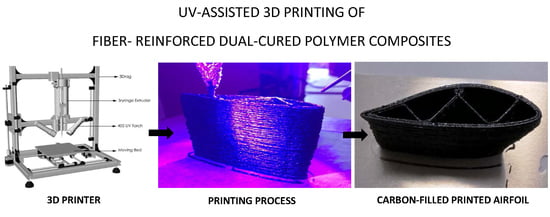

UV-Assisted 3D Printing of Glass and Carbon Fiber-Reinforced Dual-Cure Polymer Composites

Abstract

:1. Introduction

2. Results and Discussion

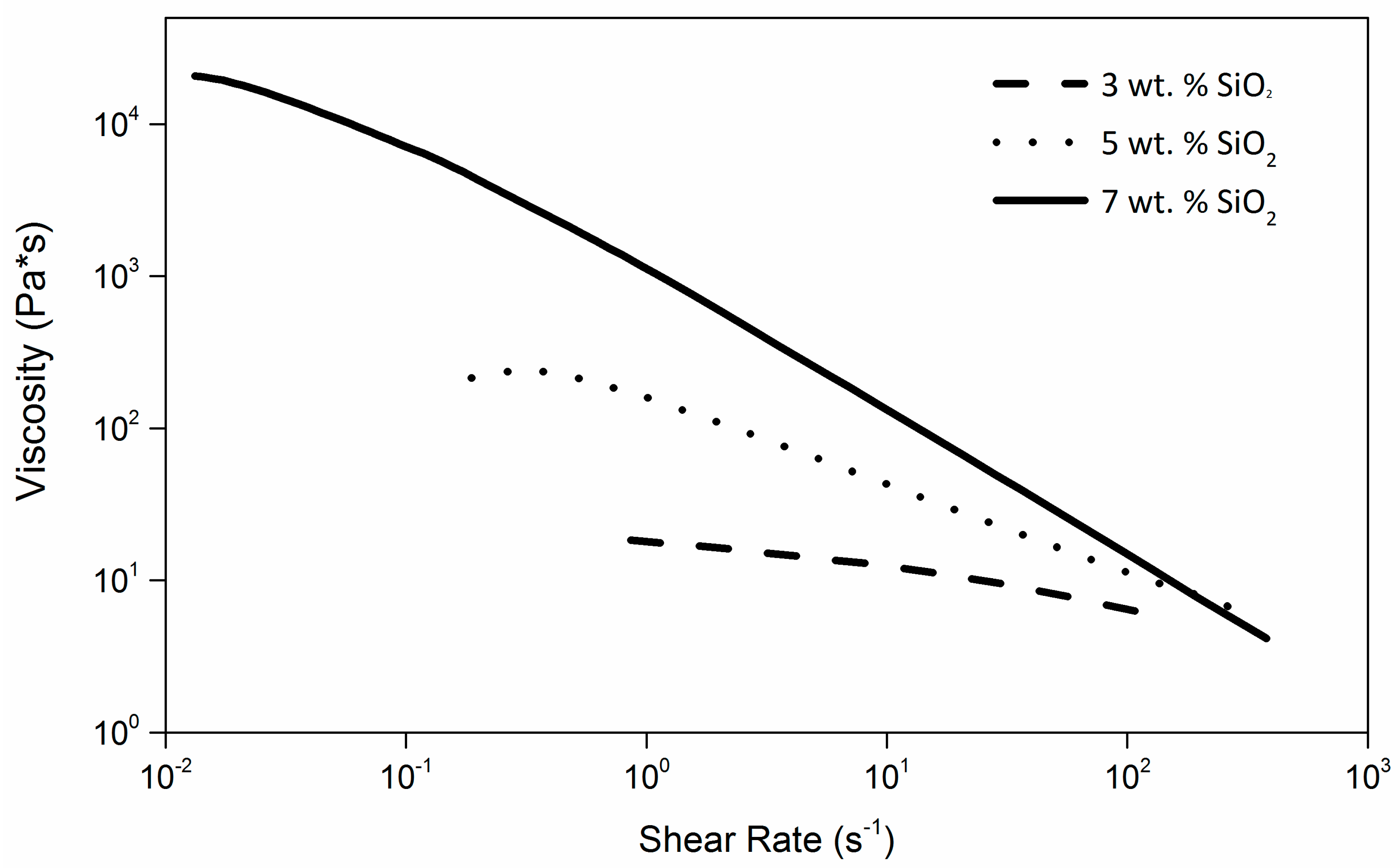

2.1. Rheological Characterization of the Composite Inks

2.2. Dynamic Mechanical Analysis (DMA)

2.3. Differential Scanning Calorimetry (DSC)

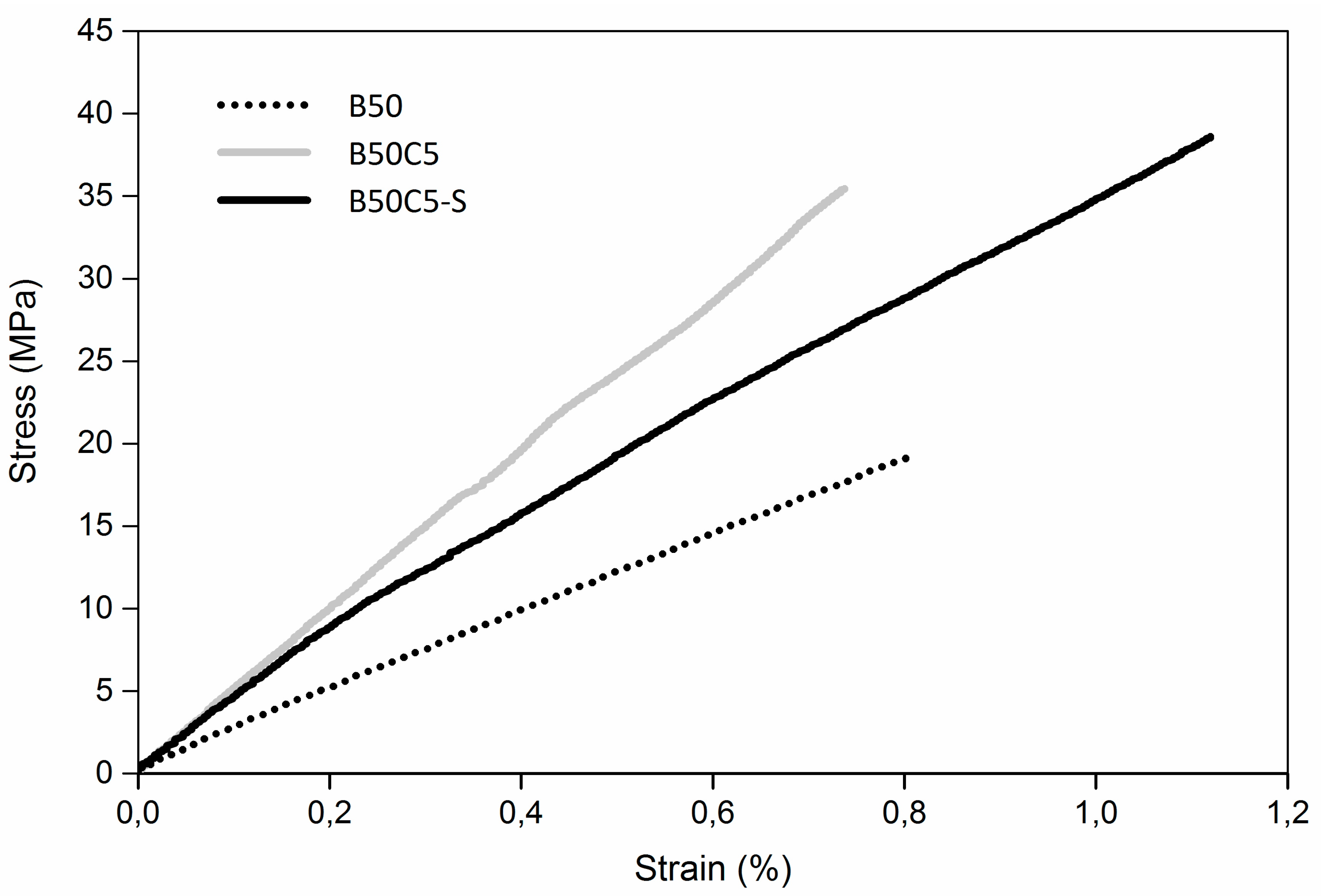

2.4. Uniaxial Tensile Tests

2.5. Scanning Electron Microscopy (SEM)

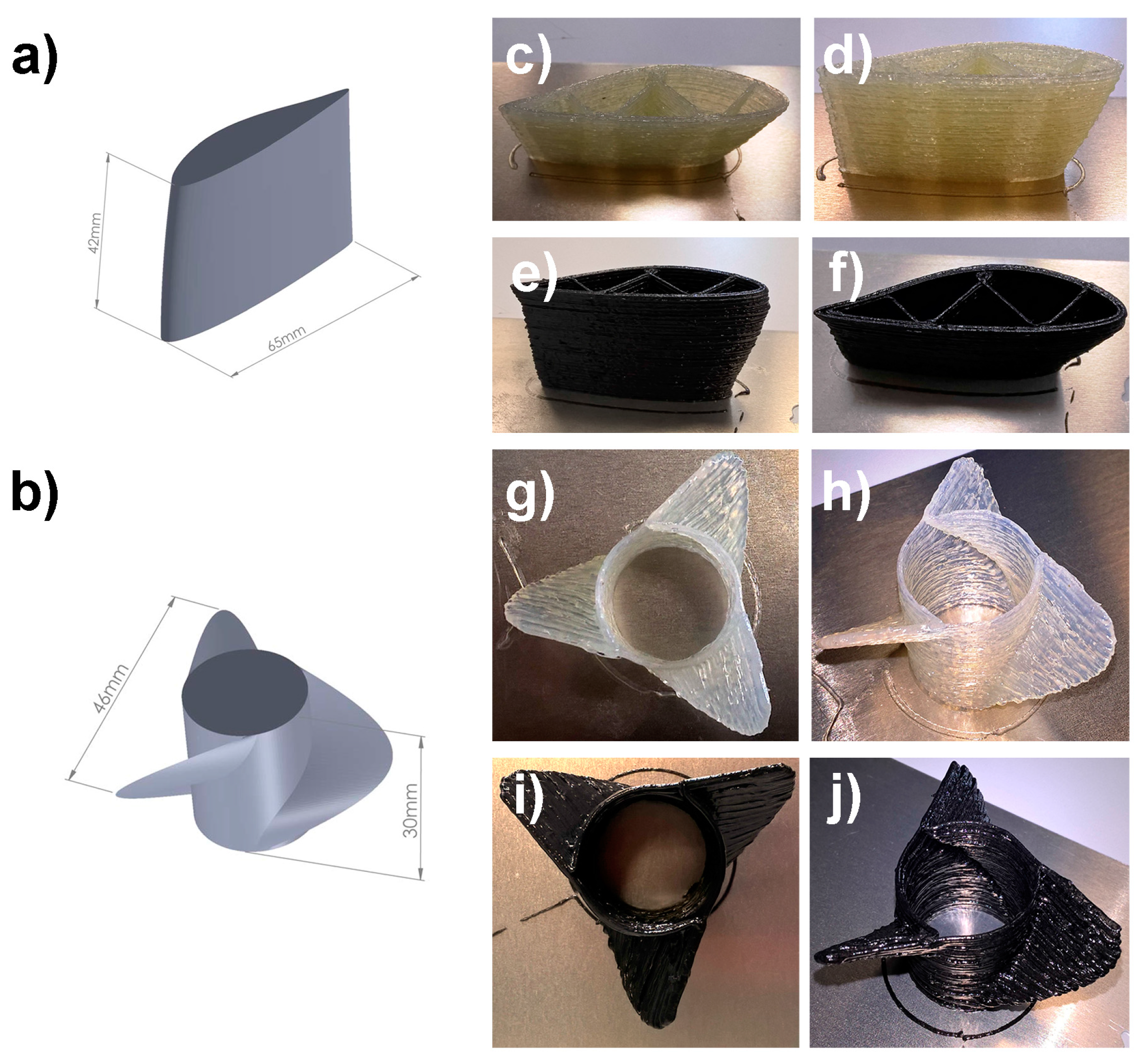

2.6. UV-3D Printing Tests

3. Experimental

3.1. Materials

3.2. Preparation of the Composite Inks and 3D Printing

3.3. Rheological Characterization of the Composite Inks

3.4. Dynamic Mechanical Analysis (DMA)

3.5. Differential Scanning Calorimetry (DSC)

3.6. Uniaxial Tensile Tests

3.7. Scanning Electron Microscopy (SEM)

4. Conclusions

Supplementary Materials

Author Contributions

Conflicts of Interest

References

