver nanocomposites with high dielectric constant and high thermal conductivity. Appl. Phys. Lett. 2009, 95, 242901. [Google Scholar] [CrossRef]

- Chen, G.; Fu, M.; Liu, X.Z.; Zhong, L.S. Ac aging and space-charge characteristics in low-density polyethylene polymeric insulation. J. Appl. Phys. 2005, 97, 083713. [Google Scholar] [CrossRef]

- Li, S.T.; Zhao, N.; Nie, Y.; Wang, X.; Chen, G. Space charge characteristics of LDPE nanocomposite/LDPE insulation system. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 92–100. [Google Scholar] [CrossRef]

- Montanari, G.C.; Mazzanti, G.; Palmieri, F.; Motori, A.; Perego, G. Space-charge trapping and conduction in LDPE, HDPE and XLPE. J. Phys. D Appl. Phys. 2001, 34, 2902–2911. [Google Scholar] [CrossRef]

- An, Z.; Liu, C.; Chen, X.; Zheng, F.; Zhang, Y. Correlation between space charge accumulation in polyethylene and its fluorinated surface layer characteristics. J. Phys. D Appl. Phys. 2011, 45, 35302. [Google Scholar] [CrossRef]

- Tanaka, Y.; Li, Y.; Takada, T.; Ikeda, M. Space charge distribution in low-density polyethylene with charge-injection suppression layers. J. Phys. D Appl. Phys. 1998, 28, 1232–1238. [Google Scholar] [CrossRef]

- Fleming, R.J.; Pawlowski, T.; Ammala, A.; Casey, P.S. Electrical conductivity and space charge in LDPE containing TiO2 nanoparticles. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 745–753. [Google Scholar] [CrossRef]

- Yang, J.; Liu, C.; Zheng, C.; Zhao, H.; Wang, X.; Gao, M. Effects of interfacial charge on the DC dielectric properties of nanocomposites. J. Nanomater. 2016, 5, 1–11. [Google Scholar] [CrossRef]

- Tian, F.; Lei, Q.; Wang, X.; Wang, Y. Effect of deep trapping states on space charge suppression in polyethylene/ZnO nanocomposite. Appl. Phys. Lett. 2011, 99, 142903. [Google Scholar] [CrossRef]

- Ishimoto, K.; Kanegae, E.; Ohki, Y.; Tanaka, T.; Sekiguchi, Y. Superiority of dielectric properties of LDPE/MgO nanocomposites over microcomposites. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1735–1742. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Nam, H.K.; Saswata, B.; Joong, H.L. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Kim, H.; Kobayashi, S.; Abdurrahim, M.A.; Minglun, J.Z.; Albina, K.; Marc, A.H.; Ahmed, A.A.; Christopher, W.M. Graphene/polyethylene nanocomposites: Effect of polyethylene functionalization and blending methods. Polymer 2011, 52, 1837–1846. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Mishra, A.K. Effect of functionalized graphene on the physical properties of linear low density polyethylene nanocomposites. Polym. Test. 2012, 31, 31–38. [Google Scholar] [CrossRef]

- Montanari, B.; Jones, R.O. Density functional study of crystalline polyethylene. Chem. Phys. Lett. 1997, 272, 347–352. [Google Scholar] [CrossRef]

- Righi, M.C.; Scandolo, S.; Serra, S.; Larlori, S.; Tosatti, E. Surface states and negative electron affinity in polyethylene. Phys. Rev. Lett. 2001, 87, 076802. [Google Scholar] [CrossRef] [PubMed]

- Huzayyin, A.; Boggs, S.; Ramprasad, R. Density functional analysis of chemical impurities in dielectric polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 926–930. [Google Scholar] [CrossRef]

- Meunier, M.; Quirke, N. Molecular modeling of electron trapping in polymer insulators. J. Chem. Phys. 2000, 113, 369–376. [Google Scholar] [CrossRef]

- Meunier, M.; Quirke, N.; Aslanides, A. Molecular modeling of electron traps in polymer insulators: Chemical defects and impurities. J. Chem. Phys. 2001, 115, 2876–2881. [Google Scholar] [CrossRef]

- Anta, J.A.; Marcelli, G.; Meunier, M.; Quirke, N. Models of electron trapping and transport in polyethylene: Current–voltage characteristics. J. Appl. Phys. 2002, 92, 1002–1008. [Google Scholar] [CrossRef]

- XG Sciences, USA. Available online: www.xgsciences.us/index.html (accessed on 18 April 2016).