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer Science: New York, NY, USA, 2010; pp. 1–16. [Google Scholar]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Bandyopadhyay, A.; Bose, S. Additive Manufacturing, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016; pp. 28–32. [Google Scholar]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Farahani, R.D.; Dubé, M.; Therriault, D. Three-Dimensional Printing of Multifunctional Nanocomposites: Manufacturing Techniques and Applications. Adv. Mater. 2016. [CrossRef] [PubMed]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos. Part A 2015, 76, 110–114. [Google Scholar] [CrossRef]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. UV-assisted three-dimensional printing of polymer nanocomposites based on inorganic fillers. Polym. Compos. 2015. [CrossRef]

- Lebel, L.L.; Aissa, B.; El Khakani, M.A.; Therriault, D. Ultraviolet-assisted direct-write fabrication of carbon nanotube/polymer nanocomposite microcoils. Adv. Mater. 2010, 22, 592. [Google Scholar] [CrossRef] [PubMed]

- Farahani, R.D.; Dalir, H.; Le Borgne, V.; Gautier, L.A.; El Khakani, M.A.; Lévesque, M.; Therriault, D. Direct-write fabrication of freestanding nanocomposite strain sensors. Nanotechnology 2012, 23, 085502. [Google Scholar] [CrossRef] [PubMed]

- Aissa, B.; Therriault, D.; Farahani, R.D.; Lebel, L.; El Khakani, M.A. Electrical transport properties of single wall carbon nanotube/polyurethane composite based field effect transistors fabricated by UV-assisted direct-writing technology. Nanotechnology 2012, 23, 115705. [Google Scholar] [CrossRef] [PubMed]

- Lebel, L.L.; Aissa, B.; El Khakani, M.A.; Therriaul, D. Preparation and mechanical characterization of laser ablated single-walled carbon-nanotubes/polyurethane nanocomposite microbeams. Compos. Sci. Technol. 2010, 70, 518–524. [Google Scholar] [CrossRef]

- Farahani, R.D.; Dalir, H.; Le Borgne, V.; Gautier, L.A.; El Khakani, M.A.; Lévesque, M.; Therriault, D. Reinforcing epoxy nanocomposites with functionalized carbon nanotubes via biotin-streptavidin interactions. Compos. Sci. Technol. 2012, 72, 1387–1395. [Google Scholar] [CrossRef]

- Farahani, R.D.; Lebel, L.L.; Therriault, D. Processing parameters investigation for the fabrication of self-supported and freeform polymeric microstructures using ultraviolet-assisted three-dimensional printing. J. Micromech. Microeng. 2014, 24, 055020. [Google Scholar] [CrossRef]

- Bakarich, S.E.; Gorkin, R., III; in het Panhuis, M.; Spinks, G.M. Three-Dimensional Printing Fiber Reinforced Hydrogel Composites. ACS Appl. Mater. Interfaces 2014, 6, 15998–16006. [Google Scholar] [CrossRef] [PubMed]

- Griffini, G.; Invernizzi, M.; Levi, M.; Natale, G.; Postiglione, G.; Turri, S. 3D-printable CFR polymer composites with dual-cure sequential IPNs. Polymer 2016, 91, 174–179. [Google Scholar] [CrossRef]

- Ellis, B. Chemistry and Technology of Epoxy Resins, 2nd ed.; Blackie Academic & Professional: London, UK, 1994; pp. 16–22, 63–64. [Google Scholar]