- Peng, S.; He, J.; Hu, J.; Huang, X.; Jiang, P. Influence of functionalized MgO nanoparticles on electrical properties of polyethylene nanocomposites. IEEE. Trans. Dielectr. Electr. Insul. 2015, 22, 1512–1519. [Google Scholar] [CrossRef]

- Tian, F.; Yao, J.; Li, P.; Wang, Y.; Wu, M.; Lei, Q. Stepwise electric field induced charging current and its correlation with space charge formation in LDPE/ZnO nanocomposite. IEEE. Trans. Dielectr. Electr. Insul. 2015, 22, 1232–1239. [Google Scholar] [CrossRef]

- Han, B.; Wang, X.; Sun, Z.; Yang, J.; Lei, Q. Space charge suppression induced by deep traps in polyethylene/zeolite nanocomposite. Appl. Phys. Lett. 2013, 102, 012902. [Google Scholar] [CrossRef]

- Lei, Q.; Tian, F.; Yang, C.; He, L.; Wang, Y. Modified isothermal discharge current theory and its application in the determination of trap level distribution in polyimide films. J. Electrost. 2010, 68, 243–248. [Google Scholar]

- Tian, F.; Bu, W.; Shi, L.; Yang, C.; Wang, Y. Theory of modified thermally stimulated current and direct determination of trap level distribution. J. Electrost. 2011, 69, 7–10. [Google Scholar] [CrossRef]

- Ieda, M. Electrical conduction and carrier traps in polymeric materials. IEEE Trans. Dielectr. Electr. Insul. 1984, 19, 162–178. [Google Scholar] [CrossRef]

- Nelson, J.K. Dielectric Polymer Nanocomposites; Springer: New York, NY, USA, 2010. [Google Scholar]

- Taylor, J.; Guo, H.; Wang, J. Ab Initio Modeling of Quantum Transport Properties of Molecular Electronic Devices. Phys. Rev. B Condens. Matter Mater. Phys. 2001, 63, 245407. [Google Scholar] [CrossRef]

- Brandbyge, M.; Mozos, J.L.; Ordejón, P.; Taylor, J.; Stokbro, K. Density-Functional Method for Nonequilibrium Electron Transport. Phys. Rev. B Condens. Matter Mater. Phys. 2002, 65, 165401. [Google Scholar] [CrossRef]

- Soler, J.M.; Artacho, E.; Gale, J.D.; Garcia, A.; Junquera, J.; Ordejon, P.; Sanchez-Portal, D. The SISTA method for Ab Initio Order-N Materials Simulation. J. Phys. Condens. Matter 2002, 14, 2745–2779. [Google Scholar] [CrossRef]

- ATK, Version 13.8, Atomistix a/s. 2013. Available online: www.quantumwise.com (accessed on 15 June 2015).

- Serra, S.; Tosatti, E.; Iarlori, S.; Scandolo, S.; Santoro, G. Interchain electron states in polyethylene. Phys. Rev. B 2000, 62, 4389–4393. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, Z.; Li, C.; Zhao, H.; Zhang, G.; Han, B. Doping Effect of Graphene Nanoplatelets on Electrical Insulation Properties of Polyethylene: From Macroscopic to Molecular Scale. Materials 2016, 9, 680. https://doi.org/10.3390/ma9080680

Jing Z, Li C, Zhao H, Zhang G, Han B. Doping Effect of Graphene Nanoplatelets on Electrical Insulation Properties of Polyethylene: From Macroscopic to Molecular Scale. Materials. 2016; 9(8):680. https://doi.org/10.3390/ma9080680

Chicago/Turabian StyleJing, Ziang, Changming Li, Hong Zhao, Guiling Zhang, and Baozhong Han. 2016. "Doping Effect of Graphene Nanoplatelets on Electrical Insulation Properties of Polyethylene: From Macroscopic to Molecular Scale" Materials 9, no. 8: 680. https://doi.org/10.3390/ma9080680

APA StyleJing, Z., Li, C., Zhao, H., Zhang, G., & Han, B. (2016). Doping Effect of Graphene Nanoplatelets on Electrical Insulation Properties of Polyethylene: From Macroscopic to Molecular Scale. Materials, 9(8), 680. https://doi.org/10.3390/ma9080680