- Boey, F.Y.C.; Qiang, W. Glass-Transition Temperature—Conversion relationship for an epoxy-hexahydro-4-methylphthalic anhydride system. J. Appl. Polym. Sci. 2000, 78, 511–516. [Google Scholar] [CrossRef]

- Stevens, G.C.; Richardson, M.J. Factors influencing the glass transition of DGEBA-anhydride epoxy resins. Polymer 1983, 24, 851–858. [Google Scholar] [CrossRef]

- Kothmann, M.H.; Zeiler, R.; Rios de Anda, A.; Brückner, A.; Altstädt, V. Fatigue crack propagation behaviour of epoxy resins modified with silica-nanoparticles. Polymer 2015, 60, 157–163. [Google Scholar] [CrossRef]

- Tsotra, P.; Friedrich, K. Electrical and mechanical properties of functionally graded epoxy resin/carbon fibre composites. Compos. Part A 2003, 34, 75–82. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Breidt, C. Comparison of short carbon fibre surface treatments on epoxy composites: I. Enhancement of the mechanical properties. Compos. Sci. Technol. 2004, 64, 2021–2029. [Google Scholar] [CrossRef]

- Kim, S.Y.; Baek, S.J.; Youn, J.R. New hybrid method for simultaneous improvement of tensile and impact properties of carbon fiber reinforced composites. Carbon 2011, 49, 5329–5338. [Google Scholar] [CrossRef]

- Dai, Z.; Shi, F.; Zhang, B.; Li, M.; Zhang, Z. Effect of sizing on carbon fiber surface properties and fibers/epoxy interfacial adhesion. Appl. Surf. Sci. 2011, 257, 6980–6985. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

| Property | B33 | B50 | B33G5 | B50C5 |

|---|---|---|---|---|

| Storage modulus E′ (GPa) 1 | 3.15 ± 1.0 | 3.15 ± 0.6 | 4.30 ± 0.3 | 5.18 ± 0.6 |

| Theoretical prediction of E′ (GPa) 2 | - | - | 4.65 | 5.58 |

| Tg,DMA (°C) | 127 | 128 | 155 | 123 |

| Tg,DSC (°C) | 106 | 100 | 105 | 74 |

| Property | B33 | B50 | B33G5 | B50C5 | B50C5-S |

|---|---|---|---|---|---|

| Elastic modulus E′ (GPa) | 2.6 ± 0.7 | 2.7 ± 0.4 | 3.5 ± 0.3 | 3.9 ± 0.8 | 4.4 ± 0.9 |

| Maximum tensile strength σmax (MPa) | 35.1 ± 8.9 | 16.0 ± 2.9 | 41.7 ± 5.1 | 30.6 ± 5.9 | 33.8 ± 4.9 |

| Elongation at break εB (%) | 1.8 ± 0.7 | 0.6 ± 0.2 | 1.6 ± 0.1 | 0.9 ± 0.2 | 1.0 ± 0.2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Invernizzi, M.; Natale, G.; Levi, M.; Turri, S.; Griffini, G. UV-Assisted 3D Printing of Glass and Carbon Fiber-Reinforced Dual-Cure Polymer Composites. Materials 2016, 9, 583. https://doi.org/10.3390/ma9070583

Invernizzi M, Natale G, Levi M, Turri S, Griffini G. UV-Assisted 3D Printing of Glass and Carbon Fiber-Reinforced Dual-Cure Polymer Composites. Materials. 2016; 9(7):583. https://doi.org/10.3390/ma9070583

Chicago/Turabian StyleInvernizzi, Marta, Gabriele Natale, Marinella Levi, Stefano Turri, and Gianmarco Griffini. 2016. "UV-Assisted 3D Printing of Glass and Carbon Fiber-Reinforced Dual-Cure Polymer Composites" Materials 9, no. 7: 583. https://doi.org/10.3390/ma9070583

APA StyleInvernizzi, M., Natale, G., Levi, M., Turri, S., & Griffini, G. (2016). UV-Assisted 3D Printing of Glass and Carbon Fiber-Reinforced Dual-Cure Polymer Composites. Materials, 9(7), 583. https://doi.org/10.3390/ma9070583